cnc rotary table manufacturers pricelist

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

CNC Indexing has both pneumatic and hydraulic tables in stock for immediate delivery! Looking for a TJR rotary table price? We have a range of cost-effective options to suit your needs!

For TJR’s pneumatic series of rotary tables, prices start at $5,685. The AR Series is offered in both right hand and left hand motor mount options, with face plate diameter ranges of 125mm – 255mm.

Both the pneumatic and hydraulic brake series TJR rotary table price includes standard features such as an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. For new TJR tables, a standard 3-year parts warranty is included.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

Our online store aims to cater to your professional needs, ranging from motion and flexibility testing, manual muscle testing, evaluations, combination therapy machines to blood flow restriction devices. Please scroll through our online store to find classic exercise machines that help develop stamina, coordination, and strength, or treatment tables for patients to comfortably rest in various positions. Also, find ultrasound equipment to treat and identify areas under the skin that are stressed, fractured, or cracked.

Are you looking for a wholesale tilting rotary table? Alibaba.com is the place to go. If you have many devices that require an internet connection, but your router has fewer ethernet ports a tilingting rotory table is a must-have. This switch connects devices to a network commonly referred to as a LAN and transmits data packets. One thing to note about a network switch is that it transmitters to data allocated one. This might be a router, computer, or another switch. this switch can also help you increase the internet speed delivered to your devices.

Alibaba.com remains home to one of the largest inventories of both used and new tilting rotary table. If you run a rental equipment shop, then the supply at Alibaba.com will be a great place to browse. From tractors and excavators, skid steers and forklifts to dozers and backhoes for your construction, everything you need, Alibaba.com has it. The product variety goes beyond loaders and utility trailers, cranes, and dump trucks to small ones used to compress and package materials. The dairy and food processing equipment will be a good category to look through if you operate a farm.

Then there are rotary indexing tables for creative individuals and businesses. With a vinyl sticker maker, you can put your imagination to good use, turning almost any image into adhesive stickers for bedrooms, commercial premises, or educational spaces. Labeling machines are a great way to inform customers, bring order to offices, and create beautiful images. And at Alibaba, you"ll find every type of machine at wholesale prices. Look around and find the right labeler for your needs.

Find wholesale rotary indexing tables here with amazing bargains. Outdoor tables such as patio dining sets can help add luxury to the spaces where there are put. These are fashionable patio sets and are known for their texture. Patio tables, Picnic tables, conservatory patio sets, and many others are now available here with super-saving deals just for you. You can purchase these amazing patio furniture dining sets at stunning prices. In this online ofplace, you can get a patio set that will suit your exact needs.

Find your rotary indexing tables precisely, slewing bearing for sale by searching slewing ring bearing price by name or keyword, such as large slewing bearings, and as you know, they are all very affordable. Get the merchandise shipped directly from the factory in a prompt manner. We put an array of convenient vehicle parts and accessories that facilitate vehicle servicing, repair, and maintenance, as well as a wide assortment of accessories for the automotive market. So if you are after professional vehicle repair or replacement parts, find the item you want here at Alibaba.com.

Our company is a prominent in the industry as a manufactures and supplies Rotary Table. We offer our product in diverse specifications to fulfill the differentread more...

We provide exclusive range of Goizper make Turn tables (CAM based), rotary tables (indexers), Clutch-Brake units, Spares, Couplings, customized Gear boxes. Goizperread more... Brochure

Roller cam: Compared with worm gears type it is with higher wear resistance, high transmission efficiency , affordable prices and basically maintenance-free of table.

Table directly driven by a motor, high rotary speed , no backlash, no weariness and low inertia. But relatively technical requirement is high and difficulty, the price is the most expensive. Generally used for five-axis machine tools.

Our rotary table can be used in the aerospace industry, 3C high-tech industry semiconductor parts, auto parts and components automation manufacturing, or bathroom equipment and daily necessities manufacturing etc.

The backlash control of our rotary table is stable and reliable, it can be adjusted at the same time and is easy to operate to meet high-precision processing and production requirements, so that it can help customers reduce costs and create more profits.

Ucam has a range of products in its 4th axis solutions. Depending on the application we can offer precision standard rotary tables, rotary production system, largebore rotary tables, multi spindle rotary table, large rotary. These rotary tables can be intergrated into 3 axis machines to from intergrated 4 axis solution for interpolation as well as positioning applications.

