vertical injection molding machine with rotary table quotation

Challenging injection molding production lines require expert injection molding partners so you can create the high-quality plastic parts you customers expect effectively and economically. Arlington Plastics Machinery offers a wide range of vertical injection molding machines and parts for your shop. Arlington offers new and used injection molding machines from all the major manufacturers such as Milacron, Engel, Van Dorn, and Nissei. Our experienced experts understand that each application is unique and can help you address any challenges.

Vertical injection molders are used to create molded plastic pieces that are attached to or inserted in other materials. Think of a screwdriver; the plastic handle is molded around a metal shaft. Vertical injection molders feature a clamp which holds the mold from which the end product will be made.

Rotary table vertical injection molding machines rotates the mold first to a load station, then a molding station, and finally an unloading station. Rotary tables allow for complex parts to be formed and maximize production.

Shuttle table configurations move two molds that slide in and out of the injection area. These are great for safe and easy product handling, simultaneously loading and unloading parts during molding.

At Arlington Plastics Machinery, we buy and sell injection molding machines, so you can be sure that we have the knowledge to help you find the right fit for your needs and budget. In fact, our machines offer an affordable alternative to new machinery without compromising quality.

We encourage you to look through our new and used vertical injection molding machine inventory to find a product that fits your production needs. If you need any assistance, you can speak with one of our experts. You can also fill out our online form to request a free, no-obligation quote for any of our machines!

The plastic injection molders at Alibaba are durable and designed for long service life. Each vertical rotary injection molding machine undergoes constant design improvement for high-speed work. With versatility at heart, some molding tools allow for multi-select high-end applications. From consumer electronics to pharmaceuticals to food & beverage, and also the automotive industry. Limit your concern of experiencing considerable defective rates. Get ready for a fast and industry-standard response rate thanks to the single-cylinder system with servo-valve. You’ll also be investing in a vertical rotary injection molding machine of precise industry-standard. Long-lasting service and durability will be your rewards.

The plastic vertical rotary injection molding machine products from wholesalers on Alibaba are specialized for different sizes of preforms. The special screw in the equipment highly increases plasticizing shot weight and speed. And with a clamping force ranging between 2,000 kN to 13,000 kN, molding machines boast the capacity to resist external machining forces. This plastic injection moulding machine is suitable for the packaging industry: thin wall containers, caps, pails, buckets, etc. Your go-for equipment for designing a wide range of PVC pipe fittings. The special design of the plastic molder means you’re investing in the exact clamping force you actually require.

Each wholesale vertical rotary injection molding machine from Alibaba takes plastic granules and shapes them into your required dimensions. Here’s where you’ll get improved accuracy on your applications. The steel bush in the clamping unit adopts a new structure. This construction minimizes wear resistance and reduces the effect of steel bush lubrication. That means you can now save the costs used on lubrication oil. Invest in plastic injection moulders today. Simply browse the wholesale vertical rotary injection molding machine listing from leading Chinese wholesalers and get one for use in your plastic processing business.

The following materials are suitable for our products:GPPS, HIPS, SAN, ABS,LDPE, HDPE,PP, PPO, PA6, PA66, ACEAL COPOLYMER, CAB, PET, PBT,PC, PMMA, hard PVC, soft PVC,PU, EVA, PSF, Bakelite, BMC.

Established in the year 1997, weSwift Auxi Technik Private Limitedare one of the accredited organizations, engaged in manufacturing a comprehensive array ofInjection Moulding Machine, Insert Moulding Machine, Water Chiller and much more to our prestigious vendors. Our offered array of auxiliary equipment is manufactured using premium quality machines and other requite material, sourced from the vendors of high prestige. The whole manufacturing process of equipment is carried out under the watch of quality controllers, who ensure their compliance with international quality standards and norms. In addition to this, our professionals check the auxiliary equipment post production to ensure these are able to stand tall on the expectations of patrons. Owing to our meticulous efforts, our range has longer service life, resistance against abrasion & corrosion and accurate design. Along with these, the offered equipment ensure reliable & optimum performance and decrease the requirement of manual handling. Owing to these features, compliance with international quality norms and availability in various specifications, our plastic auxiliary equipment are widely appreciated and demanded.

Portal and virtual trade fair for the industry, with Industry Plaza you will compare the products and get in touch with industrial suppliers, in order to get free quotes or information.

