little machine shop rotary table made in china

My first rotab was a Wholesale Tool 6 inch. I was turning a 12 inch wheel center (had to weld it up to make it 12.25 dia) on the rotab with a large roughing endmill in the spindle while rotating the rotab (my lathe swing dia is 12.2 inches w/o locally grinding a divot into the lathe bed (partially into the tailstock way) - not that the tailstock would ever be that close to the chuck - I just did not want to be that much of a hack so I used the mill and rotab). I ended up shearing teeth on the ring gear in the rotab. Had I used a less aggressive cut, maybe roughed in the shape with a hand grinder before machining the rotab probably would have survived. Finished turning the wheel center at work during my lunch time (with the blessing of the guys in the machine/fab shop) on a 20 inch swing lathe - I"ve never operated a lathe that big and the pucker facter was high!

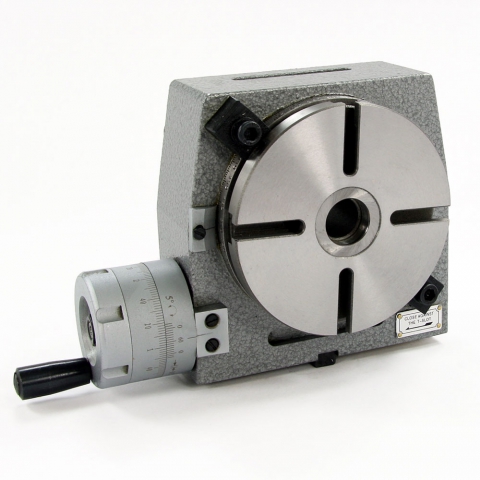

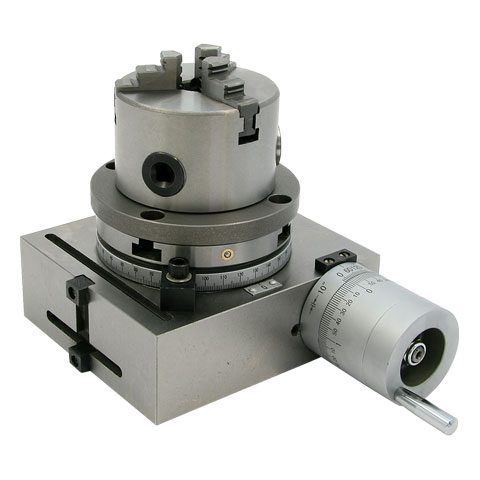

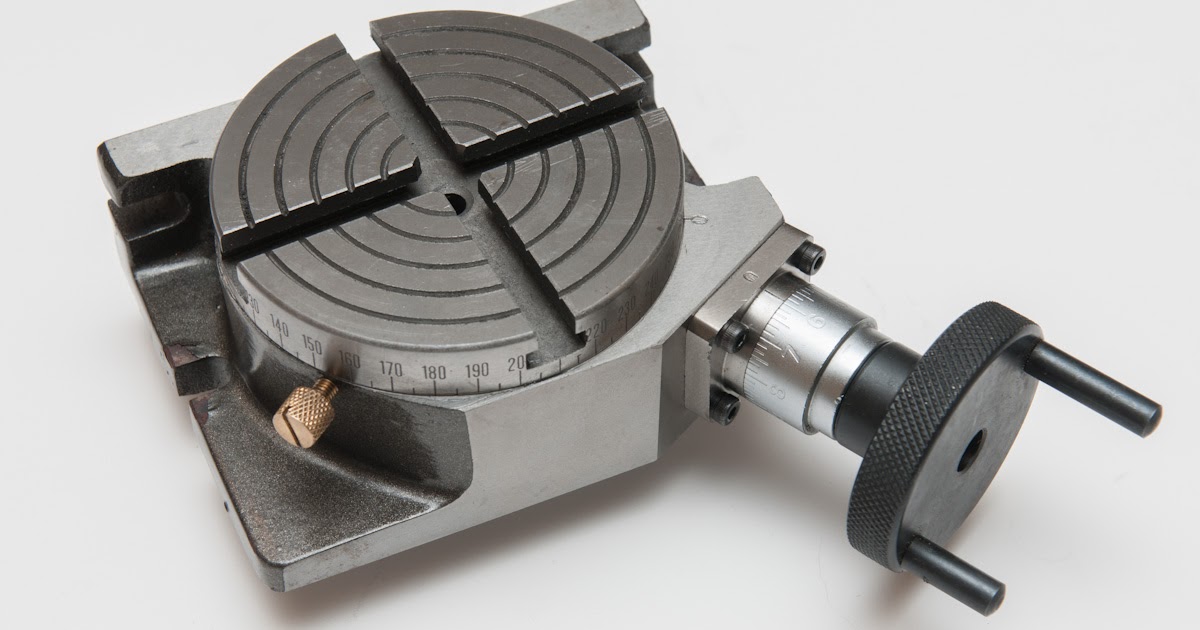

This horizontal / vertical rotary table is for indexing, circular cutting, angle setting, boring, and spot facing operations. The meehanite cast iron table is precision machined and has a 2 Morse taper center hole. The table is graduated with a 360° scale. A micro collar graduated to one minute with a ten second accuracy vernier scale is provided. The rotary table has lock down clamps and the crank can be disengaged.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Not sure I agree with you folks that claim that one needs a rotab in order to make a rotab. However, depending on the size of table you want to make you will need a lathe with a swing at least as large as the rotab. IOW your rotab will be a teensy one.

Home Shop Machinist magazine is full of such projects. Look in the Periodicals/Crafts section of your local Barnes & Noble or Borders book store. You may have to dig a bit to find it behind all the wood working mags.

The mill works better than I had expected. I think the last mill project I had was to duplicate the "jaw" of a movement post: the brass one had stripped out, so I replaced it with a steel one, salvaging the steel from a trash-can axle. As on any machine tool you have to expect some flexing, and so light cuts are helpful if you"re dealing with anything but aluminum. I don"t think I can use any but the smallest and simplest rotary table-thing (with or without chuck) given the space constraints.

I"ve been threatening to buy a four-jaw independent chuck for this machine since I"ve owned it, but thus far the 3-jaw self-centering scroll chuck that came with it has proven just fine.

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost.

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