Rotary tables are used for perfection metalworking. They"re generally made with a solid base that can be clamped on to another institution. The table is a slice that rotates freely or by use of a worm( hand coil).

A rotary table is a slice- shaped metalworking device used to gain precise workpiece positioning. It enables a metalworker to cut or drill a workpiece at precise intervals around a vertically or horizontally fixed axis. A rotary table can be both manually or computer numerical controlled. Certain types of rotary tables are designed to be used with indexing plates or dividing plates for technical operations. A rotary table used together with one of these positioning plates is generally appertained to as a dividing or indexing head.

The rotary table device generally has a solid base that can be attached to a separate institution or table using clamps. This device is principally a rotating slice which holds the workpiece in place during slice or drilling operations. The slice portion of a rotary table can be freely rotated for indexing procedures or turned by an attached control arm known as a worm wheel. Tables used in high perfection operations are generally turned by a duplex- type worm wheel to compensate for counterreaction. Rotary tables used in automated essence working processes are turned by computer numerical controlled ministry.

Rotary tables are most frequently used in a flat position with the table’s axis having a perpendicular exposure. They"re occasionally mounted with the axis acquainted in a vertical fashion so that a tailstock can be used to support the free end of the workpiece. When this device is attached to a secondary table, the workpiece can be centered on the rotary table’s axis which is also centered on the slice tool’s axis. In this configuration, the axes of the rotary table, secondary table, and cutting tool are coextensive to grease concentric slice operations. This configuration also permits the secondary table to be neutralize for drilling equidistant holes in a workpiece.

One thing that is sorta misleading about the CNC tables unless you"re seen one first hand is just how big they are. I"ve got a Tsudakoma THNC-301, which is a 320mm (12"+) table thats rotary powered and manually tiltable from horizontal to a bit past vertical. It weighs somewhere between 400 and 450 lbs, and I guess the new cost now is somewhere north of $16,000. They have positioning accuracy within a few arc seconds, and are capable of holding accuracies like this with a part that weighs a couple hundred pounds and cutting forces that can generate several hundred ft-lbs of torque.

Pricewise, assuming my 16K current estimate is accurate, that would work out to a bit less than $40/lb, because it definitely weighs over 400#. For comparison, a 10" Kitagawa power chuck for a lathe retails now for about $4000, and although I"ve never weighed one, I guess they weigh less than a hundred lbs from picking one up a "few" times. So that puts the chuck at over $40/lb. If you ever have cause to take one of these chucks apart, they are surprisingly simple. They"re accurate and repeatable, and everything is hardened and ground, but they"re still simple, especially when compared to a rotary table. A good sized collet chuck from Royal to fit an A-8 spindle nose on a lathe weighs barely over 40 lbs and costs close to $2500. Once again, its all hardened and ground, but this is the price of a pullback type chuck which is just one single piece of steel with no moving parts whatsoever, yet it sells for over $60/lb. When you compare the rotary tables and their size and complexity to other machine tool parts of similar complexity and quality, the price begins to look not so far out of line, even though its still not cheap by a long shot.

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

The 9/35 Stallion Trunnion Table allows for even larger parts than the 9/23. At this size, we recommend adding our hydraulic clamping outboard braking system to decrease the possibility of tool forces moving the rotary table by overpowering the rotary table brake system. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Trunnion Table minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary.

