accumulating rotary table manufacturer

The Globaltek rotary tables can be used to unscramble product and feed a conveyor, also as a buffer space to accumulate product until the downstream conveyor is ready for additional product or collect. Accumulating rotary tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation. Accumulating rotary tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation.

The Globaltek rotary tables can be used to unscramble product and feed a conveyor, also as a buffer space to accumulate product until the downstream conveyor is ready for additional product or collect. Accumulating rotary tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation. Accumulating rotary tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation.

Rotary accumulation tables are a small footprint conveyor solution designed for accumulating and unscrambling products at various points during the conveying or packing processes. An efficient process to balance production rates, a buffer space accumulates product allowing production to continue while downstream product is temporarily stopped. This accumulation solution is also ideal for end of the production lines accumulation needs with limited floorspace. Rotary accumulation tables are often used in conjunction with bulk round, flat-bottom products to be off-loaded in a single-file line.

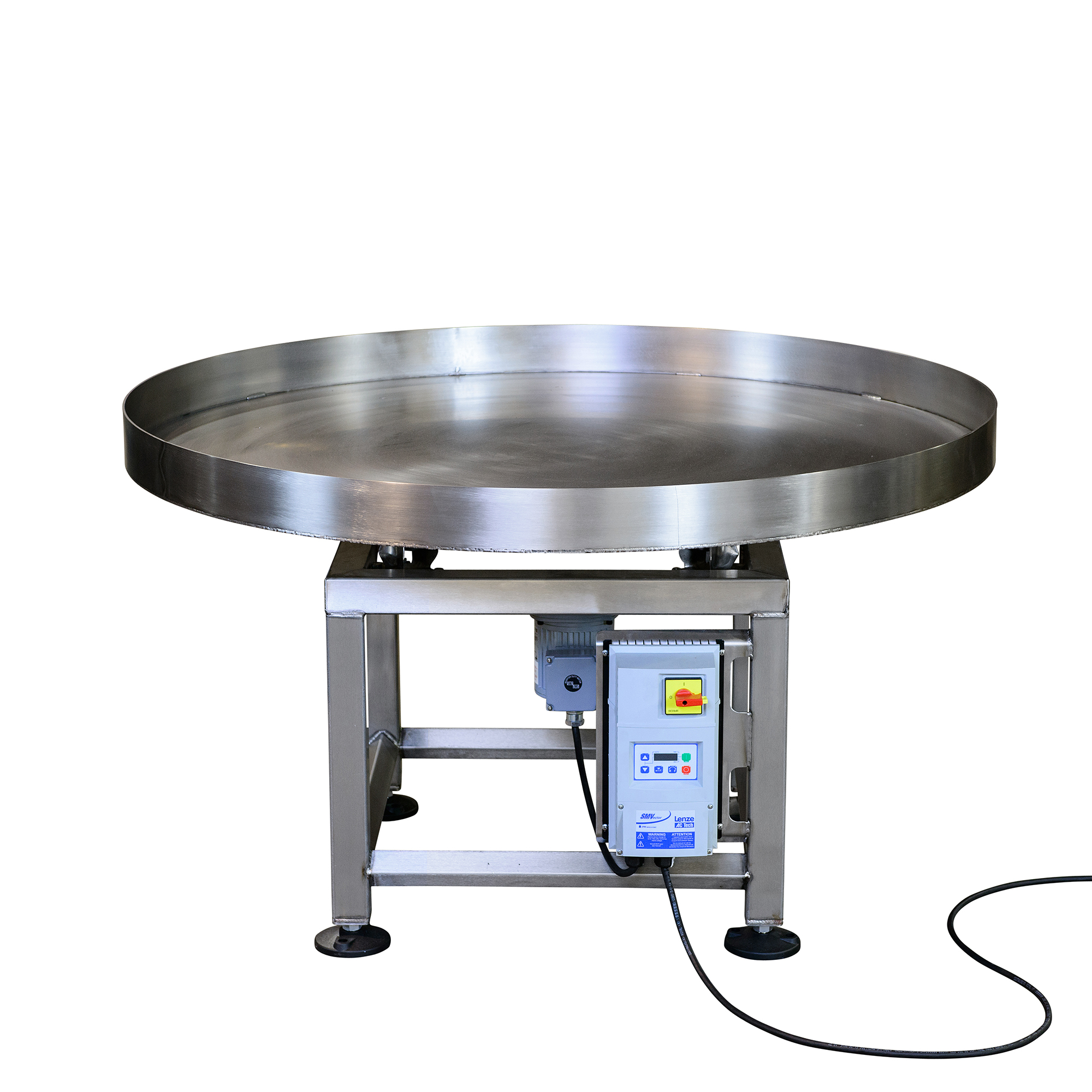

Variable Frequency Drive (VFD) speed control sets the optimum table rotation speed. Nercon’s rotary accumulation table is designed to handle extremes with ease reducing wear and tear on the motor that can otherwise lead to early motor burnout. Temporarily off-loading product flow due to inconsistent speeds between processes maintains production schedule and decreases downtime.

Height adjustable to integrate seamlessly into current production lines, the adjustable supports also allow for leveling on uneven floors to keep the rotary accumulation table stable.

One of the earliest designs for accumulation or unscrambling is the rotary table. Both configurations can handle multiple container sizes and materials. The rotary design is flexible and effective. Standard (non-custom) diameters are 36", 48" and 60”. Top discs are stainless steel with machined backer plates for trueness. Accumulators are usually supplied with an enclosed cabinet and variable speed controls, using either DC or VFD controllers. Infeed and discharge conveyors are recommended to be designed with a close interface for smooth transfers. A smooth edge bowl top is available for hand packing applications.

