stepper motor rotary table in stock

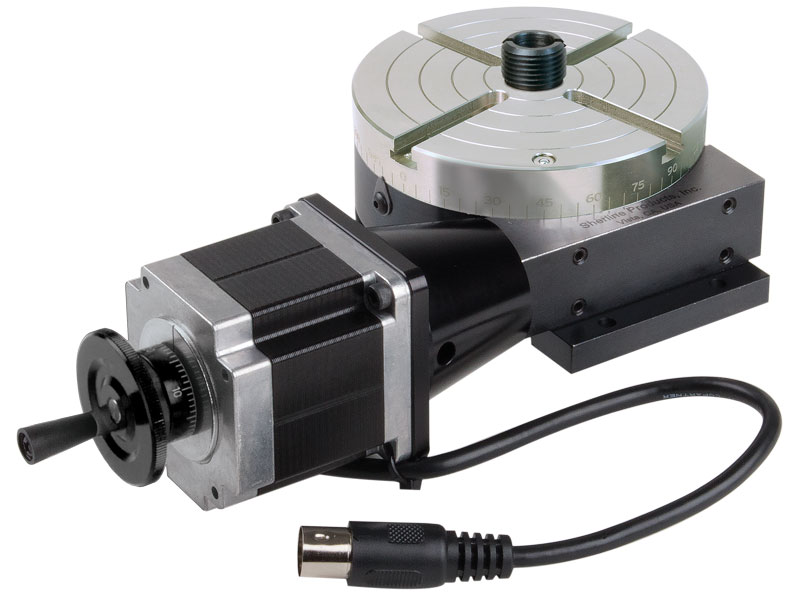

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer.

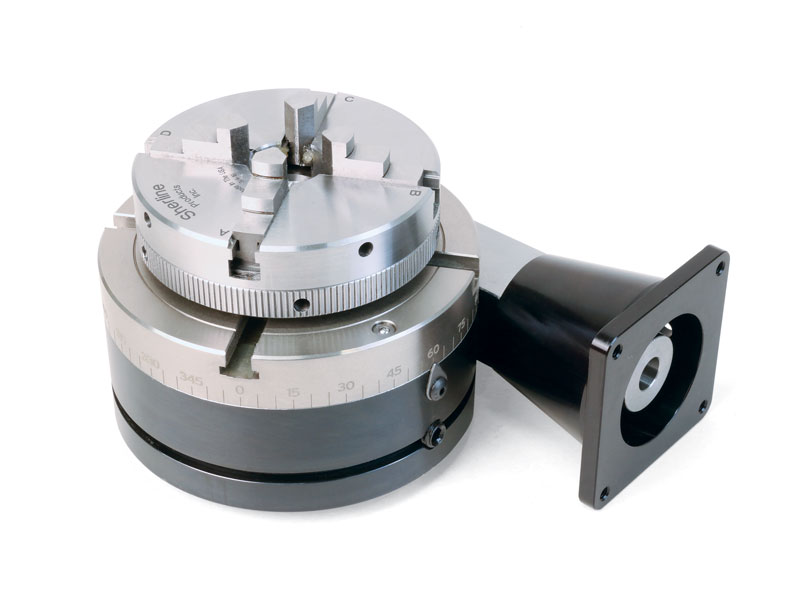

can mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

Sherline�s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures. Visit our Video page to watch a Sherline CNC-ready rotary table in use in a laser marking application on round parts, illustrating the difference between trying to mark on a round part without rotating it vs. rotating it. Some of the videos are from Jimani Inc. Laser Marking Systems who use a high-speed motor to drive the table.

This is a modification of our 4″ CNC Rotary Table with Stepper Motor. This modification came about after requests from our laser engraving customers. They wanted a rotary table that had a larger through hole to which you could mount our chucks.