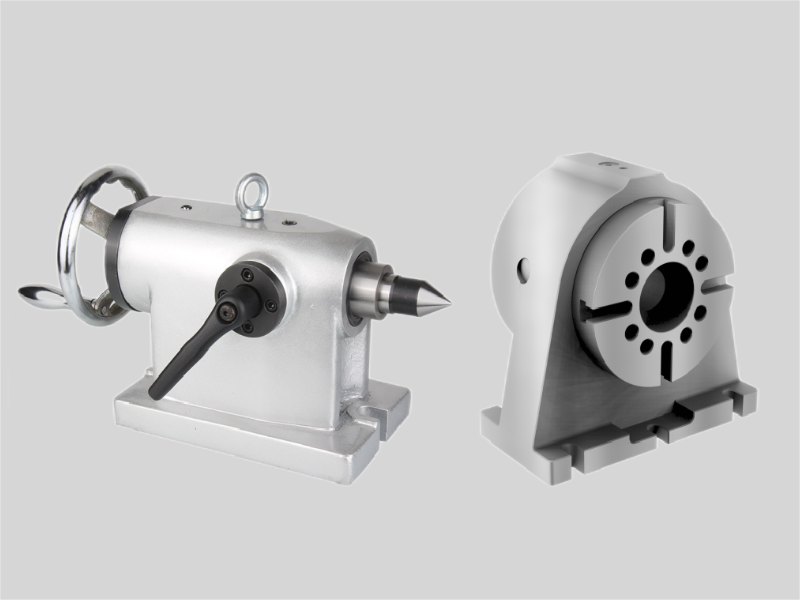

Fig. 4—On this tilting rotary table, one servo controls rotation, another controls tilt. Both servocontrols are slaves to the CNC with RS-232 communication, providing five-axis capability from a standard three-axis CNC.

Fig. 1—Modern rotary tables such as this one from SMW Systems have large, widely spaced spindle bearings, large diameter wormwheels and built-in spindle brakes.

If you want to make parts similar to the complex valve body (upper left), an indexer using M-code, RS-232, or “full fourth axis” control is appropriate. Only positioning and rotary cutting moves are required. The center workpiece is a cam that requires simultaneous rotary and linear moves. You’ll need full four-axis control for such workpieces. If you want to do parts similar to the impeller on the right, the contour cutting will require simultaneous five-axis machining.

Earlier rotary tables and indexers didn’t have the accuracy, rigidity or control flexibility of today’s models. Many shops that tried using indexers in the past had been disappointed in the performance of the older models and abandoned their use in favor of multiple operations, multiple holding fixtures and multiple handlings of the workpiece. They decided that the manual, multiple-operation process was better than trying to use ineffective early model indexers and rotary tables. Today, the situation is different. Manufacturers now offer units that are very accurate, very rigid and have a variety of control and interface options.

Terminology in the area of indexers is not standard. Terms such as fourth axis, indexer, rotary table and so on are used interchangeably by different machine tool and accessory companies. So, when selecting and buying, you must ask a few questions before assuming you know what you’re going to get. Also, beware of terms such as “precision,” “high precision,” “accurate,” and “rigid.” Is the “brake torque” specification some absolute break away spec or the torque at which some “unacceptable” amount of rotary deflection occurs? Is the “ten arc seconds” accuracy specification certified every one degree, or is it inspected only every 15 degrees? There are no industry standards for specifications and testing. So ask questions and deal with a supplier in which you have confidence, or buy with a guarantee of performance to make your parts.

We’ll start with the mechanical hardware and discuss the electronic control options later. There are at least three common mechanical indexer/rotary table types.

These tables provide infinite positioning as well as the possibility of rotary cutting. A servomotor controlled directly either by the CNC or by a secondary servocontrol rotates a wormscrew, which drives a wormwheel on the rotary table spindle.

The absolute position accuracy of these systems is a function of the quality (precision and accuracy) of the wormgear set (wormscrew and wormwheel), the accuracy and resolution of the servosystem, and the means of servoposition feedback. Most of these servosystems utilize an encoder to monitor the position of the motor rather than the rotary spindle directly. To eliminate any inaccuracies in the wormgears and servo system, some high-end systems use a glass scale or other encoder directly on the rotary spindle to monitor actual rotary spindle position. Figure 1 (at right) shows a typical wormgear rotary table cross section.

If controlled directly by the machine tool’s CNC, they are most commonly referred to as a “full fourth axis.” A full fourth axis has the advantages of having only one CNC program, no programming required by the operator on the shop floor, minimum chance of a crash due to operator error, and the ability to make simultaneous rotary and X, Y or Z moves to do true helical milling operations as required by some more exotic workpieces.

Claims of position accuracy are often misleading since there are no industry standards. Although some manufacturers test and certify absolute position accuracy every one degree, most do not state exactly what their specification means.For all except those few expensive systems with glass scales directly on the rotary spindle, any accuracy specification is for a new table before it has been subjected to any “crashes,” which are not uncommon. Even seemingly small crashes can damage wormgear sets.

Typical infinite positioning wormgear systems utilize a friction brake to hold position against cutting forces. When cutting forces are applied directly on the rotary spindle centerline, friction brakes are generally adequate for most work. However, when cutting forces are applied to workpieces far off centerline, such as on the edge of a part on a tombstone fixture, the resulting torque on the rotary spindle can cause it to deflect. This result is especially likely when heavy cuts produce high thrust forces.

