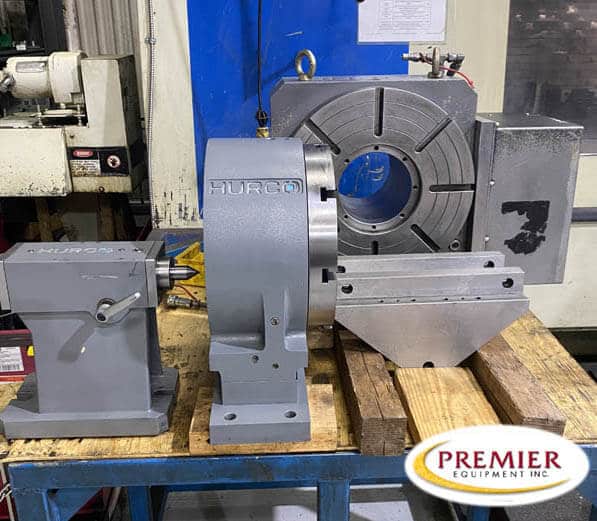

hurco 4th axis rotary table supplier

The Hurco manufacturing team is relentless when it comes to quality and attention to detail. Like you, they take pride in what they do and what they produce—you can count on a Hurco lathe to last. All of our machine design is conducted in the USA using both static and finite element analysis in addition to reliability analysis. The Hurco team is skilled at user-centric design that results in ergonomic features, such as convenient front access to chuck and tailstock pressure controls in addition to a front loading coolant tank design that makes maintenance easy.

More importantly, the design of Hurco turning centers supports flexible manufacturing, rigidity, and efficient chip removal. It starts with a one-piece slant bed casting that provides higher rigidity in a compact design. The 30-degree slant bed also promotes faster and easier chip removal. All Hurco turning centers are designed with a component isolation system, which keeps the components that generate the most heat isolated to fight heat dissipation and minimise spindle growth. Premium components add to the advanced performance and rigidity, with Yaskawa or Bosch/Rexroth drives, servos, and motors. Additionally, the multiple V-belt design of the spindle promotes higher power transfer with quieter operation.

Numerous chip management features minimise time wasted on cleanup and protect internal components. All of the Hurco turning centers have telescopic way covers to keep chips out and protect the premium components inside your lathe. The inside door keeps coolant and chips inside the machine.

Hurco is an industrial technology company that designs, manufactures, and sells computerized machine tools to companies to companies in the metal cutting industry. Since our founding in 1968, we have pioneered the application of computer technologies for use in machine tools.

Click here to learn more about Hurco’s history. Hurco is focused on delivering its customers products equipped with technologies that help them increase their company’s profitability by increasing their manufacturing productivity.

The Hurco brand is our flagship brand that provides premium technologies and includes sophisticated 5-axis CNC machines and multi-axis CNC lathes in addition to vertical machining centers and turning centers.

MAX5 control powered by WinMax® leverages sophisticated technology to simplify complex processes for our customers. Additionally, the integrated control of the Hurco CNC machines provides customers with the flexibility to program parts using conversational programming or industry standard NC programming.

In addition to our CNC machine brands, Hurco Companies, Inc., has LCM, which offers a line of machine tool components and accessories, including CNC rotary and tilt tables, and swivel heads and electro-spindles. Hurco also opened an automation division in 2019 with a line of collaborative robots that provide the portability and flexibility high-mix/low volume manufacturing companies need to increase their productivity.

The executive offices and principal design and engineering operations of Hurco Companies, Inc., are in Indianapolis, Indiana, USA. We have manufacturing and assembly operations in Taiwan, the USA, Italy, and China. Our company sells its products through direct and indirect sales forces throughout North America, Europe, and Asia. The company has sales, application engineering support and service subsidiaries in Canada, China,

distributors to sell and service our CNC machines. We are proud these family-owned businesses have chosen to represent our products. Since Hurco is located in the heartland (Indianapolis, Indiana), our sales team travels a great deal to make sure all distributors have the information and tools they need to represent Hurco.

