trunnion rotary table free sample

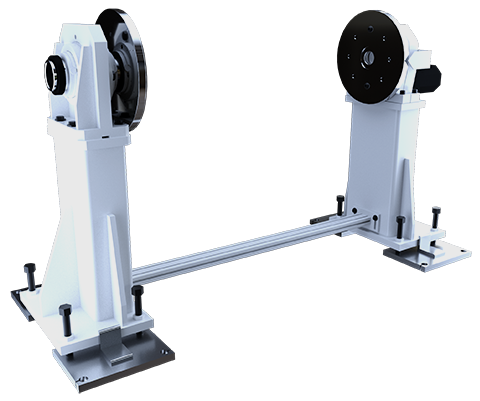

The Motion Index Drives RT Fixed Trunnion Series Rotary Tables encompass a large range of sizes, ranging from our model RT100 up to our RT1250. In addition, special cam-driven devices can be custom made to order for your automation needs. RT Series Rotary Indexing Tables are offered in a fixed number of stations or as a flexible turntable with a servo motor or standard AC brake motor with encoder. With the addition of Motion’s patented NANO Indexer Technology, the RT Fixed Trunnion Series becomes the world’s most accurate barrel cam indexers. RT Series indexing tables are constructed with strength and reliability in mind. Robust design and components ensure this device will maintain precision in intense factory settings.

Here"s a scenario that you"re likely familiar with: you"ve just completed a rush order of 10 parts on your 4th-axis trunnion solution, but before you even made the parts, you had to take your collet chuck off of your rotary table, install the trunnion, indicate it in, set your tools and work offsets, and probably more. But who cares, right? Your parts are complete, they"ve passed inspection, and everyone is happy. But wait, now you need your collet chuck back for the job you were previously running. You know the drill: take the trunnion off, mount the chuck to the t slots, tram it in, and go.

Our solution to this inefficiency was rather simple: let"s just mount our collet chuck, or other workholding, to a bolt pattern on the back of our TS400 so that the setup never has to leave the machine. This completely eliminates the hassle of constantly reinstalling a specific workholding device for your variety of jobs. The TS400 is a dual-disc pneumatic braking system that hooks directly to the solenoid valve of just about any rotary table on the market. Its role is to keep the trunnion table rigid and unaffected by leverage during machining. The design now features a 3" OD boss that can be located on a fixture or adapter plate, along with a 2.25" diameter bolt-hole circle with (6) 3/8-16 tapped holes. This simple addition allows you to mount just about any workholding device to the end of your trunnion table.

The days of a shop surviving on only a table vise and a 3-jaw chuck are over. Now we have quick change bases, zero point workholding, robot-ready pneumatic vises, pneumatic collet blocks, and much more. While we don"t claim to have all of the answers, there are a few fantastic options on the market that can be used in conjunction with our Stallion Hybrid, and we"d like to go over a couple of these.

Another option for our hybrid system is a self centering vise from 5th Axis. In this animation, we are displaying the added versatility of a trunnion system when it"s used in conjunction with RockLock tooling. Quickly exchange self centering vises for dovetail vises, double station vises, and more.

As our friends at Advanced Machine and Engineering say, every workholding system needs to start with a solid foundation. There are many ways to achieve a repeatable solution for your mill, and a fixture plate with a standard grid pattern is certainly one of them. Our foundation plates for HAAS machine tools feature a 2" grid pattern with 1/2-13 tapped holes and .501" ID bushings to allow for accurate and fast setup change over between jobs. It locates straight into the T slots of your machine tool and is held flat within .001" over the entire length. This foundation is absolutely vital to any high mix shop that is tired of wasting setup time with traditional t-slots. Many other workholding companies have solid options for repeatable setups, and we would be foolish to say our system is the only one available. You can use RockLock bases, VERO-S workholding, and other systems to achieve this foundational setup for your automation solution.

Our bread and butter, the original Stallion Trunnion was originally made for a simple Kurt vise. Today, it"s been outfitted with a variety of autonomous workholding systems. We are using the Stallion 9/23 in this setup, which is perfect for reaching multiple sides of your parts and keeping your robot from handling your workpiece more than necessary. It is cast from class #35 iron, making it rigid and capable of superior vibration damping to traditional steel. This system is also outfitted with pneumatic lines to feed air to your vises as well as the necessary rotary union on the HRT-210 to keep everything compact and tangle free.

