rotary table motor manufacturer

... RIGIDIAL" rotary tables by COLOMBO FILIPPETTI spa have a globoidal cam which transforms the uniform rotary input motion into an intermittent rotary output motion.

The indexing rotary tables of the "IR" Minindex series by COLOMBO FILIPPETTI spa are cylindrical cam mechanical units that transform the uniform rotary motion of the ...

... a heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

The HT Ring Table Series are designed to propose new solutions for fixed or flexible positioning of heavy loads, thanks to the high performance of the cross-roller bearing.

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ...

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide range of product ...

Direct drive: Electronically commutated 3-phase-synchronous motor with permanent magnetically excited rotor. The motor develops a high torque up to revolutions zero. ...

... with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives with integrated absolute ...

The rotary indexer RT is often used in the assembly technology, the testing technology, the welding technology, the printing, the pressing, the automotive industry, the microelectronics, the food industry, ...

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

Numerous advantages are offered by indexing tables. No matter whatever is the transfer velocity or the load is, the motion is very smooth and progressive. Robust and accurate MCPI cam shaft movement design ...

This turnkey, four-station rotary indexing assembly station from ISUMATIC is meant for driving multiple fasteners simultaneously. They have horizontal and vertical heads, X-Y robots, rotary ...

The TS Series is manufactured by SOPAP Automation. It is a rotary indexing table, that is constructed mainly for plates of a large diameter. Features of the TS includes continuous or ...

... cantilever type tilting rotary tables are designed specifically for compact multi-sided EDM machining. Fully sealed, air purges, and impervious to EDM debris, oil or water; SAT rotary ...

... distributed on the turntable (or total weight)(*) – the maximum total load refers to the forces on the turntable. This does not mean that the indexing table will be able to rotate this ...

Motion’s Multi-dex Indexer solution provides one large base rotary index table with smaller satellite indexers. This allows the tooling or part to be rotated on one end of the work cell ...

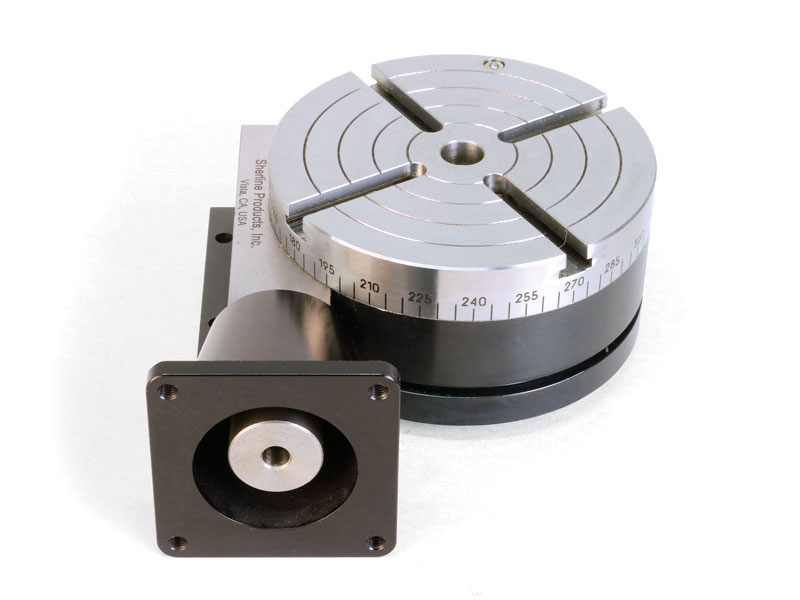

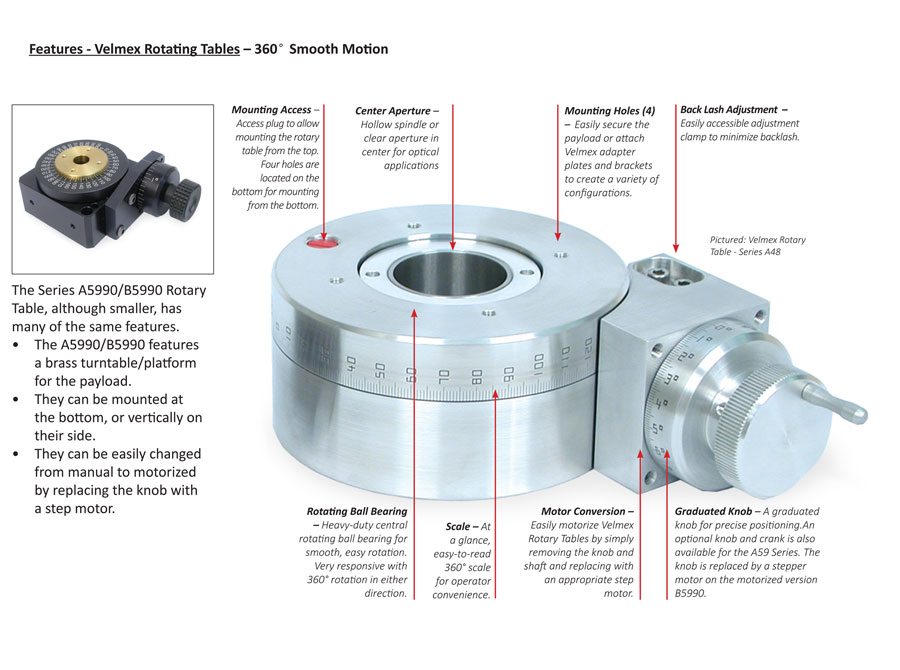

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

HIWIN Corporation torque motor and rotary tables ensure excellent acceleration capabilities and high precision uniform movements. Hiwin torque motor and rotary tables are backlash free, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

Hiwin Corp., a manufacturer in motion control and system technology, highlights its families of precision motion control components with a focus on its Torque Motor Rotary Tables (TMRT).

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy, Hiwin says. Directly coupled encoders and zero backlash intend to enable tighter part tolerance. Direct drives are designed provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, promoting thermal stability even during high-duty cycle, high-load conditions, which yields consistent part quality, Hiwin says.

Hiwin Torque Motor Rotary Tables utilize Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hexram CNC machines feature FANUC controls, moving gantry, moving portal, moving table, as well as moving and fixed rotary table options. According to the company, a selection of durable cutting heads enable manufacturers to take on applications from nearly any industry.

TJR provides torque motor rotary tables with excellent acceleration and deceleration capabilities. Our torque motor rotary tables are zero-backlash, extremely rigid, wear-free durability, have high dynamic accuracy, are suitable for a wide range of automated production machining.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

Sherline has taken its manual 4″ rotary table with reverse mount and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

The reverse rotary table is perfect for using on the tilting angle table. The reverse mount allows access to the handwheel from the front of the machine (see photo below). If you used a standard rotary table in the previously described set-up the handwheel would be mounted facing the backside of the X-axis.

NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. This rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a CNC ready rotary table and a stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

HIWIN Corp. will feature families of precision motion control components this year at IMTS, with their torque motor rotary tables as a highlight of their booth.

The TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates gear reducers, resulting in dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

The series is compatible with most major CNC brands and uses HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

8613371530291

8613371530291