4 axis cnc rotary table quotation

A rotary table is a workbench, designed to cut wood, metal, and other surfaces with a built-in tablebench, to make work easier. It is so compact and easy to use as a 4th axis tablebench, so that the work can be harder.

There are many types of rotary tables depending on your client"s needs. The rotary table is also called a rotary table, if it is a client"s design or a business, it can be compared to other rotary tables depending on the client"s needs. A rotary table is also called a rotary table, which allows users to cut many projects at once and have a different finish compared to the original rotary table.

Martin Trunnion Tables offers complete 4th axis packages for Samchully rotary tables. Ready to be mounted into your machine, your Stallion Trunnion Table will already be attached to your Samchully rotary table and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis CNC machining. Scroll down for examples and package options! Don"t hesitate to reach out to us to discuss your manufacturing needs. Our applications engineers are always happy to help!

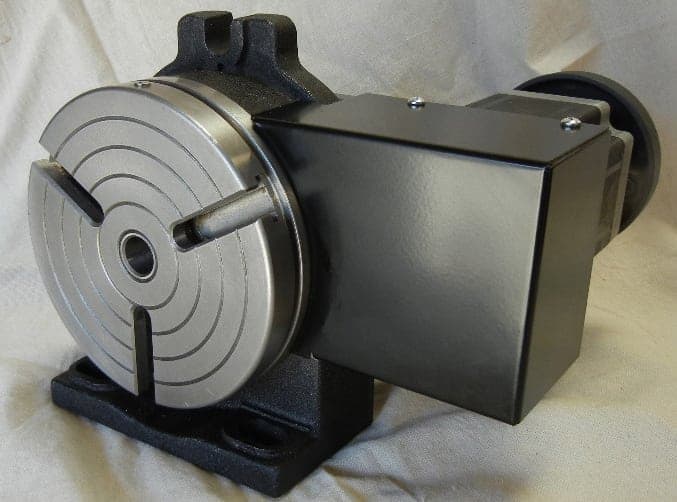

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

4th Axis rotary table for use with the Pulsar milling machine. Bipolar 200 step drive motor with adjustable worm gear (90:1 ratio) engagement for zero backlash. Includes tail stock.

2022 best desktop CNC router with 2x3 4th axis rotary table is an entry level CNC machine kit designed for for craftsman, home shop, hobby, small business, advertising, woodworking, arts, gifts, crafts, sign making, and mold making.

STG6090 desktop CNC router kit is an entry level CNC router machine with 2x3 rotary table for hobbyists, small business, home business, small shop, home shop and craftsman. The rotary 4th axis CNC router table adopts whole cast iron machine bed, cast aluminum gantry with dustproof system, under impact resistance beam more stronger with higher machining precision. The 4th roatry axis CNC router machine adopts high quality ball screw and high accuracy segmentation to achieve the final high precision machining result. It adopts high precision all steel linear guide rail to ensure the machine frame more stability and durability. The desktop CNC router kit adopts high power driver system and stepper motor to drive the machine to run smoothly with higher efficiency. The spindle motor adopt high-speed water frequency conversion brushless motors from domestic famous manufacturer, not only can cut vigorously, but also can carve with higher precision. NCStudio, DSP, and Mach3 CNC controllers are optional with high stability and high efficiency for the desktop CNC router kits, they are easy to learn and use. It has good software compatibility, it is compatible with the Artcam, Type3, Ucancam, JDPaint and other CAD/CAM softwares for 2D/3D routing. The desktop CNC router is equipped with a 4th axis rotary table for 3D carving. It is also known as 4th axis CNC router, rotary axis CNC router, desktop CNC machine, benchtop CNC router, benchtop CNC machine, tabletop CNC machine, tabletop CNC router.

The 4th axis CNC router kit adopts Mach3 or advanced DSP numerical control system and large liquid crystal display brings out much convenient operation and simpler maintenance.

2. The machine adopts water-cooling spindle, suitable for all kinds material (wood, aluminum, copper, stone, plastic and foam ). The water cooling spindle adopts water cycle to cooling the spindle, so the cooling effect is very good, almost no noise and long life time.

4. Guide rail: Taiwan Hiwin square rails (the world famous rail and guide manufacturer), self-lubricating sliding block. This will ensure equal force in all directions and accuracy and strength of the 4th axis CNC router table.

The 4th axis desktop CNC router machine has a wide range of 2D/3D applications for small business, small shop, home business, home shop and craftsman:

The 4th axis desktop CNC router can be used for wood, stone, plastic, acrylic, double color boards, PVC, ABS, aluminum composite panels and other soft metals, etc.