The SCHUNK KSP3 160 pneumatic vise is, in our humble opinion, the best pneumatic vise on the market for automation. If you are looking for a long lasting, high clamping force vise for your robotics solution, this is the line to go with. It has 45kN of clamping force with .01mm repeatability and can be mounted straight to the deck of our Stallion 9/23. All of the pneumatic lines, rotary unions, and other fittings will be supplied and tested by our team before shipment.

While this option is typically used on our larger trunnion models, it is a great solution if you for-see needing to take heavy, off center cuts on your fixture. When machining far from centerline of rotation or from the faceplate of the rotary table, it is often the case that the standard rotary table brake needs additional support to eliminate any movement while machining. Our TS1200 hydraulic braking system utilizes a squeeze bushing design, an outboard support held to .0003" of the rotary table center height, and an air over oil booster. The air over oil booster connects straight to the solenoid valve of the rotary table, making any additional machine parameter changes unnecessary.

From time to time or very often for some shops, a batch of parts comes through the door that not only requires multi-op machining, but also a high volume solution. The traditional way to handle this is to design 3 or 4 special fixtures to hold this part for each operation and manually rotate the workpiece until the finished part is complete. Today, with the growing interest and market for 5 axis machines, this process can be eliminated relatively easily, but not for an inexpensive price tag. So what does one do when presented with a high volume job that requires multiple operations? Using a tombstone style trunnion table with flexible and repeatable workholding, high volume can be achieved in your 3 axis mill affordably and smoothly.

Today we are discussing the combination of 5th Axis Workholding products, Lyndex Nikken rotary tables, and the Stallion Tombstone fixture. Last week we put out a new animation that featured products from all three of these companies. You can view this video below for context.

First, let"s talk about the rotary table. This CNC 260 from Lyndex Nikken has a center height of 170mm, a 260mm faceplate with 8 key slots for mounting, and a weight capacity, as stated earlier, of 673 lbs. Because we decided to go with the rocklock bases, we had no choice but to include a 2.5" center height. The trunnion table fixture locates into the through hole in the faceplate of the rotary table and mounts using t-nuts and SHCS.

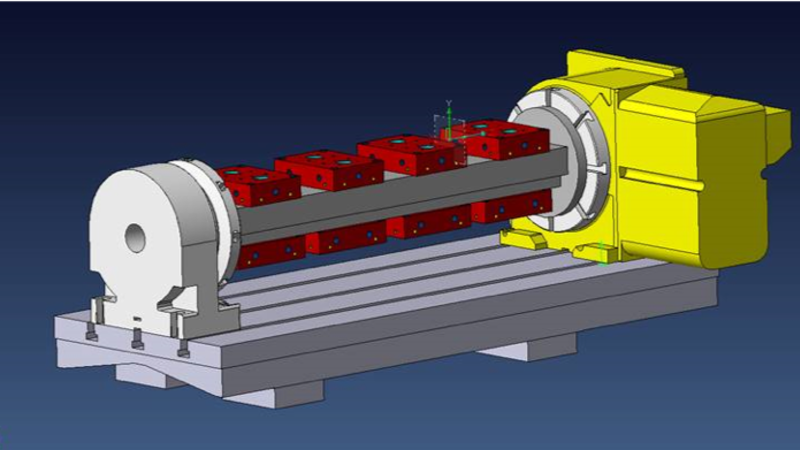

Moving on to the trunnion fixture itself, this is a 6" tombstone measuring 36" in length and of course features the mounting pattern for the rocklock bases from 5th Axis. This tombstone is made entire from class 35 cast iron, making it extremely rigid and capable of absorbing vibration. These features help to eliminate chatter and flex. It also features the TS1200 hydraulic braking system, which allows for heavy, off center milling and drilling with its 500 ft. lbs. of clamping torque. In this application we decided to go with the RL52S-4560 RockLock bases as well as the V75100X Self-Centering Vises. These vises offer plenty of clamping range to support the workpieces.