A rotary accumulation table installed at the beginning of a bottle packaging line allows operators to quickly fill the table with empty bottles rather than feed bottles onto a conveyor one by one. The rotary table then automatically discharges the bottles onto the conveyor in a single file line.

Rotary tables located at the beginning of the line are often fitted with unscramblers and in-feed tables. The unscrambler attachment consists of a paddle diverter that pushes the containers to the edge of the rotary table where they are discharged onto the conveyor. The in-feed table allows operators to quickly place large quantities of bottles onto the rotary table.

Rotary accumulation tables installed in the middle of a packaging line allow you to deal with production bottlenecks and service issues. Mid-line accumulation tables can be fitted with upstream and downstream gates. If a machine on the line needs to be serviced, the downstream gate on the accumulation table is closed to prevent bottles from flowing into the machine being serviced. When the service on the machine has been completed, open the downstream gate on the accumulation table to again allow the bottles to flow downstream.

Rotary accumulation tables installed at the end of a bottle packaging line serve a critical purpose. They provide an outlet for the finished product to collect in preparation for packing and prevent the bottles from backing up and slowing down your entire bottle packaging line. In-feed tables, also called pack-off tables, are a popular option for end of the line accumulation tables because they enable operators to quickly and easily remove finished product from the rotary table.

Our Rotary Accumulation tables can be used at the end of production lines, as an infeed to a conveyor, and as a buffer space to accumulate product until the downstream conveyor is ready for additional product or collect. Rotary accumulation tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation.

Rotary Work Tables were designed to accept product flow from discharging belt or other general material handling systems. The rotary table or some times called spinning table is a robust design, which is engineered to take demanding punishment from an industrial environment. The rotary table is the key component in designing a flexible work cell for jobs requiring manual inspection, degating, assembly or packing. In typical applications, the product is conveyed on to a the table to allow multiple operators can efficiently handle tasks or allows multiple products (sub-assemblies) to be conveyed from multiple machines to one location and have one operator handle multiple tasks without added effort or ergonomic strain.

