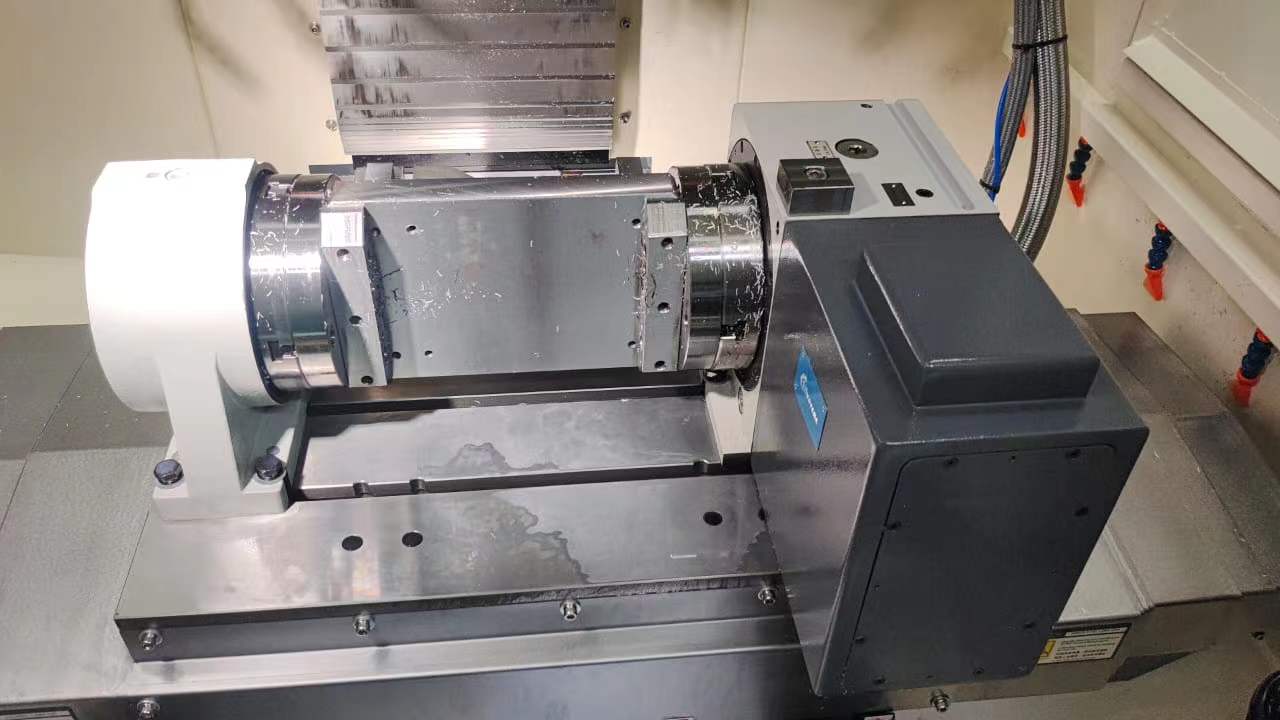

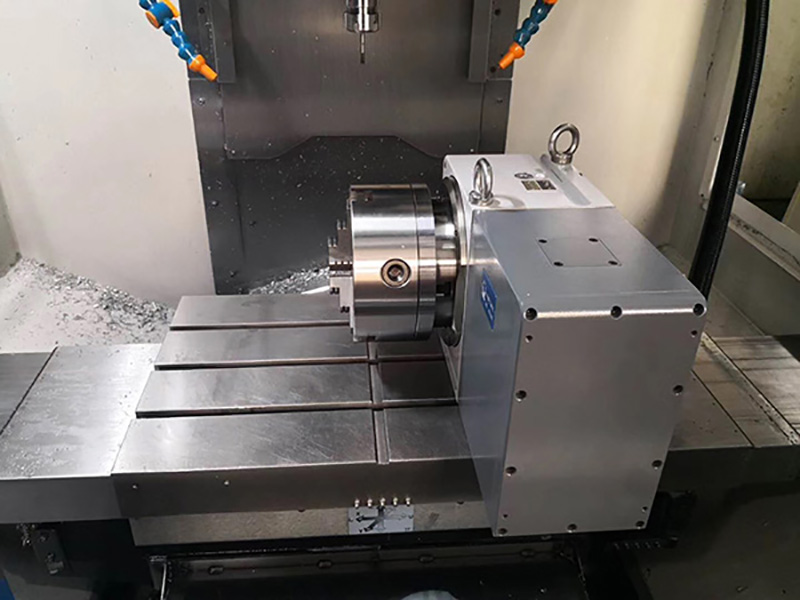

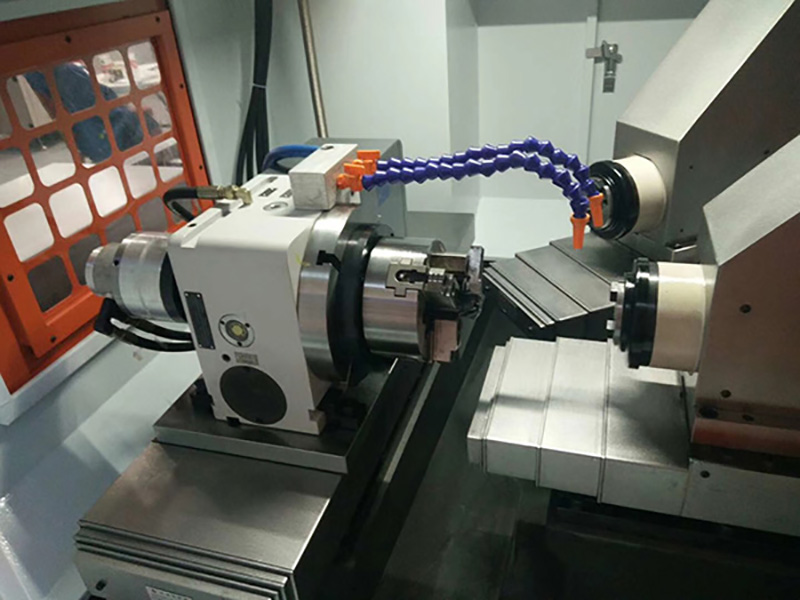

hurco 4th axis rotary table made in china

The Hurco VMX42SRTi 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a torque B axis swivel head and C axis style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.Request PriceScroll to Machine Specifications

The Hurco manufacturing team is relentless when it comes to quality and attention to detail. Like you, they take pride in what they do and what they produce—you can count on a Hurco lathe to last. All of our machine design is conducted in the USA using both static and finite element analysis in addition to reliability analysis. The Hurco team is skilled at user-centric design that results in ergonomic features, such as convenient front access to chuck and tailstock pressure controls in addition to a front loading coolant tank design that makes maintenance easy.

More importantly, the design of Hurco turning centers supports flexible manufacturing, rigidity, and efficient chip removal. It starts with a one-piece slant bed casting that provides higher rigidity in a compact design. The 30-degree slant bed also promotes faster and easier chip removal. All Hurco turning centers are designed with a component isolation system, which keeps the components that generate the most heat isolated to fight heat dissipation and minimise spindle growth. Premium components add to the advanced performance and rigidity, with Yaskawa or Bosch/Rexroth drives, servos, and motors. Additionally, the multiple V-belt design of the spindle promotes higher power transfer with quieter operation.

Numerous chip management features minimise time wasted on cleanup and protect internal components. All of the Hurco turning centers have telescopic way covers to keep chips out and protect the premium components inside your lathe. The inside door keeps coolant and chips inside the machine.

