4 axis cnc rotary table for sale

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

2022 top rated 4 axis CNC router 1325 with 4x8 rotary table (4th axis) is popular for woodworking, cabinet making, home decorations, mold making, sign making, arts, and crafts, now the best budget 4x8 CNC wood router machine for sale at affordable price.

1325 refers to the CNC router table size of 1300mm x 2500mm, someone may name it as 4" x 8" by feet or 48" x 96" by inches. 1325 is the most common used model in CNC machines to make a full sheet project. As the name implies, it is named by the manufacturer according to the table size of the machine. The maximum table size is 2500mm in length, 1300mm in width, and 200mm in height. It is widely used in popular woodworking plans and projects, such as cabinets making, door making, home decoration, advertising, and sign making. CNC router 1325 is designed as 1325 single spindle, 1325 dual head, 1325 multi head, 3-axis 1325, 4th-axis 1325, 4-axis 1325, 5-axis 1325, and 1325 ATC CNC router with automatic tool changer spindle based on the configuration level.

4 axis is based on 3 axis, and the 4th axis (A axis) is added to the rotation axis. In addition, 4 axis is divided into four-axis three-linking and four-axis four-linking CNC machines, adding a rotating axis and the control system is also a four-axis linkage system to be called a true four-axis linkage CNC machine. Because of the rotary motion of the 4th rotary axis, 3D machining of cylindrical, arc, and circular surfaces is realized.

If the 4 axis you purchased has only three feed axes (X, Y, Z), the Y axis can be manually replaced with a rotary axis, and only a maximum of three axes can be linked. This is a four-axis three-link CNC machine, which is also known as 4th axis.

If the 4 axis you bought has four feed axes (X, Y, Z, A), it can be processed by four-axis linkage, and it can process planes, reliefs, cylinders, non-standard three-dimensional patterns, corner repair of 3D patterns, etc.

The rotary axis CNC router kit uses a DSP handle industrial control system. The four-axis linkage control has excellent and stable quality, good maintainability, and usability. It can control the completion of the 3D machining of the cylinder and the rotation of the tetrahedron. It is suitable for three-dimensional sculpture of figure statues and legs of European furniture. The cylinder engraving machine has the following advantages:

Woodworking industry: 3D wave board, furnitures, solid wood door, kitchen cabinets, wardrobe cabinets, tables, beds, computer desk, table legs, sofa legs, wood crafts, paint door, screen, windows, shoe polisher, game cabinets and panels, mahjong table, auxiliary machining.

4 axis CNC machine can do all 3 axis CNC machine can do. The 4 axis spindle (B axis) can rotate ±90 degree, which is suitable for side milling, drilling, cutting, lock slot and so on. It is especially designed for processing on different 3D curved surface carving.

We will offer you with our detail quotation according to the consulted 4x8 CNC machine. You will get the most suitable specifications, the best accessories and the affordable price.

We will arrange the 48x96 CNC machine production as soon as receiving your signed sales contract and deposit. The latest news about production will be updated and informed to the buyer during the production.

4. Do not use one side of the machine frequently, which will cause the lead screw and guide rail to not contact the beam for a long time and can not be lubricated reasonably.

When using the machine to work, how to avoid errors is a concern of many customers, because errors are prone to occur due to incorrect path settings or operating errors, resulting in wasted materials. The following are some common problems and solutions summarized by STYLECNC.

All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

2022 best desktop CNC router with 2x3 4th axis rotary table is an entry level CNC machine kit designed for for craftsman, home shop, hobby, small business, advertising, woodworking, arts, gifts, crafts, sign making, and mold making.

