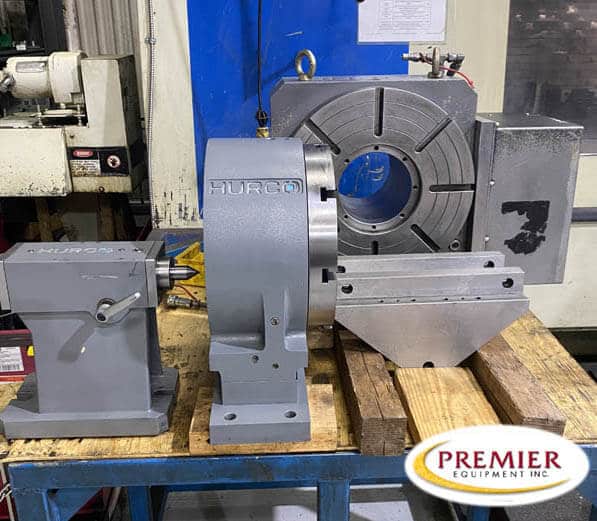

hurco 4th axis rotary table manufacturer

The Hurco manufacturing team is relentless when it comes to quality and attention to detail. Like you, they take pride in what they do and what they produce—you can count on a Hurco lathe to last. All of our machine design is conducted in the USA using both static and finite element analysis in addition to reliability analysis. The Hurco team is skilled at user-centric design that results in ergonomic features, such as convenient front access to chuck and tailstock pressure controls in addition to a front loading coolant tank design that makes maintenance easy.

More importantly, the design of Hurco turning centers supports flexible manufacturing, rigidity, and efficient chip removal. It starts with a one-piece slant bed casting that provides higher rigidity in a compact design. The 30-degree slant bed also promotes faster and easier chip removal. All Hurco turning centers are designed with a component isolation system, which keeps the components that generate the most heat isolated to fight heat dissipation and minimise spindle growth. Premium components add to the advanced performance and rigidity, with Yaskawa or Bosch/Rexroth drives, servos, and motors. Additionally, the multiple V-belt design of the spindle promotes higher power transfer with quieter operation.

Numerous chip management features minimise time wasted on cleanup and protect internal components. All of the Hurco turning centers have telescopic way covers to keep chips out and protect the premium components inside your lathe. The inside door keeps coolant and chips inside the machine.

The Hurco VMX42SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a torque B axis swivel head and C axis style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.Request PriceScroll to Machine Specifications

Hurco is an industrial technology company that designs, manufactures, and sells computerized machine tools to companies to companies in the metal cutting industry. Since our founding in 1968, we have pioneered the application of computer technologies for use in machine tools.

Click here to learn more about Hurco’s history. Hurco is focused on delivering its customers products equipped with technologies that help them increase their company’s profitability by increasing their manufacturing productivity.

The Hurco brand is our flagship brand that provides premium technologies and includes sophisticated 5-axis CNC machines and multi-axis CNC lathes in addition to vertical machining centers and turning centers.

MAX5 control powered by WinMax® leverages sophisticated technology to simplify complex processes for our customers. Additionally, the integrated control of the Hurco CNC machines provides customers with the flexibility to program parts using conversational programming or industry standard NC programming.

In addition to our CNC machine brands, Hurco Companies, Inc., has LCM, which offers a line of machine tool components and accessories, including CNC rotary and tilt tables, and swivel heads and electro-spindles. Hurco also opened an automation division in 2019 with a line of collaborative robots that provide the portability and flexibility high-mix/low volume manufacturing companies need to increase their productivity.

The executive offices and principal design and engineering operations of Hurco Companies, Inc., are in Indianapolis, Indiana, USA. We have manufacturing and assembly operations in Taiwan, the USA, Italy, and China. Our company sells its products through direct and indirect sales forces throughout North America, Europe, and Asia. The company has sales, application engineering support and service subsidiaries in Canada, China,

distributors to sell and service our CNC machines. We are proud these family-owned businesses have chosen to represent our products. Since Hurco is located in the heartland (Indianapolis, Indiana), our sales team travels a great deal to make sure all distributors have the information and tools they need to represent Hurco.

The Hurco VMX50i w/4th Axis is an exclusive part of our Vertical Machining Centers inventory which we own and service. We"re the international CNC specialists with the best guarantee in the industry.

At EMO 2017 Hurco demonstrated how 3-axis CNC machining centers in its VMXi series can further improve your milling performance with the addition of a Kitagawa GT 200 rotary table as a fourth axis.

Hurco is sure that the highly efficient machining centers in its VMXi series will help increase profitability, especially when it comes to one-off part or small series production. A major advantage of the VMXi machines is their compact construction.

“For example, you don’t need much space to set up a VMX 30i, but it has a comparatively generous working area and cutting performance that is something to be proud of,” said Michael Auer, Managing Director of Hurco GmbH.

The addition of a Kitagawa GT 200 rotary table as a fourth axis significantly increases the range of applications these CNC 3-axis machining centers are capable of. When you start the programme, up to four sides of a component can be machined at once, without reclamping, and if surface machining is needed on circular components, it can do that too. The additional axis can be installed or uninstalled with ease, to suit current needs.

Hurco’s machining centers are equipped with the “WinMax” conversational control system, with optional DXF. The powerful control system software simplifies programming and sets the machine up for producing precision parts in just three steps.

Hurco also demonstrated how cooperation between a machine tool and a loading robot ensures greater efficiency in production. For example, the VMX 30Ui CNC machining center will be loaded and unloaded using an automated system featuring a loading robot from the Dutch provider BMO. This increases productivity while saving on human resources.

Hurco opted for the “Titanium” BMO system. This system allows a CNC machining center to be docked on both the left and right. Blanks are fed in the loading robot cell on trays. The robot arm integrated into the cell positions the blanks in the machining center, removes them after production and places them back into trays in the cell.

1MTA offers a large range of 4th axis rotary tables supplied by Kitagawa, specialists in high-quality machining equipment. 4 axis CNC rotary tables add an additional, rotary axis to your indexing table allowing for greater precision and versatility.

Pre-owned HURCO VMX42SR 2012 Vertical Machining Center. This Vertical Machining Center has average cutting time and is equipped with a CNC control. This CNC Machine is currently located in USA. This HURCO Vertical Machining Center is available for a limited time. Get a quote today on this

8613371530291

8613371530291