This version of the Sherline rotary table has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel or stepper motor. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

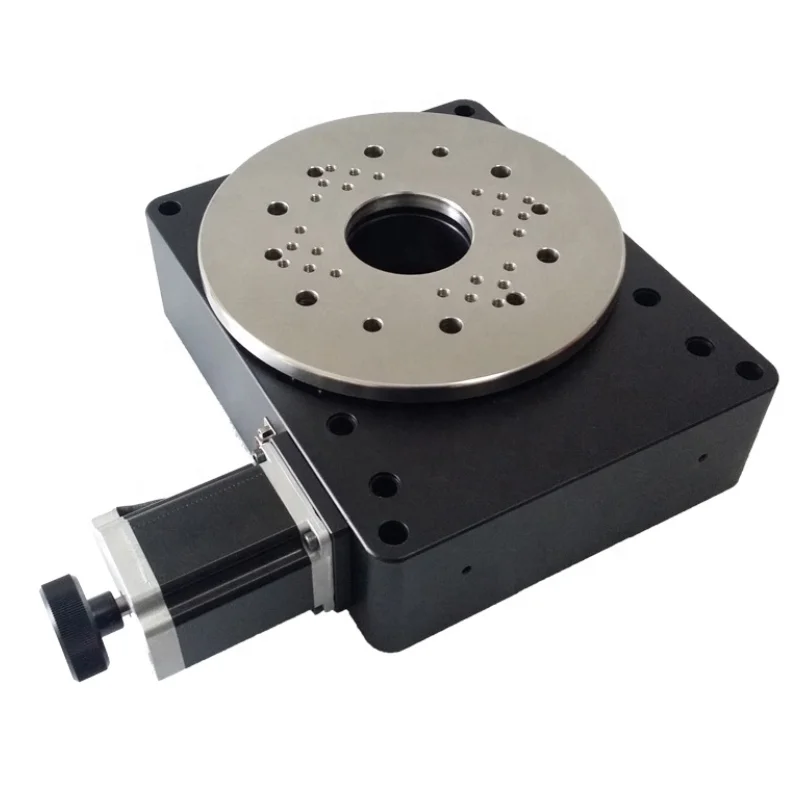

Control digital devices and make machinery more precise with a stepper motor from Alibaba.com"s wholesale equipment store. Our catalogue is the place to come when you need a replacement stepper motor rotary table or any other motor related products. You"ll find a huge array of wholesale motors, including step motors with high torque ratings that can offer incredibly precise control. Whether you"re constructing an astronomical telescope or a digital network for broadcasting, these motors will do the job.

Stepper motors are used in situations where devices need to be calibrated to extremely high levels of precision. They aren"t always the most powerful motors, but they do have very high torque levels, and this allows them to control devices in ways that other motors cannot. And they also tend to work well with digital devices due to their "step" mechanism. For instance, you can find step motors in many hard drives, handling millions of operations every minute. They have also become a go-to motor style for robotics installations. So you might need one for an advanced production line. When you need a stepper motor rotary table, finding the right motor is easy. Just search Alibaba.com"s catalogue and you"ll easily find what"s required.

Our stepper motor collection covers every base. Browse motors for use with mini computers like the Raspberry Pi or models designed for use with Arduino components. Look for permanent magnet motors, variable reluctance steppers, or hybrid syncronous steppers, and models with micro step, half step, and full step modes. Our listings include everything you need to control the most complex systems. So find a stepper motor rotary table and order what you need today. Everything can be handled with a couple of clicks, putting specialist stepper motor components within easy reach.

Motorized worm gear driven rotary tables provide high angular resolution (the worm gear ratio directly multiplies the motor output torque and motor angle resolution) and holding torque. PI offers precision motorized worm gear rotary tables with both stepper motors and closed-loop servo motors with encoder feedback. While open-loop stepper motors are often used for their lower cost and ease of control, closed loop servo motors with encoder feedback provide higher speed, higher accuracy, and repeatability. PI also provides closed-loop stepper motor rotary stages, combining the best of both worlds. PI stepper motor rotation stages are provided with stepper motor controllers featuring a micro stepping mode for higher performance. For single axis applications, a compact and very cost effective single axis stepper motor controller is available.

