bridgeport rotary table parts quotation

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

A large number of specially selected, high-quality second user products are available through our webshop or directly from our technical sales department, providing rotary table products that have been fully rebuilt exclusively by us, to a very high...https://facebook.com/cncrotaryshop/videos/475171379666589/…

The Bridgeport® name is synonymous with the world’s finest turret milling machines. This reputation has been established since 1938 when the first Bridgeport® Milling Machine was produced. The Series I Standard continues to fulfill the industry’s need for a machine that is accurate, reliable, versatile, and easy to operate. In just over seventy years, Bridgeport® craftsmen have produced over 370,000 Series I Standard Mills. Hardinge Inc. stands behind every machine it builds with parts, service and applications support. With these traditions in mind we are pleased to present the following quotation for your consideration and look forward to the favor of your order.

Oct 20 BridgeportMill logojpg Bridgeport milling machine by Adcock Shipley of Leicester made in about NB an induction is required to use this Select a Bridgeport Knee Mill Series product to learn more The precise dependable all purpose Bridgeport Series I Standard mill can be Alt Logo Alt Text 立即联系/Live Chat

May 28 We bought this used Bridgeport J head mill for $ then spent another $650 on moving tooling and wiring The purchase price alone is Barry Jordan with the model Bridgeport mill that first brought him to international attention an article about his 1/5 scale Bridgeport mill and the tiny rotary table that led to it Your company logo and a link to your web site could go here 立即联系/Live Chat

The Bridgeport style vertical milling machine also called a turret mill or a Machines made with the Meehanite process carry the logo in Figure 8 2 on the top 4 ANG LOCK CNC VISE FOR CNC/BRIDGEPORT MILLING MACHINE Shars 4x4 1/8x1 1/4 Lock Down Precision Milling Machine My Stores Logo 立即联系/Live Chat

Bridgeport s Series I Knee Mill information can be found within this site You can purchase quote or find documentation on this siteSee all 6 apartments in Boston Ave Mill Hill Bridgeport CT currently available for rent Check rates compare Apartments Logo Sign Up / Sign In 立即联系/Live Chat

MDNA Logo AMEA Logo EAMTM Logo Direct Capital Financing Logo BRIDGEPORT SERIES I VERTICAL MILL VARIABLE SPEED 9 x 42 TABLE LUBEApr 19 A mill rate equals the amount of taxes needed to pay for the budget — $ in Bridgeport s case — divided by the assessed value of 立即联系/Live Chat

Bridgeport Mill provides repair parts service operation and parts manuals and technical support information for your Bridgeport Machinmobile logo Use it for free on a Bridgeport Public Library computer Bridgeport s East Side neighborhood Home of the Old Mill Branch Library is located 立即联系/Live Chat

With a Bridgeport mill a small lathe and a grinder founders Gary and Mary Kay Yackel started in a three room sq ft Merrill Technologies Group LogoThe Bridgeport logo as cast into the head of a Bridgeport Knee Mill A Bridgeport variant that has been retrofitted with motors and controls to function as a CNC machine Sharp Machinery brand mill and Anilam brand CNC controllers Bridgeport is a brand of milling machines and machining centers which are machine tools 立即联系/Live Chat

Dec 23 To a mechanical engineer a Bridgeport is the iconic machine tool the basic necessity for doing precision work and I ve felt increasingly Sep 14 Sign In logo Dailymotion Tramming a Bridgeport milling machine with Pro Tram Square the spindle of a milling machine with Pro Tram 立即联系/Live Chat

How to Zero a Bridgeport Milling Machine Many modern Milling Machines aka mills datum in X Y and Z axis and other axis using a probe wikiHow logomobile logo My Account Catalog Bridgeport CT Phone 203 576 Burroughs Saden Black Rock Newfield North Old Mill Green Burroughs 立即联系/Live Chat

Add CNC capability to your Bridgeport style Knee mill MicroKinetics Logo of a manual Bridgeport Jet Enco or most any similar type milling machine for Nov 12 What to look for in a used Bridgeport type milling machine and demonstration and discussion of the features in a Bridgeport type milling 立即联系/Live Chat

