building a rotary table pricelist

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new rotary table price or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement rotary table price, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new rotary table price are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

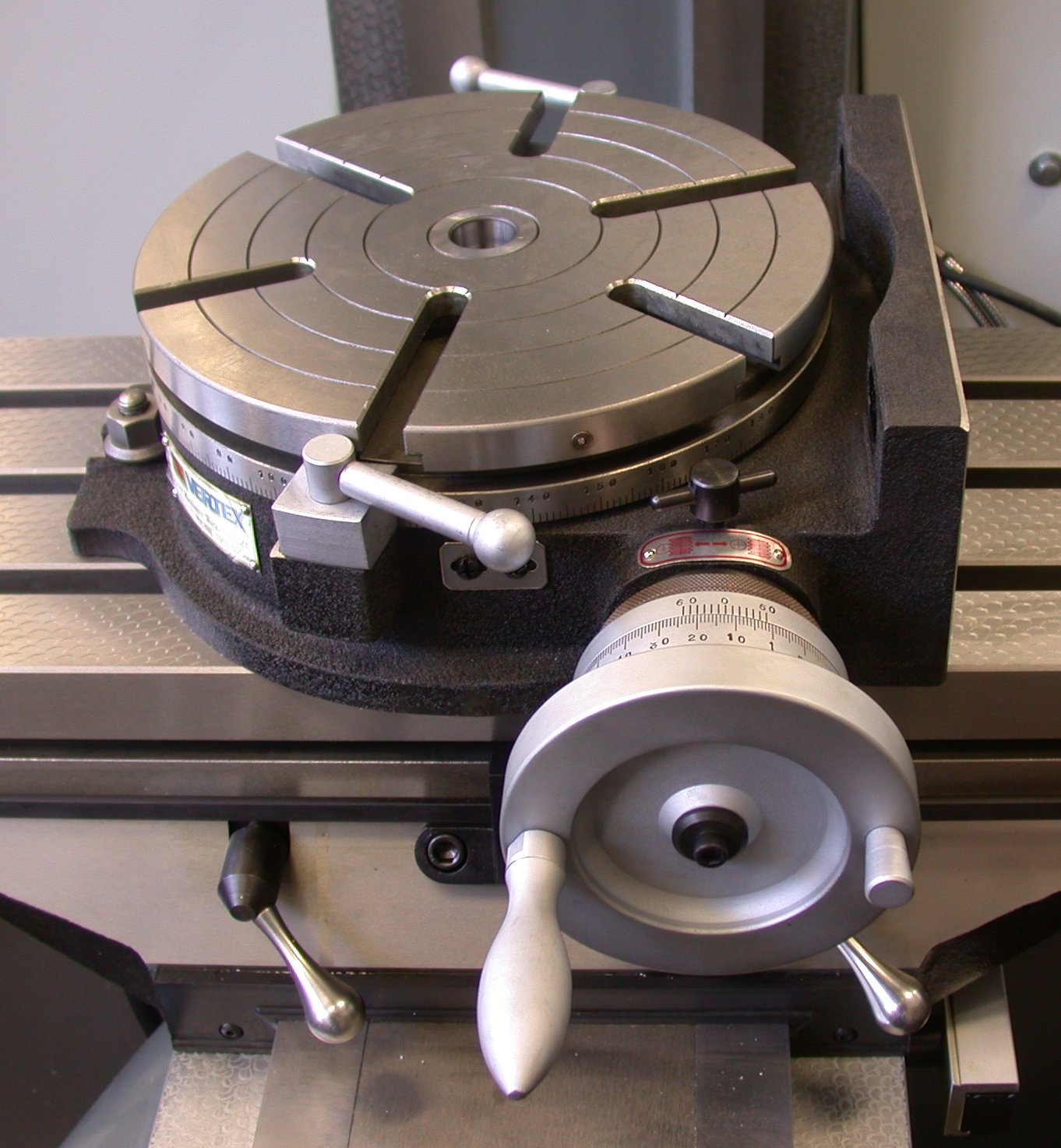

One thing that is sorta misleading about the CNC tables unless you"re seen one first hand is just how big they are. I"ve got a Tsudakoma THNC-301, which is a 320mm (12"+) table thats rotary powered and manually tiltable from horizontal to a bit past vertical. It weighs somewhere between 400 and 450 lbs, and I guess the new cost now is somewhere north of $16,000. They have positioning accuracy within a few arc seconds, and are capable of holding accuracies like this with a part that weighs a couple hundred pounds and cutting forces that can generate several hundred ft-lbs of torque.

Pricewise, assuming my 16K current estimate is accurate, that would work out to a bit less than $40/lb, because it definitely weighs over 400#. For comparison, a 10" Kitagawa power chuck for a lathe retails now