Combining products from Lyndex Nikken, Martin Trunnion Tables, and 5th Axis can potentially save you hundreds of thousands of dollars that would be spent on a 5 axis mill. Reach out to us today for a free consultation on improving your 3 axis mill with a complete 4th axis workholding solution.

We often work and collaborate with our partners, Lyndex Nikken, to provide fixtures to our mutual customers. In this blog post we are going to run through some of our most commonly use applications that feature both the Stallion Trunnion Table and the line of Nikken rotary tables. The rigidity and immense clamping torque of the Nikken rotary table, when paired with our products, offers the perfect 4th axis solution to your vertical machining center. Our first highlighted fixture is the Stallion 9/20 attached to the Lyndex Nikken CNC 302. While a rotary table of this size is not needed to rotate this smaller trunnion table fixture, it is what the customer had purchased, so we adapted the center height of the outboard support to meet that of the rotary table. We are also using paws workholding clamps, which offer an affordable, low profile solution to CNC workholding. It is also worth noting that the combined clamping torque of the CNC 302 and the TS1200 hydraulic braking system make this workholding solution extremely rigid. The beauty of this design is its ability to rotate to all of the five sides of the workpiece that need machined. Watch the animation below for a visual representation of this concept:

The next concept features the Lyndex Nikken CNC 180 and the Stallion Tombstone. In this case, we are utilizing the Delta IV Compact vise and the Stallion Tombstone in order to maximize part density. In this case, we are left with up to eight finished parts each cycle. The tombstone style trunnion table can be made to virtually any length and can be manufactured with 4", 6", 8" or 10" faces. The faceplate of the CNC180 rotary table has 4 t-slots, therefore, a 4-holed, 90 degree pattern was machined into the endplate of the trunnion table to allow for immediate and easy installation when the product arrived at the customer"s plant. This design also features a riser block, which allows for full, 360 degree rotation of the fixture when inserting blanks into the the set of cnc vises. Watch the animation below for a visual of this:

In recent years, pneumatic clamping has become a very popular feature to pair with a 4th axis solution. Pneumatic clamping opens manufacturers up to the benefits of automated part loading and more accurate clamping solutions. In this demonstration, we are featuring the Stallion 9/20 Trunnion Table, the Nikken CNC 302 rotary table, and the SCHUNK Vero-S pneumatic clamping solution.

Aside from some of our custom made products, our standard Stallion models with a two inch grid pattern offer immense setup flexibility and repeatability. By including a grid pattern on a 4th axis fixture, the setup and fixturing possibilities greatly expand. Many of the workholding companies that we work with offer products that will easily mount and locate on this two inch grid pattern, such as 5th Axis, AME, Triag International, and many others. Overall, the Stallion Trunnion Table and Lyndex Nikken rotary tables offer a great pair to introduce your manufacturing process to the benefits of 4th axis machining. For more information, visit this page: https://www.trunniontable.com/lyndexnikken.html

We have been working closely with our partners, KOMA Precision, for years to build fixtures for manufacturers using their rotary tables. Today we are going to review some of the workholding solutions that we have put together and the applications that these designs are best used for. The first concept involves the RBS-160R rotary table, the Stallion 5/18 Trunnion Table, and the Orange Vise Delta IV compact vise. The Stallion 5/18 is primarily designed for smaller rotary tables, making it the perfect fixture for this particular model. Orange Vise also offers ball receivers, which we are using here, to allow for fast and repeatable reorientation of the Deltav IV vise. With that said, this 4th axis fixture can be used for two, smaller parts or one large part when the vises are turned 90 degrees.

Autonomous clamping added to the 4th Axis is often the perfect solution to a fully automated vertical milling machine. Our partners, SCHUNK, offer a wide range of pneumatic clamping products that take the efficiency and productivity of our products to a different level. Here we are featuring the SCHUNK KSP-160 PLUS pneumatic vises, the Stallion 9/20 Trunnion Table, and the KOMA RWA-200. While you can"t see it in these renders, a rotary union resides on the back end of the rotary table, which keeps the air lines from tangling while the 4th axis Stallion is rotating. Pneumatic clamping allows for more precise part location, resulting in tighter tolerances, less operator error, and the possibility of using a robotics solution.

