cnc rotary table manufacturers quotation

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

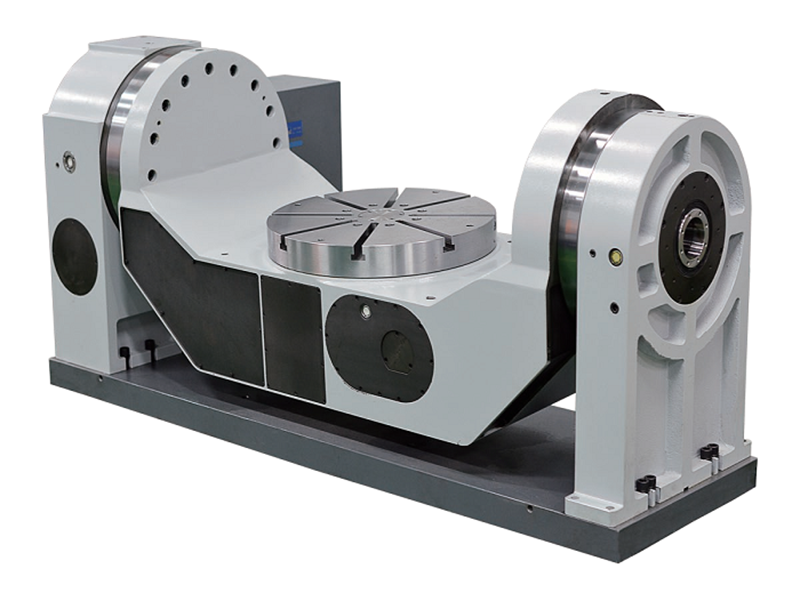

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

Our company is a prominent in the industry as a manufactures and supplies Rotary Table. We offer our product in diverse specifications to fulfill the differentread more...

We provide exclusive range of Goizper make Turn tables (CAM based), rotary tables (indexers), Clutch-Brake units, Spares, Couplings, customized Gear boxes. Goizperread more... Brochure

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

Rotary tables are used for perfection metalworking. They"re generally made with a solid base that can be clamped on to another institution. The table is a slice that rotates freely or by use of a worm( hand coil).

A rotary table is a slice- shaped metalworking device used to gain precise workpiece positioning. It enables a metalworker to cut or drill a workpiece at precise intervals around a vertically or horizontally fixed axis. A rotary table can be both manually or computer numerical controlled. Certain types of rotary tables are designed to be used with indexing plates or dividing plates for technical operations. A rotary table used together with one of these positioning plates is generally appertained to as a dividing or indexing head.

The rotary table device generally has a solid base that can be attached to a separate institution or table using clamps. This device is principally a rotating slice which holds the workpiece in place during slice or drilling operations. The slice portion of a rotary table can be freely rotated for indexing procedures or turned by an attached control arm known as a worm wheel. Tables used in high perfection operations are generally turned by a duplex- type worm wheel to compensate for counterreaction. Rotary tables used in automated essence working processes are turned by computer numerical controlled ministry.

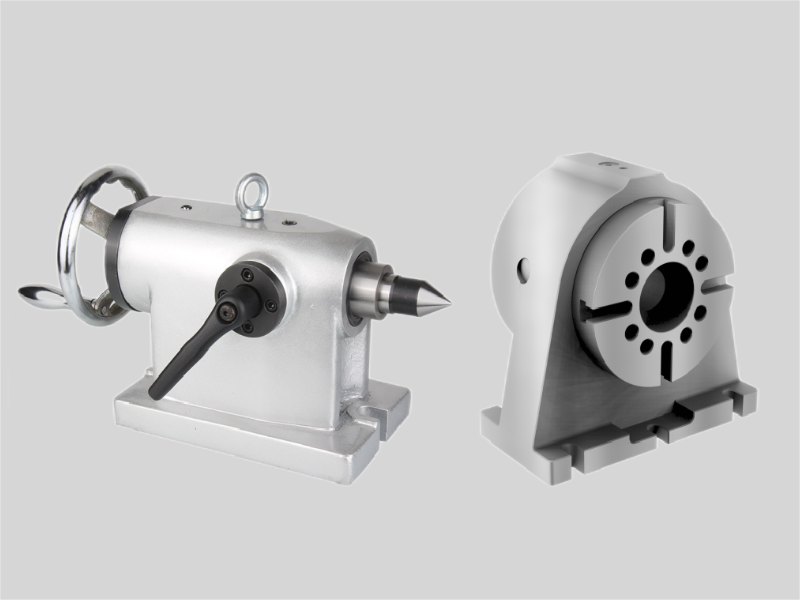

Rotary tables are most frequently used in a flat position with the table’s axis having a perpendicular exposure. They"re occasionally mounted with the axis acquainted in a vertical fashion so that a tailstock can be used to support the free end of the workpiece. When this device is attached to a secondary table, the workpiece can be centered on the rotary table’s axis which is also centered on the slice tool’s axis. In this configuration, the axes of the rotary table, secondary table, and cutting tool are coextensive to grease concentric slice operations. This configuration also permits the secondary table to be neutralize for drilling equidistant holes in a workpiece.