for about $4000, and although I"ve never weighed one, I guess they weigh less than a hundred lbs from picking one up a "few" times. So that puts the chuck at over $40/lb. If you ever have cause to take one of these chucks apart, they are surprisingly simple. They"re accurate and repeatable, and everything is hardened and ground, but they"re still simple, especially when compared to a rotary table. A good sized collet chuck from Royal to fit an A-8 spindle nose on a lathe weighs barely over 40 lbs and costs close to $2500. Once again, its all hardened and ground, but this is the price of a pullback type chuck which is just one single piece of steel with no moving parts whatsoever, yet it sells for over $60/lb. When you compare the rotary tables and their size and complexity to other machine tool parts of similar complexity and quality, the price begins to look not so far out of line, even though its still not cheap by a long shot.

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

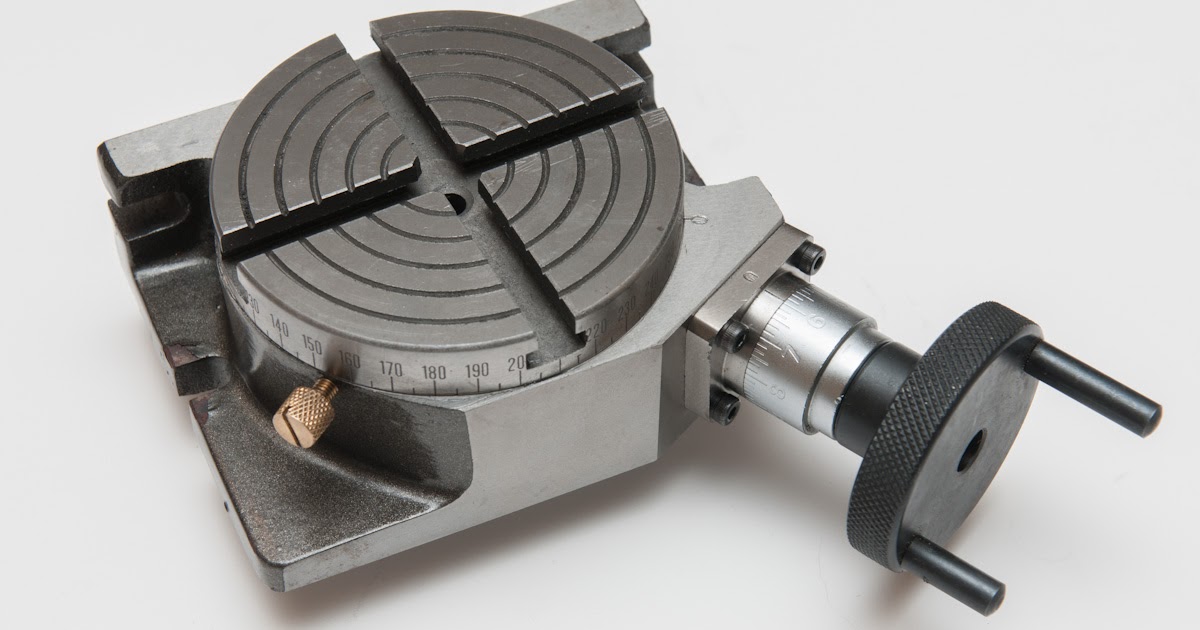

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from casting with high quality, can work with a set of dividing plate.