If you own a vertical machining center, you will know that it is often difficult to justify purchasing a fixture that will take up your entire machine table. We developed the shelf unit trunnion tables out of pure necessity: we needed something small that was still just as efficient and productive as our standard, but longer units. Here, we are featuring the KOMA RBS-160R with single, double, triple, and 4-sided unit trunnion tables. The single and double sided configurations feature the rocklock bases from 5th axis workholding along with the V552 self centering vises. The 3 and 4 sided models instead feature the V5100X vise; this style is best suited for smaller, high volume parts.

While the Stallion Trunnion Table can be designed and manufactured for any CNC rotary table on the market, we have more experience making fixtures for HAAS rotary tables than any other brand. We are often faced with limitations due to machine table size, machine travel and rotary table capabilities. In this post we are running through potential 4th axis applications specifically for your HAAS rotary tables and how they resolved certain limitations.

In our first workholding solution, we are featuring the HRT-210 and the Stallion 9/23. In this case, we were faced with a job that included many parts at many different sizes. With that said, we knew we needed to use a modular workholding system that would allow us to machine parts at many different lengths. The solution: Triag International Workholding. This vise system features a base rail that allows for the clamping modules to be moved to different positions, which creates immense setup flexibility as the Triag product can be used for a wide variety of parts. The deck of the trunnion table has a two inch grid pattern with hardened bushings in every other hole, which works seamlessly with the triag rail and power clamps. On the support end of the fixture resides our TS400PNU braking system. At over 400 ft. lbs of clamping torque, this pneumatic brake keeps the trunnion table extremely rigid when making heavy, off center cuts to the workpiece. While this animation instead features a KOMA Precision Rotary Table, it displays this concept perfectly:

The second setup features the HRT-160 and the Stallion 9/20 Trunnion Table. One of our most often faced obstacles in fixture design is making sure that the customer"s parts can be rotated 360 degrees. The HRT-160 has a center height of just 5 inches, which prompted us to provide a 1" riser block for this customer"s rotary table while simultaneously adjusting our outboard support center height to match this 6 inch mark. This adjustment allowed for our customer"s parts, along with the 5th Axis V552 vises, to be rotated 360 degrees. This design also features our TS1200 Hydraulic braking system, which has 500 ft. lbs of clamping torque at 100 PSI. Similarly to the TS400PNU from the previous setup, this feature is designed to allow for heavy, off center milling and drilling of the customer"s workpiece.

Our last fixture highlighted in this post features a HAAS HRT-310 with a Stallion Triangle Trunnion Table attached. This design again features the Triag International Rail and Power Clamps. The triangle configuration offers the immense benefit of tool clearance. Because the trunnion table features three sides on 60 degree angles as opposed to four sides on 90 degree angles, there becomes less concern about investing in longer tools. The bolt-hole pattern on the end plate of the fixture is customized for the HRT-310, allowing the manufacturer to easily insert and remove the trunnion when necessary, Additionally, the entire assembly resides on a baseplate, which results in a very short and simple setup time.

Samchully Workholding offers a wide variety of rotary table options for vertical machining centers. Martin Trunnion Tables often supplies workholding fixtures for these units, greatly increasing their productivity and versatility. In this week"s post we are going to breakdown a few of our favorite applications featuring samchully rotary tables and why each of them is especially unique.

The first workholding solution includes the S-170 with a Stallion 9/20 Trunnion Table fixture attached. This design was made specifically for the Doosan DNM-4500 machine tool. The fixture plate bolts directly to the machine table, providing a flexible and repeatable solution for all of the your fixturing needs. Above that, the trunnion assembly resides on a baseplate which provides ease of transportation in and out of the machine tool. Underneath of the rotary table, you will find a 1" riser, which is there to provide full 360 degree rotation of the working trunnion surface. The deck of the trunnion includes the Jergens fixture pro cnc vises, making this a perfect solution for small, high production parts:

There are often times when a 4th CNC operation must be completed on a different workholding device or machine tool. The following fixture solves this issue and leaves you with a completed part every cycle. This setup was built specifically for the Doosan DNM-5700 and features a Stallion 9/23 Trunnion Table attached to a Samchully S-250 Rotary Table. Similarly to the previous setup, here we have a fixture plate designed for the DNM-5700 machine table with a baseplate and 4th Axis assembly residing on its surface. Aside from the large amount of time saving that comes from a 4th axis solution, the additional benefit of this cnc fixture is the vise that sits to the left of the 4th axis assembly. This additional allows for the machining of an additional operation, independent from the machining that takes place on the trunnion table. As stated, this leaves the operator with a completed part each cycle,

