compact rotary table quotation

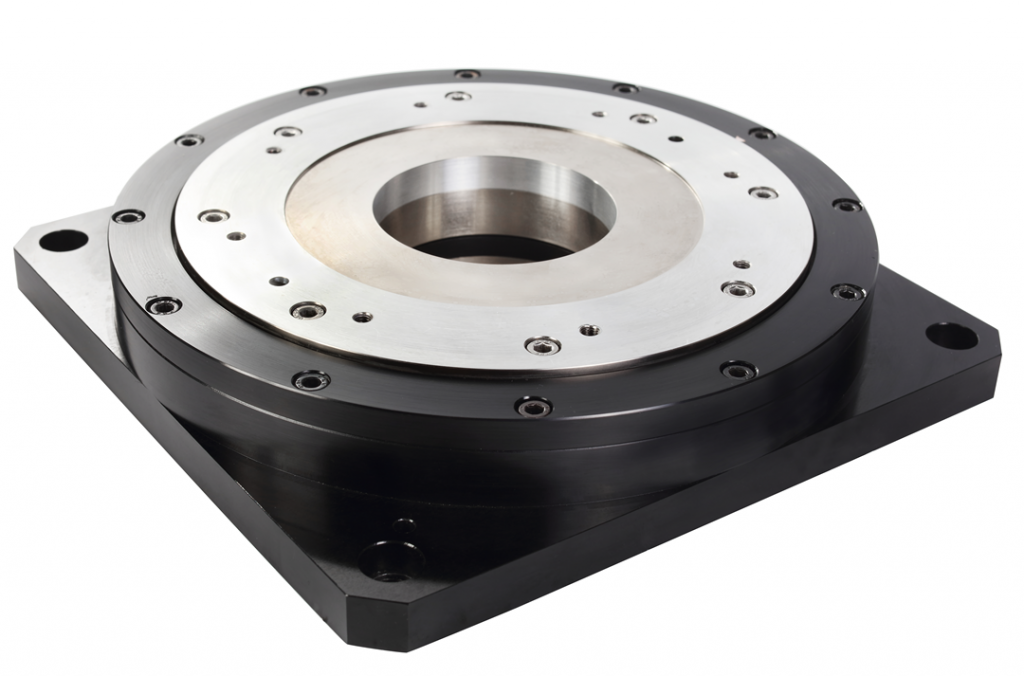

RotoRingrotary tables provide superior angular positioning and are designed to eliminate backlash, friction and wear problems associated with worm, gear and belt drives.

Radially distributed brushless RotoLinear motoring modules provide high positioning stiffness during rotary indexing and when installed on moving XY tables.

RotoRingsfeature "large open center design".In general automation applications large open center offers the opportunity to access parts from inside and outside of the table simultaneously.

This feature allows robotic devices, pick and place and ancillary tooling to be mounted inside the table, saving floor space and reducing parts handling with increased productivity.

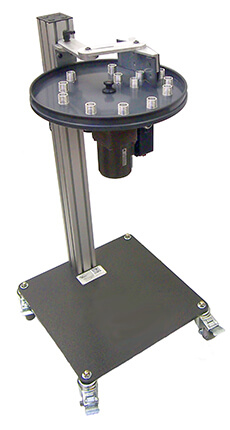

Mini-Mover Rotary Table Accumulators (RTAs) were originally designed for the metalworking marketplace to promote unattended machine operation and separation of sensitive parts after machining.

Our RTA units are well suited for various applications in assembly and packaging, such as cycle tolerance inspection, surge table on production lines and staging for manual or pick & place case packing.

Parts are delivered to table via part chute or conveyor. Parts are stopped by in-feed cushion on the diverter arm. As table rotates, parts are directed away from part-drop area by the diverter and accumulate in a spiral toward the table center.

Mini-Mover Rotary Table Accumulators (RTAs) were originally designed for the metalworking marketplace to promote unattended machine operation and separation of sensitive parts after machining.

Our RTA units are well suited for various applications in assembly and packaging, such as cycle tolerance inspection, surge table on production lines and staging for manual or pick & place case packing.

Parts are delivered to table via part chute or conveyor. Parts are stopped by in-feed cushion. As table rotates, parts are directed away from part drop area by the diverter fence and accumulate at the table center.

This is an accurate designed table for milling, boring and other machine tools. This table allows indexing, facing and other work to be carried out rapidly with extreme precision. Tiliting range 0-90 degrees fromread more...

Avail from us a wide range of Rotary Milling Tables, as we are engaged in offering these products in small as well as in huge bulk as per the needs of our clients. These tables are well designed with latest styles and modern technologies. In addition to this, we are offering our range in standard finishing. Lastly, our rangeread more...

We hold expertise in offering an exclusive range of Manual Rotary Table to our esteemed clients. The offered rotary table is designed by latest technology according to the requirements laid down by our patrons. Apart from this, the offered rotary table is carefully inspected on each section in order to supply fault free range.read more...

