stepper rotary table manufacturer

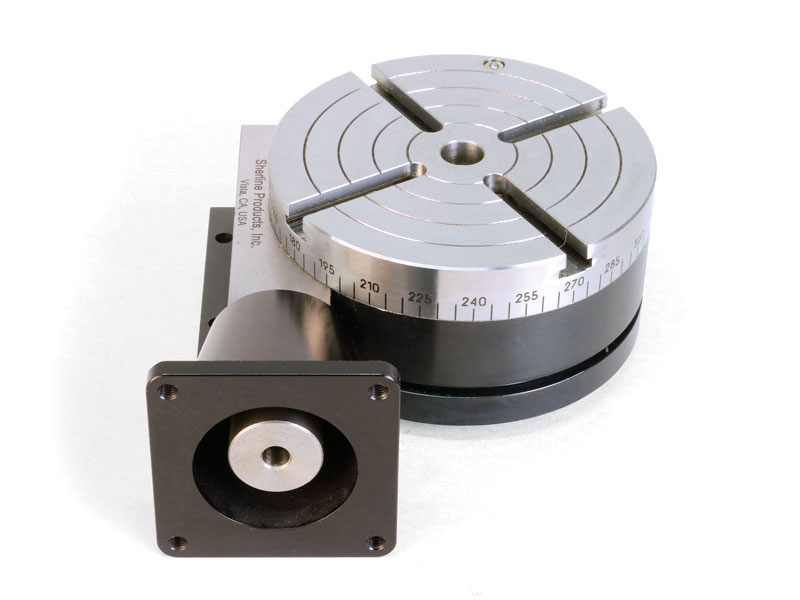

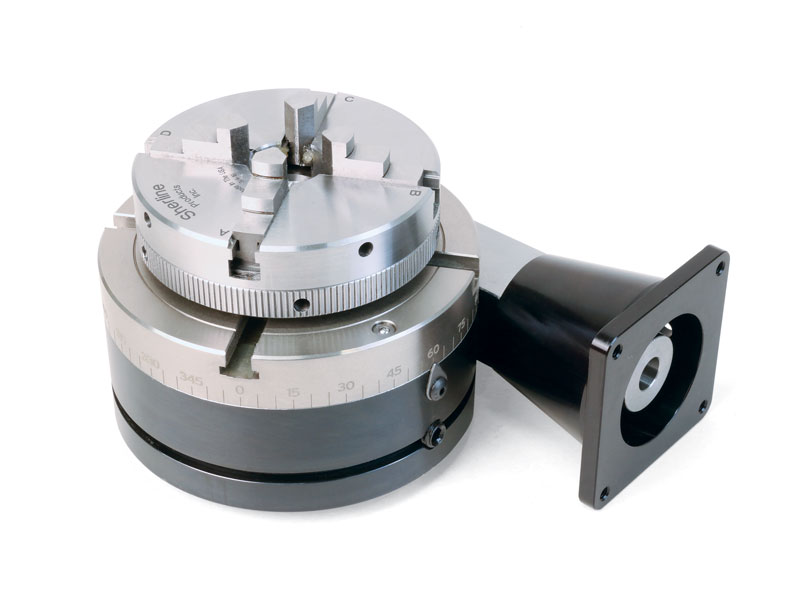

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. This rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a CNC ready rotary table and a stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

A Rotary Stage is a mechanical component of a motion system used to rotate an object in a single axis or plane of rotation. The terms rotary stage or rotary table are often used interchangeably with rotary stage. All rotary stages consist of a platform and a base, joined by some form of bearing or guide in such a way that the platform is restricted to rotation about a single axis or plane with respect to the base. In common usage, the term rotary stage may or may not also include the mechanism by which the angular position of the platform is controlled relative to the base.