STG6090 desktop CNC router kit is an entry level CNC router machine with 2x3 rotary table for hobbyists, small business, home business, small shop, home shop and craftsman. The rotary 4th axis CNC router table adopts whole cast iron machine bed, cast aluminum gantry with dustproof system, under impact resistance beam more stronger with higher machining precision. The 4th roatry axis CNC router machine adopts high quality ball screw and high accuracy segmentation to achieve the final high precision machining result. It adopts high precision all steel linear guide rail to ensure the machine frame more stability and durability. The desktop CNC router kit adopts high power driver system and stepper motor to drive the machine to run smoothly with higher efficiency. The spindle motor adopt high-speed water frequency conversion brushless motors from domestic famous manufacturer, not only can cut vigorously, but also can carve with higher precision. NCStudio, DSP, and Mach3 CNC controllers are optional with high stability and high efficiency for the desktop CNC router kits, they are easy to learn and use. It has good software compatibility, it is compatible with the Artcam, Type3, Ucancam, JDPaint and other CAD/CAM softwares for 2D/3D routing. The desktop CNC router is equipped with a 4th axis rotary table for 3D carving. It is also known as 4th axis CNC router, rotary axis CNC router, desktop CNC machine, benchtop CNC router, benchtop CNC machine, tabletop CNC machine, tabletop CNC router.

The 4th axis CNC router kit adopts Mach3 or advanced DSP numerical control system and large liquid crystal display brings out much convenient operation and simpler maintenance.

2. The machine adopts water-cooling spindle, suitable for all kinds material (wood, aluminum, copper, stone, plastic and foam ). The water cooling spindle adopts water cycle to cooling the spindle, so the cooling effect is very good, almost no noise and long life time.

4. Guide rail: Taiwan Hiwin square rails (the world famous rail and guide manufacturer), self-lubricating sliding block. This will ensure equal force in all directions and accuracy and strength of the 4th axis CNC router table.

The 4th axis desktop CNC router machine has a wide range of 2D/3D applications for small business, small shop, home business, home shop and craftsman:

The 4th axis desktop CNC router can be used for wood, stone, plastic, acrylic, double color boards, PVC, ABS, aluminum composite panels and other soft metals, etc.

Yes, in order to give you a suitable entry level CNC kit, please tell me the max working area, materials for processing and the thickness for the materials to be cut. Then an affordable CNC router machine will be recommended to fit your requirements.

Our MOQ is 1 set CNC router kit. We could send the machine to your country port directly, please tell us your port name. There will be best shipping freight and machine price for you.

All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

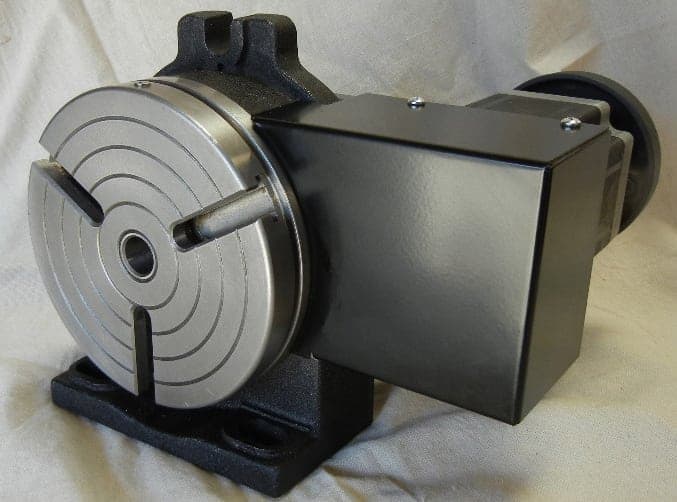

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Technical data: - center distance 1500 mm- center height 400 mm- max. machining diameter FI 400 mm- motor power 4,0 kW- voltage 400 V / 50 Hz- spindle speed 3000 rpm- number of controlled axes 3- guide linear guides and ball screw- control MACH3 + software- pneumatic workpiece clamping- V-shape steel- milling spindle for flat engraving- compressed air supply 6 bar- dimensions L=2700, W=1400, H=1750 mm- net weight 1800 kg

Reversible clamp, 4th axis, rotary table, rotary dividing table, controlled rotary table, dividing attachment, dividing head, rotary indexing table rotary coupling

This 4th axis rotary table system can be added to any of our machines, even if you already have your machine. Just send us the electronics panel and we can add the electronics for you. Includes all necessary electronics installed inside the machine with a plug on the front console. Wired, installed, and completely ready to run.