For over five decades Hurco has continually focused on the development of technology that yields measurable productivity improvements for our customers. Our years of experience provide us the knowledge to build rigid and reliable machining centers with the most powerfully simplistic, user-friendlycontrol technology in the industry. Our experience has also allowed us to implement a unique business model within the machine tool industry that expands our global supply chain, manufacturing, and distribution capabilities. This proven system benefits our customers because we are able to ship our machine tools with shorter lead times than most competitors. Additionally, we are able to continue product development schedules and targeted technology growth even during difficult economic cycles because our efficiency promotes financial stability.

In 1968, Gerald Roch and Edward Humston formed a company they called Hurco ("Hu" for Humston, "R" for Roch, and "CO" for Company ). Roch was the idea guy and Humston was the business guy...actually, Mr. Humston was Mr. Roch"s boss as the owner of E.L. Humston Company where Mr. Roch was a sales representative for eight years.

Mr. Roch grew up around his grandfather"s tool and die shop where he discovered his passion for building things. After he graduated from Purdue University with an industrial engineering degree, he returned to his grandfather"s shop (which was now owned by Mr. Roch"s father and two other partners). Mr. Roch"s fascination with simplifying processes, combined with the emergence of computers, would lead Mr. Roch to start Hurco.

People often talk about innovation, but rarely talk about the innovators. Mr. Roch is the epitome of a true innovator. He is curious. Asks questions and he never accepts the status quo. He has acquired more than 60 patents, due in large part to his fascination with efficiency combined with his background at the family tool and die shop, his collaborative personality, and his drive to solve problems. His patents for interactive control technology, which we refer to as conversational programming, are considered the most significant. Machine tool builders throughout the world had to obtain a license from Hurco to implement this technology into their products because Mr. Roch, Hurco co-founder, invented it.

