building a rotary table made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

For a corner fillet weld such as those, it may help if you grind off half of each corner on the slotted plates giving a 45 deg V. This will help to ensure the weld gets good penetration and strength at the same time as allowing you to retain the original edges for alignment.

Looks to me like you are using a 240V single phase welder. In Oz I would use a Satin craft 13 electrode as these have a slower flux than a Satin craft 12. This helps stop the flux from running into the weld pool and stopping the arc. My welder has only 2 settings 2.5 and 3.2 mm so I try and use the shortest possible cable between the power point and the welder. If I have to go longer a heavier duty cable helps keep up the volts and amps.

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

My first rotab was a Wholesale Tool 6 inch. I was turning a 12 inch wheel center (had to weld it up to make it 12.25 dia) on the rotab with a large roughing endmill in the spindle while rotating the rotab (my lathe swing dia is 12.2 inches w/o locally grinding a divot into the lathe bed (partially into the tailstock way) - not that the tailstock would ever be that close to the chuck - I just did not want to be that much of a hack so I used the mill and rotab). I ended up shearing teeth on the ring gear in the rotab. Had I used a less aggressive cut, maybe roughed in the shape with a hand grinder before machining the rotab probably would have survived. Finished turning the wheel center at work during my lunch time (with the blessing of the guys in the machine/fab shop) on a 20 inch swing lathe - I"ve never operated a lathe that big and the pucker facter was high!

Now I have a PhaseII 6 inch rotab but have not had need to abuse it like I did the Wholesale Tool rotab. I still have the damaged rotab - figured I might make some sort of a tool out of it someday (4 yrs later still have not figured out what I might use it for).

For my needs an 8 inch rotab would probably be more durable but with a 6 inch 3-jaw attached to the 6 inch rotab, its at the weight limit that I can comfortably lift.

Depending on the size of rotary working tables, you can find the office rotary table that is suitable for your customers. They have long steel rotary table and work heavy in conjunction with the office rotary table.

There are also torsion rotary tables, such as 3D rotary tables, and evenD rotary tables. These working tables can be used in manufacturing, construction, and home office working tables for people of all ages.

A rotary table is also called a rotary table, it is designed to cut heavy-duty steel, making it a larger product. The advantage of a circular table is that it is possible to cut large objects in a variety of ways, depending on the size and shape of the material it is made of, heavy-duty steel, making it a larger product. The circular table usually is in size but it can also be used to cut laminated or in-ior on heavy-duty steel, making it a larger product.

A rotary table, also known as a rotary table, is a toolbench that is heavy with work equipment, allowing users to cut or grind heavy work equipment on the surface. A rotary table is a wheelbench designed for users to sit or lay on heavy work equipment, allowing users to cut hard or unurfaced work. It is a portable table designed to for heavy work and allowing users to cut large or up holes in the workbench.

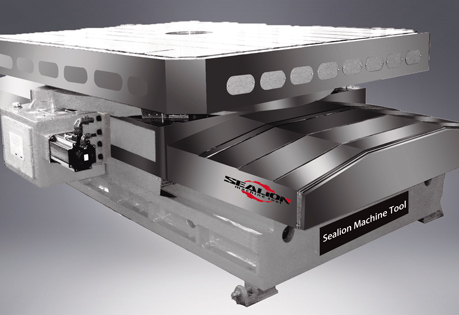

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost.

Eppinger, a toolholder manufacturer, is entering a new market by presenting a range of rotary tables. The company made its first display at EMO Hannover earlier this year. The new rotary tables are available with rotary plate sizes ranging from 160 to 320 mm and are suitable for both initial installation and retrofitting of vertical and horizontal milling machines.

“We have used more than 30 rotary tables of different brands at our production sites for many years,” says managing director Uwe Eppinger. “That’s why we are well aware of the pros and cons of installation, flexible application, maintenance costs and decreasing accuracy.”

Although the existing market is already highly competitive, Eppinger company is venturing into this segment now. “Our rotary tables differ significantly from existing solutions,” says Mr. Eppinger. “They have been used for some time in our own manufacturing, where they gradually replaced the third-party products.”

“We were not always satisfied with the products that previously existed on the market,” he continues. “The reason is that for our own production of tools, wheel gears and gear units, we need rotary tables that can be quickly and precisely positioned, tables which are extremely compact and suitable for fine grinding as well as for rough milling operations. In addition, they should be easily integrated into existing vertical and horizontal machining centers and used there in a flexible way. Since we could not find suitable rotary tables on the market for our specific requirements in this specific combination, we developed them ourselves.”

A distinguishing feature of Eppinger’s rotary tables is the pre-loaded, backlash-free twin-engine drive which is said to enable quick indexing without clamping. An integrated angle sensor on the rotary plate keeps positioning accuracy high, even with changing loads, the company says. Although this principle is already used for larger rotary tables, Eppinger says it found a way to implement it in rotary tables with plate sizes under 320 mm in diameter. Although the angle measuring system integrated into the housing measures the angle directly on the rotary plate and compensates for mechanical interferences, the pre-loaded drive makes it possible to set up a high control loop gain, the company explains. Only in this way is it possible to bring bidirectional positioning into the angular seconds range of precision.

These vise jaws use protruding, mechanical pins to repeatedly support workpieces either horizontally or at angles. They are said to allow quicker setups than conventional parallels.

Holding metal parts with magnets is migrating from surface grinding to broader application in general metalworking processes, especially milling. Advances in magnetic technology are causing many shops to re-evaluate how they hang on to workpieces. Here’s a look at how magnets may be a viable workholding solution for your shop.

Further we display our products at IMTS-Chicago, EMO-Hannover, JIMTOF-Tokyo and TIMTOS-Taipei, and receiving reputation from the customer of the worldwide.

To meet the request of customer, both upgrading the quality of our produces and purchasing new machinery of testing and inspection, collecting update technology to develop value-added products.

The sales & service had been built around the network of worldwide, technical supporting and customer service are connected through our agents and dealers more than 30 countries of the world.

We stay improving and innovating our products as the goal of never ending story, the satisfied of our customer and continuing devotion of our products are what we working for the mutual benefits of our customers and members of GSA.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Axial-radial bearings are double-direction axial bearings for screw mounting with a radial guidance bearing. These ready-to-fit, pregreased units are very rigid, have high load-carrying capacity and operate with particularly high accuracy. They can support radial forces, axial forces from both directions and tilting moments free from clearance. ZKLDF axial angular contact ball bearings are low-friction, ready-to-fit, greased bearing units with high accuracy for very high speeds, high axial and radial loads and high demands on tilting rigidity. Axial-radial bearings with angular measuring system YRTM and YRTSM correspond in mechanical terms to series YRT and YRTS but are additionally fitted with an angular measuring system.

When autocomplete results are available use up and down arrows to review and enter to select. Touch device users, explore by touch or with swipe gestures.

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at info@accusizetools.com. If your return is accepted, we’ll send you a return shipping label, as well as instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

Please inspect your order upon reception and contact us immediately if the item is defective, damaged or if you receive the wrong item so that we can evaluate the issue and make it right.

Certain types of items cannot be returned, like custom products (such as special orders or personalized items), and personal care goods (such as beauty products). We also do not accept returns for hazardous materials, flammable liquids, or gases. Please get in touch if you have questions or concerns about your specific item.

The fastest way to ensure you get what you want is to return the item you have, and once the return is accepted, make a separate purchase for the new item.

We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method. Please remember it can take some time for your bank or credit card company to process and post the refund too.

8613371530291

8613371530291