direct drive rotary table manufacturer

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

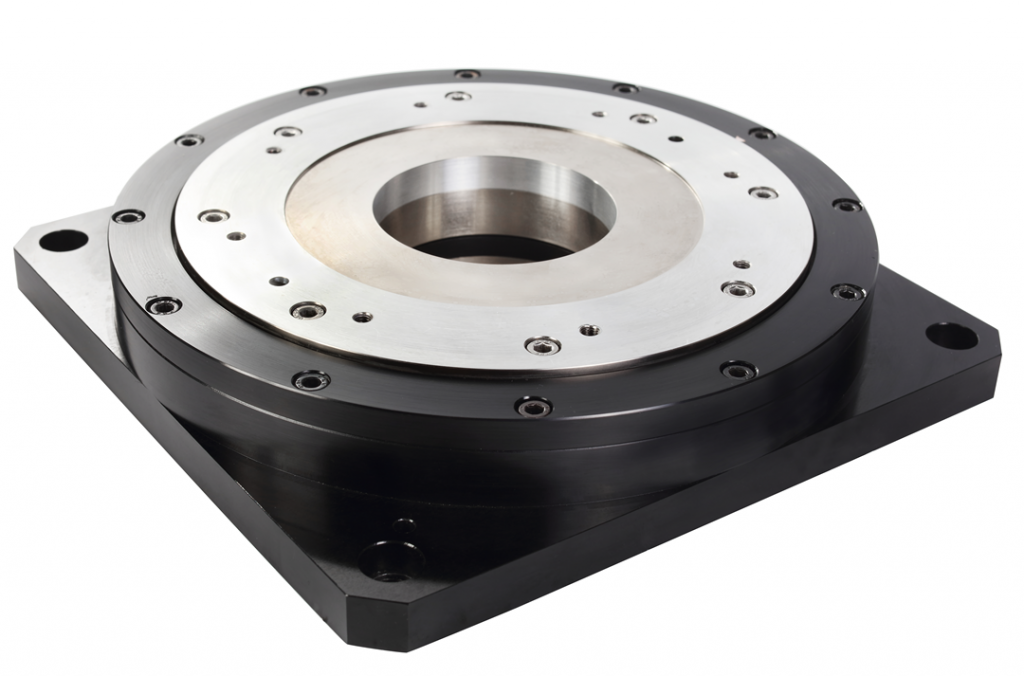

The AD-Series is TJR’s Direct Drive rotary table that is offered in multiple sizes. The sizes range from 170mm (6.69”) to 260mm (10.23”) face plate diameter.

These units truly have zero backlash during rotation in either direction. In addition there is zero wear do to the design of the units, which ensures long-lasting high precision accuracy. They are also capable of high speed rotation 100-200 rpms with high rate of acceleration. The AD- Series direct drive rotary table also uses the powerful pneumatic braking system that is employed in the AR-Series.

The particularly flat and lightweight DMN rotary tables are suitable for all applications in which high rigidity and accuracy are needed along with ...

... assemblies with integrated direct drive (torque motor) are characterized by high dynamics, maximum energy efficiency and a compact installation space combined with center-free design.

Compact package and Superior design of the AccuRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

... Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system working ...

... Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system working ...

While the conventional drives are dependent on an external controller unit, for the compact drives no additional controller is needed. The complete electrical parts, including the drive ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

High Performance in a Compact Package Parkers Direct Drive Rotary Stage, featuring an integral brushless DC servomotor, has several distinct advantages over traditional worm gear-driven stages. The elimination of the worm gearing offers the ability to reduce wear with zero backlash while exhibiting near frictionless motion. Its high positioning accuracy, solely based on the stages encoder, provides repeatability within + 2 encoder counts, with resolutions ranging to 1.4 arc seconds. The RD Direct Drive features speeds up to 700 RPM with significant torque capability

There is no mechanical reduction mechanism such as a worm system in a rotary table with a DD motor. DD (Direct Drive) motor is built in the rotary table to drive directly. The compact two-axis direct drive rotary table enables rapid acceleration/deceleration and high-speed rotation. Its biggest advantage is the super high speed up to 2000 rpm. Thus, it can work as a mill/turn component. As a result of the lack of a mechanical reduction mechanism, the driving torque of the rotary table is not strong. It is necessary to choose an application for the rotary table with a DD motor.