For the best performance and highest velocity, direct-drive rotary stages with torque motors are recommended (link to new Rotary Stage Page with Direct Drive Torque Motors).

A Rotary Stage is a mechanical component of a motion system used to rotate an object in a single axis or plane of rotation. The terms rotary stage or rotary table are often used interchangeably with rotary stage. All rotary stages consist of a platform and a base, joined by some form of bearing or guide in such a way that the platform is restricted to rotation about a single axis or plane with respect to the base. In common usage, the term rotary stage may or may not also include the mechanism by which the angular position of the platform is controlled relative to the base.

ServoBelt Rotary Stages from Bell Everman are compact, high-torque rotary stages that offer through hole size and speed comparable to direct-drive rotary tables costing thousands more.

Room in the Middle. ServoBelt Rotary stages offer two different through hole configurations. Available with 50-, 100- or 200-mm center openings, our large through hole stages accommodate large bundles of power, signal and pnuematic conductors. They also make it easy to integrate laser and optical systems. Standard-sized models with 16- or 25-mm through holes offer a more economical choice when fewer utilities need to pass through the center of the stage.

Direct Drive Performance. Designed for NEMA 23 and 34 motors, the ServoBelt rotary stages offer speeds up to 1,000 rpm, continuous torque to 6.6 N-m and resolution down to 0.16 arc-sec with Renishaw ring encoders or tape scales for partial rotation.

Robust, Lubed-for-Life Bearings. ServoBelt Rotary stages incorporate large full duplex, angular contact bearings, imparting moment and load capacities far in excess of its usual application requirements. This excess load capacity translates into virtually limitless bearing life.

Cost Effective. ServoBelt Rotary stages offer an economical solution for a variety of medium-duty rotary motion jobs such as driving carousel tables on packaging and assembly machines and providing fourth-axis rotary motion for laser cutting and mini CNC machines.

The 300 Series tables feature a rigid pair of quality angular contact bearings which produce smooth table top rotation. The low backlash precision worm gear drive provides exceptional accuracy and repeatability. All aluminum components have a black anodized finish and each table can have either a NEMA 23 or 34 motor mount attached. Threaded steel inserts in the table top provide for easy mounting of the user load while the 0.75 inch (19 mm) through hole provides easy access from below.

The 400 Series tables feature a rigid pair of 4 point contact radial ball bearings which produce smooth table top rotation. The low backlash precision bronze and steel worm gear drive provide years of high accuracy and superb repeatability. This rugged construction offers load capacities of 1000 pounds (453 kgf) and moment loads of 225 ft-lbs (305 N-m). The NEMA 34 motor mount and bushing can be positioned radially 360 degrees for convenient motor location. The large 4.5 inch (114 mm) through hole provides easy access from below.

Optional: Cover plates, gearheads, EOT & Home switches, linear & rotary encoders, power-off electric brakes, motor wrap packages and versatile mounting brackets for multiple axis applications

The maximum capacity of the turntable is not easily specified as it very much depends on how the turntable is used. If you apply a load axially the capacity is very high - in fact it is possible to stand on the rotary table and have it spin you in a circle. If however you have a large over-hanging load that creates a lever arm the capacity is significantly less. The maximum recommended load for the pan/tilt bracket is about 5kg. This can be significantly increased if the load is attached to the side of the turntable instead of over the top.

Sherline’s CNC driver box comes equipped with an A-axis output cable ready to drive a 4th rotary axis. The 8730 rotary table is all you need to turn your Sherline CNC mill into a 4-axis machine. Just plug the A-axis cable from the external 8760 driver box or the built-in driver box in your Sherline computer into the matching plug on the stepper motor. The EMC2 software is already set up to handle G-code for the A-axis, and numbers entered after the letter “A” in your code are interpreted in degrees.

The same end result can be obtained by ordering a 3700-CNC rotary table and a 67127 stepper motor and attaching the motor, but this single part number does the same thing, making it easier to order and saving you the trouble of installing the motor on the rotary table.

NOTE: We are stating the following weight limits for our rotary tables for continual use. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

8613371530291

8613371530291