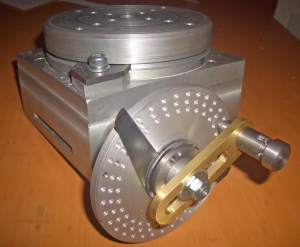

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

Three dividing plate set(Plate "A" - 15, 16, 17, 18, 19, 20 Plate "B" - 21, 23, 27, 29, 31, 33 Plate "C" - 37, 39, 41, 43, 47, 49). A set of wrench and screws are free for you with your installation.

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at info@accusizetools.com. If your return is accepted, we’ll send you a return shipping label, as well as instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

Please inspect your order upon reception and contact us immediately if the item is defective, damaged or if you receive the wrong item so that we can evaluate the issue and make it right.

Certain types of items cannot be returned, like custom products (such as special orders or personalized items), and personal care goods (such as beauty products). We also do not accept returns for hazardous materials, flammable liquids, or gases. Please get in touch if you have questions or concerns about your specific item.

The fastest way to ensure you get what you want is to return the item you have, and once the return is accepted, make a separate purchase for the new item.

We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method. Please remember it can take some time for your bank or credit card company to process and post the refund too.

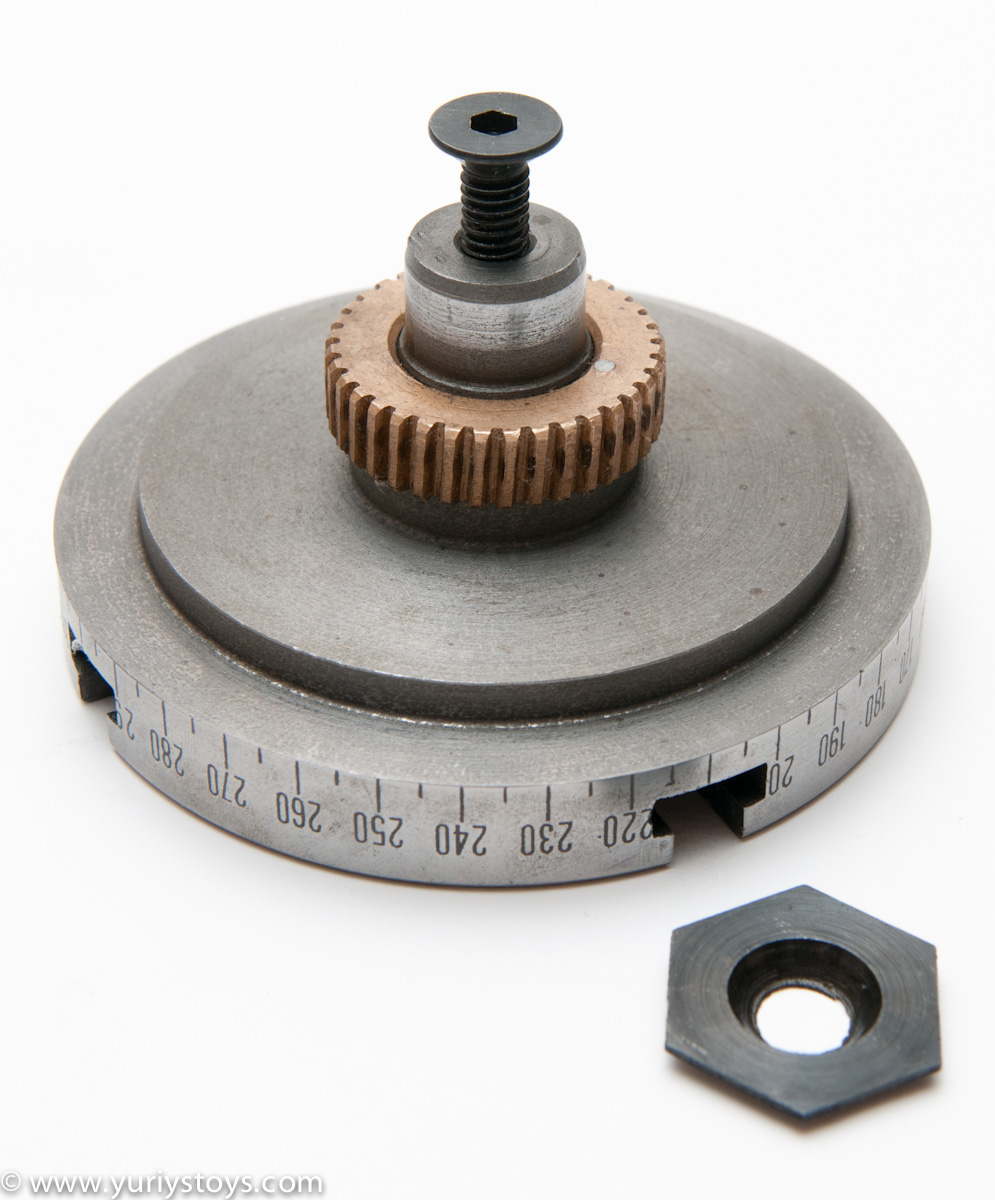

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer. Below are links to the pages on the various versions of the Sherline 4″ rotary table. The table is driven by a worm gear with a 72:1 ratio making each turn of the handwheel equal to 5°. Fifty laser engraved handwheel marks indicate positions 1/10 of a degree apart. A 90° fixture is available to position the table in a vertical position. Our P/N 3750 Tilting Angle Table is also available for positioning at any angle from 0° to 90°.