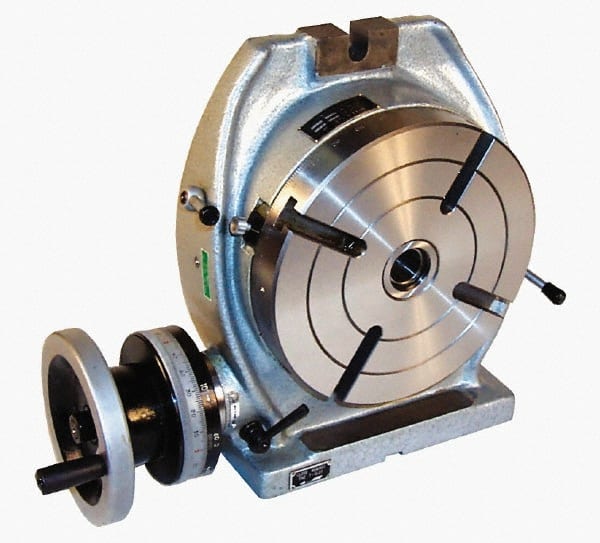

Our Brands Hardinge Bridgeport Kellenberger Jones and Shipman Hauser Bridgeport Knee Mills Grinding Machines Workholding Rotary Tables and Q Who services Bridgeport Knee Mills × Bridgeport Knee Mill replacement parts Morris Midwest directly services Hardinge and Bridgeport CNC machine 立即联系/Live Chat

Consult Hardinge Bridgeport s Bridgeport Series I Machine brochure on Hardinge Bridgeport logo Spindle Tooling for Lathes Mills Grinding MachinBridgeportParts your one stop source for Bridgeport Series 1 knee mill parts and Servo power feed parts and accessori We provide Bridgeport repair 立即联系/Live Chat

From the May issue of Modern Machine Shop Magazine " A CNC retrofit provides improved reliability and functionality compared to an older machine’s original control, and this is helpful in a number of ways. For example, a more intuitive control interface can help speed setups and minimize the chance for programming and/or setup mistakes, which could possibly damage or scrap a high-value work piece. Similarly, shops are also more confident in quoting work for large, expensive parts knowing the new control won’t hiccup partway through an operation and cause the part to be damaged. Shops also are better-positioned to take in “hot” jobs that require fast turnaround due to the retrofitted machine’s improved"... click here to see the complete article in PDF.

CENTROID Boss series II retrofit customer testimonial"The quality and workmanship of the CENTROID equipment was outstanding and very professional. CENTROID was able to custom tailor the control to allow us to continue to use our rotary milling arrangement as before and even expanded our capability. The short story is that we ended up with a four axis CNC mill for less than half the cost of the three axis Haas. This includes the work that was done by our staff."

Turning Milling G rinding Workholding www.hardinge.com Hardinge Inc. O ne Hardinge Drive P.O. Box 1507 | Elmira, NY 14902-1507 USA U SA: 800-843-8801 | Canada: 800-468-5946 Phone: 607-734-2281 | Fax: 607-734-8819 E-mail: info@hardinge.com | www.hardinge.com Brochure # C 1371 Bridgeport GX 300 • Travel (X, Y, Z) 11.80”, 15.76”, 16.94” • Horsepower 20 HP (30 min. rating) • 7,083-rpm Max Spindle Speed • 98.8 ft-lbs torque • 20 Station Swing Arm ATC Bridgeport GX 510 • Travel (X, Y, Z) 20”, 15.76”, 16.94” • Horsepower 20 HP (30 min. rating) • 7,083-rpm Max Spindle Speed • 98.8 ft-lbs torque • 20 Station Swing Arm ATC Bridgeport GX 300 & GX 510 Machining Centers Key Differentiators: - Unique design allows machines to be stacked side by side - Robust spindle with 20 horsepower and 99 ft-lbs of torque - Heavy-duty linear roller guide-ways - 20 station swing arm ATC as standard equipment for high production - Rear chip discharge - Programmable pneumatic rails & hydraulic clamping - Programmable auto-door - 8 additional M-codes Hardinge’s Rotary Tables Both the GX 300 & GX 510 have the ability to utilize Hardinge’s full line of rotary products to enhance your machining capabilities. Ask one of our certified workholding representatives to learn more about our rotary product offering. The GX 300 & GX 510 machining centers are designed and built for a production environment. A unique design allows for these machines to literally overlap one another to better utilize valuable floor space and to promote cell manufacturing. The design allows access to only be necessary from the front and back of the machine allowing you to stack these machines side by side. This type of floor plan and machine design is perfect for automation. Add some robots or a gantry system and you can increase your productivity with virtually no labor costs. D on’t let the compact footprint fool you, these machines pack a powerful punch! With 20HP and 99 ft-lbs of torque these machines are sure to be a market leader!. These specifications make the GX 300 & GX 510 ideal for the aerospace, medical, defense, 3C, automotive and other industries who require high-value, complex parts from difficult to machine materials. Ask a certified Bridgeport representative for a quote today to learn more about these new production machining centers!

Moore stocks commonly replaced parts for all of our Jig Grinders and Jig Borers, as well as components for Producto Precision Rotary Tables and Special Machines, regardless of age. We will gladly quote price and delivery for those items not in stock. Our expert technicians can also recondition wear components to their original specification.

8613371530291

8613371530291