Our last 4th axis solution features the Samchully S-320 rotary table with a Stallion 6" Tombstone attached. This setup was designed specifically for the Doosan DNM 6700. This setup, along with the previous two, features a TS1200 hydraulic braking system. This brake, designed and manufactured by Martin Trunnion Tables, is purposed to keep the 4th axis fixture from flexing and rotating during heavy, off center machining. In terms of workholding, we went with the CDV centering vises from Advanced Machine and Engineering. This 4th axis solution is perfect for high quantity jobs.

Here at Martin Trunnion Tables, we frequently make fixtures for a variety of machine tools and rotary tables, including Doosan and Samchully Workholding. To view more example fixtures such as these, visit our 4th axis solutions page exclusive to Samchully Rotary Tables.

In this week"s highlighted CNC 4th Axis fixture, we are utilizing PAWS Workholding Wedge Clamps, the Stallion 9/20 Quick Change, the Lyndex Nikken CNC 302 Rotary Table and Jergens Ball Lock Workholding. Our main concern with this setup was cutting out time consuming setups and increasing part density. Prior to utilizing the tools mentioned above, our customer was machining just one part and one setup at a time. This particular part has 5 angles that need face-milled, as well as drilled and tapped. We were able to cut all of these out, allowing the operator to only open the doors on the machine once every eight parts!

The combination of the Lyndex Nikken Rotary Table and the Stallion 9/20 Quick Change Trunnion Table allowed us full 360 degree rotation of the aluminum blanks. Without this, we would not have been able to reach all 5 sides of the part. Customized for the CNC 302, the Trunnion Table 4th Axis fixture bolts directly to the faceplate of the rotary table. The entire assembly is also mounted on a baseplate, which allowed for an easy installation.

There are huge benefits to using modular workholding such as these PAWS Wedge Clamps. Should we have used a regular vise, we would have been limited to a maximum of two parts per cycle. While this is still better than the previous method of doing one part and one angle at a time, why machine two parts when you can machine eight? The small and low profile nature of the wedge clamps allowed us to truly utilize the entire 20" working surface of the Trunnion Table.

Overall, the partnerships that Martin Trunnion Tables holds with these forward-thinking companies allowed us to greatly increase the throughput for the end user.

Trunnion tables aren"t limited to standard pneumatic clamping. These versatile and efficient machines can also be outfitted with automatic, hydraulic clamping systems to minimize loading error and greatly increase efficiency and spindle time. Over the years, we have made several hydraulic fixtures featuring Vektek Swing Clamps:

You may have seen the video via our instagram account of the Stallion 9/23 featuring the swing clamps in the image above. This trunnion was made for Mako Finished Products. In this case, six single acting clamps are fed with a manifold block that is hooked to an air over oil intensifier. By using a Trunnion Table fixture, the customer was able to machine all three sides of this part in a single setup, greatly increasing the efficiency of their machine, while simultaneously reducing the likelihood of scrap. In order to achieve full 360 degree rotation, we outfitted the HRT-210 with a riser block and created a larger outboard support. This, of course, created concern for tool clearance, but we were able to make it work in this customer"s HAAS VF-2. Watch the video:

In this case, the Stallion Trunnion also has a TS 1200 Hydraulic braking system on the outboard support. This created the need for a second air over hydraulic pump to allow both the brake and the vektek clamps to work simultaneously. Unlike the previous design, this part did not warrant a riser block, as 360 degree rotation could be achieved with the standard 6 inch center height of the HRT-210. Watch it in action:

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

The rotary tables and trunnion drives of the EXPERT-TÜNKERS EDX series are precision indexer with fixed pitch and maximum torque. They are used for dynamic cycles of loads up to 20 tons. The drive takes place via an energy-efficient geared three-phase motor.

