trunnion rotary table factory

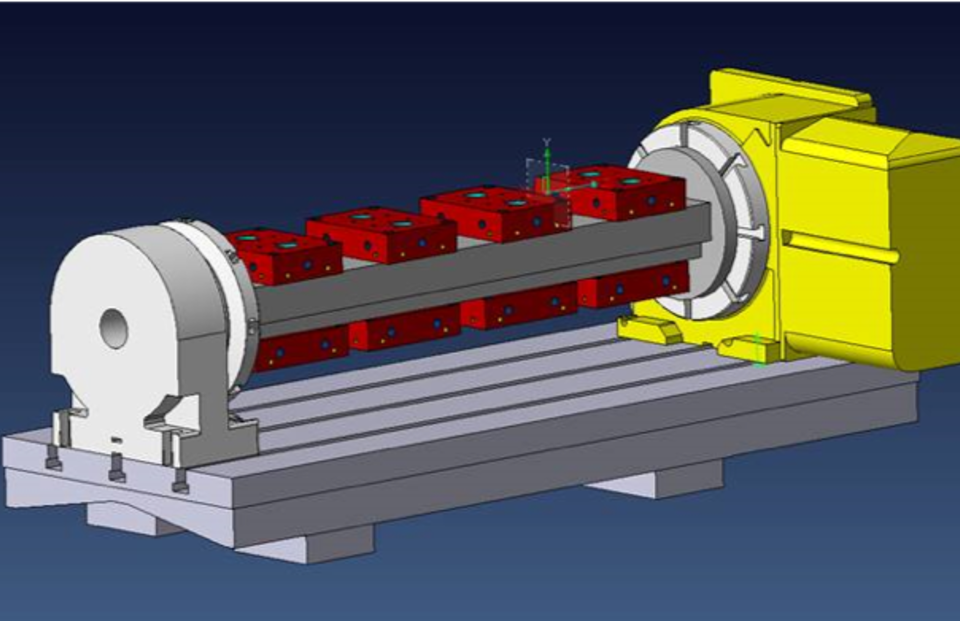

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

Martin Trunnion Tables offers complete 4th axis packages for Sankyo Automation rotary tables. Ready to be mounted into your machine, your Stallion Trunnion Table will already be attached to your Sankyo Automation Rotary Table and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis CNC machining. Scroll down for examples and package options! Don"t hesitate to reach out to us to discuss your manufacturing needs. Our applications engineers are always happy to help!

The TN4 Trunnion Table is a very compact yet rigid device offering rapid, zero backlash rotary motion using maintenance free Harmonic Reducers and Crossroller bearings. It is engineered and built here in California with all aluminum and stainless steel construction. This 2-Axis Trunnion is primary designed for machining applications and can be purchased as part of a complete 5 axis mill or as a retrofit to one of our existing 3 axis cnc mills. Both rotary axes are sealed to allow for operation with liquid coolant. Homing Switches are integrated into each axis to provide a repeatable reference point.

This trunnion table can also be used for non-machining applications such as dispensing and 2-Axis rotary positioning for sensor calibration. Call use today to discuss your custom application!

Sankyo Automation is the worldwide leader in cam indexer technology; continuously working to develop new, innovative technologies in motion control. Our collection of high-speed, high-precision rotary indexing solutions are frequently utilized in manufacturing systems that require accurate, high speed actions.

Benefit from one of AMROK"s complete 4th axis solutions through dramatic increased efficiency of your vertical machining center and rotary table. The Stallion Trunnion Table is made from Class 35 cast iron, making it a rigid and robust solution to your CNC machining needs. The Stallion Trunnion Table can be made in a variety of shapes and sizes, ranging from 10" to 10" in length and from one to eight faces. The 4th Axis fixture can also be integrated with all of your favorite workholding devices, including Schunk, AME, Mitee-bite, Triag, Jergens, and more! Scroll down to find your perfect 4th axis workholding solution.