Quality is the hallmark of our company, in order to maintain quality standards we offer wide range of Rotary Tables. Our products are sturdy and durable. We offer Rotary Tables to our clients as per their needs and in recommended specifications. Moreover, customers can avail Rotary Tables from us as per the need of theread more...

We offer a comprehensive range of Rotary Tables that is made using high grade material, sourced from reliable vendors. This range is highly demanded owing to its durability and reliability. Moreover, our range generates low noise and is corrosion resistant. Besides, our range stands on the quality parameters set by the clientsread more...

Table Rotator provides accurate and steady rotation for medium to large work pieces. Speed is infinitely variable in various ranges and in both forward and reverse directions. A heavy duty foot pedal controls rotation. Table Rotator allows the welder to rotate the work piece through out 360o reposition for welding positioning.read more...

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact ...

The HRT160SS is a high-speed cycloidal drive rotary table that provides a maximum speed of 500° per second – nearly four times the speed of the standard HRT160. The compact size and high ...

These units have been designed for incorporation into rotating automatic transport or assembly machines. Their features and size are ideal for constructing particularly compact and rapid assemblies.

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

... the Hollow Rotary Actuator model number GSN130-18K-CS with table size 130mm gear ratio 1:18 and closed loop stepper motor. The CS type of GIGAGER Hollow Rotary Actuator is a line of ...

The TR160 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. Scale feedback on the ...

The TR160-2 is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. The dual-spindle design ...

The TR200Y is a dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of small to medium parts. Scale feedback on the ...

The base and circular positioning tables are made out of anodized aluminium alloy. The self-locking spindle is made from steel and its slide bearing is maintenance-free. The table has ...

... X-RSW-E Series products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages are ...

... Series feature a 120 mm diameter table with a 50.8 mm (2 inch) aperture, and the ease of a built-in controller and motor encoder. With a compact footprint, low profile and load capability of 60 kg, these ...

At a total height of 21 mm, Zaber"s X-RSM-E Series rotation stages are our most compact stepper and worm gear driven devices. These devices have 0.02° repeatability, an aperture of 4 mm, and a load capacity ...

... versions of TRV rotary table involve electric rotation via double Brushless motor with precision reducer instead. In these big TRV tables position and rigidity are granted by Hirth coupling ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on their small ...

The EGD series is a globoidal rotary table that has a rated repeatability and angular accuracy of 20 seconds. The unit has a zero backlash positioning function, and has an utmost load ...

The table top center bearing is extremely precise: concentricity is less than .0004 inches, typically as small as .0002 inches. This gives you ultra center positioning, makes your parts very ...

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

Lagun’s BM RT is a bed type mill with C-Axis rotation and equipped with a rotary table. With a compact and robust design, this milling machine is ideal for machining bulky workpieces on all 5 sides.

Additionally the sturdy, oversized mill bed comes with reinforced ribbing, fortifying its stability during heavy milling. The hardy table, measuring at 63” x 47” (1600mm x 1200mm), column, slide and ram systems have been studied and as a result designed with roller/shoes that exceed the manufacturing requirements. Designed to be as close to the column as possible, the mills ram placement ensures a sturdy column-slide-ram assembly. This results in a rigid and light slide for vertical movement. To correct any ram deflection during cross movement they come equipped with special wedges.

200 mm (7.9") Compact Tilting 2-Axis Trunnion Rotary Table, with scale feedback on the A (tilting) axis. Mounts along Y axis of VF- 3 and larger machines. Requires Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Scale feedback functional only on Haas mills with software version 18.xx or later. Scale feedback does not function with rotary control box.

Mini-Mover Rotary Accumulator Tables (RTAs) were originally designed for the metalworking marketplace to promote unattended machine operation and separation of sensitive parts after machining.

Our RTAs are well suited for various applications in assembly and packaging, such as cycle tolerance inspection, surge table on production lines and staging for manual or pick & place case packing.

Parts are delivered to table via part chute or conveyor. Parts are stopped by in-feed cushion. As table rotates, parts are directed away from part drop area by the diverter fence and accumulate at the table center.

Compact, high performance, electric rotary actuator with position, speed, acceleration/deceleration control – Series LER. Suitable for all handling applications, with smooth, shock-less, high speed actuation up to 420º/s and acceleration up to 3000º/s2, Series LER actuators are delivered with their own controller with pre-set actuator parameters, reducing both installation and programming time.

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product"s lifetime, Matsumoto Machine Corporation (MMK) has taken a pragmatic two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

Founded in Japan in 1948, Matsumoto Machine Corporation is a technology-leading provider of innovative, high quality jaw chucks and numerically controlled rotary tables used by industrial machine tool makers throughout the world. A key feature of MMK"s CNC rotary tables is a patented worm and wheel gear assembly developed by OTT GmbH, Germany. Unlike double lead worm gears, the OTT worm and wheel gear is able to minimise backlash, ensuring outstanding accuracy and long life, efficiency and durability.

