enco rotary table manufacturer

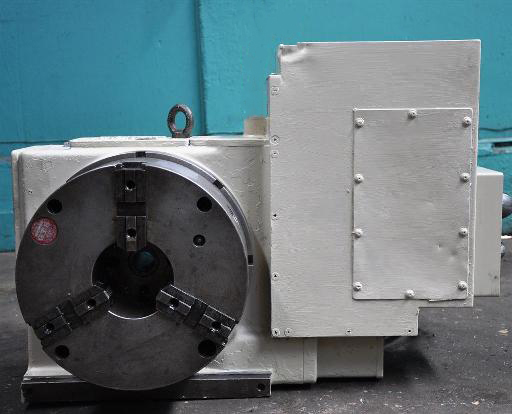

Im in the market for a 10-12" rotary table, and while I was at a local machine and tool supply house, I noticed a brand new, but older, Enco 12" H/V rotary table. The tag on the table said $600. The owner noticed my interest, and struck up a conversation, long story short, they said they"d take $300 for it because they had it for about 15 years now and really need to clear out some inventory. It says made in Taiwan, and it turns very smooth, and generally looks good, but there is a lot of backlash, but the handle felt like it had some loose bolts. What Im wondering:

3. What should I do to check out the accuracy of it? Can I put a mag-base dial indicator on the table base and spin the table to check flatness and runout?

This will be a bit convoluted but...that Enco table looks very much like an "Advance" table (there is one for sale here, w an X-Y slide on top but still...) anyway, there is some discussion here

Unfortualy im not completely sure if its the set screws in the silver part or black part. And if that black "knob" part that sticks out has anything to do with it. But basicly the operation is getting that handle to freely move (its locked in place by SOMETHING, and will freely rotate once that is removed), rotate it about 90~180 degrees and the table should spin freely (Well, with a really strong nudge, but no need to beat on it with a hammer)

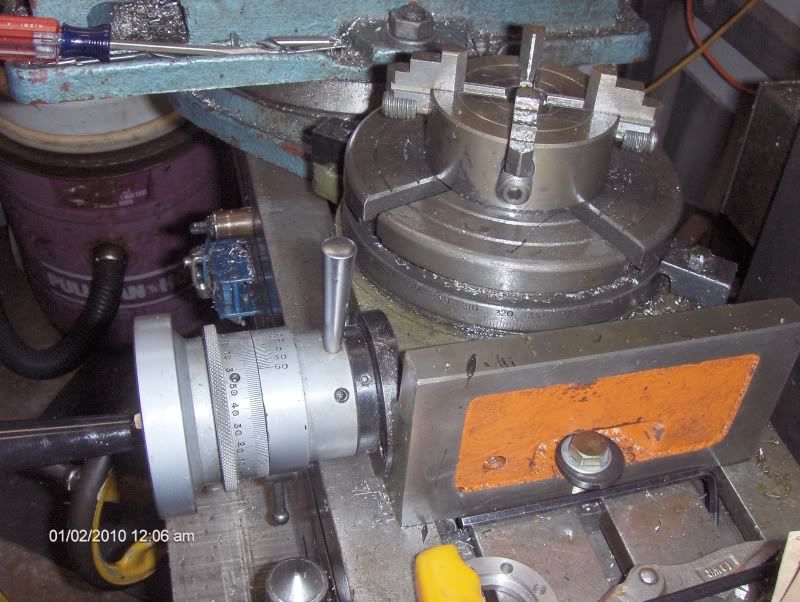

I have an eight inch that I ordered from Enco but it looks different (has two vertical mounting lugs and two horizontal lugs). Mine also came with the dividing apparatus and a 17 - 47 hole set of plates. It IS very heavy, as you mentioned, and I have made a small roll-around platform for mine so that I can move it around the bench during setup. I"m considering a crane to move mine, too, but in the meantime, here"s what I do:

After I get the table set up to my liking, I lower the mill table so that it is an inch or two lower than my workbench. Placing a plywood ramp between the workbench and the mill table, I roll the rotab down to the mill and carefully slide it off the little wheeled platform onto the table. To get it back on the workbench, reverse the process only raising the mill table an inch or two above workbench level.

Mine hasn"t seen extensive use but works well ... I"ve made a couple of large milling cutters from 1-1/2 diameter drill rod and a number of smaller projects. (I even used it for a couple of woodworking projects with my home-made router spindle attached to the mill quill.) The cool thing about it is that the backlash in the worm can be completely adjusted out. Frankly, I"ve thought about a smaller table (for convenience) but the argument for the bigger table is that more mass prevents chatter and makes for a smoother cut. If yours doesn"t come with dividing plates, you might consider that as one of your first projects.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines. However, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right-angle attachment is available (P/N 3701) to mount the table in the vertical position to increase its versatility further. With the table mounted vertically, an optional adjustable right-angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

20. INSURANCE – All successful Bidders, or the their riggers must provide the Auctioneer and the owner of the premises of the sale a certificate of insurance in amounts acceptable to the Auctioneer prior to removal of any Lot.

I am thinking of adding an 8" horizontal/vertical rotary table to my PM935 mill setup and need some suggestions. The candidates I have seen so far are Yuasa, Vertex, and Phase II. Their are other but these seem to be the most readily available in 8".

In case of any errors or malfunctions of hardware or software, we reserve the right to cancel any transaction even if you have received confirmation of the transaction by email. We strive to make this system as stable as possible; however errors and equipment malfunctions are possible and may happen without notice. We cannot and will not guarantee uninterrupted access to the Site or its services

In case of any errors or malfunctions of hardware or software, we reserve the right to cancel any transaction even if you have received confirmation of the transaction by email. We strive to make this system as stable as possible; however errors and equipment malfunctions are possible and may happen without notice. We cannot and will not guarantee uninterrupted access to the Site or its services

Turret tool posts, magnetic tools, centers, boring and facing heads, drilling and tapping heads, measuring tools, cutting tools, milling machine vises, clamping kits, safety shields, and accessories. Rotary tables ; arbors ; boring bars ; calipers ; cam locking toolposts ; centers ; chuck block parallels ; collets ; compound replacement toolposts ; demagnetizer ; diving heads ; end mills ; flange nuts ; granite surface plates ; magnetic base lights ; magnetic vise ; plain clamps ; radius and angle dresser ; shields; guards ; step clamps ; studs ; t-nuts ; toe clamps ; turret quick change toolposts ; etc.... this comprises the uncataloged portion.

8613371530291

8613371530291