The combination of the Shelf Unit Trunnion Table and AMROK Dovetail Vises provides a simple, small, and affordable workholding solution that takes the productivity of your rotary table to the next level. Still made from Class 35 Cast Iron, these smaller Trunnion Tables are still as rigid and durable as their big brother, the Stallion Trunnion Table, but are better for smaller machines, smaller parts, and smaller rotary tables.

The smallest standard trunnion table size, made 100% from Class 35 Cast Iron, is designed for smaller machine tools and rotary tables. Riser blocks and braking systems are available to accommodate for your machining needs.

The 9/23 Stallion Trunnion Table is designed to hold a double station 6-inch vise and features a through hole to open/close workholding device of choice. The outboard support is customized to the center height of your indexer along with faceplate dimensions.

The 9/35 and 10/30 trunnion table fixtures feature heavy bracing for the most demanding cuts. Large face mills are not a problem. The outboard support is customized to the center height of your indexer along with faceplate dimensions. Hydraulic and Pneumatic braking systems are recommended at this size.

The Stallion 12/48, the largest standard trunnion table, is highly engineered for rigidity and accuracy. This 4th axis fixture is made for the largest rotary tables and machine tools. At this size, our hydraulic and pneumatic braking systems are highly recommended.

The trunnion table is a rotary table designed to provide two additional axes to the 3-axis machine tools and increase the positioning accuracy. It is a very compact yet rigid accessory for modern CNC machining centers.

The trunnion table is designed to provide additional 2 axes to the 3-axis machine tools and increase the positional accuracy, which is a very compact yet rigid accessory for modern CNC machining centers. A trunnion type indexer is typically made from heavy-duty cast iron, providing maximum rigidity and quick rotation that is free of backlash. It is available for accurate machining operations like milling and drilling, which is suitable for medium to large applications.

Similar to 4th axis indexers, which is added onto the vertical machining center, in general, the tilting axes of trunnion tables upgrades the capability of cutting multiple sides of the intricate part simultaneously, the positional accuracy, the repeatability, and also productivity with a full 360° rotation. It usually comes with work-holding devices like machine vises, chucks, sub-plates, and also spacers. As for the power source and control system of this work holding device, there are manual, pneumatic, hydraulic and also computerized types in the market.

Trunnion tables rotational axes for various CNC machining centers enhance the productivity and surface properties of the intricate machining applications. These features make them highly sought-after accessories for machinining in aerospace, shipbuilding, automotive industry and more.

Different from the integrated 5 axis machining center, adding the high-performance rotary positioning technology, the trunnion rotary table can achieve the 5-axis machining operations with less cost and simple installation, expanding the available work of the general 3-axis machine tools. The structure is considered as the “3+2 axes machining”.

The trunnion platter upgrades the machining center by adding the rotational axes, or tilting axes, to the original three linear axes, which are known as the X-axis, Y-axis, and Z-axis. The X-axis on a machining center is the linear direction where the column travels along, which is typically the left-to-right direction in a VMC. The Y-axis is aligned with the path the workpiece moves along from front to back. The Z-axis is typically aligned with the main axis of the machine tool; it is vertical in a VMC.

A trunnion-type model offers the rotational axes around the X-axis and the Z-axis, achieving the 3+2 machining technology and high-end accuracy and productivity of CNC machines. However, before adding one to your machine tool, you should check if the CNC system of the 3-axis machine can accommodate the controlling of simultaneous 4- or 5-axis machining operations.

On the other hand, the 5-axis machines that have integrated tables or rotary work holding tools are also advantageous to ensure simultaneous 5-axis machining with a simpler setup. Although the acquisition cost of 5-axis CNC machining centers is much higher than adding an external accesory, they still have their advantages.