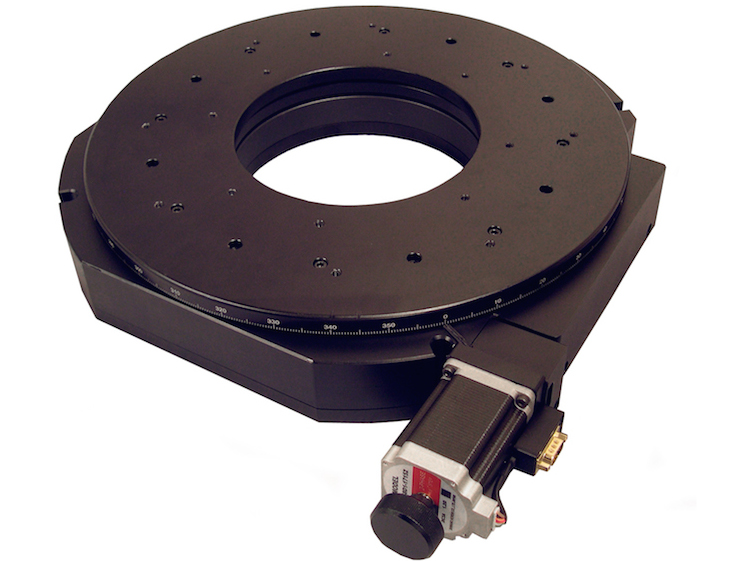

ServoBelt Rotary Stages from Bell Everman are compact, high-torque rotary stages that offer through hole size and speed comparable to direct-drive rotary tables costing thousands more.

Room in the Middle. ServoBelt Rotary stages offer two different through hole configurations. Available with 50-, 100- or 200-mm center openings, our large through hole stages accommodate large bundles of power, signal and pnuematic conductors. They also make it easy to integrate laser and optical systems. Standard-sized models with 16- or 25-mm through holes offer a more economical choice when fewer utilities need to pass through the center of the stage.

Direct Drive Performance. Designed for NEMA 23 and 34 motors, the ServoBelt rotary stages offer speeds up to 1,000 rpm, continuous torque to 6.6 N-m and resolution down to 0.16 arc-sec with Renishaw ring encoders or tape scales for partial rotation.

Robust, Lubed-for-Life Bearings. ServoBelt Rotary stages incorporate large full duplex, angular contact bearings, imparting moment and load capacities far in excess of its usual application requirements. This excess load capacity translates into virtually limitless bearing life.

Cost Effective. ServoBelt Rotary stages offer an economical solution for a variety of medium-duty rotary motion jobs such as driving carousel tables on packaging and assembly machines and providing fourth-axis rotary motion for laser cutting and mini CNC machines.

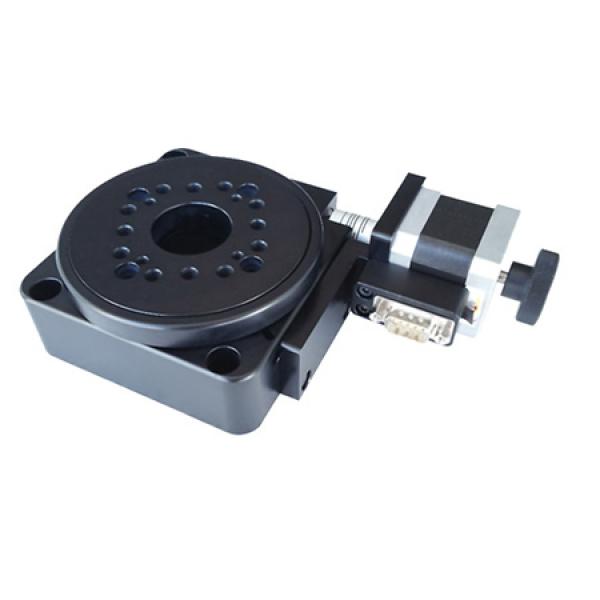

The 300 Series tables feature a rigid pair of quality angular contact bearings which produce smooth table top rotation. The low backlash precision worm gear drive provides exceptional accuracy and repeatability. All aluminum components have a black anodized finish and each table can have either a NEMA 23 or 34 motor mount attached. Threaded steel inserts in the table top provide for easy mounting of the user load while the 0.75 inch (19 mm) through hole provides easy access from below.

