bridgeport rotary table parts made in china

I do this for a living as most of you know and have since 1981. I have had 2 mills, my 1st was a Kent mill, wore out piece of **** with no parts available, made in 1980, I used that thing for 8 years and made lots of money. Didn"t sell it I took it to the scrap yard when I was finished. I now have a Bridgeport clone made by Willis, heavier frame than a Bridgeport, just as accurate and will take a heavier cut. Bridgeport used to be an industry standard for this type of mill, not anymore, to costly when compared to other mills.

Stick with R8 collets, way cheaper than NMT taper holders. A 30 or 40 taper is as big as will go into a Bridgeport size head, sturdier than collets but cost prohibitive in the long run, unless you get a bunch with the machine.

My picks would be Acer, Acra, Lagun, Willis, Birmingham, Millport, Newport. Or newer Kent from say 1988 up to present. All are as good as a Bridgeport, I have run them all over the years. The Lagun would be my top pick.

I do agree stay away from the M model Bridgeports with the round ram, horrible beasts. If you can find a Bridgeport in good shape under $1500-1600 go for it. I paid $800 for my current machine. Digital readouts will help a lot on a used machine especially for a newby and make doing things more accurate and faster.

The new 4+1 axis vertical machining centers are high quality machine tools designed to achieve maximum capacity and performance ideal for for medical, aerospace, power-generation, automotive and allied industries including mold making and complex 4-axis components. The Bridgeport V320 5F is manufactured to the highest industry standards to exceed the requirements of the demanding metalcutting market. 4+1 machining allows the part to be machined on 5 faces in a single set up drastically reducing setup time, reducing part handling, while improving overall part accuracy. Bridgeport’s...

BRIDGEPORT V320 5F The Bridgeport V320 5F vertical machining centers are designed for accuracy, speed and productivity. They are built to provide years of dependable machining on parts requiring consistent tolerances, tough to machine materials and fine surface finishes. features • 4+1 machining center with simultaneous 4-axis operation • Stable & rigid structure • Mitsubishi M80 control • 10K, 12K, 15K RPM direct drive spindle • BIG-PLUS® spindle • 30 tool servo driven ATC • 2 axis trunnion table diameter: 12.60” (320 mm) • Axis (Tilt )+30° ~ -120°; C-axis (Rotary) 360° • Table max. swing...

One key feature is the integrated 2-axis trunnion rotary table with 4-axis simultaneous motion and one positioning axis giving you the ability to machine a part on five different faces. This configuration greatly reduces cycle time and eliminates multiple set-ups when compared to a 3-axis machine. The machining methods are similar to 3-axis machining but with the addition of a 2-axis trunnion rotary table you can simply machine up to five different sides (or faces) in one set-up making this machines efficiency much higher than a 3-axis machine. tilt axis specification TILT ROTARY TABLE •...

MITSUBISHI M80 TYPE A - 10.4” Color LCD Display with Full Keyboard BRIDGEPORT V320 5F MitsubishiSpindle Motor-I0,000 RPM Power& TorqueCharacteristic Curve - Inch/Metric Data Selection by G-Code - 1280 Meters Part Program Storage - (2) SD card (32G part storage) - Data Input/output - USB or SD card - MDI (Manual Data Input) Operation - Reader/Punch Interface RS232 - Ethernet interface (Data Transfer Capability) MITSUBISHI ELECTRIC Low-Speed winding KW 30

