harbor freight rotary table for sale

There are no locking bolts in the Grizzly model table. There is a ball bearing that is pressed onto the table shaft. On mine, it isn"t a tight fit and is easily removed with slight pressure. It isn"t easy to hold the casting while pressing on the table shaft, but it is fairly easy to remove, once you remove the worm gear.

The screw in the bottom is used to adjust the spacing between the edge of the table and the casting. I tighten it until it barely moves, back off the screw about 1/8 turn and smack it with a brass hammer.

One note, there is a slight bit of space between the side of the table and the base casting, so if you plan on using the locking screw, center the table with the screw tight. It can make a thousandths or two difference.

The main problem with it, is the double nut that hold the table on/dowm to the base doesnt function properly. It has 3 screws at 120deg that are supposed to lock the nuts but the nuts appear to be machined at the same time so the threads match up perfectly preventing a decent lock and it will back off causing the table to chatter.

I backed off the top nut 120deg and tightened the screw that way so the gap squeezes the nuts togheter. Its better but not perfect as there is no way of getting the bottom nut tight enough to pull the table down with no chatter.

Most of the Grizzly tables are actually Phase 2 or one of the other better mid grade brands rebadged. I think the 4 inch are Phase 2"s, but either way a 4 in Rotary is a great addition to a mini mill and will be a great fit for the machine in the pic. Sometimes LMS has the 4 and 6 inchers on sale too. Worth a look, but you"ll do well either way with a grizz or an LMS. Don"t forget the dividing plate kit too. Makes it very precise for flanges and other spacing issues.

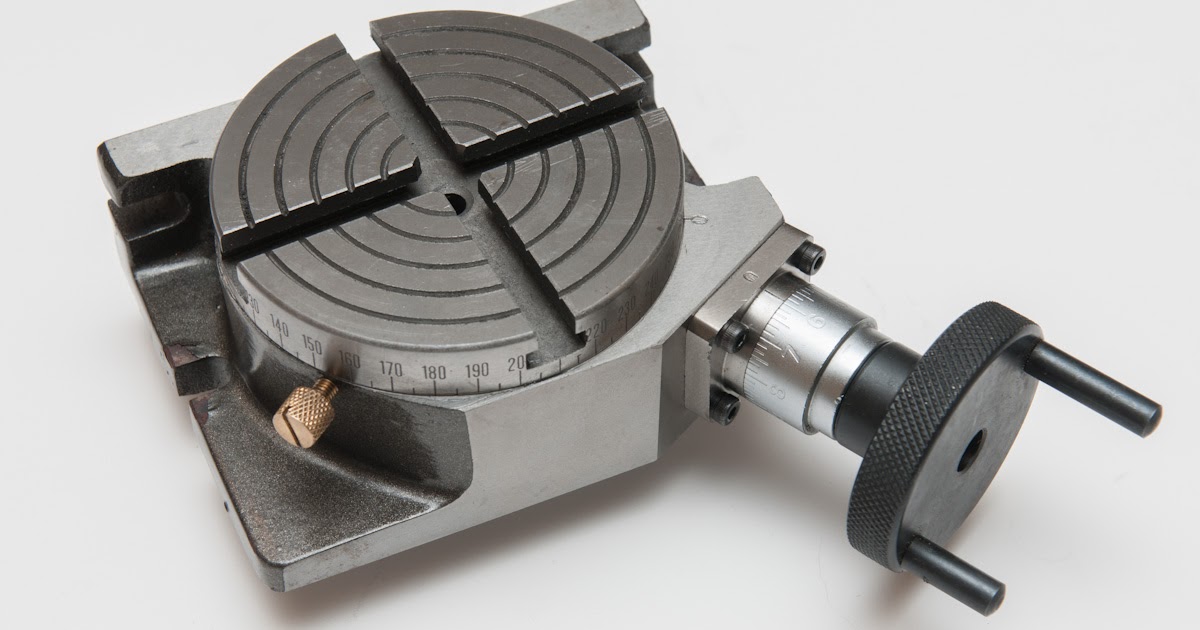

Here is a close-up of one of the two clamps provided. These fit in the t-slots on the rotary table. As can be seen, these are just stamped out metal pieces, screws, and T-nuts.