Sherline’s rotary table is one of the most popular accessories in the tool line. Its popularity extends from the home shop to the professional machine shop due to its compact size, solid construction, and long-lasting accuracy. The handwheel is calibrated in 1/10° increments with marks every 5° around the table’s periphery. Included is a set of hold-down clamps, T-nuts, and a threaded center fixture for attaching Sherline chucks with a 3/4-16 center thread. Read more about the Sherline manual rotary table.

P/N 3700-CNC 4″ CNC-Ready rotary table with stepper motor mount: In place of the manual handwheel, a NEMA 23 stepper motor mount is attached, allowing use of the rotary table as a 4th axis on Sherline CNC mills or for whatever CNC application a customer may have where a small but accurate rotary table is needed. Read more about the Sherline CNC-Ready rotary table.

P/N 8730 4″ CNC rotary table with stepper motor mount and NEMA 23 stepper motor: This takes the above rotary table one step further with the inclusion of Sherline’s own NEMA 23 stepper motor already attached to the rotary table and including a 5-pin plug that connects directly to the Sherline 8760 4-axis driver box. Read more about the Sherline CNC rotary table with stepper motor.

Sherline offers the answer to your small rotary indexer needs by providing a programmable control box with its own power supply and driver for running the rotary table. Inputs can be entered by either degrees (to 3 decimal points) or by divisions of a circle (up to 999 divisions). Also programmable are the direction of rotation, the speed of rotation and backlash compensation. In the PROGRAM mode, two different programs of up to 40 blocks each can be entered that control rotation speed, direction and degrees or divisions plus the option to continue or pause at the end of each block. Read more about the Sherline programmable rotary indexer.

For the laser marking industry, Sherline now offers several accessories including three sizes of tooling plates designed for holding parts during scanning. Read more about the Sherline laser scanning plates.

To be eligible for a return, your item must be in the same condition that you received it, unworn or unused, with tags, and in its original packaging. You’ll also need the receipt or proof of purchase.