In the turning or milling machine, whether the spindle with the cutting tools is locked or not, the rotating trunnion table is used to turn the symmetrically round parts under a predetermined high speed. The workpieces are mostly large aerospace, energy industry components, or other medium to heavy-duty applications. Some CNC machines that leveraged the two rotational axes at once, which adds tilting movement to spin, can let the tools get further closer to the surfaces of the parts. It offers a stable plane for heavy workpieces to rest.

The open working area translates the power to a large range of movement for the trunnion table, providing fully 360° rotation. The wider the range of the rotational movement, the easier it is to operate the jobs, permitting much more high performance and rapid turning or milling of intricate contours. To provide high speed and high turning force during mill-turn operations, the trunnion rotary table used in the mill-turn machines will require drives that supply higher torque such as a 4,000-Nm torque drive to complete the tasks.

For starters, since it provides exceptional rigidity and flexibility for the machining center with the extra rotary motion, the machines can allow shorter and more hard cutters, which are produced with aggressive parameters.

These tooling options can upgrade the surface finishes, tool life and also reduce the cycle time. As for the trunnion table itself, it typically has heavily ribbed cast iron construction, making it durable and rigid to bear the vibrations and repeated operations in long-term use.

When it comes to the simple setups and installation, trunnion type models in the metalworking environment are designed to be flexible, which can be simply bolted onto a wide range of CNC machinery, allowing the user to cut on multiple sides of the parts for mid-range productions. The fast setups and ease of operations for precise 5-axis turning, milling, drilling and other machining tasks provide the solution to significantly upgrade the productivity of the shop in a short time.

Attached simply to the rotary table of practically any indexer, MMS trunnion fixtures eliminate multiple setups in product runs and allow machine operators to precisely modify three different part surfaces without repeatedly changing cumbersome clamps and vises that create costly downtime. And, because they are constructed of heavy-duty cast iron, MMS trunnion table fixtures are highly rigid and durable — built to withstand long-term, repeated use in even the most demanding Shop environments. Available in a variety of standard sizes with free center height alterations, or in custom configurations.

The FAR Series is TJR’s standard pneumatic brake tilt rotary table line comes in single arm, cradle type dual arm, extended cradle type dual arm options. The FHR Series is TJR’s standard hydraulic brake line offered in dual arm cradle type and dual arm extended cradle type tilt rotary tables

The compact tilt rotary table design with a 170mm(6.69”) face plate diameter and is ideal for smaller machining centers and smaller workpieces. Featuring full rotation and tilt capabilities, they can be integrated into your existing machine control for 5 axis operation.

The manual tilt table is designed with a full 4th axis (rotating axis) and a manual tilting axis. It is available in 255mm table diameter and is ideal for customers who need a rotating axis but only occasionally require tilting axis capabilities.

The following example shows how you can load 8 basic prismatic components onto a trunnion fixture and produce 4 finished parts every completed cycle providing reduced fixturing, setup times and also equating to longer machine cycle utilisation time. In turn, this allows the operator to do complete other duties/run other machines.

The trunnion setups can incorporate the Zero Point system allowing reduced component loading in the machine time but enabling a quick and accurate fixture change over at the end of the cycle. This enables the reloading of the fixture to be completed while the machine is running the next set of components.

Turn Your Vertical Machining Center into a 5-Axis Production Machine. Designed specifically for Vertical Machining Centers, KME CNC’s 5-axis platters are built right into a precision rigid meehanite cast iron trunnion frame and table.

Standard models come with 1, 2, or 3 independent 5-axis platters on the trunnion table, giving your VMC full-range production capability. Just like the 5-axis tombstones, KME CNC’s trunnions are able to completely integrate with control systems, so you do not need to program the control box.

Martin Trunnion Tables, a company located near Cincinnati OH, manufactures custom and standard CNC Trunnion Table Fixtures for Vertical and Horizontal Machining Centers and Rotary Tables. They sell their products worldwide to companies converting from 3 to 4 axis machining.

