4th and 5th axis cnc rotary table quotation

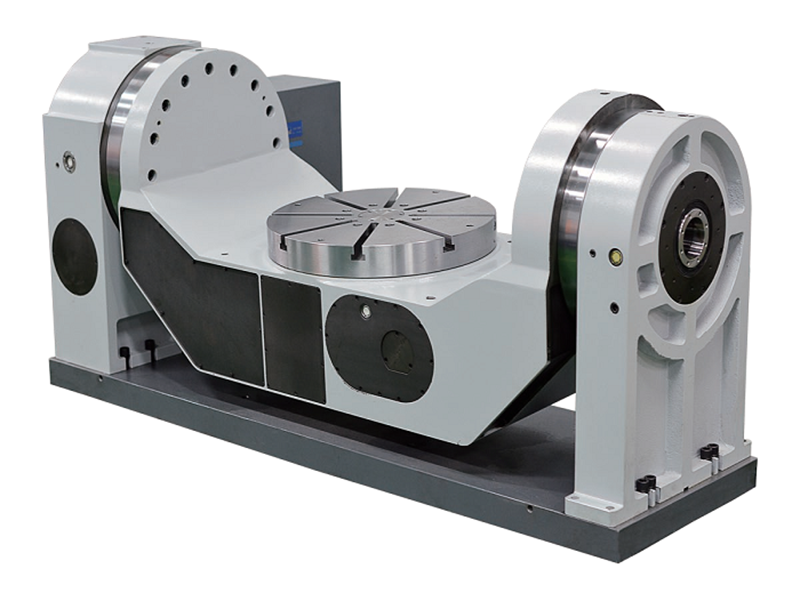

New Trunnion model TR 100RF has all of the features of the standard wired models while being the perfect application for palletizing VMC An easy to use system with no messy cables

KME CNC can design a trunnion for your application. Custom 5-axis trunnions can be made to specific matching needs including different drive configuration, large or smaller sizes, less

KME CNC’s trunnions have the lowest platter height in the industry, with 7.87” from table to platter, allowing maximum Z height clearance. KME CNC can also manufacture trunnions with 10” platters, depending on their specific needs. No additional drive cards necessary!

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new 5 axis rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement 5 axis rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new 5 axis rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

Martin Trunnion Tables offers complete 4th axis packages for Samchully rotary tables. Ready to be mounted into your machine, your Stallion Trunnion Table will already be attached to your Samchully rotary table and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis CNC machining. Scroll down for examples and package options! Don"t hesitate to reach out to us to discuss your manufacturing needs. Our applications engineers are always happy to help!

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

It’s true that less than 10% of machined parts require simultaneous 5-axis movement. Which means that more than 90% of the parts machined in a typical job shop would not benefit from expensive, complicated, full 5-axis contouring; but that doesn’t mean your shop wouldn’t benefit from simple, affordable, 5-axis indexing capability. Work platter: Available in 6.75" diameter, T-sloted platters with drilled and tapped holes to accept Raptor or any brand work-holding, vises, fixtures, chucks, etc. Also available in dual-spindle system for increased efficiencies by cutting the number of tool changes in half.

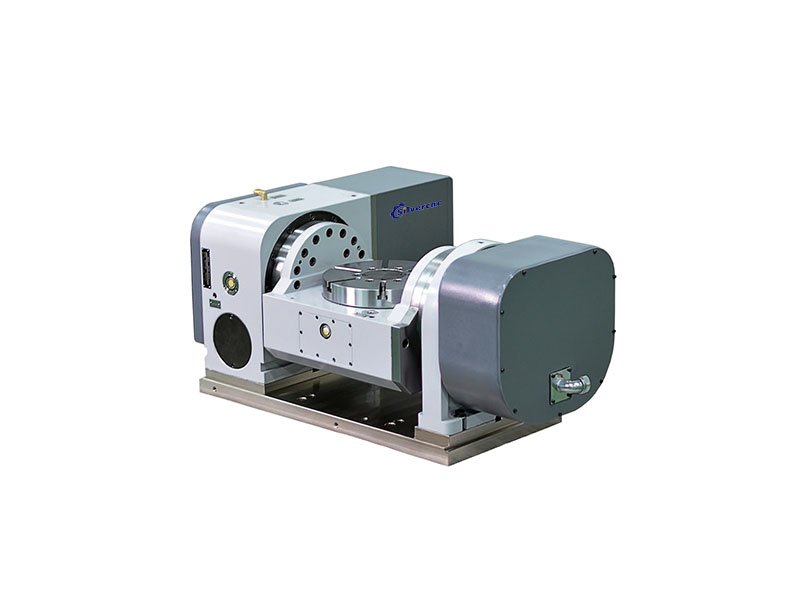

1. QuindexPneumatic 5th Axis Bolt-on kit:Easily bolts-up to your existing true 4th or semi-4th axis rotary table. Shop air drives the spindle 90 degrees up against hard stops as well as provides 300 lbs. of brake force to allow for heavy cuts. A simple M-code or relay closure triggers indexing. This is the most cost-effective option to start 5-sided machining and is designed to mount to most other brands of rotary tables. (As well as ours of course!)