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

VHS Mechatronics Service (P) Ltd is the most preferred brand in the Indian CNC machine industry. We are the best Cnc Rotary Table Manufacturers in chennai. The vital goal of our company is to satisfy our clients all around the world through best quality product and on time delivery. We are located in Sriperumpudur, Tamil Nadu. We are servicing all over the India. Backed by the State-of-the-art manufacturing unit powered with latest technology, our team of professionals actively engaged in manufacturing and offering the high precision CNC rotary tables in chennai. With the innovative skills and vast industrial experience of more than 20 years in this domain, our team of professionals manufacture and offer the comprehensive range of standard and custom built CNC rotary tables Our top quality CNC rotary tables are often utilized for the purpose of high accuracy indexing. According to the various applications, our specially designed CNC rotary tables can be utilized horizontally and vertically.

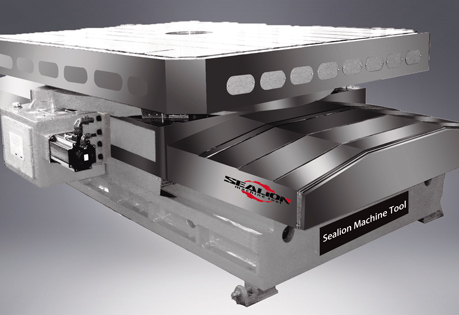

The Rotary table models VRT series are designed for integrating with any CNC horizontal boring machine fitted with Siemens 840D controller having additional axis capacity or with an independent controller Siemens 802 D .The rotary table position can be continuously controlled in two axis one rotary ‘B’ axis and the another longitudinal ‘V’ axis. The rotary table bed made of grey cast iron grade 30 heavily ribbed. The Rotary table movement is through a Double Pinion Gear Box driven by one or two Servo motors as required. The table and saddle guide ways are hydrostatic and can be hydraulically locked after indexing.

The Stallion Tombstone provides manufacturers with the ultimate time saver. With 4 sides, handling and tool change time decreases substantially. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Tombstone minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary. Our smallest tombstone model, at 4", is perfect for machining small parts at large volume.

Our CNC Rotary Table, Rotary Index Table offers the solution to achieve the high precision machining of parts.Faceplate Diameter 220mm, Rotational Torque (6Nm motor) 432Nm more...

Designed for smaller milling machines. Table diameter 100 mm table is graduated 360 degrees. Worm gear ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 degrees. Center height in vertical position: 2-116" (50 mm approx) hand wheel is graduated in divi more...

We are offering programmable rotary table. Features: 1. Model: sq-20v4 2. Angle range : 360 deg 3. Transmission ratio : 5:1 or customized as per the requirement 4. Actuator type : timer belt pulley 5. Travel guide : bearings 6. Motor : stepper motor 7. Base material : aluminum ca more...

the sm series of indexers are servo-mechanical indexers designed for application where different output motions are required on the same table. These indexers provide highly accurate motion, with the added capability to move medium to heavy loads. Our preloaded cam & turret mecha more...

25mm movement on both axes on Micrometer Head 0.01 mm Circular Rotary top plate with ground slot 50mm vice fine adjustment lock with T nut Alloy Steel with Nickel Chrome Plating more...

ERT series of Rotary Tilting Tables enables accurate and productive machining. These tables are designed so that the surface of the table top is on the center line of the tilting axis, for a greater piece part capacity, easier programming and less interference in the work zone. more...

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product"s lifetime, Matsumoto Machine Corporation (MMK) has taken a pragmatic two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

Founded in Japan in 1948, Matsumoto Machine Corporation is a technology-leading provider of innovative, high quality jaw chucks and numerically controlled rotary tables used by industrial machine tool makers throughout the world. A key feature of MMK"s CNC rotary tables is a patented worm and wheel gear assembly developed by OTT GmbH, Germany. Unlike double lead worm gears, the OTT worm and wheel gear is able to minimise backlash, ensuring outstanding accuracy and long life, efficiency and durability.

A further advantageous characteristic of the MMK CNC rotary table is a large diameter through-hole in the table spindle. This greatly increases machine versatility and rigidity, supporting a wider variety of chucks and jigs and the machining of longer workpieces.

By enabling most metal-machining operations to be undertaken on a single machine, the benefits of MMK CNC rotary table are far-reaching. These include the time and cost saving of single machine set-up and single fixturing setup, reduced parts handling and the elimination of tolerance errors as workpieces pass from machine to machine.

Of critical importance in this one-hit machining centre scenario is ensuring the high accuracy of CNC rotary table indexing and control throughout its working lifetime.