A characteristic of EDX Series rotary tables is the fact that the dial plate is continuously driven by two cam followers. In addition, this double meshing of the roller pins ensures virtually zero-backlash locking of the turntable plate in the operating position. Alternatively, this can be achieved by widening the zero position.

The indexing positions of the rotary table are defined in the motion profile specified in the indexing cam. Most common, partitions are 2-stop = 180°, 3-stop = 120° and 4-stop = 90°. Individual solutions are available on request.

Typical applications for EXPERT-TÜNKERS turntables are, for example, the change of work pieces in body shop welding systems, the insertion and removal of work piece carriers, or as a turntable for clocked work sequences in series production. The EDX Series of rotary tables are not only suitable for conventional use as rotary tables but also as trunnion drive units with a horizontal axis of rotation. These trunnion systems can provide several tooling’s for flexible production lines.

The EDX Series of rotary tables are not only suitable for conventional use as rotary tables but also as trunnion drive units with a horizontal axis of rotation. These trunnion systems can provide several toolings for flexible productionlines.

The trunnion table is a rotary table designed to provide two additional axes to the 3-axis machine tools and increase the positioning accuracy. It is a very compact yet rigid accessory for modern CNC machining centers.

The trunnion table is designed to provide additional 2 axes to the 3-axis machine tools and increase the positional accuracy, which is a very compact yet rigid accessory for modern CNC machining centers. A trunnion type indexer is typically made from heavy-duty cast iron, providing maximum rigidity and quick rotation that is free of backlash. It is available for accurate machining operations like milling and drilling, which is suitable for medium to large applications.

Similar to 4th axis indexers, which is added onto the vertical machining center, in general, the tilting axes of trunnion tables upgrades the capability of cutting multiple sides of the intricate part simultaneously, the positional accuracy, the repeatability, and also productivity with a full 360° rotation. It usually comes with work-holding devices like machine vises, chucks, sub-plates, and also spacers. As for the power source and control system of this work holding device, there are manual, pneumatic, hydraulic and also computerized types in the market.

Trunnion tables rotational axes for various CNC machining centers enhance the productivity and surface properties of the intricate machining applications. These features make them highly sought-after accessories for machinining in aerospace, shipbuilding, automotive industry and more.

Different from the integrated 5 axis machining center, adding the high-performance rotary positioning technology, the trunnion rotary table can achieve the 5-axis machining operations with less cost and simple installation, expanding the available work of the general 3-axis machine tools. The structure is considered as the “3+2 axes machining”.

The trunnion platter upgrades the machining center by adding the rotational axes, or tilting axes, to the original three linear axes, which are known as the X-axis, Y-axis, and Z-axis. The X-axis on a machining center is the linear direction where the column travels along, which is typically the left-to-right direction in a VMC. The Y-axis is aligned with the path the workpiece moves along from front to back. The Z-axis is typically aligned with the main axis of the machine tool; it is vertical in a VMC.

A trunnion-type model offers the rotational axes around the X-axis and the Z-axis, achieving the 3+2 machining technology and high-end accuracy and productivity of CNC machines. However, before adding one to your machine tool, you should check if the CNC system of the 3-axis machine can accommodate the controlling of simultaneous 4- or 5-axis machining operations.

On the other hand, the 5-axis machines that have integrated tables or rotary work holding tools are also advantageous to ensure simultaneous 5-axis machining with a simpler setup. Although the acquisition cost of 5-axis CNC machining centers is much higher than adding an external accesory, they still have their advantages.

In the turning or milling machine, whether the spindle with the cutting tools is locked or not, the rotating trunnion table is used to turn the symmetrically round parts under a predetermined high speed. The workpieces are mostly large aerospace, energy industry components, or other medium to heavy-duty applications. Some CNC machines that leveraged the two rotational axes at once, which adds tilting movement to spin, can let the tools get further closer to the surfaces of the parts. It offers a stable plane for heavy workpieces to rest.

The open working area translates the power to a large range of movement for the trunnion table, providing fully 360° rotation. The wider the range of the rotational movement, the easier it is to operate the jobs, permitting much more high performance and rapid turning or milling of intricate contours. To provide high speed and high turning force during mill-turn operations, the trunnion rotary table used in the mill-turn machines will require drives that supply higher torque such as a 4,000-Nm torque drive to complete the tasks.