Yes, in order to give you a suitable entry level CNC kit, please tell me the max working area, materials for processing and the thickness for the materials to be cut. Then an affordable CNC router machine will be recommended to fit your requirements.

Our MOQ is 1 set CNC router kit. We could send the machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price for you.

All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

2022 top rated 4 axis CNC router 1325 with 4x8 rotary table (4th axis) is popular for woodworking, cabinet making, home decorations, mold making, sign making, arts, and crafts, now the best budget 4x8 CNC wood router machine for sale at affordable price.

1325 refers to the CNC router table size of 1300mm x 2500mm, someone may name it as 4" x 8" by feet or 48" x 96" by inches. 1325 is the most common used model in CNC machines to make a full sheet project. As the name implies, it is named by the manufacturer according to the table size of the machine. The maximum table size is 2500mm in length, 1300mm in width, and 200mm in height. It is widely used in popular woodworking plans and projects, such as cabinets making, door making, home decoration, advertising, and sign making. CNC router 1325 is designed as 1325 single spindle, 1325 dual head, 1325 multi head, 3-axis 1325, 4th-axis 1325, 4-axis 1325, 5-axis 1325, and 1325 ATC CNC router with automatic tool changer spindle based on the configuration level.

4 axis is based on 3 axis, and the 4th axis (A axis) is added to the rotation axis. In addition, 4 axis is divided into four-axis three-linking and four-axis four-linking CNC machines, adding a rotating axis and the control system is also a four-axis linkage system to be called a true four-axis linkage CNC machine. Because of the rotary motion of the 4th rotary axis, 3D machining of cylindrical, arc, and circular surfaces is realized.

If the 4 axis you purchased has only three feed axes (X, Y, Z), the Y axis can be manually replaced with a rotary axis, and only a maximum of three axes can be linked. This is a four-axis three-link CNC machine, which is also known as 4th axis.

If the 4 axis you bought has four feed axes (X, Y, Z, A), it can be processed by four-axis linkage, and it can process planes, reliefs, cylinders, non-standard three-dimensional patterns, corner repair of 3D patterns, etc.

The rotary axis CNC router kit uses a DSP handle industrial control system. The four-axis linkage control has excellent and stable quality, good maintainability, and usability. It can control the completion of the 3D machining of the cylinder and the rotation of the tetrahedron. It is suitable for three-dimensional sculpture of figure statues and legs of European furniture. The cylinder engraving machine has the following advantages:

Woodworking industry: 3D wave board, furnitures, solid wood door, kitchen cabinets, wardrobe cabinets, tables, beds, computer desk, table legs, sofa legs, wood crafts, paint door, screen, windows, shoe polisher, game cabinets and panels, mahjong table, auxiliary machining.

4 axis CNC machine can do all 3 axis CNC machine can do. The 4 axis spindle (B axis) can rotate ±90 degree, which is suitable for side milling, drilling, cutting, lock slot and so on. It is especially designed for processing on different 3D curved surface carving.

We will offer you with our detail quotation according to the consulted 4x8 CNC machine. You will get the most suitable specifications, the best accessories and the affordable price.

We will arrange the 48x96 CNC machine production as soon as receiving your signed sales contract and deposit. The latest news about production will be updated and informed to the buyer during the production.

4. Do not use one side of the machine frequently, which will cause the lead screw and guide rail to not contact the beam for a long time and can not be lubricated reasonably.

When using the machine to work, how to avoid errors is a concern of many customers, because errors are prone to occur due to incorrect path settings or operating errors, resulting in wasted materials. The following are some common problems and solutions summarized by STYLECNC.

All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

This video includes a demonstration of plane working and a display of four-axis rotary machining. The flat-working is taken in our workshop when we test the machine before delivery. The job is a relief of a lamp. Rotary processing is carried by the customer when he made his first operation in their plant after receiving the cnc. Here is the demo, please enjoy it!

For your reference, we"d like to share a customer case with you here. They bought the exact woodworking 4x8 4 axis cnc router EA-1325SVR from us. The customer just started his new project – Queen Anne style furniture; we guide them through everything from programming to the CNC operation. When he finished his first queen leg sample under our guidance, he sent us the review below. If you have an interest, please click here to read the whole story.

• For the convenience of operation, we abandoned the removable design and adopted the built-in rotary table construction. This way, you no longer need to disassemble and frequently assemble the rotary.

• The rotary headstock is a three-jaw chuck driven by an individual NEMA34 stepper motor with worm gear. The tailstock is a thimble-type fixture. It is capable of clamping a 300mmD x 2000mmL workpiece at maximum.