Face gear mechanisms used in indexers are similar to those most commonly found in the turrets of CNC lathes, which by function must index very accurately and very rigidly to withstand the high cutting forces the lathe turret encounters. Face gear mechanisms generally fall into two categories, the two-piece and the three-piece design. Two-piece designs require the face plate of the indexer to “lift” to disengage the face gears. Three-piece designs maintain the same accuracy and rigidity of a two-piece without the need to “lift” the faceplate. In Figure 2 (at right), note the massive face gear that locks the indexer spindle in position.

Whether you select an infinite positioning wormgear rotary system or a facegear system as the best mechanical design for your work, your next decision involves how you will control the rotary axis.

With a pneumatic incremental indexer, you probably will have no choice. Your machine’s CNC will control the indexer by communicating with a special indexer control via an M-code.

If you select a system with a servodrive, you have three choices: 1.) direct “full fourth axis” using only the machine’s CNC, 2.) an M-code command from the CNC to a separate rotary control, or 3.) RS-232 communication between the machine’s CNC and a separate rotary control. Each of these choices has advantages and disadvantages.

A single, four-axis CNC is the easiest to use and provides the most control. Four-axis CNC is best for certain kinds of workpieces. Full four-axis control systems are usually ordered for delivery with a new machine. Systems can be retrofitted; however, retrofitting is complicated and expensive. The advantages of a single four-axis control are numerous, and the disadvantages are primarily related to cost.

The single CNC constantly tracks all three linear axes (X,Y,Z) and the rotary axis. This provides the ability to do precise helical cutting with simultaneous rotary and X, Y or Z moves.

While a few machine builders offer a full four-axis control with rotary table for about 10 percent of the base price of the machine, most charge more than 20 percent.

Very few machine builders make it easy to retrofit a full four-axis rotary table. For most builders, retrofitting is a complicated process, and the cost typically exceeds 30 percent of a base machine price.

The motor for the rotary axis must be matched to the servodrive of the CNC. Because cable connections are not standard from one machine builder to another, rotary tables can not generally be used on more than one machine.

An M-code actuated system provides a fourth axis of motion by combining a standard three-axis CNC with a rotary table or face gear indexer that has its own separate rotary servocontrol. The rotary program is entered and stored in the separate rotary servocontrol. The CNC communicates with the rotary control via an M-code. When the rotary control receives the M-code signal, it executes the next rotary move stored in its memory, then sends a signal back to the CNC, telling it that the move has been completed.

Typically, the rotary program includes many separate rotary moves. One move might be a simple index to position at full rapid speed. Another might be a slower rotary move to machine a groove or other feature on the workpiece. Figure 3 (at right) shows a typical rotary servocontrol system.

High quality M-code controlled systems are available from several suppliers for a price of about 10 percent of a base machine price. (For example, a 5C rotary system at $6,000; a 6-inch faceplate system at $7,000; a 9-inch system at $10,000; and so on).

Requiring only one M-code, 110V power and an air line for operation, these systems can be retrofitted to almost any CNC machine, typically with less than a day of downtime.

Systems can be moved from one machine to another as long as the next machine can issue M-codes. A shop with multiple machines and multiple rotary systems can select the best system for each job regardless of the machine. For example, a small indexer can be used for small parts to avoid cutting tool interference problems and to minimize indexing times. A big indexer can be used for big parts. A face gear indexer can be used when the maximum in accuracy and rigidity are needed and the work can be accommodated by multiples of 5 degrees of index.

The machine operator needs to enter the rotary program into the rotary servocontrol, or select the right program if it’s already stored in the rotary control’s memory. This takes some time, and there is the chance of an error.

If the machining cycle is ever interrupted in mid-cycle, such as to inspect a workpiece feature or replace a worn cutting tool, the operator must be sure to back up the rotary program and the CNC program to a point that keeps the two programs in sync. This step can be confusing, and any error can result in a “crash,” with a cutting tool coming down to a workpiece rotated to the wrong position.

Although it is possible to perform simultaneous rotary and X, Y or Z moves, they are not recommended. If you have patience and can afford to scrap a few parts, you can use trial and error to find the right rotary speed to match the linear move and determine starting points that match.

