direct drive rotary table supplier

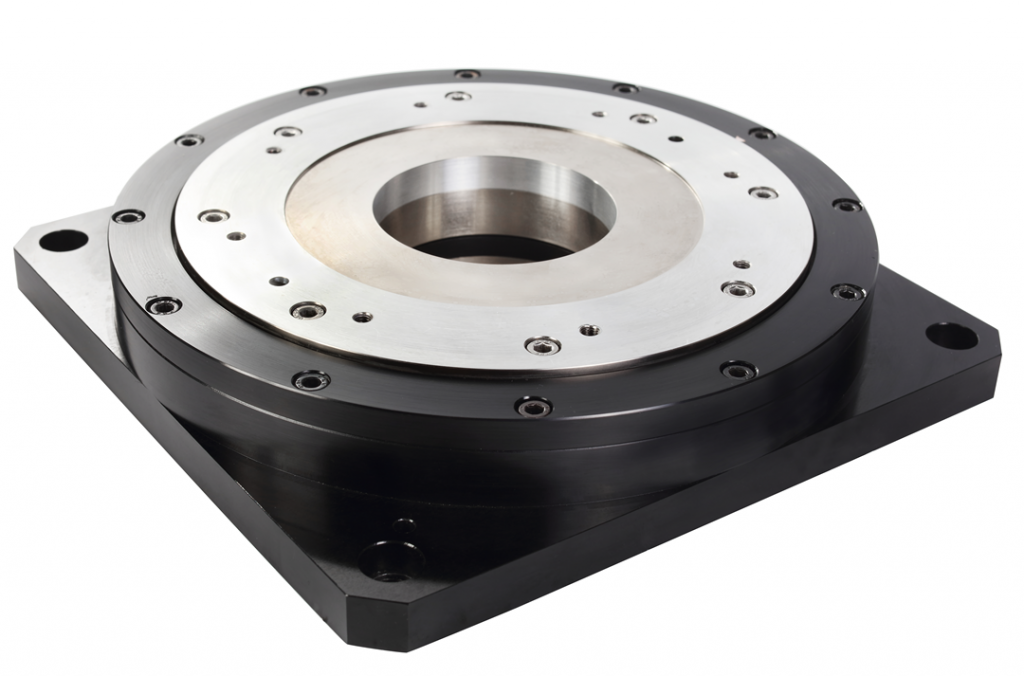

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

The AD-Series is TJR’s Direct Drive rotary table that is offered in multiple sizes. The sizes range from 170mm (6.69”) to 260mm (10.23”) face plate diameter.

These units truly have zero backlash during rotation in either direction. In addition there is zero wear do to the design of the units, which ensures long-lasting high precision accuracy. They are also capable of high speed rotation 100-200 rpms with high rate of acceleration. The AD- Series direct drive rotary table also uses the powerful pneumatic braking system that is employed in the AR-Series.

The particularly flat and lightweight DMN rotary tables are suitable for all applications in which high rigidity and accuracy are needed along with ...

... assemblies with integrated direct drive (torque motor) are characterized by high dynamics, maximum energy efficiency and a compact installation space combined with center-free design.

Compact package and Superior design of the AccuRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

... Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system working ...

... Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system working ...

While the conventional drives are dependent on an external controller unit, for the compact drives no additional controller is needed. The complete electrical parts, including the drive ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

The “HOMGE” PRECISION INDEXING TABLES are constructed with an AIR CYLINDER between the mating surfaces. This system ensures reduces friction when heavy loads ...

The TO750 is a direct drive rotary table. The device consists of an impressive dynamics and high degree of repeat accuracy. The device can be programmed freely and is ...

Peiseler’s AWD 400 Horizontal Direct Drive Tables feature 400-mm faceplate diametric measurements, horizontal axes of rotation, and 1.000-kg load capacities. They exhibit 130-rpm rotational ...

Matsumoto direct drive rotary unites are very quick, precise, and low-maintenance. DD indexers are most widely used in grinding applications where precision and quickness ...

The RTMBi Series is a family of high precision indexing tables proposed with 5 different active lengths. Integrating ETEL direct drive torque motors, the RTMBi Series ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

High Performance in a Compact Package Parkers Direct Drive Rotary Stage, featuring an integral brushless DC servomotor, has several distinct advantages over traditional worm gear-driven stages. The elimination of the worm gearing offers the ability to reduce wear with zero backlash while exhibiting near frictionless motion. Its high positioning accuracy, solely based on the stages encoder, provides repeatability within + 2 encoder counts, with resolutions ranging to 1.4 arc seconds. The RD Direct Drive features speeds up to 700 RPM with significant torque capability

There is no mechanical reduction mechanism such as a worm system in a rotary table with a DD motor. DD (Direct Drive) motor is built in the rotary table to drive directly. The compact two-axis direct drive rotary table enables rapid acceleration/deceleration and high-speed rotation. Its biggest advantage is the super high speed up to 2000 rpm. Thus, it can work as a mill/turn component. As a result of the lack of a mechanical reduction mechanism, the driving torque of the rotary table is not strong. It is necessary to choose an application for the rotary table with a DD motor.

A high torque motor drives the direct drive rotary table directly. There is no backlash or abrasion generated during rotation because it is not driven by worms and gears. Typically, these rotary tables are used in applications requiring high accelerations and decelerations, such as blade machining. For high-speed drilling centers with very important indexing times, a two-axis direct drive rotary table is an excellent choice.