A high torque motor drives the direct drive rotary table directly. There is no backlash or abrasion generated during rotation because it is not driven by worms and gears. Typically, these rotary tables are used in applications requiring high accelerations and decelerations, such as blade machining. For high-speed drilling centers with very important indexing times, a two-axis direct drive rotary table is an excellent choice.

Direct drive (DDR) rotary tables eliminate backlash and provide a stiff mechanical system for highly dynamic applications. Integrated with precision bearings and ring encoders, these rotary tables provide ultimate performance in rotary indexing applications

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

Direct drive rotary table is a type of rotary table used for continuous operation, and is many times more precise and flexible than the conventional face gear, or rack and pinion rotary tables.

Director drive rotary tables are characterized by the specialized bearing, and the highly rigid and robust nature that has a low runout of less than 0.015mm in a very compact configuration.

The high power torque motor is generally coupled with the direct drive rotary table to allow rapid and power operation. The process is often monitored by a high resolution encoder to ensure that maximum flexibility and accuracy are maintained.

Some of the key advantages of a direct drive rotary table include the repeatability, short time of indexing, flexible indexing positions, as well as the tolerability of exceptionally high axial and radial torques during rotation and stopping.

Systems based on direct drive rotary table are generally very durable, and will not require a repair until a longer period of time. Depending on the applications, the rotary table may be complemented with an internal or external clamp.

● Direct drive rotary tables do not consist of many mechanical parts like other machinery, which results in superior lifespan as well as low maintenance requirement.

● High Accuracy: Direct drive rotary tables are primarily known as having high accuracy because of the standard direct measuring scale feedback system incorporated.

● High Speed Rotation and Indexing: The speed can go up as high as to 1,000 RPM. The rotary table also comes with a variety of high speed options that are available based on direct drive motor selection.

● Reversal Error Free: The table is free of mechanical reversal error, making it the perfect mean for finishing. It is in fact able to provide exceptional surface finish when contouring.

● Maintenance Free: As mentioned previously, the rotary table has minimal mechanical parts, which almost completely eliminate its need for maintenance for a long period of time.

● High Thermal Deformation: The direct drive motors can generate tons of heat, which is why a coolant unit is almost always required to complement the table based on the intended applications and accuracy requirement.

● Maintenance: Although this may seem contradicting, you typically do not want the need for maintenance to happen at all because this type of rotary type is extremely difficult to adjust or repair, and the resulting crashes can be very troubling.

The main application is to accurately position a component in desired angle in CNC machining centers to perform multi-face operation in a simple setup. Direct drive rotary tables can be interpolated as the 4th axis along with the three standard axes to enable tasks such as blade machining, cam machining, helical grooves and so on.

Rotary tables are used for perfection metalworking. They"re generally made with a solid base that can be clamped on to another institution. The table is a slice that rotates freely or by use of a worm( hand coil).

A rotary table is a slice- shaped metalworking device used to gain precise workpiece positioning. It enables a metalworker to cut or drill a workpiece at precise intervals around a vertically or horizontally fixed axis. A rotary table can be both manually or computer numerical controlled. Certain types of rotary tables are designed to be used with indexing plates or dividing plates for technical operations. A rotary table used together with one of these positioning plates is generally appertained to as a dividing or indexing head.

The rotary table device generally has a solid base that can be attached to a separate institution or table using clamps. This device is principally a rotating slice which holds the workpiece in place during slice or drilling operations. The slice portion of a rotary table can be freely rotated for indexing procedures or turned by an attached control arm known as a worm wheel. Tables used in high perfection operations are generally turned by a duplex- type worm wheel to compensate for counterreaction. Rotary tables used in automated essence working processes are turned by computer numerical controlled ministry.

Rotary tables are most frequently used in a flat position with the table’s axis having a perpendicular exposure. They"re occasionally mounted with the axis acquainted in a vertical fashion so that a tailstock can be used to support the free end of the workpiece. When this device is attached to a secondary table, the workpiece can be centered on the rotary table’s axis which is also centered on the slice tool’s axis. In this configuration, the axes of the rotary table, secondary table, and cutting tool are coextensive to grease concentric slice operations. This configuration also permits the secondary table to be neutralize for drilling equidistant holes in a workpiece.

8613371530291

8613371530291