For starters, since it provides exceptional rigidity and flexibility for the machining center with the extra rotary motion, the machines can allow shorter and more hard cutters, which are produced with aggressive parameters.

These tooling options can upgrade the surface finishes, tool life and also reduce the cycle time. As for the trunnion table itself, it typically has heavily ribbed cast iron construction, making it durable and rigid to bear the vibrations and repeated operations in long-term use.

When it comes to the simple setups and installation, trunnion type models in the metalworking environment are designed to be flexible, which can be simply bolted onto a wide range of CNC machinery, allowing the user to cut on multiple sides of the parts for mid-range productions. The fast setups and ease of operations for precise 5-axis turning, milling, drilling and other machining tasks provide the solution to significantly upgrade the productivity of the shop in a short time.

In 1996, Precision Detroit Company established a relationship with WEISS GmbH. WEISS has been manufacturing high quality index tables for decades and is the leading automation component manufacturer in Europe today.

In August, 2007, WEISS GmbH established WEISS North America, Inc. as a wholly-owned subsidiary. On September 30, 2007, WEISS North America, Inc. acquired the assets of Precision Detroit Company, Inc. relative to its PDC Geneva Motion index tables and its network of sales representatives throughout the U.S. and Canada.

Today, WEISS North America is not only a rotary table manufacturer but your complete automation manufacturer and solutions partner. WEISS has decades of expertise in providing automation, drive and control solutions to industrial markets. WEISS offers industry-specific, cost-effective and efficient technology solutions to help you maximize your efficiency, increase your productivity and achieve optimal system performance. We understand that your application has unique processes and specific requirements and we work closely with you to develop the perfect automation solution for your particular needs.

In 1996, Precision Detroit Company established a relationship with WEISS GmbH. WEISS has been manufacturing high quality index tables for decades and is the leading automation component manufacturer in Europe today.

In August, 2007, WEISS GmbH established WEISS North America, Inc. as a wholly-owned subsidiary. On September 30, 2007, WEISS North America, Inc. acquired the assets of Precision Detroit Company, Inc. relative to its PDC Geneva Motion index tables and its network of sales representatives throughout the U.S. and Canada.

Today, WEISS North America is not only a rotary table manufacturer but your complete automation manufacturer and solutions partner. WEISS has decades of expertise in providing automation, drive and control solutions to industrial markets. WEISS offers industry-specific, cost-effective and efficient technology solutions to help you maximize your efficiency, increase your productivity and achieve optimal system performance. We understand that your application has unique processes and specific requirements and we work closely with you to develop the perfect automation solution for your particular needs.

The trunnion table is a rotary table designed to provide two additional axes to the 3-axis machine tools and increase the positioning accuracy. It is a very compact yet rigid accessory for modern CNC machining centers.

The trunnion table is designed to provide additional 2 axes to the 3-axis machine tools and increase the positional accuracy, which is a very compact yet rigid accessory for modern CNC machining centers. A trunnion type indexer is typically made from heavy-duty cast iron, providing maximum rigidity and quick rotation that is free of backlash. It is available for accurate machining operations like milling and drilling, which is suitable for medium to large applications.

Similar to 4th axis indexers, which is added onto the vertical machining center, in general, the tilting axes of trunnion tables upgrades the capability of cutting multiple sides of the intricate part simultaneously, the positional accuracy, the repeatability, and also productivity with a full 360° rotation. It usually comes with work-holding devices like machine vises, chucks, sub-plates, and also spacers. As for the power source and control system of this work holding device, there are manual, pneumatic, hydraulic and also computerized types in the market.

Trunnion tables rotational axes for various CNC machining centers enhance the productivity and surface properties of the intricate machining applications. These features make them highly sought-after accessories for machinining in aerospace, shipbuilding, automotive industry and more.

Different from the integrated 5 axis machining center, adding the high-performance rotary positioning technology, the trunnion rotary table can achieve the 5-axis machining operations with less cost and simple installation, expanding the available work of the general 3-axis machine tools. The structure is considered as the “3+2 axes machining”.