Generally, this device style would be mounted on a sufficiently large machine tool that there will not be an issue due to the width of the unit, such as collision with machine doors with Y-axis travel. In selecting a side mount motor version you should always consider the Y-axis travel of the machine and if there would be any interference between the guard of the rotary table and the doors of the machine, particularly when referencing the machine as a lot of VMC machines reference with the Y-axis travelling to the front of the machine, towards the operator. This is an ideal design of product for use with any machine tool, particularly those with a good working envelope. The design is versatile as it can be used in either plane. Due to the carrying capacity, however, if you have a larger machine tool and are doing lighter work you could mount this device on a raiser block and swing larger diameters than its standard design suggests.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

An accuracy specification of ± 3 arcseconds with repeatability of ± 2 arcseconds for this direct-drive rotary indexing table is verified using precision laser measurement.

The advantages of applying fourth-axis machining capability to the shop floor are self evident, especially when high accuracy, ±3 arcsec and ±2 arcsec repeatability class are called for. The question becomes what type of rotary tables should be under consideration? This article makes the case for direct-drive rotary technology as applied to high accuracy rotary tables.

A direct-drive rotary table consists of housing, bearings, an encoder, and a spindle that uses a high-energy, rare-earth permanent magnet DC torque motor rotor wrapped around itself—sometimes referred to as an integral spindle motor. The encoder is mounted directly to the spindle to provide position feedback.

Play or “slop” is virtually eliminated in a direct-drive system because one potential source for such compliance—indirect gear drives—is not used in a direct-drive system. Therefore, no compliant couplings exist between the motor and the load.

Also, since there are no gears between the motor and the load, there is no backlash. Accordingly, the servo gain (stiffness) can be high without any concern regarding servo instability. And since there is no backlash, bidirectional movement can be made without the need to compensate for backlash error.

Positioning speed is limited only by the torque available to accelerate the inertia from the load (work-piece) to be positioned. Very high accelerations and positioning speeds are achievable on models of these rotary table types. These high accelerations/decelerations are the same as seen with DC linear motors that are used as axis drives on some machine tools.

The only losses that will create heat are in motor losses and bearing losses. However, brushless permanent-magnet DC torque motors are typically run 90 percent (or more) efficient. The direct-drive rotary system used on these rotary tables was designed with a predictable continuous duty cycle at a certain torque output.

For all practical purposes, a table will not be used in this manner, so intermediate-duty cycles that use much more torque than the continuous rating up to the peak torque available can be used without much concern. If cooling liquid is required for loads generated by off-center drilling or other rigorous duty cycles, you simply connect a standard coolant line to the housing, using the existing machine’s coolant supply.

Another advantage of direct-drive rotary tables is that if a position move is made with the intent of cutting while stationary, it may not be necessary to clamp the spindle. If the cutting forces to be applied are within the torque available from the motor, the servo will hold position with plenty of stiffness to permit the cut, since there is negligible compliance in the direct-drive system.

This is a different approach from traditional geared systems that use a servomotor at the end of a power transmission linkage. With the direct-drive system, after the cut, since no clamp was applied, there is no time delay to wait for the clamp to release, so movement to the next programmed position will be faster.

The CNC machining centers available on the market today generally have fast axis travels as machine builders have attempted to reduce the time a machine is not in the cut and to increase the amount of material removed. If the machine axes travels are faster than the positioning speeds available from the rotary unit, the machine will often be waiting for the unit to position.

The faster a rotary unit can move from one position to another, the less time the machine is waiting to cut and the faster the cycle time. Hardinge’s fourth-axis direct-drive rotary system is capable of indexing speeds as high as 4,200 degrees per second. Faster direct-drive rotary technology provides speeds that will take advantage of the faster axis travels, but it also offers the ability to do complex bidirectional machining at rates faster than can typically be done on geared systems.

These rotary systems are available for use not only on Bridgeport, but also for most other brands of machining centers. It is designed to take advantage of “look-ahead” programming when integrated on machines with that capability.

irect-drive rotary technology may not be the answer for all applications, of course, but when it fits the application, it will produce outstanding results and will enable the user to stay on the cutting edge of productivity. Its high-precision positioning and repeatability has opened the door to jobs that were previously out of reach, or jobs that were lost to competitors who could simply get the job done faster.

Rotary Tables allow machine shops to increase their production and meet their customer’s demand for quicker lead times while manufacturing increasingly complex components.

Production of a machine shop is restricted by the limited floor space the facility has. Due to this issue, Hyfore Workholding has seen an increase in customers looking to invest in 4th axis and 5th axis rotary tables.

A typical customer would be a CNC machinist who already has a 3-axis machine but is looking for greater flexibility, without having to spend a considerable amount of money on a 5-axis machine. For example, the software, motors, cables and rotary table could cost between £25k and £30k, compared to a new machine starting from £140K.

UCAM’s CNC Rotary Tables are renowned for their quality, reliability and performance. The tilting capability allows components to manoeuvre 360 degrees, so that the cutting tool can machine on all five sides, reducing secondary and third operations in the process.

CNC Rotary tables arean effectivecomponent for increasing production machine shops. Adding an extra dimension to your capabilities at a relatively low cost.

directory.newequipment.com is using a security service for protection against online attacks. An action has triggered the service and blocked your request.

8613371530291

8613371530291