phase ii rotary table manufacturer

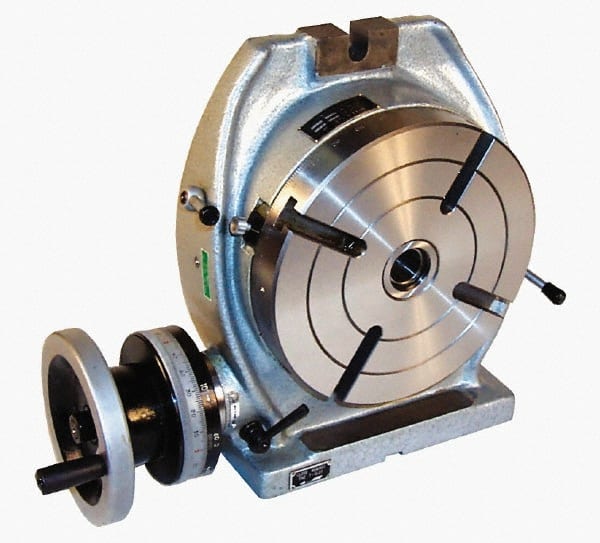

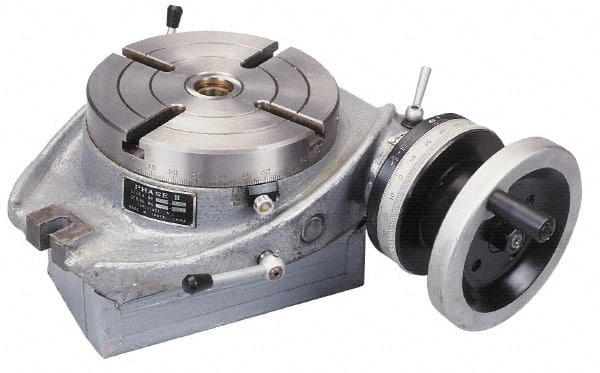

I am in the process of outfitting my new(old) Ex-Cell-O mill with some tooling. I have a line on a Phase II 222-410 10 inch tilting rotary table for what I believe is a good price. I believe that it fits in well with some of the work I am planning on doing, but I really don"t have a good feel for how it would work out in practice as opposed to in theory. The work I am planning on setting up for is checkering pistol front straps, specifically 1911 style. There are other patterns I plan to work with, but they all involve the same basic setups on the table. The cuts are made in vertical, as well as horizontal axis, around a radius. I included an example of the work I am describing. I have the basic idea for indexing the radius (which varies somewhat by manufacturer) as well as a fixture to hold the frames without marring the surface. My specific question is related to the accuracy/repeatability of the tilt. I would prefer to just turn the dial to 90 degrees without having to re-setup in the new axis. Are these units(assuming in good shape) able to consistently go between horizontal and vertical, once set up correctly. If so, It would probably save a great deal of time and eliminate at least some of the potential for human error? Also, Is it rigid enough to perform that type of work without inducing a lot of chatter or deflection. The work will all be light cuts.

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

High precision bearing surfaces insure ultra-smooth rotation. Superior grade meehanite castings provide the ultimate rigidity. All rotary tables are precision ground to meet the most extracting requirements and are individually supplied with a certificate of inspection.

I have a similar PhaseII, although it"s a vertical-horizontal model. The "black thingy" does indeed rotate about a half turn to engage or disengage the worm. It should work very smoothly if your table is in good shape, although sometimes a slight turn of the wheel (front part of the black thingy) is needed to engage the gear. However, it appears to be part of the PhaseII experience that the engagement, which is very finely fitted, is easily damaged if the table is dropped or the "black thingy" bangs into something. The manual specifically warns of this.

Unfortunately I banged my table, and it promptly locked up much as you describe. I managed to disassemble it --- there is a link in this forum to an old post of mine detailing exactly how to do this --- and found that a very small bump --- so small I was able to work it out with an extra fine jeweler"s file and some 800 grit emery paper --- was enough to lock the rotating eccentric which effects the worm engagement.

If you are not able to easily and smoothly engage the worm, it is very possible that the eccentric is damaged in the manner I described. Search this forum for my name and phaseII and you will find a post with an exploded-parts diagram, and a later post with disassembly info. Sorry I don"t have it at hand to attach to this post.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

In addition, since rotary motion is often performed for the purpose of processing, measurement, or some other subsequent operation, the use of rotary tables by themselves is rare.

Rotation mechanisms used in chairs and other equipment are also classified as rotary stages in the broad sense of the term, so they are used not only in manufacturing but also in home applications.

A crossed roller bearing is a bearing structure in which rollers are arranged between the inner and outer rings. The rollers are arranged in a straight row with a 45° contact angle, enabling the back bearing structure of a ball bearing to be realized with a single row, and the structure is capable of receiving loads from multiple directions simultaneously. The rotary table and cross roller bearings can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the rotary table is directly related to the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads can be used in the fine-tuning rotation mechanism to obtain high positioning accuracy.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

8613371530291

8613371530291