4 rotary table with chuck pricelist

Before assembling the jaws to its designated chuck body, the jaws finish machining is performed on a close tolerance state of the art CNC machine from JapanThe scroll plate"s thread flank are ground on both sides to achieve tighter contact with the master jaw

Each chuck has gone through rigorous accuracy and repeatability inspection by clamping and jamming multiple random testing rods or ringsAccuracy is maintained for the entire clamping range

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

The vertical & horizontal rotary table, one of the main accessories of the milling machine, is a precision work positioning device. This machine is widely used in metalworking, enabling the operator to drill or cut work at exact intervals around a fixed axis.

It can be mounted "flat," with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. Or, mounted the rotary table on its end (or mount it "flat" on a 90° angle plate) so that it rotates about a horizontal axis. In this configuration, a tail stock can also be used, thus holding the workpiece "between centers."

It"s not difficult for you to adjust the rotary table milling machine. What you should do is to adjust the handle to the position where you want because the precise scale is marked on the dial.

Except for the 5.9""(150 mm) rotary machine table, we also offer you four locating blocks. The center can be corrected quickly and accurately by the Key guide block.

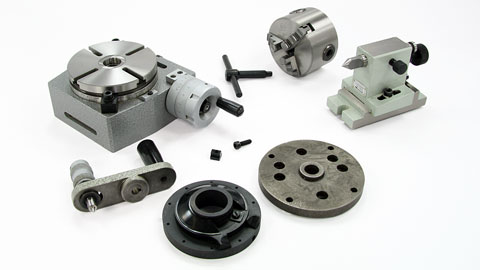

This 4" Rotary Table comes complete with a Chuck Backplate, 2 Hold-down clamps and 4xT-Nuts. The product may be used horizontally or vertically.The chuck backplate is for Chinese 80mm 3-jaw or 4-jaw chucks and is also for ER25 / ER32 95mm lathe collet chucks.Rotary Table Combo ( 050-040-00105 ) includes 4" Rotary Table ( 050-040-00100 ), Dividing Plate ( 050-040-00102 ), and Tailstock ( 050-040-00101 ).Specidications:Table Dia.: 100mm / 4"Length: 140mmWidth ( excl. h/wheel ): 126mmHeight: 73mmBore Taper: MT2T-Slot: 8mm ( Please use M6 clamping kit )Locating Key Width: 10mmCentre Height ( when vertical ): 68mmGear Ratio: 1:72Handwheel Divisions: 2"Min. Vernier Reading: 10"Chuck Backplate Register: 55mmDividing Plate Divisions 6 - 1080

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

Overall height of table under 2″ – a useful feature if it is to be used with smaller milling attachments. The table can be locked in any position. Centre height in vertical position 2 1/16 in bringing the table within the range of most model engineering lathes & mills. The hand wheel scale which can be zeroed, is marked in degrees and 10 min divisions. The table is calibrated in 5 deg increments around the rim. Bronze worm wheel and steel worm with 36 to 1 ratio. Gear meshing is adjustable to take up wear.

Why do we have to do that? Quite simply, you have forbidden us to watch Your steps on our site with Google Analytics. That sounds dramatically to You, we know. But look at it: we do not even know who YOU are, we just see that SOMEONE looks at our pages, how he/she does that, how long this SOMEONE lingers on the respective pages, etc. We do not know who You are, whether You are male or female, how old You are, how Your weight is - no idea. Nor do we pass this data on to Google, we don not have them not at all! Nevertheless, this data of SOMEONE will provide us with valuable information about our site, we want You to like everything here, that You feel good and - of course - buy our products ...

The Soba 4 jaw comes with an adapter plate to allow mounting on a tee slotted rotary table or face plate/mounting. This is pretty basic but functional - the adapter location recess in the chuck is 55mm diameter, and the male register on the aluminium plate measures 54.9mm using my vernier in last few minutes. This site does to accept photos show cannot show you.

I have ditched the adapter plate to save wiring height on the milling machine, and drill through the chuck and counterbored front face so I can mount direct to the rotary table. There is lots of meat in this chuck.

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at info@accusizetools.com. If your return is accepted, we’ll send you a return shipping label, as well as instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

Prices and offers are subject to change without notice. All rights reserved. Hardinge, Inc, ShopHardinge.com and the tag design are trademarks of Hardinge Inc.

I"m a wanna-be machinist newbie. I have a small mill (no lathe). I obtained this small 6" rotary table (a Griz product). I would like to get a small 3-jaw chuck mounted to it, but have NO CLUE as to how to choose a chuck that will be compatible with this RoTab. Am I looking for a 6" chuck? Or 4"? I can"t go too "tall" or I waste all my Z axis. I don"t even know how the chuck would mount to the RoTab. The hole in the center is a MT#2, would a chuck use the MT? Or attached how?

Can someone guide me to some options regarding how to get a chuck on here, where to find the components needed? I am not looking for gold-plated accuracy. (It"s just an inexpensive $900 ChiCom mill with an inexpensive $250 ChiCom RoTab. Not proud of it, but I"m lucky to have it, and it works good enough.) In fact I"d love to buy a chuck used if possible and save some coin. Ideas?

More info on my intended useage of chuck-on-rotab, if you are interested: This RoTab will mount horizontal or vertical. With the RoTab in the vertical position, with its associated tailstock, I believe you can "fake" some lathe operations on a mill. I need to do some small lathe operations with it, which will entail bringing down an endmill to the work and then slowly turning the RoTab. So sort of reverse of a lathe, in this setup the bit is powered and the work is being turned slowly by hand. Yeah, I wish had a lathe but in this obanomy, you make do with what you got.

Alternately, I think I can do some vertical lathing without the RoTab. If the stock is small enough to go into the mill"s chuck (5/8 max) and stout enough to hang free, some lathing can be done by clamping a lathe bit in the vise and running it up and down the work using the Z axis. For small work only.

I suppose you could also chuck a larger round piece in the rotab/chuck (with the rotab/chuck in the horizontal position, and the work sticking up vertically), and use an endmill to make bushings, and other short, squat round work, etc. by spinning the work in the rotab/chuck against the endmill.

8613371530291

8613371530291