To start a return, you can contact us at info@accusizetools.com. If your return is accepted, we’ll send you a return shipping label, as well as instructions on how and where to send your package. Items sent back to us without first requesting a return will not be accepted.

Please inspect your order upon reception and contact us immediately if the item is defective, damaged or if you receive the wrong item so that we can evaluate the issue and make it right.

Certain types of items cannot be returned, like custom products (such as special orders or personalized items), and personal care goods (such as beauty products). We also do not accept returns for hazardous materials, flammable liquids, or gases. Please get in touch if you have questions or concerns about your specific item.

The fastest way to ensure you get what you want is to return the item you have, and once the return is accepted, make a separate purchase for the new item.

We will notify you once we’ve received and inspected your return, and let you know if the refund was approved or not. If approved, you’ll be automatically refunded on your original payment method. Please remember it can take some time for your bank or credit card company to process and post the refund too.

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer. Below are links to the pages on the various versions of the Sherline 4″ rotary table. The table is driven by a worm gear with a 72:1 ratio making each turn of the handwheel equal to 5°. Fifty laser engraved handwheel marks indicate positions 1/10 of a degree apart. A 90° fixture is available to position the table in a vertical position. Our P/N 3750 Tilting Angle Table is also available for positioning at any angle from 0° to 90°.

Sherline’s rotary table is one of the most popular accessories in the tool line. Its popularity extends from the home shop to the professional machine shop due to its compact size, solid construction, and long-lasting accuracy. The handwheel is calibrated in 1/10° increments with marks every 5° around the table’s periphery. Included is a set of hold-down clamps, T-nuts, and a threaded center fixture for attaching Sherline chucks with a 3/4-16 center thread. Read more about the Sherline manual rotary table.

P/N 3700-CNC 4″ CNC-Ready rotary table with stepper motor mount: In place of the manual handwheel, a NEMA 23 stepper motor mount is attached, allowing use of the rotary table as a 4th axis on Sherline CNC mills or for whatever CNC application a customer may have where a small but accurate rotary table is needed. Read more about the Sherline CNC-Ready rotary table.

P/N 8730 4″ CNC rotary table with stepper motor mount and NEMA 23 stepper motor: This takes the above rotary table one step further with the inclusion of Sherline’s own NEMA 23 stepper motor already attached to the rotary table and including a 5-pin plug that connects directly to the Sherline 8760 4-axis driver box. Read more about the Sherline CNC rotary table with stepper motor.

Sherline offers the answer to your small rotary indexer needs by providing a programmable control box with its own power supply and driver for running the rotary table. Inputs can be entered by either degrees (to 3 decimal points) or by divisions of a circle (up to 999 divisions). Also programmable are the direction of rotation, the speed of rotation and backlash compensation. In the PROGRAM mode, two different programs of up to 40 blocks each can be entered that control rotation speed, direction and degrees or divisions plus the option to continue or pause at the end of each block. Read more about the Sherline programmable rotary indexer.

For the laser marking industry, Sherline now offers several accessories including three sizes of tooling plates designed for holding parts during scanning. Read more about the Sherline laser scanning plates.

pL LEHMANN has been developing and producing CNC rotary tables for over 40 years. – genuine SWISS QUALITY. The experience gained is incorporated into our products and services. With innovative CNC rotary axes, organized in a standard modular system, we want to meet the international needs for economical production of very small to medium-sized workpieces in the machining industry by satisfying individual requirements with appropriate combinations.

We focus ourselves, our organization, resources and partnerships on this objective, immersed in a lean business system, where we avoid waste of any kind. In this way we make a significant contribution to protecting the environment and conserving valuable resources. Our goal is to take a stance in the manufacturing industry that is long-lasting, sustainable and innovative – unpretentious, reliable and down to earth based on the principle "What may be briefly of interest, but wrong in the long term, will be discarded"

* pL SOLUTIONS Shanghai Co. Ltd is part of a network of locally owned, independent representatives and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Italia is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS Japan is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS South Korea is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEA is part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS USAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

* pL SOLUTIONS India/SEAis part of a network of locally owned, independent distributors and service specialists dedicated exclusively to the sales, service, and support of CNC rotary tables designed and manufactured by the Swiss firm Peter Lehmann AG (pL)

Prices and offers are subject to change without notice. All rights reserved. Hardinge, Inc, ShopHardinge.com and the tag design are trademarks of Hardinge Inc.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure ...