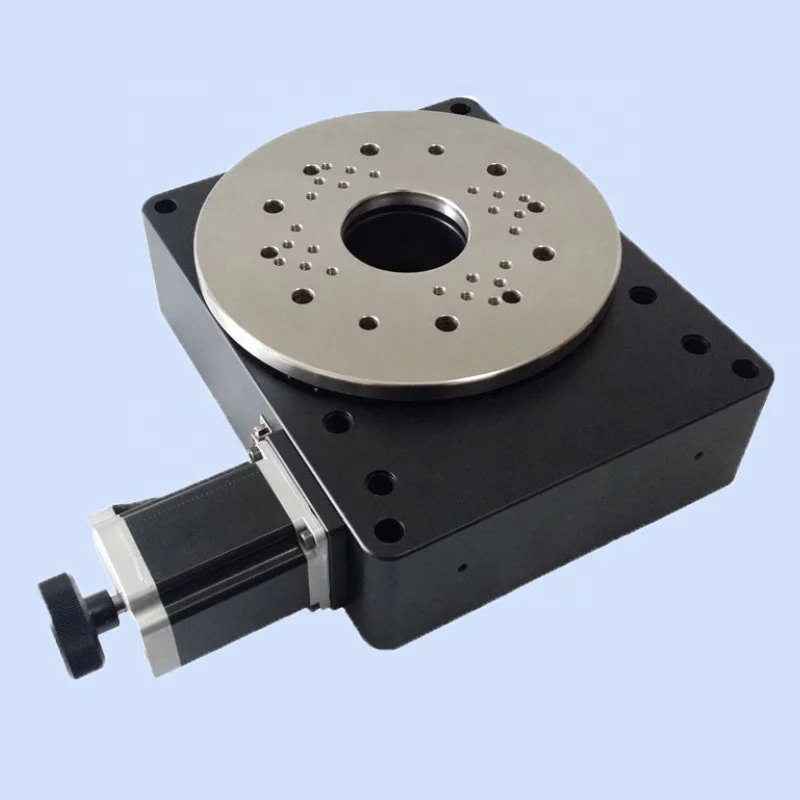

The 400 Series tables feature a rigid pair of 4 point contact radial ball bearings which produce smooth table top rotation. The low backlash precision bronze and steel worm gear drive provide years of high accuracy and superb repeatability. This rugged construction offers load capacities of 1000 pounds (453 kgf) and moment loads of 225 ft-lbs (305 N-m). The NEMA 34 motor mount and bushing can be positioned radially 360 degrees for convenient motor location. The large 4.5 inch (114 mm) through hole provides easy access from below.

Optional: Cover plates, gearheads, EOT & Home switches, linear & rotary encoders, power-off electric brakes, motor wrap packages and versatile mounting brackets for multiple axis applications

Motorized worm gear driven rotary tables provide high angular resolution (the worm gear ratio directly multiplies the motor output torque and motor angle resolution) and holding torque. PI offers precision motorized worm gear rotary tables with both stepper motors and closed-loop servo motors with encoder feedback. While open-loop stepper motors are often used for their lower cost and ease of control, closed loop servo motors with encoder feedback provide higher speed, higher accuracy, and repeatability. PI also provides closed-loop stepper motor rotary stages, combining the best of both worlds. PI stepper motor rotation stages are provided with stepper motor controllers featuring a micro stepping mode for higher performance. For single axis applications, a compact and very cost effective single axis stepper motor controller is available.

For the best performance and highest velocity, direct-drive rotary stages with torque motors are recommended (link to new Rotary Stage Page with Direct Drive Torque Motors).

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an AlphaStep closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

AlphaStep products are stepper motor based hybrid motors with a unique hybrid control system combining the benefits of "open loop control" and "closed loop control".

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer.

can mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

Sherline�s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures. Visit our Video page to watch a Sherline CNC-ready rotary table in use in a laser marking application on round parts, illustrating the difference between trying to mark on a round part without rotating it vs. rotating it. Some of the videos are from Jimani Inc. Laser Marking Systems who use a high-speed motor to drive the table.