4th axis programming can be done with a 3 axis CAD program by converting the Y axis to A axis in the post processor. Just make the Y dimension of your drawing the same dimension as the cylindrical circumference of your work piece.

This item can be shipped with or without a shipping charge attached. The waiver of the shipping fee can only be applied when you purchase a CNC package along with this product. If you are purchasing this item by itself, the shipping charge will apply. All orders will be checked for accuracy.

TheRT4 4th Axis Rotary Table is a compact CNC rotary table offering rapid, zero backlash rotary motion using maintenance free Harmonic Reducers and Crossroller Bearings. It is engineered and built here in California with all aluminum and stainless steel construction.A rotary seal allows for operation with liquid coolant and an integrated Homing Switch provides a repeatable reference point. A number of different workholding accessories are available such as 3 and 4 jaw chucks, 5C collet chucks and two jaw chuck(see below accessories tab). This CNC 4th Axis can be purchased separately at anytime and is plug and play ready with any of MDA Precision’s CNC Milling machines.

If you would like to discuss your Rotary application with us please give us a call and we will be happy to help you determine which of our Rotary applications is best for you.

In a four-axis CNC router, there is an additional rotary axis (A-axis) that allows you to do rotary cutting and indexing for making cylindrical/round parts.

It has a height of 43 3/8" from its foot to the top and weighs around 483 lbs. With the optional leg kit upgrade, the height can be increased to 77 1/2".

PRO4896 CNC uses a PRO rack and pinion system with linear guides to guide the X and Y-axis machine movement. Y-axis is driven by two stepper motors to prevent it from racking.

The control system from Avid CNC is plug-and-play compatible, it houses a 32-bit CRP5056 stepper motor driver and uses an Ethernet SmoothStepper breakout board.

You can also choose between NEMA 23 and NEMA 34 stepper motors while purchasing the product. I suggest you get NEMA 34 stepper motors if you need a high rate of production.

Avid PRO4896 CNC router is greatly customizable, while buying you have the option of choosing stepper motors, spindle, controller, gantry width, and Z-travel of your choice.

Avid provides many upgrade options for the PRO4896 CNC. The Rotary Axis attachment is the one you need to achieve fourth axis capability on this CNC router.

Avid also offers software-guided alignment for the rotor. It"s fully integrated with their Auto Z and corner-finding touch plate and will work seamlessly with Mach4 software.

Their post-processor uses inverse time feed rates that prevent the production speed from slowing down during programs with combined linear and rotary motion.

The rotary axis is highly versatile, it can be mounted to the PRO4896 CNC router parallel to the X or Y-axis and can be recessed to the machine to help maximize the workpiece diameter.

The 49" rotary axis used in the Avid PRO4896 CNC router can be mounted with a maximum workpiece length of 34" if mounted parallel to Y-axis, and 28" if mounted parallel to X-axis.

Avid CNC"s post-processor for rotary control is available for all the Ventric software products and for the Autodesk Fusion 360 software. It can be downloaded either directly from the Avid CNC website.

They also have detailed instructions on assembly, different mounting options, and the electronics of the rotor axis. It is available on the website and in the user manual.

Avid offers various accessories like a leg kit, auto Z and corner finding touch plate, proximity sensor kit, composite nailer, dust shoe, plasma kit, and a rotary axis.

ShopSabre 23 has an optional stand that can add 22"more height to the base height of 34". It"ll be helpful if you don"t have a rigid desk to place the machine on.

The chuck and tailstock of ShopSabre"s 4th axis system don"t come attached to a frame, so each can be mounted on the worktable in different configurations.

ShopSabre 23 has a wide list of accessories like the 4th axis kit, braille kit, computer mount, digitizing touch probe, laser sight, tool measure switch, tabletop, vacuum pump, warning light bar, and wireless pendant.

GDAE10 6040 CNC router is the best budget-friendly 4-axis CNC router on this list. It comes with a rotary axis that can be attached along the Y-axis to attain 4-axis control.