I own a Sherline 4" rotab and it is quite good. However, it is also somewhat limited in that it does not accept dividing wheels and it does not have a table release; you have to crank it around to get to your next location. It is quite well made, reliable and accurate. It will mount to a milling table as well as a tilting angle table without eating up that much room in Z.

I also own a Japan-made 6" Yuasa that is pretty much fully tooled up. This is a really fine, fully featured rotab that is probably the most cloned rotary table out there. Vertex makes a clone that is quite close. Smooth, accurate and no longer made.

The only other import I have heard of that might meet your needs is the Warco HV-4: https://www.warco.co.uk/rotary-tables-engineering-tools/124-hv4-rotary-table.html. At that price, I"m pretty sure it will be a Warco design but Chinese made. Cannot attest to how good it is but Warco sells some nice small stuff so you might inquire.

What are some of the best Rotary table brands you can buy? I only buy tools once so quality of the most important thing. I’ll happily buy vintage if people truly think they are better. I have a Bridgeport (pictured below)

Here"s a mystery for all you hobby milling machine enthusiasts. Help me ID this rotary table. I"m considering purchasing it, but can"t figure out who made it.

Finally complete. The casting came out very nice, little if any hydrogen bubbles or oxide inclusions. 11" diameter x 1" thick, 6 T slots, referencing rings 1/2" apart. See if I can get a photo to post.

So, here"s what I"m wondering. About half the time I use the rotary table I find the hand wheel interferes with where I"d like to clamp it down. Looking at other tables this seems to be the common configuration, where the handwheel interferes with the mounting plane(s) of the table. Why would...

not getting any feedback to a previous post I gotta wonder if there isn"t something wrong with an Advance Rotary Table. I see lots of posts regarding "what to buy" and "I settled for a Chinese knockoff". Just wondering what is the problem? This seems to be an extremely well built and accurate...

I have a vertex 10" Rotary table with mounted chuck, I use it often. There are quite a few occasions I wish it was motorized. Has anyone done a DIY motor on their rotary table and not spent a fortune ? I"ve seen pretty expensive motors so i"m looking for DIY options. I think I may have even...

I"ve become a (happy) owner of a new-to-me 8" Phase II horizontal rotary table. Unfortunately it came with the dividing plate setup and no handwheel, so I need to make one. If you have this model of the table, I would really appreciate if you could post a picture and/or dimensions of...

So I need a rotary table for a couple of projects I have in mind, making round things on my Jet 15 mill/drill. I don"t have a lathe. I"m thinking 6" would be a reasonable size both for the things I need to make and the size of my mill. I see cheap imports on ebay starting around $160, Phase...

8613371530291

8613371530291