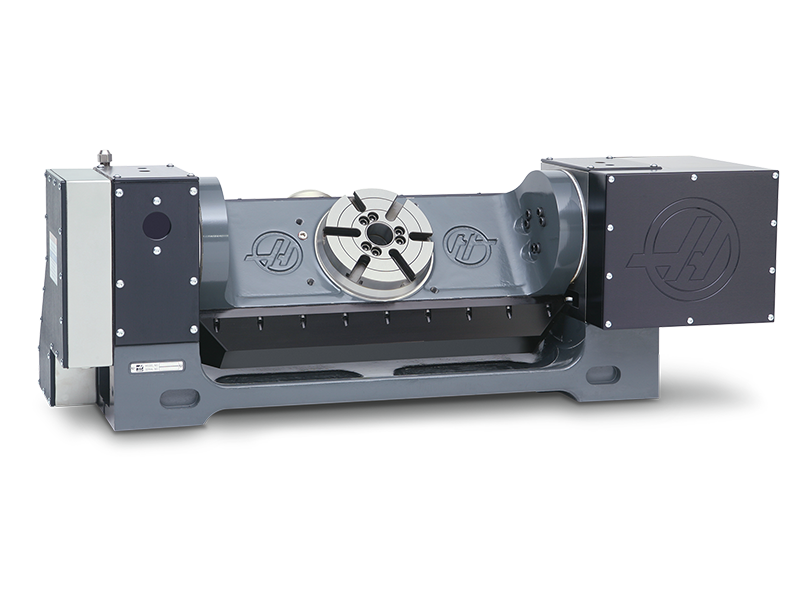

The TR160Y dual-axis trunnion rotary table puts 5-axis capabilities well within reach of the average job shop, and its compact size provides greater mounting flexibility.

Five-axis machining is becoming more common today as a means to reduce set-up time and increase accuracy for complex parts. But investing in a 5-axis machine tool can be prohibitively expensive, especially for smaller shops. The TR160Y dual-axis trunnion rotary table from Haas Automation (Oxnard, CA) puts 5-axis capabilities well within reach of the average job shop, and its compact size provides greater mounting flexibility.

The TR160Y is designed to mount in the Y direction (front to back on the table) of a mid-size vertical machining center. At less than 25 in wide and only 20 in deep, the TR160Y easily fits on one end of the machine’s table, freeing up the remainder for additional fixtures or vises. The TR160Y has a 160 mm T-slot platter, and will swing parts up to 7.5 in diameter. The maximum platter capacity is 80 lb. The trunnion provides ±120 deg of tilt and 360 deg of rotation for full simultaneous 5-axis motion, or to position parts to almost any angle for machining. Yet, like all Haas rotary tables, it can easily be removed when not needed.

Powerful brushless servomotors provide 150 ft-lb of spindle torque on both axes of the TR160Y. Brake torque is 300 ft-lb and 100 ft-lb respectively, and speeds are 130 deg/sec on the rotary axis and 100 deg/sec on the tilt axis. The trunnion’s precision-ground platter of heat-treated 4140 alloy steel has six standard 5/8 in T-slots equally spaced at 60 deg for easy fixturing. Three servo-control configurations are available, making the TR160Y easy to interface to almost any machine.

Roller cam: Compared with worm gears type it is with higher wear resistance, high transmission efficiency , affordable prices and basically maintenance-free of table.

Table directly driven by a motor, high rotary speed , no backlash, no weariness and low inertia. But relatively technical requirement is high and difficulty, the price is the most expensive. Generally used for five-axis machine tools.

Our rotary table can be used in the aerospace industry, 3C high-tech industry semiconductor parts, auto parts and components automation manufacturing, or bathroom equipment and daily necessities manufacturing etc.

The backlash control of our rotary table is stable and reliable, it can be adjusted at the same time and is easy to operate to meet high-precision processing and production requirements, so that it can help customers reduce costs and create more profits.

8613371530291

8613371530291