2. Quindex Semi 4th and Pneumatic 5th Axis Package:This package is everything you need to turn your 3-axis machine into a 5-axis workhorse.This package comes completely assembled and mounted on a subplate for a fast, accurate set-ups.

•Index Designs true 4th axis rotary table with Quindex 5th axis head, outboard support all mounted on a subplate. Call or email for quote on your specific machine. Please provide year, machine and control

brand with model number and if machine is 4th axis ready including amplifier. For example: 2015, XYZ machine with Fanuc OiMF control, not 4th axis ready, no amp.

•Dual Quindex heads on any of the above configurations. Increase your output and cut your tool changes in half by machining two parts in one set-up. Add $4995.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and other dealer installed accessories are not included. All prices are in U.S. dollars.

Increase productivity and reduce setup time with the TR-8, 4th- and 5th-axis rotary table by eliminating second and third operations. In a single set-up, achieve multi-sided machining capability as well as the ability to tackle tough complex shapes and difficult to reach angles. Both housings were based on our VH8 and still come packed with the same quality. Both spindles and worms have dual bearings. Each worm wheel is helically cut and throated for greater surface contact between the wheel and worm. The B axis housing uses a stronger motor to make up for the extra weight of tilting the A axis housing and maintain accuracy.

Our control box is a cost-efficient solution for machining parts not needing true 5-axis, simultaneous motion. Add a single-axis controller with our 5th axis head turning your 4th axis machine into 4+1. Or add our dual-axis controller with our 5th axis head turning your 3 axis machine into 3+2.Either way, this allows you tomachine 5 sides of a part, thus reducing the number of machining operations and dramatically increasing efficiency and accuracy.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th and 5th axis drive needed.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and other dealer installed accessories are not included. All prices are in U.S. dollars.

Our 4C software and control system powers all models. Standard and optional equipment is the same across all models. The only differences between models are machine size, travels, spindle power, and part size capacity.

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater ...

... more compact and versatile 5-axis solution for mid-size mills. The new unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises. ...

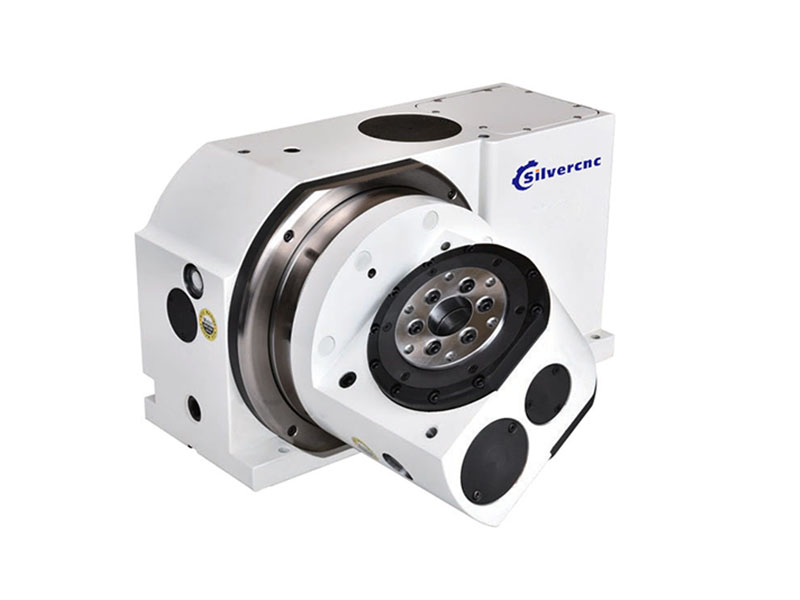

The new designed rotary swivel unit RT2A is the ideal solution for retrofitting your machine with a 4th and 5th axis. It is based on the proven and robust rotary tables ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

"twitter:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

"og:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

Machine Tech’s focus is on close-tolerance parts specializing in complex CNC milling, using the latest computer technology and equipment. We have grown to specialize into various industries and technologies including medical, defense, aerospace, robotics, military, process equipment, and industrial. We are able to service our customers with highly-skilled vertical and horizontal milling, turning, and sinker EDM manufacturing, as well as complex and close-tolerance assembly. Our capabilities include the operation of 3rd, 4th, and 5th axis CNC vertical and horizontal mills.

The purpose of all rotary tables is to rotate the piece being shaped by a set number of degrees, which allows shaping of material at exact intervals. Rotary tables can be used in all types of applications, the most basic example of their use would be to create regular grooves or holes in an object. Through rotation of the rotary table you are able to shape the object on a 4th axis, in addition to the three that a standard milling machine provides.