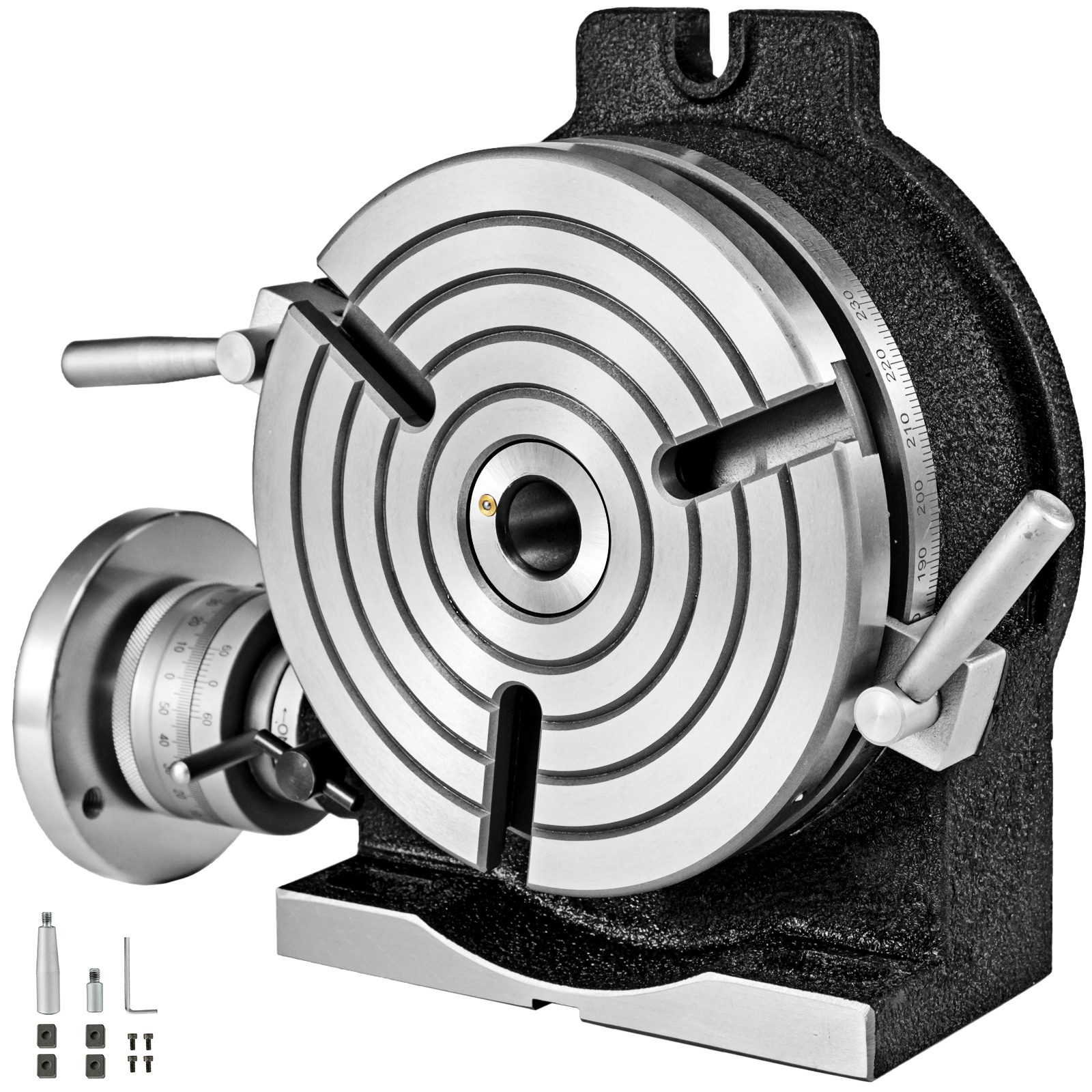

The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on.

Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice!

Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work.

It"s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial.

If you purchase our product, we are going to give you a free wrench, 2 positioning keys and screws. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences.

I recently bought a 8" H/V Phase II RT from MSC. So far I have been quite happy with it, as I needed it for a current project. I can lift it, but genrally prefer to slide it on and off a rolling cart from my milling table. The 10" would have been too heavy to lift. The T-slots are smaller than the mills, so my first job was to make a set for use with the RT. Clamps for milling can also be too large for clamping small pieces to the table, so some fabrication might be in order as well.

I"ve been thinking of getting a rotary table for use on my bridgeport, but haven"t fully formed an idea about what I really want. Based on what I"ve seen, I"m starting to think that I probably want to end up with 2, first a smaller one that would either do horizontal and vertical mounting or adjustable angle, probably in the 6-10" range (small enough that I can easily move), and then a larger one like a big, used bridgeport one for larger work.

Well, I got one as a gift for my birthday a couple of days ago (a PhaseII), and after getting a good look at it close up I realized that I"m probably going to end up returning this one and going with something else. The biggest thing is slot sizes... it has an indexing piece for use up on end that looks like it is intended for one slot size, and the slots on the table face are a smaller size, both smaller than the standard slots/holddowns that I have for the bridgeport. Seems like it would be a hassle mount it down to the table securely and then I"d need another set of hold down hardware just for use with the table.

wide range and selection for our customers.*Power Feeds *Motion Control *Drives*Servo*Readout Systems*Tooling*Parts to repair all these systems as well.

We offer Bridgeport Milling Machines that have been serviced by our TAS IRON LTD facility in Berea, Ohio. Some of the best pricing around. Your need to have your Bridgeport serviced and brought back to a good service. Send it to us, we will send it back ready to work. We have serveral in stock machines available as well as we take orders, if you want one unit or ten units, we will build them for you.