... the table is the rotation, the user may require the rotary table for drilling operations and milling. Using the servo drives in conjunction with the machine CNC control ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

For cancellations, you can reach us out at +91 9319511441 / support@chandcompany.in or request for Order cancellation from the My Orders section in your My Account option.

You have up to 48 hours from the time of placing your order to cancel your order. Once the order is cancelled, the amount will be reimbursed for all ‘PREPAID ORDERS’

Order can be cancelled before the shipment of the order has been processed i.e 48 hours after placing the order. CHAND COMPANY can cancel the order for various reasons such as:-

Unavailability of products – in exceptional cases, is a product runs “out of stock” with us at our warehouse, the product will be cancelled and all the necessary information will be given beforehand to the customer about the unavailability of the order and order cancellation

Chand Company and its logistic partners take due care in delivering the product(s) in the best condition, however, in the rare occasions of damaged goods being received or any discrepancies with the products received, you can reach us out with the images of the damaged product along with the packaging pictures at support@chandcompany.in and +919319511441 within 48 hours of receiving the material, to resolve your issue.

All products have a Warranty against Manufacturing defects IF STATED OTHERWISE IN THE ITEM DESCRIPTION, which can be easily identified when the product is put to use. In case of any manufacturing defect in the product, the customer needs to inform us within 5 days of receiving the order. The return intimation will then be taken into consideration and will be followed up with the customer, ensuring a proper solution to the customer and change the material with the same product, if need be. Please note that the products can not be interchanged with any other item even if the return has been accepted.

In case of any manufacturing defect in the product, the customer needs to inform us at support@chandcompany.in or +919319511441 within 5 days of receiving the material. Our executive team will then get in touch with the customer and work their best to solve the issue as soon as they can with utmost diligence and precision. If the product, in a perfect working condition, is deemed faulty and irreparable, then the customer will be provided with a new piece once the old material has been received by us

In case the product is delivered damaged, the customer needs to inform us at support@chandcompany.in or +919319511441 within 48 hours of receiving the material along with the pictures of the damaged item and the packaging of the product. The customer is then entitled to send us the material back and a proper inspection will be made by our engineers to infer the reason for the damage. If the item is then informed by our engineers to be damaged in transit. the customer will be provided with a fresh new piece within 2-3 working days.

All items must be returned in their original condition, with packaging and boxes intact, user manual, Calibration / Inspection certificates and original accessories in it

In order to return the product, the customer has to send the product to us through the India Post only. Once the product is received by us, then the courier charges will be reversed to the customer if a manufacturing defect has been found by our team after a thorough inspection

The customer needs to pack the product with brand packaging. keep the invoice inside the box and courier it to us at CHAND COMPANY, 4772, HAUZ QAZI DELHI-06.

After a thorough inspection of the product, the customer will be informed about the situation of his product and also if the return is possible on the product or not. Our Quality inspection team will do their best to reach maximum customer satisfaction and help them in all ways possible.

In case, after receiving the material if we find any discrepancy by our Quality check team, a new product will be shipped to the customer free of cost and will reach the customer in 3-4 working days.

Products marked as “non-refundable” on the item description page cannot be returned under any circumstance. If any problem against manufacturing is observed in the product, then our executive team will look into the matter and get it resolved for the customer"s satisfaction.

After receiving the required information for a refund, a refund will be processed in 2 business days and the same will reflect in the customer account in another 2-4 business days

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost.

8613371530291

8613371530291