The Hurco VMX42SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a torque B axis swivel head and C axis style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.Request PriceScroll to Machine Specifications

The Hurco VMX42HSRTi high-speed 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head and C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.Request PriceScroll to Machine Specifications

For over five decades Hurco has continually focused on the development of technology that yields measurable productivity improvements for our customers. Our years of experience provide us the knowledge to build rigid and reliable machining centers with the most powerfully simplistic, user-friendlycontrol technology in the industry. Our experience has also allowed us to implement a unique business model within the machine tool industry that expands our global supply chain, manufacturing, and distribution capabilities. This proven system benefits our customers because we are able to ship our machine tools with shorter lead times than most competitors. Additionally, we are able to continue product development schedules and targeted technology growth even during difficult economic cycles because our efficiency promotes financial stability.

The Hurco VMX50i w/4th Axis is an exclusive part of our Vertical Machining Centers inventory which we own and service. We"re the international CNC specialists with the best guarantee in the industry.

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

Increase efficiency and production of your CNC machine with our Dual VH-8. Perfect for making 2 parts at a time thus reducing the number of tool changes and allowing the operator more time to complete other tasks. The standard configuration places the motor at the side or we also offer the option to wrap the motor around the back to save space, reduce overall length and eliminate possible machine interferences. The Dual VH-8 has twin 8.25" spindles (210mm) with dual tapered roller bearings supporting the front and back of each spindle. The VH-8 worm wheel is helically cut and throated for increased surface contact between the wheel and worm. This provides longevity and helps maintain the accuracy of the rotary table over time. There are optional 8" 3-Jaw chucks and adapter plates available as well as a 5C nose pieces with either manual or air collet closers for your workholding needs.

The Index Designs Dual VH-8 is a true 4th-axis rotary table with two platters,complete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head with either an A or C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work.

Heavier Parts. Because the table is stationary, the swivel head/rotary table 5-axis machining centers are typically preferred when machining heavier parts.

Unlimited angular movement of C-axis. With a swivel head/rotary table 5-axis machining center, it is extremely important to make sure the table (C-axis) supports unlimited angular movement. For example, if you are machining down a steep wall and going around the part, the table needs to rotate in a continuous motion. If the C-axis is limited to +360 / -360 degrees of motion, it will literally need to unwind at regular intervals to machine the part. Conversely, the tables on the Hurco SR 5-axis mills are built with unlimited and continuous rotation because our focus from design to delivery is to maximize productivity and profitability for our customers.

Tool access for swept surfaces and complex contours. There are certain applications, such as impellers or turbines, when it is beneficial to approach the part from underneath. When you mill uphill, as it is sometimes called, the base of the spindle is lower than the tool tip. The B-axis tilting head with the C-axis rotary table of the SR machining center supports this type of cutting strategy, whereas a trunnion style 5-axis mill doesn’t.

The Hurco VMX42SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a torque B axis swivel head and C axis style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.

Managing director Chris Smith favours this style of 5-axis machining centre over the trunnion-mounted rotary table arrangement due to its versatility for tackling a greater variety of work, including 4-axis machining of large components.

Last year saw the arrival of a Hurco VMX30i, purchased with a fourth axis rotary table to speed set-ups, increase production efficiency and reduce delivery times, plus a larger 3-axis VMX60i with 1,525 x 660 x 610mm working volume that significantly extends the size of component that can be machined on the Livingston site.

Celebrating the 40th anniversary of its inauguration this year, Almond Engineering now operates eight Hurco machine tools, a TM8 CNC lathe with 8-inch chuck and seven machining centres. The latter form the vast majority of prismatic metalcutting capacity on site, the only other machining centre being a Bohner & Koehle bought in the 1970s.

As to the subcontractor"s continued purchase of the Hurco brand, Mr Smith comments: "Ours is a prototype and small batch production environment, so efficient shopfloor programming is important to us. We rely on it 90% of the time.

"Back in 2004, we had a number of manual tool change mills and one vertical machining centre, but spent more time programming them than actually cutting metal. To take over from them, in 2004 we bought our first VMX42 with a 1m X-axis. The Hurco control was clearly ahead at the time in terms of the speed and capability of its conversational programming and has continued to lead the market ever since.

He pointed also to the user friendliness of Hurco machines, with staff able to move seamlessly between the twin-screen WinMAX controls powering the larger machining centres and the single-screen MAX controls on the smaller VM1 machining centre and TM8 lathe.

The subcontractor"s hyperMILL offline CAM system is used mostly for programming more complex 3+2 axis cycles to reduce set-ups and improve accuracy on the 5-axis machines and to create some fully interpolative cycles as well.

8613371530291

8613371530291