The fourth axis control in GDAE10 6040 CNC is achieved through a rotary system with a 3-jaw chuck and a tailstock. It comes with a belt, tailstock, rotary axis, and five wrenches.

There are a lot of videos on youtube on cutting different materials using GDAE10"s 4th axis, you can refer to them to get a visual idea of its operation.

The 6040 CNC router comes pre-assembled and is ready to work right out of the box. The only work for you is to connect everything to the respective slots.

The 6040 CNC router has a large user base because of its low price. It is a great introductory 4-axis CNC to many people trying to come into 4-axis CNC machining.

The iQ CNC has a footprint of 39 1/2" x 50 1/2" with an effective work area of 24" x 36". It provides a Z-travel of 6" and the machine weighs around 425 lbs.

You can use any CAD/CAM software of your choice for working with the iQ CNC. Some of my recommendations would be VCarve Pro, Aspire, RhinoCam, Mozaik, and Enroute FAB Advanced.

For control operations, you"ll have to export and feed the G-code file to the CNC through a USB flash drive. The CNC can operate without a computer connected to it.

The iQ CNC router machine can be upgraded with the Laguna Fourth-Axis Attachment for achieving 4-axis control. It helps you machine complicated designs.

The 4th axis attached to Laguna iQ can work on workpieces having a length ranging from 12" - 26" and a maximum diameter of 7" depending on the optional table size you opted for.

You can use 4-axis G-codes generated from any G-code generator directly on Laguna iQ through a USB flash drive and iQ CNC can operate without a computer.

Next Wave CNC"s Shark HD520 is a popular choice among small businesses and many woodworkers. It can do 4-axis machining with a 4th axis rotary system installed in its work area.

The machine comes with a spindle mound and Next Wave CNC recommends using spindles like Bosch1617, DeWalt DW618, or NWCNC’s water-cooled spindle with the machine.

The Shark HD520 CNC can be upgraded with the Shark Standard 4th axis rotary system. The rotary system provides 4-axis machining capability to your HD520 CNC router.

You can place the 4th axis driver board on the controller slot by facing the pins out of the box, then you"ll have to tighten it with provided screws to hold it in place.

The 4th axis post-processor can be downloaded from the Next Wave CNC"s website. These post-processors are used to process and convert designs and toolpaths to CNC readable G-Code.

You can add the post-processor to the V-Carve Pro software that you get with the Shark HD520 CNC router. It can also be used with software like Aspire which supports post-processor integration.

In most cases, a 4-axis router kit is used to achieve 4-axis machine movement but to control this additional axis you"ll need to have a 4-axis compatible controller.

To put it in a simple form, the standard 3-axis together with the A-axis gives you a 4-axis setup. A-axis is the rotational axis that turns the workpiece.

4-axis machining brings in a great deal of flexibility to your CNC machining process, enabling you to create some of the complex designs that otherwise would not be possible.

4-axis CNC machines are costly because there is a lot of research and development going into building all these machines. You require 4-axis supported controllers, software, and CNC machines to do 4-axis machining.

Also, 4-axis designs require a high precision system to design those models. To make high precision systems you need to use a rigid machine built with well-calibrated electronics. As there are more moving parts in the machine, the operating complexity increases, and a lot of support systems are required to keep the machine running.

In 5-axis machining, two rotational axes operate separately to rotate the workpiece in many different angles with respect to the cutting tool. The machine may utilize either A-axis or B-axis with the C-Axis to achieve this feat, all these are rotational axes.

In 4-axis CNC machining only one rotational axis is there, but with 5-axis machining you can achieve two rotational axes that can operate independently. It brings in a great deal of flexibility in your CNC machining.

Yes, due to the advanced system, a 4-axis CNC requires specialized software to control the movement of the fourth axis. It requires CAM and control software that supports 4-axis machining. To control the machine properly, the software must understand the geometry of the 4th axis and how it relates to the other axes.

8613371530291

8613371530291