Now, Machine Tech has rotary tables with a tilting mechanism providing the ability to apply the milling machine on an additional 5th axis. Tilting the object either up or down, the tool is able to approach the object at varying angles. The use of 4th axis rotary tables greatly reduces the amount of time that it takes to shape an object; without it, you would be forced to reposition the object several times for the same results.

5th axis rotary tables are used for the manufacturing of more complex parts that are needed. These machines also save time in the same fashion. Their precision helps to promote uniformity in components and provides a quality that otherwise could not be achieved, because machines with a 4-axis or 5-axis component can create complex geometries faster, as well as cheaper. These machines provide vast improvements in efficiency by reducing setup times, cycle times, tool wear, and by increasing capability. That is why when it comes to Machine Tech’s 5-axis CNC machining, the part that generally comes to mind is a turbine or impeller. Machining a turbine requires the simultaneous movement of all 5 axes to create the desired geometric shape. For example, in the aerospace industry there are contours that can be machined by a 3-axis machine, but the process becomes much simpler with a 5-axis machine, ultimately saving the company money.

To fully understand the need for 4-axis or 5-axis machining, knowledge of 3-axis milling is required. The 3-axis machine is the most commonly used CNC milling machine. The 3-axis system consists of 3 vectors in space, two perpendicular to each other and in the same plane commonly known as the x and y axis with the third being z.

4-axis is the next level of capability in milling. Defined by rotation about one of the 3 primary axes. Depending on which axis the rotation is about, the 4th axis is called A if about the X-axis, or B if about the Y-axis, or C if about the Z-axis. To be considered 4-axis, the machine must be capable of simultaneous motion in each axis. The 4th axis may be used while cutting or to rotate the part to machine a different surface. Many of Machine Tech’s machines can mount a separate piece of equipment to add a 4th axis, or machines can be purchased with 4-axis built into the machine.

To increase the capabilities of our CNC mill a 5th axis is incorporated. Our 5-axis setup is more complex and there are two main methods of achieving 5th axis capability.

The first method consists of a 4-axis set-up with using the A-axis or B-axis with the spindle unit tilting. The second method in a 5-axis setup is called a trunnion. A trunnion system is generally less expensive than a tilt head system. Even though less expensive, a trunnion system adds some complexity. If the part clamped to the rotary is not centered on the A-axis, a 5-axis set-up provides greater control of orientation of the machining envelope. This allows for less re-fixturing of all parts and allows machining of very complex geometries, such as an impeller in a single setup, using 5-axis simultaneously where the tool does not leave the part until complete. By using 5th axis machining, most parts can be manufactured in one or two setups, eliminating the need for extra placement. With our reduction of time, we can reduce the cost per parts we are manufacturing, while increasing part quality, with no need to move the part the risk of misalignment is void.

APO/FPO, Afghanistan, Africa, Alaska/Hawaii, Albania, American Samoa, Andorra, Armenia, Azerbaijan Republic, Bahrain, Bangladesh, Belarus, Bermuda, Bhutan, Bosnia and Herzegovina, Brunei Darussalam, Cambodia, Central America and Caribbean, Cook Islands, Cyprus, Fiji, French Polynesia, Georgia, Gibraltar, Greenland, Guam, Guernsey, Iceland, India, Indonesia, Iraq, Jersey, Jordan, Kazakhstan, Kiribati, Kuwait, Kyrgyzstan, Laos, Lebanon, Liechtenstein, Macau, Macedonia, Malaysia, Maldives, Malta, Marshall Islands, Micronesia, Moldova, Monaco, Mongolia, Montenegro, Nauru, Nepal, New Caledonia, New Zealand, Niue, Oman, Pakistan, Palau, Papua New Guinea, Philippines, Qatar, Russian Federation, Saint Pierre and Miquelon, San Marino, Serbia, Solomon Islands, South America, Sri Lanka, Svalbard and Jan Mayen, Tajikistan, Tonga, Turkey, Turkmenistan, Tuvalu, US Protectorates, Ukraine, Uzbekistan, Vanuatu, Vatican City State, Wallis and Futuna, Western Samoa, Yemen

160 mm (6.3") Dual-Spindle Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box. Requires a Haas mill with software version 18.00 or later.

Dapode, Thane Gala No. 22, Building No. A 21, Harihar Complex, Anjurphata Road, Behind Gajanan Petrol Pump Village Dapode, Near Mankoli Naka, Tal-Bhiwandi, 9 Km From Thane City, Dapode, Thane - 421302, Dist. Thane, Maharashtra

Our company is a prominent in the industry as a manufactures and supplies Rotary Table. We offer our product in diverse specifications to fulfill the differentread more...

We provide exclusive range of Goizper make Turn tables (CAM based), rotary tables (indexers), Clutch-Brake units, Spares, Couplings, customized Gear boxes. Goizperread more... Brochure

8613371530291

8613371530291