A further advantageous characteristic of the MMK CNC rotary table is a large diameter through-hole in the table spindle. This greatly increases machine versatility and rigidity, supporting a wider variety of chucks and jigs and the machining of longer workpieces.

By enabling most metal-machining operations to be undertaken on a single machine, the benefits of MMK CNC rotary table are far-reaching. These include the time and cost saving of single machine set-up and single fixturing setup, reduced parts handling and the elimination of tolerance errors as workpieces pass from machine to machine.

Of critical importance in this one-hit machining centre scenario is ensuring the high accuracy of CNC rotary table indexing and control throughout its working lifetime.

As with a machine tool"s linear XYZ axes, the rotary axis is just as susceptible to uncontrollable events that may introduce angular positioning or axis alignment errors. Risking the production of defects in finished parts, these errors can be due to a number of reasons including, mistakes made in the initial machine installation, impact damage caused by collision or general wear-and-tear in use.

With its global reputation for product quality and design innovation, MMK therefore sought to equip its CNC rotary tables with a highly accurate and reliable means of tracking and controlling the indexing of its product throughout its lifetime, irrespective of the type of machine tool, workpiece complexity and duty cycle.

At the same time, in an increasingly competitive global market for CNC rotary tables, MMK also wanted to further enhance its product quality inspection processes. Specifically, the company set itself the task of augmenting index angle measurement as a key component of pre-shipment quality assurance procedures.

To provide machine tool makers and users with the ability to accurately track and control CNC rotary table indexing, MMK elected to integrate Renishaw"s super-compact TONiC™ non-contact optical incremental encoder system. Simple to install and with a compact readhead measuring just 35 mm x 13.5 mm x 10 mm, the TONiC encoder presented MMK with a minimal footprint solution capable of supporting machine speeds up to 10 m/s and resolutions down to 1 nm.

The rotary table readhead was designed to be used in conjunction with Renishaw"s RESM, a one-piece stainless steel ring marked on its periphery with 20 µm pitch graduations and featuring the IN-TRAC™ optical reference mark. With its low profile, large internal diameter and wide choice of diameters from 52 mm to 550 mm, the high stability RESM ring provided MMK with a versatile and easy to integrate scale that is well-suited to the company"s wide range of CNC rotary tables.

MMK selected Renishaw"s compact and lightweight XR20-W rotary axis calibrator to verify the accuracy of its rotary tables during manufacturing and immediately prior to shipment. The XR20-W was used in conjunction with Renishaw"s XL-80 laser interferometer to provide a non-contact reference measurement, independent of the axis under test, with an accuracy of ±1 arc second.

Motorised by a servo-controlled drive and with data capture synchronised to axis movement, the XR20-W requires no operator intervention during measurement. Being lithium battery powered and Bluetooth enabled, it ensures quick and easy setup, and the avoidance of trailing cable hazards. The calibrator"s modular design and flexible mounting systems allow far easier setup than alternative solutions and can be readily configured for a wide variety of rotary tables, chucks and spindles.

By integrating Renishaw"s TONiC non-contact optical encoder system into its CNC rotary tables, MMK has further assured the accuracy and reliability of its products in the field, along with an overall superior motion control performance. For a wide range of different machine tools and end uses, the rotary tables" combination of compact readhead and one-piece stainless steel ring scale has delivered a higher level of tolerance to dust, scratches, grease and oil, and a reduction in indexing errors. The encoder system"s ability to output highly stable position signals of unrivalled purity and ultra-low sub-divisional error have provided smoother velocity control, improved scanning performance and increased positional stability.

MMK"s introduction of Renishaw"s XR20-W rotary axis calibrator and XL-80 laser interferometer has reduced product measurement times by a half compared to conventional autocollimator techniques. Measurement procedures have been simplified and automated. Capable of taking accurate measurements at any indexing angle pitch, the calibrator enables evaluation of the accuracy of the worm and wheel gear-driven table for ultra-fine pitch measurement movements as small as 0.001°. This has allowed any loss of motion control or worm and wheel gear efficiency to be evaluated in detail and addressed. Product performance is now backed by a thorough analysis meeting ISO quality standards.

CNC rotary tables play a vital role in the performance of multi-axis machining centres. As table accuracy and reliability are of paramount concern throughout the product’s lifetime, Matsumoto Machine Company has taken a pragmatic

two-pronged approach to reducing indexing errors and improving performance. By enhancing both product calibration and encoder technologies the company has set new standards for rotary table accuracy.

Technitron has been integrating rotary tables and accessories on machine tools since 1992. Over the past 30 years Technitron has pioneered new technology and techniques to allow us to set the industry standard for rotary table and accessory integrations. By utilizing our vast experience, we have been able to meet and exceed our customers’ expectations. No other company has our experience on a variety of machines and controls.

Technitron is dedicated to supplying high quality Integration Services to the Machine Tool Industry. Our Turn-Key Integration Services are designed to enhance the productivity from both new and existing machine tools. We have installed more than 3500 rotary tables to date.

8613371530291

8613371530291