Control digital devices and make machinery more precise with a stepper motor from Alibaba.com"s wholesale equipment store. Our catalogue is the place to come when you need a replacement stepper motor rotary table or any other motor related products. You"ll find a huge array of wholesale motors, including step motors with high torque ratings that can offer incredibly precise control. Whether you"re constructing an astronomical telescope or a digital network for broadcasting, these motors will do the job.

Stepper motors are used in situations where devices need to be calibrated to extremely high levels of precision. They aren"t always the most powerful motors, but they do have very high torque levels, and this allows them to control devices in ways that other motors cannot. And they also tend to work well with digital devices due to their "step" mechanism. For instance, you can find step motors in many hard drives, handling millions of operations every minute. They have also become a go-to motor style for robotics installations. So you might need one for an advanced production line. When you need a stepper motor rotary table, finding the right motor is easy. Just search Alibaba.com"s catalogue and you"ll easily find what"s required.

Our stepper motor collection covers every base. Browse motors for use with mini computers like the Raspberry Pi or models designed for use with Arduino components. Look for permanent magnet motors, variable reluctance steppers, or hybrid syncronous steppers, and models with micro step, half step, and full step modes. Our listings include everything you need to control the most complex systems. So find a stepper motor rotary table and order what you need today. Everything can be handled with a couple of clicks, putting specialist stepper motor components within easy reach.

With four different product lines, our motor rotary tables solve a wide range of positioning tasks. They are suitable for the exact, fast and repeatable setting of angular positions.

As a turntable manufacturer, we offer advanced solutions for Industry 4.0. We offer the universally applicable Basic Line with compact precision, the High-Performance Line, which is particularly fast and precise, and our strongest product line, the Strong Line, with maximum power. The powerful turntable motor of the SG-Line precisely positions the turntable via the cross rollers, even under high mechanical loads.

In our latest product line, the "QN-Line", the turntable is not driven by a worm gear. The turntable stepper motor drives the turntable via a toothed belt drive. This enables the turntable to rotate quickly and dynamically.

Our turntables with motor are used in test laboratories, research, in mechanical engineering and automation, in the plastics processing industry or as welding turntables.

We supply our motor turntable in different sizes, suitable for small and large-format applications. As a rotary table manufacturer, we offer equal precision and performance for all sizes. The motor turntables differ in the diameter of the turntable and in the transmittable torque. The turntable motor is always arranged coaxially to the worm of the worm gear.

For example, the MDT36008-AK-S model from our BS line is a small turntable with a stepper motor and controller. This rotary table with drive has an outer diameter of 54 millimeters. The maximum output torque is 1.2 Nm. As a product in the upper size class, we offer the turntable with stepper motor MDT36012-HP. The HP-Line has a turntable diameter of 80 millimeters and a maximum torque of 3 Nm.

We offer the motorized turntables in three configurations. The complete solution includes the turntable stepper motor with integrated positioning control.

In addition, our turntables are also available without a motor. This ensures the greatest flexibility when integrating into new designs. Furthermore, the customer can fall back on drives and controls that he is familiar with.

They are characterized by a whole new machine concept and design approach, allowing flexible use. All components are freely programmable and represent sound solutions for re-engineering. It could be added planetary gearbox to increase the gear ratio, available for matching with any brand servo motor and stepper motor based on our flexible flange system, thus make it easy for automation production line building and robot designing.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

Using precision research and development of worm gear and worm structure, it is comfortable to move, can rotate in any forward and reverse directions and has very small backlash.

The scale circle on the periphery of the table is a laser marking ruler. The scale can be rotated relative to the table to facilitate initial positioning and reading.

The electric rotary table can be used in flat or vertical, and can be combined with other types of tables to form a multi-dimensional electric adjustment table.

It can increase the limit function, increase the initial zero position, replace the servo motor, install the rotary encoder, accept the product modification and tailor-made.

There are many types of rotary tables in the market, such as the stepper motor rotary table, all of which essentially work positioning devices widely used in metalworking applications. It allows work to be cut or drilled at identical intervals around a fixed axis (normally horizontal or vertical). Some of the key advantages of a rotary table include the repeatability, short time of indexing, flexible indexing positions, as well as the tolerability of exceptionally high axial and radial torques during rotation and stopping.

