zeiss rotary table quotation

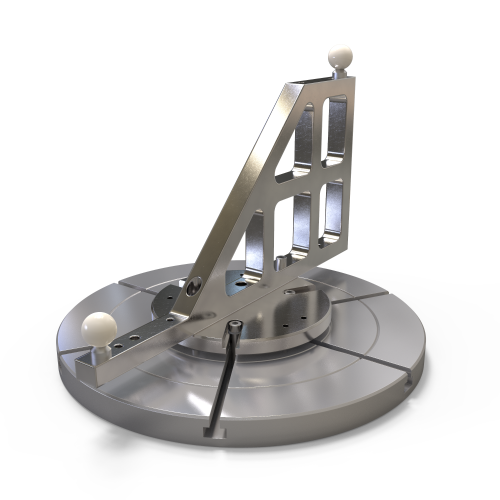

Rotary table set kit for the definition of the rotary table axis (in general) and/or definition of perpendicularity error on the position of the rotary table (only for PRISMO ultra) contains a triple prism, two reference spheres DK30 and two invar cylinders

You have already attended a ZEISS CALYPSO Basic Classroom Training or you have already gained practical experience and would now like to deepen your knowledge.You can find further information on our classroom training courses here.

ZEISS eLearnings give you the freedom and flexibility to expand your knowledge of measurement technology - at your own pace. To access the training you have purchased, log in to the ZEISS Metrology Portal. In the Academy Metrology area, you will find all the training courses you have booked under eLearnings. These are available for twelve months from the start. ZEISS eLearnings are interactive and can consist of video tutorials, software simulations and numerous practical excercises. At the end of the training, you will take a test and receive a certificate upon successful completion.

You have already attended a ZEISS CALYPSO Basic Classroom Training and a ZEISS CALYPSO Optics Classroom Training or you have already gained practical experience and would now like to deepen your knowledge.You can find further informations on our classroom training courses here.This course offers online learning content to deepen the concepts of ZEISS CALYPSO Training for the ZEISS O-INSPECT.

ZEISS eLearnings give you the freedom and flexibility to expand your knowledge of measurement technology - at your own pace. To access the training you have purchased, log in to the ZEISS Metrology Portal. In the Academy Metrology area, you will find all the training courses you have booked under eLearnings. These are available for twelve months from the start. ZEISS eLearnings are interactive and can consist of video tutorials, software simulations and numerous practical excercises. At the end of the training, you will take a test and receive a certificate upon successful completion.

With interchangeable jaws, you can conveniently adapt the ring chuck to your requirements. Special jaws manufactured in-house can also be adapted. The kit version for the DuraMax rotary table is equipped with a mounted adaptation to the rotary table and also includes a reference sphere to qualifiy the rotary table.

The form tester features a movable X axis, allowing it to reach workpieces from all sides without difficulty. Another key benefit is the rotary table on air bearings that achieves extremely high rotational accuracy thanks to its excellent rigidity. In addition, the non-contact travel ensures measurement results that are totally uninfluenced by drive vibrations.

Save 9% on a ZEISS O-INSPECT 543 Multi-sensor CMM.It is the optical solution with the right touch. The perfect balance of inspection by seeing and touching, enabling you to optimally measure each characteristic in compliance with ISO-10360 – optically or by contact. Advantages include: a large visual field with high image definition, quick and precise 3D tactile measurements, optical measurements for sensitive surfaces, and increased reliability in less time.

Save $5,000 on a New SURFCOM NEX 200.The patented contact-free magnetic linear drive makes SURFCOM NEX highly efficient and low-maintenance. It enables a positioning speed that is up to seven times faster. Choose from two granite measuring table sizes and three column sizes. It’s future-proof thanks to multi-sensor capability with optical and tactile sensors. Tactile styli are exchangeable without tools or screws.

I work in a shop that has both, 2 B&S Globals, a Zeiss DB, and a Prismo Vast SuperAcc. They both do essentially the same things but they go about it very differently.

The big question you have to ask yourself is what am I trying to measure. If you can measure almost everything with a few probe configurations then something like a Zeiss Vast head wouldn"t be to bad but if you anticipate a lot of different probe configurations and / or articulations you need to look at a Renishaw PH10 or Zeiss RDS.

My personal preference is B&S for a number of reasons. PC-DMIS has much better alignment capabilities. The user interface is drastically better (programming is much quicker). Patterning in PC-DMIS is the greatest thing in PC-DMIS. You can pattern anything into a whole new set of features, moves probe rotations, etc. This really speeds programming. In Calypso you can pattern some things but once it is inside a pattern you lose the ability to edit on a specific feature basis. I have found many inherent issues in Calypso that make programming a bear, (issues that Zeiss has been reluctant to fix over the years).

The ZEISS METROTOM is an industrial computed tomography system for measuring and inspecting complete components made of plastic or light metal. With traditional measuring technology, hidden structures can only be inspected after the time- and cost-consuming process of destroying the component layer-by-layer.

With ZEISS METROTOM computed tomography system, numerous component characteristics are scanned in one run. The resulting measurements are precise and traceable. Unlike contact measuring methods, ZEISS METROTOM is significantly faster when capturing numerous measuring points.

The horizontal arm of the ZEISS CARMET is equipped with space-saving collision protection on both sides to protect people and material from injury and damage. The proven friction drives in the ZEISS machines that simply slip through when there is a blockage also contribute to safety.

For all structurally relevant components, ZEISS consistently uses steel, which allows for even, controlled heat expansion. In addition, the Z column is also thermally insulated by F.I. technology. The result: The machine can be used in a broad temperature range from 16 to 24°C within the specified measuring error. Furthermore, the machine does not have to be cooled, and temperature compensation is not required. In addition, the light insulation cover can be removed quickly and easily for maintenance.

8613371530291

8613371530291