As with a machine tool"s linear XYZ axes, the rotary axis is just as susceptible to uncontrollable events that may introduce angular positioning or axis alignment errors. Risking the production of defects in finished parts, these errors can be due to a number of reasons including, mistakes made in the initial machine installation, impact damage caused by collision or general wear-and-tear in use.

With its global reputation for product quality and design innovation, MMK therefore sought to equip its CNC rotary tables with a highly accurate and reliable means of tracking and controlling the indexing of its product throughout its lifetime, irrespective of the type of machine tool, workpiece complexity and duty cycle.

At the same time, in an increasingly competitive global market for CNC rotary tables, MMK also wanted to further enhance its product quality inspection processes. Specifically, the company set itself the task of augmenting index angle measurement as a key component of pre-shipment quality assurance procedures.

To provide machine tool makers and users with the ability to accurately track and control CNC rotary table indexing, MMK elected to integrate Renishaw"s super-compact TONiC™ non-contact optical incremental encoder system. Simple to install and with a compact readhead measuring just 35 mm x 13.5 mm x 10 mm, the TONiC encoder presented MMK with a minimal footprint solution capable of supporting machine speeds up to 10 m/s and resolutions down to 1 nm.

The rotary table readhead was designed to be used in conjunction with Renishaw"s RESM, a one-piece stainless steel ring marked on its periphery with 20 µm pitch graduations and featuring the IN-TRAC™ optical reference mark. With its low profile, large internal diameter and wide choice of diameters from 52 mm to 550 mm, the high stability RESM ring provided MMK with a versatile and easy to integrate scale that is well-suited to the company"s wide range of CNC rotary tables.

MMK selected Renishaw"s compact and lightweight XR20-W rotary axis calibrator to verify the accuracy of its rotary tables during manufacturing and immediately prior to shipment. The XR20-W was used in conjunction with Renishaw"s XL-80 laser interferometer to provide a non-contact reference measurement, independent of the axis under test, with an accuracy of ±1 arc second.

Motorised by a servo-controlled drive and with data capture synchronised to axis movement, the XR20-W requires no operator intervention during measurement. Being lithium battery powered and Bluetooth enabled, it ensures quick and easy setup, and the avoidance of trailing cable hazards. The calibrator"s modular design and flexible mounting systems allow far easier setup than alternative solutions and can be readily configured for a wide variety of rotary tables, chucks and spindles.

By integrating Renishaw"s TONiC non-contact optical encoder system into its CNC rotary tables, MMK has further assured the accuracy and reliability of its products in the field, along with an overall superior motion control performance. For a wide range of different machine tools and end uses, the rotary tables" combination of compact readhead and one-piece stainless steel ring scale has delivered a higher level of tolerance to dust, scratches, grease and oil, and a reduction in indexing errors. The encoder system"s ability to output highly stable position signals of unrivalled purity and ultra-low sub-divisional error have provided smoother velocity control, improved scanning performance and increased positional stability.

MMK"s introduction of Renishaw"s XR20-W rotary axis calibrator and XL-80 laser interferometer has reduced product measurement times by a half compared to conventional autocollimator techniques. Measurement procedures have been simplified and automated. Capable of taking accurate measurements at any indexing angle pitch, the calibrator enables evaluation of the accuracy of the worm and wheel gear-driven table for ultra-fine pitch measurement movements as small as 0.001°. This has allowed any loss of motion control or worm and wheel gear efficiency to be evaluated in detail and addressed. Product performance is now backed by a thorough analysis meeting ISO quality standards.

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product’s lifetime, Matsumoto Machine Company has taken a pragmatic

two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

We have a technical support team of UK based engineers and a dedicated sales department to assist you substantial experience in the supply and installation of Rotary tables to a wide range of CNC Machine Tools

Tables are available EX STOCK, are supplied with a standard 2 YEAR WARRANTY, which can be extended, and for a small additional cost an “any event failure” warranty which even covers crashes and accidental damage. Loan tables available to keep your production going while any repairs are carried out.

1. Cnc turning milling and drilling machine can finish different production processing, include: turning, milling, boring, grinding, drilling by one clamping.

FLCX4800 China best quality cnc turning milling machine center with rotary table is a precision machine tool with an integration of machinery, electricity, hydraulic pressure, and numerical control. The structure of the whole machine is equipped with hydrostatic double guide servo CNC turning g and milling rotary table, the beam is equipped with up-down ram, can feed cross traverse feed, servo spindle adopts NC head, can achieve vertical and horizontal transformation, CNC turning and milling rotary table that is vertical car turntable and also is Precise arbitrary degree of servo turntable, can processing flat surface, curved surface, and hole. Milling, boring, drilling and tapping all these processes can be made in one clamping and improves production efficiency and machining quality.

FLCX4800 China best quality cnc turning milling machine center with rotary table adopts NC system centralized control, AC servo drive system, high precision gear and rack drive system. Movement direction is used high-resolution grating or electromagnetic induction foot closed-loop structure It can realize the precision movement of the machine to ensure the processing precision and efficiency.

8613371530291

8613371530291