rotary table motor supplier

Linear stepper motors can dramatically reduce cost and save space. There is no coupling, no additional bearing support and no assembly work required. This not only reduces cost but also reduces failure rate due to the ...

This type of motor can be applied as mud pump motor, turntable motor or winch motor for DC electric-driven drilling machine. Installation dimension of ...

The Zikodrive ZD10N2318 is a 2.4Nm NEMA 23 Stepper Motor with integrated controller (ZD10). The package is flexible and suitable for use in a wide range of applications.

... RIGIDIAL" rotary tables by COLOMBO FILIPPETTI spa have a globoidal cam which transforms the uniform rotary input motion into an intermittent rotary output motion.

The indexing rotary tables of the "IR" Minindex series by COLOMBO FILIPPETTI spa are cylindrical cam mechanical units that transform the uniform rotary motion of the ...

... a heavy duty 160 mm servo rotary table designed for a myriad of machining applications. The HRT160 can either be used in conjunction with a HAAS mill equipped with a 4th-axis drive ...

The HRT210 is a servo rotary table manufactured by Haas. It utilizes the Haas mill that has an integrated 4th axis drive for a complete 4th axis performance and a rotary ...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

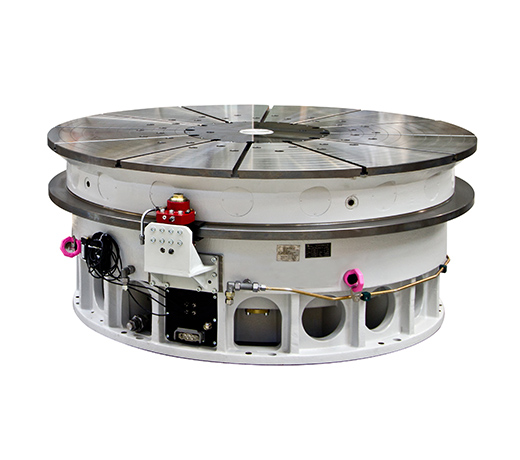

The HT Ring Table Series are designed to propose new solutions for fixed or flexible positioning of heavy loads, thanks to the high performance of the cross-roller bearing.

... can shift across the board on the rotary podium due to the pneumostatic air bearing. Additionally, the motorization can change as per the desired angular resolution from 5.120 up to 655.360 ...

This is a Servo driven rotary indexing table manufactured by Italplant which has been a study for automation of the whole unit. It comes with a wide range of product ...

Direct drive: Electronically commutated 3-phase-synchronous motor with permanent magnetically excited rotor. The motor develops a high torque up to revolutions zero. ...

... with the advantages of a user-programmable rotary table that offers a high level of torque. This is made possible by the latest generation of servo motor drives with integrated absolute ...

The rotary indexer RT is often used in the assembly technology, the testing technology, the welding technology, the printing, the pressing, the automotive industry, the microelectronics, the food industry, ...

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

Numerous advantages are offered by indexing tables. No matter whatever is the transfer velocity or the load is, the motion is very smooth and progressive. Robust and accurate MCPI cam shaft movement design ...

This turnkey, four-station rotary indexing assembly station from ISUMATIC is meant for driving multiple fasteners simultaneously. They have horizontal and vertical heads, X-Y robots, rotary ...

The TS Series is manufactured by SOPAP Automation. It is a rotary indexing table, that is constructed mainly for plates of a large diameter. Features of the TS includes continuous or ...

... cantilever type tilting rotary tables are designed specifically for compact multi-sided EDM machining. Fully sealed, air purges, and impervious to EDM debris, oil or water; SAT rotary ...

... distributed on the turntable (or total weight)(*) – the maximum total load refers to the forces on the turntable. This does not mean that the indexing table will be able to rotate this ...

Motion’s Multi-dex Indexer solution provides one large base rotary index table with smaller satellite indexers. This allows the tooling or part to be rotated on one end of the work cell ...