• The flatbed of the 4x8 4 axis cnc router for woodworking is a PVC vacuum suction table with several T-slots embedded. The clamping method can be vac-sorb or clamps.

• At the front and left side of the flat table, we have installed a total of 5 pieces of Pneumatic Material Alignment Pop-ups. This design dramatically shortens the clamping time of the wood sheets and in return, improves productivity.

It is a cnc router for general woodworking applications engineered to make door panels, Cabinetry, Exhibits and Fixtures, furniture, woodworking projects, complex 3-dimensional leg curve patterns, table or chair legs, cabriole, sculptures, 3d art, interior decoration, curved parallelogram shapes, signs, and more.

A: We shall answer in two parts: three-axis machining and four-axis machining. For the three-axis working, you can use ArtCAM or Aspire software. In terms of the four-axis mill, the software is PowerMILL. EagleTec CNC would like to provide detailed tutorials of ArtCAM and PowerMILL to you if we work together. They are practical guides for beginners with instructions step by step. And here is a demo for your reference:

A: The 4 axis wood cnc machine would come with accessories and extra parts like collets, spanner set, leveling machine feet, clamps, transmission belts, dust hood, fuses, on/off button, emergency stop button, and limit sensor.

A: Its weight is 1450KGS, and the package dimension would be 3200x2200x1900mm. We need to use a forklift to get it off the truck and get it into the building for such a machine.

A: Correct, the model EA-1325SVR did come with the 4-axis simultaneous rotary axis. And the rotary has a permanent location which is on the right side of the machine.

A: You will get a perfect solution that gets both toolpath programming and machine operation involved from us. EagleTec CNC not only sells cnc machines but also guides you step by step to put your device into production. Below is an operation demo for your reference. Technical support is also a crucial part of the product value. About this, please refer to our testimonials.

Let"s first have a look at the background of the video. In the video, the 4 axis multi head cnc router EA-1825RMS10 is milling 3D furniture parts with solid wood. There are two procedures in total: roughing and finishing. Two types of bits ( 12.7mm straight flute bits and 6mm V-shaped bits) and two pieces of toolpath files are used. Now you probably have a question:

A: For the exact design in the video, it takes 6 hours to finish. We got 10 pieces in 6 hours since 10 spindles and 10 pieces of the 4th axis work together. By calculation, we can know that each piece costs 0.6 hours on average.

Its biggest advantage comes from its dual-application working platform, a dual exchange table system for rotary and flat milling. The two platforms can be switched at will according to actual production requirements. One end of the rotational platform is a mobile carriage; when the flat platform is required, the mobile carriage can be pushed to the rear part of the machine and leave space for the flat table. So, we can get the flat table installed there and execute flat machining.

In order to make the installation easier, we installed several small pulleys under the flat table. Same as the rotational table, it is supported by the heavy-load round linear guides as well.

• The electrical part is designed with the most reliable performance standards. As shown below, the machine uses a total of 6 sets of Yaskawa servo motion systems; both the headstock and the Y-axis are dual-driven; It also uses 10 inverters, so that each one controls an electric spindle; this combination is undoubtedly the most reliable one since one control one is more stable than one control couple.

• The multi-head 4th axis cnc router machine is equipped with a WEIHONG 4-axis simultaneous motion controller based on the windows system. This is because multi-head router machines are mainly used for engraving, and the tool path files of such machining are often very large; a computer is prior to a handheld DSP unit on the performance of both reading and running files.

A: Seeing from the users" feedback, EagleTec CNC strongly recommends the water-cooled constant-torque electric spindles; this type of spindle is the most durable one and has a lifespan of 2 to 3 times longer than regular water-cooled spindles.

A: This machine has 10 spindles, and they are often worked simultaneously, so the load on the Z-axis is relatively heavy. If the machine uses the same Z-axis transmission structure as the ordinary machine, this part will soon stop working. In addition to the use of servo motors and dual-balanced cylinders, EagleTec CNC has also made a reasonable transformation of the connection between the motor and the ballscrew, which offers splendid durability in the Z-axis.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

"twitter:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

"og:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

Our 4C software and control system powers all models. Standard and optional equipment is the same across all models. The only differences between models are machine size, travels, spindle power, and part size capacity.

KME CNC can design a trunnion for your application. Custom 5-axis trunnions can be made to specific matching needs including different drive configuration, large or smaller sizes, less

KME CNC’s trunnions have the lowest platter height in the industry, with 7.87” from table to platter, allowing maximum Z height clearance. KME CNC can also manufacture trunnions with 10” platters, depending on their specific needs. No additional drive cards necessary!

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

8613371530291

8613371530291