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

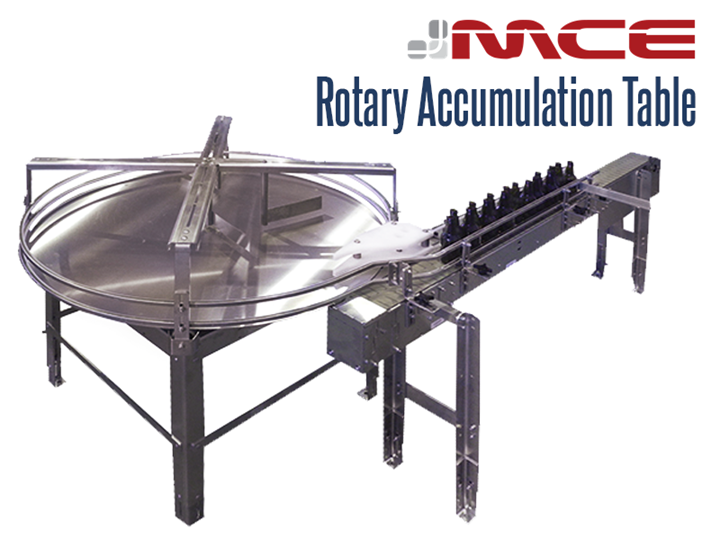

Multi-Conveyor (Winneconne, WI) recently built both an unscrambling rotary table and an accumulation rotary table which are connected by a 30’ basic plastic straight running chain conveyor in this semi-automated conveyance application.

The first mild-steel constructed rotary accepts bulk, random hand-loaded glass containers that sweep through two deflector arms. These flexible arms gently control the cluster of individual products into single file, then onto the mat top conveyor chain.

During the 30’ straight chain, labels are applied by the customer’s press-on labeler (not shown) before discharging onto the accumulation table where an attached staging shelf assists manual hand-packing into cases.

Stainless steel rotary top discs feed the guided, seamless transfers that are positioned at both the unscrambler discharge and accumulation table entrance.Note: Product in this video is for demonstration purposes only.

Unscramble style rotaries are a simple, cost-effective way to transfer bulk product to one-lane single-file conveyance. Rotary accumulation tables are supplied with an enclosed cabinet and typically variable speed controls, using either DC or VFD controllers. Multi-Conveyor’s standard rotary table sizes are 36”, 48” and 60” diameter. Custom sizes are reviewed upon request.

For more information on Rotary Turntablesplease contact a Thomas Conveyor & Equipment Automation Engineer at 844 220 0086 or click on theContact Usbutton above.

Multi-Conveyorrecently built two 48-in.-dia, 11-gauge stainless-steel rotary tables and unscramblers for a pharmaceutical application.The tables easily adapt to varying sizes and shapes of products, showing the versatility of these systems for many applications.

This particular project will be accumulating bottles from 1 to 4 in.-sq and 2 to 7-in. high.The rotary table will accumulate the bottles and then break them down into a single flow using a curved spring rail.

The rotary tables and unscramblers were designed with the appropriate motor size to accommodate 250 lb of pharmaceutical bottles on the accumulator at one time, while running from 2 to 5 revolutions/min.

The rotary accumulation table has one DC motor controller that is run on standard 110 vDC, single-phase electrical output, allowing it to be used in almost any area of the production floor without special wiring.

The rotary table is one of the earliest designs for accumulation or unscrambling.Both configurations can handle multiple container sizes and materials. The rotary design is flexible and effective. Typical diameters are 30 in., 36 in., 42 in., and 48 in. Top discs are stainless steel with machined backer plates for trueness.

Rotary accumulators are usually supplied with an enclosed cabinet and variable speed controls, using either DC or VFD controllers. The company recommends that infeed and discharge conveyors be designed with a close interface for smooth transfers. A smooth-edge bowl top is available for hand packing applications.

Alibaba.com offers 310 rotary accumulation table products. About 62% % of these are other packaging machines, 4%% are other machine tools accessories, and 3%% are table.

A wide variety of rotary accumulation table options are available to you, such as wood, plastic and glass.You can also choose from food & beverage factory, manufacturing plant and food shop rotary accumulation table,As well as from automatic, semi-automatic rotary accumulation table. and whether rotary accumulation table is 1 year, 6 months, or 1.5 years.

8613371530291

8613371530291