We offer crating service and free loading and packaging. Don"t take a chance on buying a used machine tool until you give us a chance. If you need glass scales installed, Table feed drives, what ever it may be, we do it here. So when your mill breaks down, send it in to get repaired, a lot of times its more cost effective.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

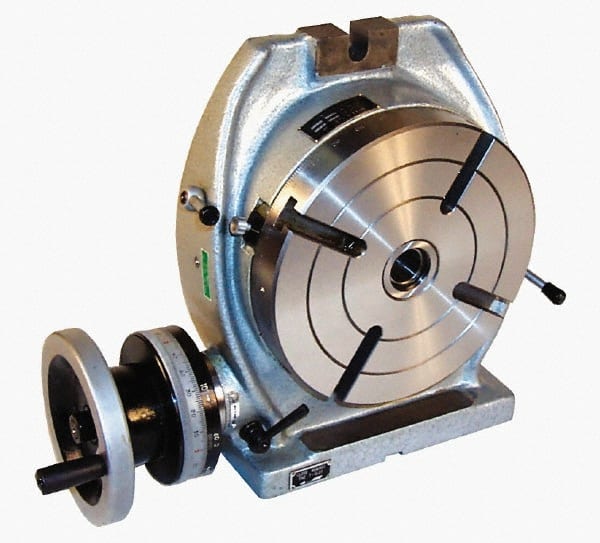

What are some of the best Rotary table brands you can buy? I only buy tools once so quality of the most important thing. I’ll happily buy vintage if people truly think they are better. I have a Bridgeport (pictured below)

Here"s a mystery for all you hobby milling machine enthusiasts. Help me ID this rotary table. I"m considering purchasing it, but can"t figure out who made it.

So, here"s what I"m wondering. About half the time I use the rotary table I find the hand wheel interferes with where I"d like to clamp it down. Looking at other tables this seems to be the common configuration, where the handwheel interferes with the mounting plane(s) of the table. Why would...

not getting any feedback to a previous post I gotta wonder if there isn"t something wrong with an Advance Rotary Table. I see lots of posts regarding "what to buy" and "I settled for a Chinese knockoff". Just wondering what is the problem? This seems to be an extremely well built and accurate...

I have a vertex 10" Rotary table with mounted chuck, I use it often. There are quite a few occasions I wish it was motorized. Has anyone done a DIY motor on their rotary table and not spent a fortune ? I"ve seen pretty expensive motors so i"m looking for DIY options. I think I may have even...

I"ve become a (happy) owner of a new-to-me 8" Phase II horizontal rotary table. Unfortunately it came with the dividing plate setup and no handwheel, so I need to make one. If you have this model of the table, I would really appreciate if you could post a picture and/or dimensions of...

So I need a rotary table for a couple of projects I have in mind, making round things on my Jet 15 mill/drill. I don"t have a lathe. I"m thinking 6" would be a reasonable size both for the things I need to make and the size of my mill. I see cheap imports on ebay starting around $160, Phase...

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

I have a pair of non bridgeport mills, an Index Super 55 and a Tree Journeyman 200 (a cnc 2UVR). I have ran bridgeports alot and I appreciate them for what they are. The best thing about them has been mentioned, there are a ton of them out there and the aftermarket has made so many accessories for them that it makes it hard to not get one. From the R8 tools to the power feed assemblies and dro kits, they are all cheaper and easier to find for the bp.

I love my Index, it has some cool features and I use it most every day. It has brown and sharpe #9 spindle and it can be bothersome to find things for compared to the R8. I do believe it is a little better than the R8, but probably not enough to notice for many people, especially when considering the availability of the R8 stuff. I have a full set of collets for mine and I have not needed anything else. My Index will not spin or nod the spindle, only tilt side to side. So it makes it a little more rigid which makes it less flexible in some projects, like getting the head off the side of the table to drill a bolt pattern in a axle hanging off the side. This is partly why the Tree showed up, it has the same nod, tilt, in/out ram and spin as a bp.

If I were in the OP"s shoes, I would find a series I J head (step pulley) in the best condition I could and add on power feeds and dro when I got the money later. The step pulley head is the simplest to fix if needed, the variable speed heads are just no fun to get into and fix. I also prefer the largest table and travel that I can get because most of my projects are not small, so the little table that can be found is not even desirable to me.

8613371530291

8613371530291