The trunnion platter upgrades the machining center by adding the rotational axes, or tilting axes, to the original three linear axes, which are known as the X-axis, Y-axis, and Z-axis. The X-axis on a machining center is the linear direction where the column travels along, which is typically the left-to-right direction in a VMC. The Y-axis is aligned with the path the workpiece moves along from front to back. The Z-axis is typically aligned with the main axis of the machine tool; it is vertical in a VMC.

A trunnion-type model offers the rotational axes around the X-axis and the Z-axis, achieving the 3+2 machining technology and high-end accuracy and productivity of CNC machines. However, before adding one to your machine tool, you should check if the CNC system of the 3-axis machine can accommodate the controlling of simultaneous 4- or 5-axis machining operations.

On the other hand, the 5-axis machines that have integrated tables or rotary work holding tools are also advantageous to ensure simultaneous 5-axis machining with a simpler setup. Although the acquisition cost of 5-axis CNC machining centers is much higher than adding an external accesory, they still have their advantages.

In the turning or milling machine, whether the spindle with the cutting tools is locked or not, the rotating trunnion table is used to turn the symmetrically round parts under a predetermined high speed. The workpieces are mostly large aerospace, energy industry components, or other medium to heavy-duty applications. Some CNC machines that leveraged the two rotational axes at once, which adds tilting movement to spin, can let the tools get further closer to the surfaces of the parts. It offers a stable plane for heavy workpieces to rest.

The open working area translates the power to a large range of movement for the trunnion table, providing fully 360° rotation. The wider the range of the rotational movement, the easier it is to operate the jobs, permitting much more high performance and rapid turning or milling of intricate contours. To provide high speed and high turning force during mill-turn operations, the trunnion rotary table used in the mill-turn machines will require drives that supply higher torque such as a 4,000-Nm torque drive to complete the tasks.

For starters, since it provides exceptional rigidity and flexibility for the machining center with the extra rotary motion, the machines can allow shorter and more hard cutters, which are produced with aggressive parameters.

These tooling options can upgrade the surface finishes, tool life and also reduce the cycle time. As for the trunnion table itself, it typically has heavily ribbed cast iron construction, making it durable and rigid to bear the vibrations and repeated operations in long-term use.

When it comes to the simple setups and installation, trunnion type models in the metalworking environment are designed to be flexible, which can be simply bolted onto a wide range of CNC machinery, allowing the user to cut on multiple sides of the parts for mid-range productions. The fast setups and ease of operations for precise 5-axis turning, milling, drilling and other machining tasks provide the solution to significantly upgrade the productivity of the shop in a short time.

The fastest way to increase the productivity of your Haas mill is to add a Haas single or dual-axis rotary product. You can reduce or totally eliminate multiple setups, and easily handle machining multi-sided parts.

With a full line of Haas rotary products, including many specialised units designed for maximum productivity, Haas continues to lead the way to higher productivity through automation.

All Haas rotary products are designed to integrate seamlessly with the control on your Haas mill. This means true simultaneous 4-axis or 5-axis motion, synchronized with the axes of your mill. Rotary setup is a simple plug-and-play process through the Haas Control, with on-screen instructions, and diagrams that are intuitive and easy to use. It’s possible to install a Haas rotary on other makes of mill as we also offer the Haas Servo Control. Activated by a single M-code, the Servo Control is easy to set up, and fully programmable.

Adding a rotary axis to your CNC mill is the fastest way to boost throughput and increase accuracy. Because Haas began as a rotary table manufacturer in the 1980s, we are able to provide the simplest and most cost-effective entry into 4-axis and 5-axis machining available.

Constructed of heavy-duty materials and designed for dependable day-in, day-out operation, Haas rotary products are the benchmark by which all others are measured. We manufacture all critical components in-house at our state-of-the-art California facility. At the core of every Haas rotary table is a large-diameter, aluminium-bronze worm gear meshing with a ground alloy steel worm (hardened to 60 Rc) submerged in a synthetic oil bath.

We just received a new machine and im trying to set it up in Fusion. The VF4SS TR220y model is great, however, we setup the physical machine the the rotary/trunnion assembly rotated 90 degrees counterclockwise and shifted to the right end of the table (X+). I cant figure out how to manipulate the machine model to reflect that. I can move the rotary table and the part of the trunnion that actually rotates but the housing for all of it will not move without the entire table.

8613371530291

8613371530291