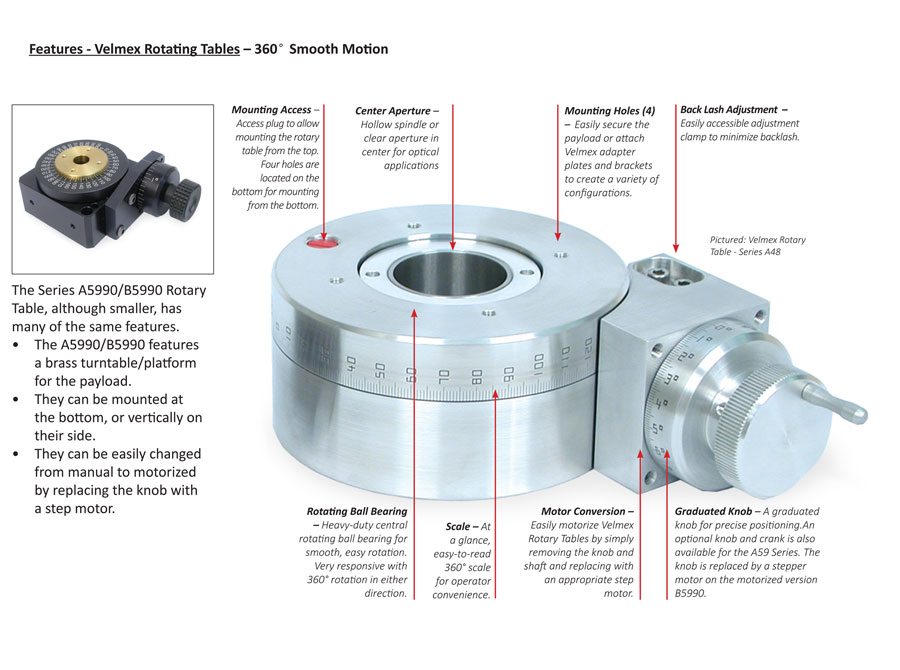

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

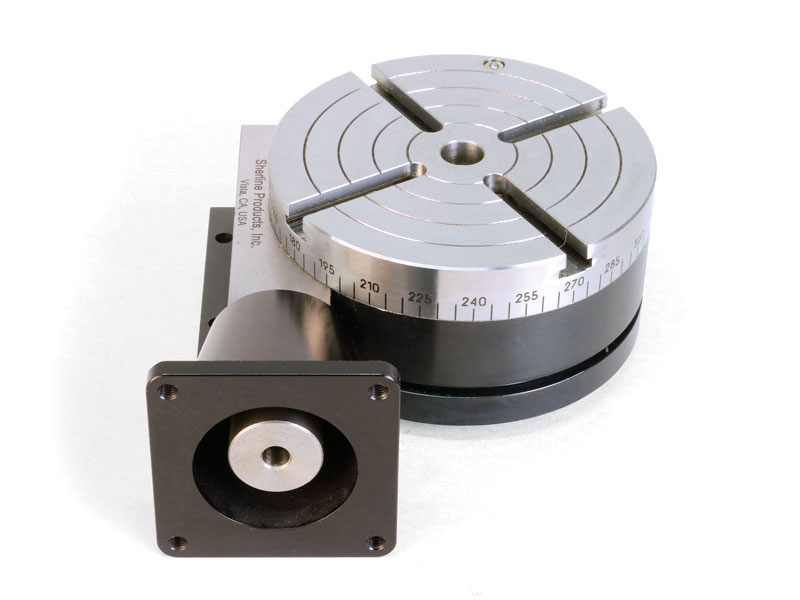

Sherline has taken its manual 4″ rotary table with reverse mount and applied a stepper motor mount with dampened coupling in place of the handwheel. The mount accepts a NEMA #23 frame size stepper motor for CNC control. This allows the table to be used as a 4th axis with CNC systems that have the capability to drive a rotary axis.

The reverse rotary table is perfect for using on the tilting angle table. The reverse mount allows access to the handwheel from the front of the machine (see photo below). If you used a standard rotary table in the previously described set-up the handwheel would be mounted facing the backside of the X-axis.

NOTE: When the worm housing is reversed to the opposite side, a clockwise rotation of the handwheel or stepper motor will result in a counter-clockwise rotation of the rotary table.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

TJR provides torque motor rotary tables with excellent acceleration and deceleration capabilities. Our torque motor rotary tables are zero-backlash, extremely rigid, wear-free durability, have high dynamic accuracy, are suitable for a wide range of automated production machining.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

Hiwin Corp., a manufacturer in motion control and system technology, highlights its families of precision motion control components with a focus on its Torque Motor Rotary Tables (TMRT).

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy, Hiwin says. Directly coupled encoders and zero backlash intend to enable tighter part tolerance. Direct drives are designed provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, promoting thermal stability even during high-duty cycle, high-load conditions, which yields consistent part quality, Hiwin says.

Hiwin Torque Motor Rotary Tables utilize Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hexram CNC machines feature FANUC controls, moving gantry, moving portal, moving table, as well as moving and fixed rotary table options. According to the company, a selection of durable cutting heads enable manufacturers to take on applications from nearly any industry.

tilting rotary table, rotary table for milling machine , Intelligent CNC vertical and horizontal rotary table electric cross - use dual - use dial Features: 1. With a display, intuitive scale, easy to operate; 2. Accuracy of up to 0.2 degrees; 3. Stepper motor and servo motor feedback system, allowing reliable, accurate than the existing servo system; 4. Circuit control system optimization, the use of user-friendly design, one-handed operation, easy to use, action instructions safe and reliable output. Model Table Base Dimensions Width of T-slot Bolt slots Center Sleeve Warm Gear Ratio Gross Weight kgs/lb Outer diameter Height D H A B e type g RT-6 150 78 210 184 10 10 MT-2 90:1 10.0 5.91 3.07 8.27 7.24 0.39 0.39 22.0 RT-8 200 105 280 250 12 14 MT-3 90:1 25.0 7.87 4.31 11.02 9.84 0.47 0.55 55.1 RT-10 250 115 340 300 12 16 MT-3 90:1 37.0 9.84 4.53 13.39 11.81 0.47 0.63 81.5 RT-12 600 135 400 364 14 18 MT-4 90:1 60.0 11.81 5.32 15.75 14.33 0.55 0.71 132.2 RT-14 350 140 460 420 14 18 MT-4 90:1 85.0 13.78 5.51 16.54 16.54 0.55 0.71 187.3