The connection between technology and people is the core of our culture at Hurco. At the end of the day, machine tools aren"t about iron, and technology isn"t about software codes. They are about people...people like Gerald Roch and people like you, who work each day to identify ways to continually improve their processes, their business, and the parts they manufacture.

benchmark data from Modern Machine Shop magazine, 44% of the highest performing shops in the U.S. use 5th axis positioning. Just as Hurco led the industry in the transition from manual machining to CNC machining with the invention of conversational programming, we have led the industry in the transition from 3-axis machining to 5-axis positioning (or 5-sided machining). At Hurco, customer productivity (which leads to customer profitability) is the primary criterion we use when deciding where to devote our research and development resources. Decades ago, the Hurco engineering team determined that 5-axis CNC machining, in particular, 5-sided machining, could significantly increase productivity at job shops. We set a path to become the experts and revolutionized the industry with the development of control technology that optimizes the process for full 5-axis and 5-sided (3+2).

With 5-sided CNC machining, also called 3+2, you reduce setup time, increase accuracy, and expand your shop’s capability for future simultaneous 5-axis work. The key to our success in helping machinists make the transition from 3-axis to 5-sided machining lies within the conversational programming features of the Hurco control, such as Transform Plane and

When you invest in a Hurco 5-axis machining center, you get two machines in one. A machine that will immediately increase the profit margin of the parts you’re producing on a 3-axis machining center due to the powerful 5-sided programming (no CAM needed) and a rigid machine that is fully compatible with CAD/CAM packages for simultaneous 5-axis.

The Hurco VMX42HSRTi high-speed 5-Axis CNC mill offers maximum flexibility. The SR series of 5-axis CNC mills offers multiple advantages, starting with the machine’s design configuration that utilizes a swivel head and C style rotary table. The generous size of the rotary table provides maximum versatility because you can use the extra table space for secondary operations or 3-axis work. Exceptional cutting feed rates are achieved with patented high-speed motion technology – resulting in the fastest cut with the best surface finish.Request PriceScroll to Machine Specifications

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

The Quindex fifth-axis indexing system from Index Designs is designed to enable five-sided machining applications. Activated with shop air, the device bolts onto fourth-axis rotary tables, enabling tools to access five sides of a part in the same setup.

The Quindex makes a 90-degree index through an M code command written within the machining program. The rotary actuator drives the 6.75" diameter spindle up against hard stops for highly accurate positioning with 5 arc-seconds of repeatability. A pneumatic brake plate provides up to 250 foot-pounds of holding torque to absorb heavy cuts.

For those without an existing fourth-axis table, Index Designs offers a packages that includes a VH-6 fourth-axis rotary table, the Quindex air-driven head with outboard support and air lines. All components are aligned and mounted on a subplate. The package is available as a true fourth-axis or as a semi-fourth-axis when paired with the Index Designs programmable control box.

Affordable indexers and fourth-axis rotary tables greatly enhance the capability of vertical machining centers. It’s almost as good as having a horizontal machining center.

Your expertise combined with our technology to produce quality parts more profitably—that’s mind over metal. That’s Hurco. Hurco Companies, Inc. (NASDAQ: HURC) is an industrial technology company that designs and produces interactive computer controls, software and computerized machine tools for the worldwide metal cutting and metal forming industry. The end market for the Company"s products consists primarily of independent job shops and short-run manufacturing operations within large corporations in industries such as aerospace, defense, medical equipment, energy, transportation and computer equipment. The Company is based in Indianapolis, Indiana, with manufacturing operations in Taiwan and China, and sells its products through direct and indirect sales forces throughout North America, Europe, and Asia. The company has sales, application engineering support and service subsidiaries in Canada, China, England, France, Germany, India, Italy, Poland, Singapore, South Africa, and the United States of America.

Does the machine error on M128? This is typically a 5 axis command and this is 4 axis. It"s missing an axis of rotation and wouldn"t be too hard to create a toolpath (tool orientation) the machine cannot position to.

The A180 roughing path gives a hint because it does not use Transform Planes G68.2. On the smart control side of things, G68.2 is used for 3+2 type operations and M128 is used for 5 axis simultaneous operations. These are "sister" commands and if one is available, the other is typically also. The A180 position machining code doesn"t show a G68.2. which leads me to believe it doesn"t know/use M128 either....

If that"s the case I think it"s a post where everything is done in the post. optimizeMachineAngles2(1) to account for the machine kinematics and Inverse time feed rate to control how it feeds. The A F feed could also be output as degrees per minute if the control understands it that way instead. (If A moves then F is interpreted as degrees per minute. No A move, F is inches per minute). Both in G94 feed/minute mode. Bolt on 4th axis usually use IPM/DPM approach as the control may not support G93 Inverse time (no need on a 3 linear axis machine). The code in Chapter 7 of the training guide, that shows how to make a post multi-axis, contains code that supports both inverse time or degree per minute output.

My inclination would be to take the Hurco 3D 3 axis post from the Post Library and add the Chapter 7 "Adding basic Multi-Axis Capabilities" to it. (or your favorite 3 axis post and add Ch 7).

8613371530291

8613371530291