compound rotary table supplier

Beijing JINGDIAO has realized the commercialization of high-precision direct-drive rotary tables which have been installed for more than 10,000 sets. This is due to the comprehensive platform including specialized R&D, precision manufacture, precision assembly and test from JINGDIAO. Direct-drive rotaries developed recently are capable of 5s positioning accuracy, 3s repetitive positioning accuracy and 130Nm maximum torque.

Your one stop SHOP for ROTARY TABLES, SUPER SPACERS TAILSTOCKS and ACCESSORIES. Serving the American Machine Shop since 1953. AJAX INDUSTRIES, Lets PUT WORKHOLDING to WORK for Your Shop.

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

Worm Shaft & Worm Wheel:The arc surface contact between the worm shaft and worm gear provides 5 times greater contact surface area than the conventional “compound lead screw”, thus the superior accuracy and durability are assured. The two section of worm structure permits convenient backlash adjustment.

Roller cam: Compared with worm gears type it is with higher wear resistance, high transmission efficiency , affordable prices and basically maintenance-free of table.

Table directly driven by a motor, high rotary speed , no backlash, no weariness and low inertia. But relatively technical requirement is high and difficulty, the price is the most expensive. Generally used for five-axis machine tools.

Our rotary table can be used in the aerospace industry, 3C high-tech industry semiconductor parts, auto parts and components automation manufacturing, or bathroom equipment and daily necessities manufacturing etc.

The backlash control of our rotary table is stable and reliable, it can be adjusted at the same time and is easy to operate to meet high-precision processing and production requirements, so that it can help customers reduce costs and create more profits.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure is set automatically and independently of production tolerances. The freedom from friction at low speeds prevents slip stick and therefore allows maximum positioning accuracy.

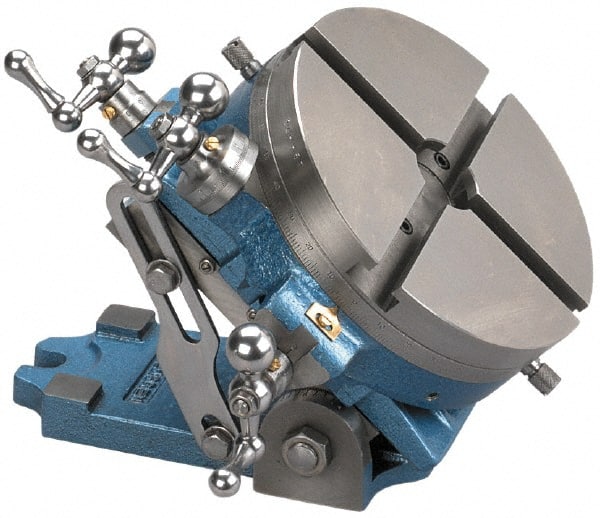

High accuracy, easy reading all dias clear & functional arrangements of all operating elements strudy yet good looking practical design. these are widely used for circular cutting, angle setting, boring and spot facing with a milling machine. Work as an index center in the vertical position, as well as conventional Rotary Table, graduated 360 Provisions for fine adjustments when setting work peice. Efficient lock provided. Worm drive disengagement is quick and precise. An eccentric sleeve with thrust bearing races encases the worm shaft. End play in worm shaft is adjustable.