A rotary table is a really nice accessory to have for your mill, but one that you can delay purchasing for a while until you master the basic milling operations. The rotary table is driven by a worm-gear and is accurately calibrated in degrees and fractions of a degree.

Finding a rotary table of the right size for the mini-mill has been a lille problematic. 8-inch tables are really much too big. Even a 6-inch is pushing the limits. I have one from Grizzly. It is well made and works well, but mounting it to the table was a little bit of a challenge.

The first rotary table I purchased was made in India and was of really poor quality. I returned it to the vendor for a refund. Unfortunately, the return shipping on a heavy object like this is not cheap, so be careful what you buy!

Sherline makes a beautifully finished 4″ rotary table which I got to see first hand at Cabin Fever 2001. I was very impressed by the high quality of this item, but It was a little small for my needs.

The table I currently use is a Grizzly G1049 6-inch model. As of 03/02 it sells for $199 plus shipping. It is well-made, and I have been very satisfied with it, although it is a little large for the mini-lathe as you will see in the photos below.

After cleaning off the packing grease with kerosene, a painbrush and a rag, I mounted it on the mini-mill table using 3/8″ carriage bolts that I also use for my 3 1/2″ Grizzly milling vise. The center hole is a #2 Morse taper.

The RT is really a little oversize for the mini-mill, but still provides enough clearance to be practical. I did not feel that the weight was beyond the capabilities of the mini-mill table.

Here’s a picture showing the table with a 12″ rule and a 1/2″ mill in an end mill adaptor. Mounting the mill in a collet would provide another 2″ or so of working room. The head is at the top of the column. Also shown is the 3″ chuck from the 7×10 mini lathe. As you can see, there is adequate clearance for most operations.

The casting has mounting lugs for both horizontal or vertical mounting. This makes it potentially much more flexlible, but the table of the mini mill is small compared to the RT which makes mounting the rotary table in the vertical orientation a little tricky.

One problem is that the lower edge of the handwheel for the RT is lower than the base of the RT, so it must be positioned off the edge of the table. If the RT is positioned perpendicular to the X-axis, the mounting holes in the RT are outside the limits of the T-slots in the mill table.

For the price, I was pretty impressed by the quality of the table. I would rate it somewhat lower in quality than the Sherline 4″, but much better than the Victor 6″.

The handwheel is satin-finish steel with cleanly etched divisions. Each full rotation of the handwheel rotates the table by 4 degrees. A brochure included with the RT illustrates an indexing plate accessory which can apparently be attached to the RT, but I’m not sure whether or not Grizzly sells this accessory.

An eccentric cam between the handwheel and the table permits you adjust the meshing of the worm-screw to minimize backlash. A screw with a T-handle locks the cam in place once it is set.

Here’s a nice little 4″ imported rotary table offered by LMS for $134.95. They offer several other models, including the Sherline 4″. I don’t have any first-hand experience with this one, so I can’t really comment on quality or capabilities.

This Harbor Freight milling machine can be used on a variety of materials from wood, plastic, and composites to hard metals. However, keep in mind that you have to pair it with the correct tool.

Harbor Freight 44991 can work on two different speed ranges of 0-1100 RPM and 0-2500 RPM. These two modes are labeled on the machine as low and high.

For more precise control over the Z-axis, Harbor Freight 44991 has a knob on the front which you can engage by pushing the main Z-axis knob until the gear teeth line up.

For holding the workpiece in place Harbor Freight offers a 4" drill press vise for around $20. This vise is made up of cast iron which provides rigidity to it.

The documentation provided with Harbor Freight 44991 is well-written with pictures. You will also get assembly drawings of the X, Y, and Z-axis which will further help in repairs and upgrades.

The Grizzly G8689 comes with a 1-year manufacturer warranty that covers manufacturing defects, on the Harbor Freight it is only a 90-day replacement guarantee.