Control digital devices and make machinery more precise with a stepper motor from Alibaba.com"s wholesale equipment store. Our catalogue is the place to come when you need a replacement stepper motor rotary table or any other motor related products. You"ll find a huge array of wholesale motors, including step motors with high torque ratings that can offer incredibly precise control. Whether you"re constructing an astronomical telescope or a digital network for broadcasting, these motors will do the job.

Stepper motors are used in situations where devices need to be calibrated to extremely high levels of precision. They aren"t always the most powerful motors, but they do have very high torque levels, and this allows them to control devices in ways that other motors cannot. And they also tend to work well with digital devices due to their "step" mechanism. For instance, you can find step motors in many hard drives, handling millions of operations every minute. They have also become a go-to motor style for robotics installations. So you might need one for an advanced production line. When you need a stepper motor rotary table, finding the right motor is easy. Just search Alibaba.com"s catalogue and you"ll easily find what"s required.

Our stepper motor collection covers every base. Browse motors for use with mini computers like the Raspberry Pi or models designed for use with Arduino components. Look for permanent magnet motors, variable reluctance steppers, or hybrid syncronous steppers, and models with micro step, half step, and full step modes. Our listings include everything you need to control the most complex systems. So find a stepper motor rotary table and order what you need today. Everything can be handled with a couple of clicks, putting specialist stepper motor components within easy reach.

Designed specially for servo motor gearbox for motion control applications. It takes full advantage of the flexibility of the servo motor, giving designers greater freedom of mechanism design.

We are identified as one of a prominent manufacturer and supplier of high qualityRotary Tables.A turbo among rotary tables – the direct driven rotary tables with torque motor are optimally suited for all handling and assembly applications that require the shortest indexing times and flexible positioning. Thanks to its measuring system directly in the rotary table axis, any position can be moved to with the highest precision. The slim design with its very space-saving, compact construction and its fitted boreholes makes it very easy to integrate the rotary tale into your system

From rotary tables as small as 160mm diameter to tables over 3,000mm capable of quickly and precisely moving loads up to 400T, the Fibro range includes NC worm drives, Hirth coupling precision indexing tables, rotary cam drives, dual pinion positioning drives and high dynamic direct drive tables, all in a wide range of configurations

Fibrotor index tables are an industry standard for fast precise indexing in assembly and automation applications. The proven dynamic cam design provides minimum index times with well controlled acceleration and precise and rigid positioning, with a wide range of standard index angles.

They are characterized by a whole new machine concept and design approach, allowing flexible use. All components are freely programmable and represent sound solutions for re-engineering. It could be added planetary gearbox to increase the gear ratio, available for matching with any brand servo motor and stepper motor based on our flexible flange system, thus make it easy for automation production line building and robot designing.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

Rotary tables are used for precision metal work. They are usually made of a solid base that can be attached to another bracket. The table is a disk that rotates freely or with the help of a spiral (hand crank).

The rotary table is a disk-shaped metalworking device that enables precise positioning of the workpiece. It allows the metalworker to cut or drill the workpiece at precise intervals vertically or horizontally around a fixed axis. The turntable can be controlled both manually and digitally by computer. Some types of rotary tables are designed to be used with indexers or separators for special operations. A rotary table used with one of these positioning plates is often called a dividing or indexing head.

The Rotary tables is usually a sturdy base that can be attached to a separate stand or table. This device is basically a rotating disc that holds the workpiece in place while cutting or drilling. The disk portion of the rotary table can be freely rotated or rotated for indexing operations by means of an attached control lever known as a worm wheel. Tables used in precision operations are usually turned with a duplex type helical wheel to compensate for clearance. Rotary tables used in automated metalworking processes are connected to a digitally controlled computer.

Rotary tables are mostly used in a flat position with the table axis vertical. Sometimes they are installed with the shaft pointing horizontally so that the suppository can be used to support the free end of the workpiece. When this device is attached to the secondary table, the workpiece can be centered on the axis of the rotary table, which is then centered on the axis of the cutter. In this configuration, the axes of the rotary table, secondary table and cutter are coaxial to facilitate concentric cutting operations. This configuration also allows the secondary table to be moved to drill evenly spaced holes in the workpiece.

Rotary Table offers an unparalleled combination of good accuracy and high load capacity. These rotary stages utilize a precision worm gear with the worm “flexed” against the gear to ensure a proper mesh. This feature provides high repeatability with very smooth operation. Additionally, the rotary stages incorporate an oversized pre loaded cross roller bearing, offering exceptional stiffness and load capacity.

8613371530291

8613371530291