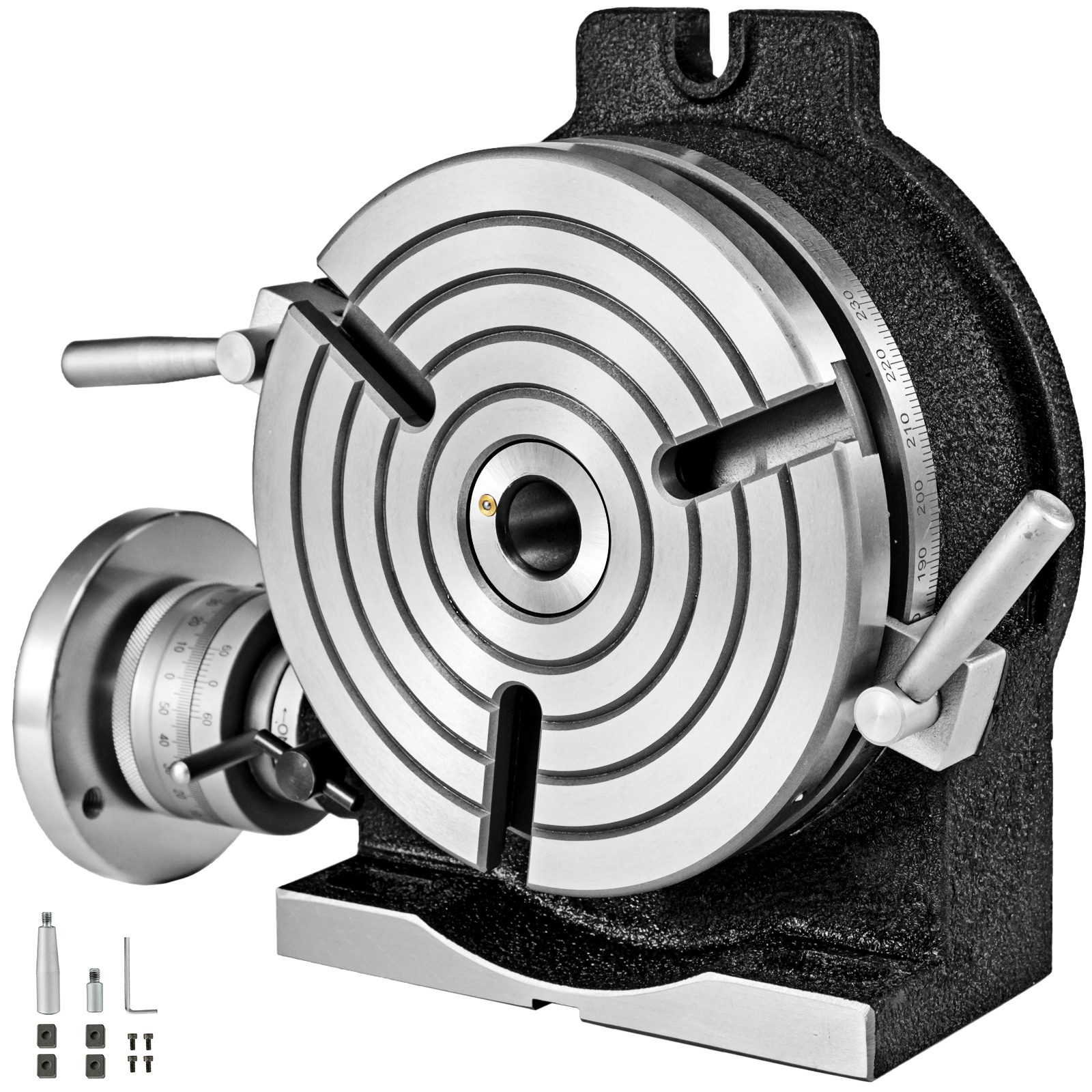

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

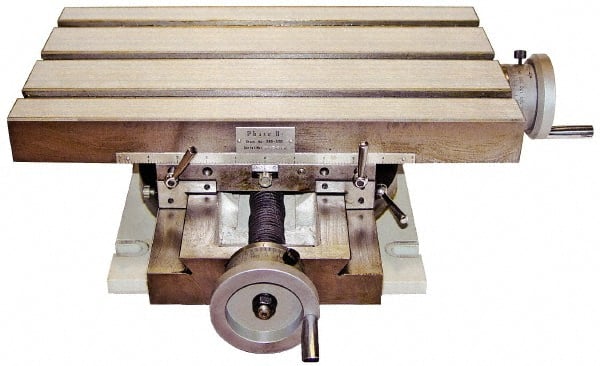

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

* With the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

Provision for fine zero adjusment when setting work piece. Works as an index centre in the vertical position as well as conventional Rotary Table graduated 360° indexing Plate is provided to enable the user to convert quickly to use indexing plates for fast setting.

8613371530291

8613371530291