Yes, you can consider buying a used Harbor Freight mini mill if you are starting with it. However, you should consider buying a new one if you are going to use it as a professional tool in a shop.

Anybody familur with the Cen-Tech rotary tables from Harbor Freight. The current sale price ($180) sounds good, but not if they are junk like some stuff I"ve seen there. The store doesn"t carry them so you can"t inspect before buying and I would rather not go thru the hassel of returning if no good. Any insight is appreceated, THANKS. PT

This package provides a complete rotary table and indexing solution. Unique to LittleMachineShop.com the set is comprised of our 4" horizontal/vertical rotary table, Dividing Plate Set, and Tailstock for 4" Rotary Table. Save by buying all three as a set!

The rotary table is perfect for indexing, circular cutting, angle setting, boring, and spot facing operations on a milling machine. Made of precision machined cast iron, this table features a 2 Morse taper center hole and comes with lock down clamps. It is graduated with a 360 degree scale, making it easy to read and use.

The table comes with an adapter to mount a 3" (3 or 4-Jaw) lathe chuck. The table is 2.87" high in horizontal position and has a centerline of 2.68" above the table in vertical position. The body of the table is 5" by 5.5" and has a worm ratio of 72 to 1. The clamping surface has a parallelism to base of 0.0008", squareness of clamping surface to angle face of 0.0012", and squareness of clamping surface to center slot of 0.0012". Concentricity of center bore is 0.0008" TIP.

The Mini Mill Dividing Plate, a handy tool for precise milling and dividing. This plate dividing plate fits a 4" precision rotary table. It consists of one plate with two sets of holes. One circle has 15 holes, and the other has 28 holes. This lets you divide a circle into 1/3 degree increments.

The tailstock is height adjustable from 68 to 69 mm center height. On mini mills, most indexing is done using a rotary table. The addition of dividing plates makes indexing easier. When working with relatively long work pieces, a tailstock can be used to support the end of the work piece. In many cases, a lathe chuck is mounted on the rotary table to hold the work piece.

Not an expert but if I could I think I would go with the one from Littlfe Machine Shop. Just looks like a better table plus you get the adapter for a 3" chuck. Of course that means somewhere down the road you will want to buy a 3" chuck. Than the indexing plates. etc.

I would buy an 8" table. A 4" table will not have much room for a workpiece and clamps. Quality wise, it is probably fine. Those imports don"t vary that much.

What Jim said. Buy the largest size you can accommodate on your mill. You"ll learn to hate a small table when you struggle with every job you attempt. I own a 12" table. When I was actively machining, often wished it was larger. I specialized in small work, so it"s not because I made large items. Often there was not enough room to make the kind of setup that I desired.

Depends a great deal on how you"ll use the table, too. Large tables are a PITA to handle, and can be difficult to use on edge when making small items. There"s a balance that you must achieve unless you own more than one table.

I need to machine a radius on an axlebox that is the width of the axle (about 6"). I have an 8" (diameter) rotary table. That"s only 4" radius. I made a jig out of 4"x1/2" HRS that hangs off the table far enough to give me enought swing. If I had a 12" table, I would not need to do that.

So now I"m back to shopping for a new rotary table. My conserns are weight. How much weight can my machine handle? The lightest RT I"ve found was the one at LittleMachineShop and it weighs in at roughly 20lbs.

SteveM wrote:I need to machine a radius on an axlebox that is the width of the axle (about 6"). I have an 8" (diameter) rotary table. That"s only 4" radius. I made a jig out of 4"x1/2" HRS that hangs off the table far enough to give me enought swing. If I had a 12" table, I would not need to do that.

It"s more complicated than that, too. I, too, have machined a large radius with my rotab. Something like 18" on my 12" table. As the table gets smaller, I have no doubt the gearing changes, so you have almost no control over the table when you extend it because the perimeter movement is quite fast. The advance of the table when I ran the large radius was way fast----and climb milling was out of the question. The end mill would easily take over because of the mechanical advantage.

8613371530291

8613371530291