Systems based on rotary table are generally very durable, and will not require a repair until a longer period of time. Depending on the applications, the rotary table may be complemented with an internal or external clamp. In this article, we’ll specifically address the stepper motor rotary table.

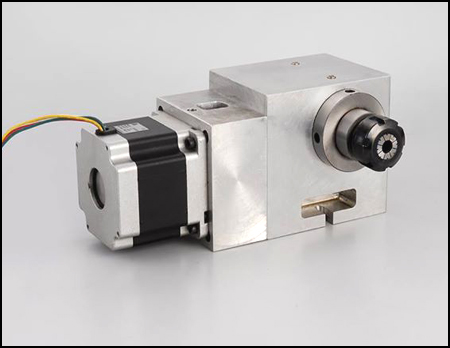

Following the above, a stepper motor rotary table is basically a motorized rotary table driven by a step motor instead of a servo motor. Stepper motor rotary tables are available in many different table diameters, size apertures, mounting options and motor choices, and are a great solution for many industrial automation applications.

Stepper motor rotary tables are mostly used alongside industrial robots, fiber optics and photonics, vision systems, machine tools, assembly, semiconductor equipment, medical component laser machining, electronic manufacturing and other high performance motion control applications.

Rotary tables are frequently coupled with servo motors. Now you may be wondering why and when a stepper motor would be preferred over a servo driven rotary table. In the rest of this article, we are going to touch base on the basics of what it means for something to be driven by a stepper motor, and how it is different from a servo motor.

A step motor is designed with windings in the stator and magnets connected to the rotor. As the name implies, a stepper motor is based on a motion increment mechanism referred to as “steps”. These steps are typically indicated in degrees. When installed on a rotary table, the stepper motor and the stepper drive rotate in pre-set angles proportional to the stepper pulses. A typical rotary table equipped with stepper motor can achieve 200 steps for every revolution, which is equivalent to approximately 1.8 degrees per full step.

That said, the stepper system of a rotary table consists of two complementary components: the stepper motor and stepper drive. The stepper drive works alongside the step motor to enable rotations of rotary table in pre-defined angles. Some common types of stepper drive include:

● Microstep Drivers: This type of stepper driver powers the step motor winding to generate torque. The step motor coupled with the driver is positioned at smaller increments among full steps, offering higher resolution with less torque. Although this system does not guarantee accuracy, the motor does run with relatively less noise. This driver is typically used when the motor’s resolution needs to be increased.

● Drivers with Oscillators: An oscillator is utilized to generate pulses to power a stepper motor at a pre-defined speed. They can generally be retrofitted onto the hardware construction of a microstepper drive.

● Full or Half Step Drivers: This type of stepper drivers, as the name already suggests, enable both full step mode and half step mode, which run at 1.8 degree per full step and 0.9 degree per full step, respectively.

Choosing the right motor for your rotary table is important to ensure good productivity and efficiency of your motion control application. And choosing between a stepper motor and a servo motor is certainly not an easy task as you have to take many factors into consideration such as the cost, efficiency, torque, speed, circuitry and so on.

With that said, the main difference between a stepper motor and a servo motor lies in the total pole count. Servo motors have a low pole count which amounts to about 4 to 12, whereas stepper motors have relatively higher pole count, ranging between 50 and 100. The pole count is directly associated with the motion increment of the motor, and the difference in these pole counts indicate that stepper motors move incrementally in a closed loop system with consistent pulse. Servo motors on the other hand need an encoder to adjust pulses to control positions.

GSN200-50K Servo Rotary Table offers an unparalleled combination of good accuracy and high load capacity. These rotary stages utilize a precision worm gear with the worm “flexed against the gear to ensure a proper mesh. This feature provides high repeatability with very smooth operation. Additionally, the rotary stages incorporate an oversized pre loaded cross roller bearing, offering exceptional stiffness and load capacity.

8613371530291

8613371530291