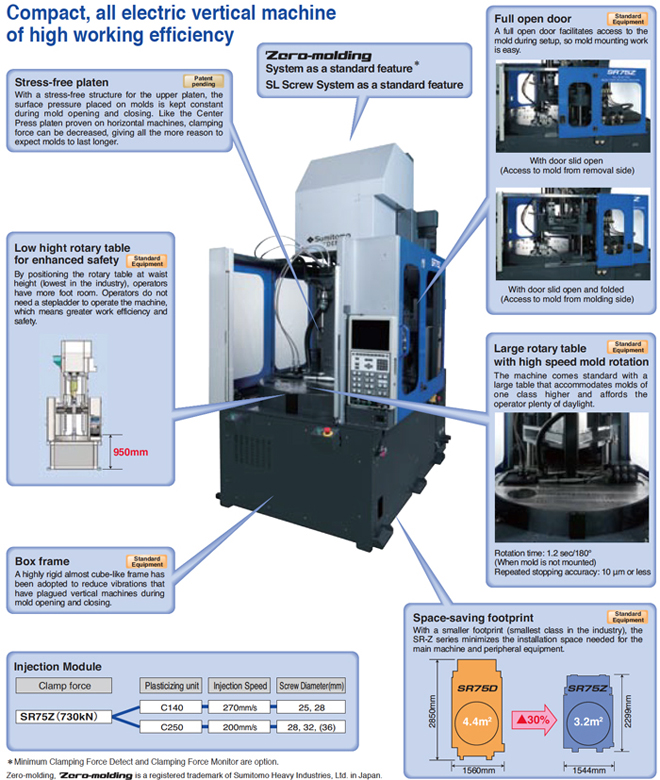

Sumitomo (SHI) Demag’s SR-Z Series of all-electric rotary-table vertical injection molding machines is available in an 83 U.S. ton model size. The SR-Z is designed for insert and over-molded parts including automotive, electrical, medical, consumer products and other applications including thin-wall parts.

The SR-Z is backed by a comprehensive Customer Satisfaction Program with Sumitomo (SHI) Demag’s standard-setting warranty program, worry-free parts, responsive field service and financing availability – plus advantages such as expert processing assistance.

COMI builds vertical injection presses for rubber,hydroblock closure with tonnage from 150 to 1000 tons and with FIFO or LIFO injectors from 1050 cc to 12,000 cc.

... measurement and injection, realized by eliminating the destabilizing factors during the plasticization measurement and injection, by separating the plasticization and injection. Sodick"s ...

... 70/65NII is a preform molding machine utilizing ASB"s well proven vertical clamping system. Compact and strong, it provides accurate and stable molding while maintaining ...

Precise & Versatile – the vertical MAPLAN ERGO+ injection moulding machines are designed to suit a variety of requirements and impress with their high quality and optimised repeat accuracy. ...

The future of the automobile is driven by lightweight design: This is why we developed the ENGEL v-duo. This vertical large-scale machine is a sensitive power package that achieves extremely precise results, ...

Leading in all disciplines. All DESMA BENCHMARK injection moulding machines unite a unique range of beneficial technology. Worldwide, thousands of vertical injection ...

VH series are upper part injection and bottom part clamping, vertical injection machines. It is suitable for insert molding such as metals, films, glass, ...

The BOY XS V features vertically arranged clamping and injection units. Being the smallest model, it supplements the reliable series of BOY insert moulding machines. This machine is suited ...

TWX220RⅢ25V was developed from the best-selling hybrid type vertical machine “TNXSeries,” which was widely used in many insert molding industries. This new hybrid type vertical ...

fastest fully automatic machine used for the heading of tubes at a speed of up to 300 pieces per minute using the injection moulding technology from Aisa.

... smooth mold movement, electric interlocking, smooth and beautiful injection head, good safety and reliability, small floor space, easy mold assembly and disassembly, etc.

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

In spite of being 220t and 300t class vertical injection molding machines, the heights of the mold mounting faces are 1,000mm, offering significantly lower height than its predecessors. It makes mold installation/setup, insert, and product takeout easier than ever before, significantly improving the usability and operability. Its optimized bed structure permits flexible robot layout. It also offers wider mold open/close stroke and maximum daylight opening, accommodating for the trends to use more complex and larger mold.

8613371530291

8613371530291