Recently developed, RS-232 communication between a three-axis CNC and a rotary servocontrol offers advantages of full four-axis and M-code operation. RS-232 is the commonly used, standard electrical interface for connecting peripheral devices to a computer. Personal computers often use the RS-232 communication protocol to send information to a printer. Another common use for RS-232 communications is connecting a PC to an external modem.

Nearly all CNC units have an RS-232 port, and it is commonly used to exchange CNC programs between a computer system and the CNC. More recently, RS-232 connections have been used by CNCs to communicate with robots and rotary tables. To communicate with the rotary table’s control, a special line of code is inserted into the CNC program. This line of code sends a string of numbers and letters through the RS-232 port to the rotary table control, which translates the string of code into rotary moves.

RS-232 communication between a three-axis CNC and a rotary servocontrol provides much of the best of both worlds of full four-axis and M-code operation. Both the linear and rotary moves are stored in the CNC as part of the workpiece program. When a rotary move is required, the CNC sends the commands for that one move (rotary speed and angle of rotation) through an RS-232 line to the rotary control.

The rotary control executes that one move and sends back a signal to the CNC, indicating that this move has been completed. The CNC then commands its next linear move. The separate rotary servocontrol simply works as a slave to the CNC. The machine operator turns the rotary control on in the morning and does not need to attend to it the rest of the day. Figure 4 (at right) shows a tilting rotary table system utilizing two rotary servocontrols with RS-232, providing five-axis capability from a standard three-axis CNC.

Crashes are nearly as unlikely as with a full four-axis control. The correct rotary program is always selected because it is part of the total workpiece program stored in the machine’s CNC. Note: Rotary moves should be programmed in “absolute position” so that if the machining cycle is interrupted, the operator can back up the CNC program to just in front of a rotary move, then safely resume the program.

Retrofitting is easy provided the machine’s CNC has an RS-232 port and appropriate communication software, which may already reside in the CNC or be available from the machine builder.

With RS-232, two rotary controls can be operated by most three-axis CNCs with only one RS-232 port. Five-axis capability with a tilting rotary table setup can be retrofitted to a three-axis machine for about $25,000 (a new, full five-axis VMC option is typically priced at $95,000).

Both the work you need to do and the machines you own or intend to purchase will influence what you select for a rotary axis. These guidelines summarize what you should consider.

When buying a new machine, get prices on everything the builder offers, no matter what kind of workpieces you’ll be machining. If the builder offers a full four-axis system with a high-quality, infinite-positioning rotary table at a price of about 10 percent off the base machine, this system will probably be your best choice.

If you’re doing a variety of work that requires simultaneous rotary and linear helical moves, you’ll probably want a true four-axis system regardless of the cost. However, you should consider a more economically priced RS-232 or M-code system when you are retrofitting an existing machine and have only a couple of jobs requiring these moves, especially if these jobs are long run and you can afford some extra programming and setup time. These systems are worth considering if you simply can’t afford the price of a true fourth axis.

If you’re retrofitting existing machines, especially if you have several and want to do rotary work on more then one of them, check with the builder on the cost of upgrading to full four axis. You may conclude that the cost and flexibility advantages of RS-232 or M-code will make one of them the best choice.

Adding a rotary axis to a VMC is worthwhile whether you want to do full four-axis simultaneous machining of exotic workpieces, simple indexing of parts that need machining on surfaces not at 90 degrees from each other, or tombstone processing of rectangular parts that benefit from a longer unmanned machining cycle. Today, many good options exist. If you’re buying a new machine, have the builder quote the optional systems it offers. If you’re going to retrofit an existing machine, contact either the original supplier or the companies that offer complete indexer and rotary table systems. Retrofitting is highly affordable. (Systems from SMW Systems, for example, generally cost a little over $1,000 per inch of faceplate diameter, including installation and training.) MMS

pL LEHMANN has been developing and producing CNC rotary tables for over 40 years. – genuine SWISS QUALITY. The experience gained is incorporated into our products and services. With innovative CNC rotary axes, organized in a standard modular system, we want to meet the international needs for economical production of very small to medium-sized workpieces in the machining industry by satisfying individual requirements with appropriate combinations.

Index Designs is an all-American company. Their founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. Index Designs entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Thier products are completely manufactured in our Chatsworth, California facility. Index Designs uses state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines.

8613371530291

8613371530291