diy rotary table for milling machine supplier

For a corner fillet weld such as those, it may help if you grind off half of each corner on the slotted plates giving a 45 deg V. This will help to ensure the weld gets good penetration and strength at the same time as allowing you to retain the original edges for alignment.

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

Alibaba.com offers 2894 milling rotary tables products. About 44% % of these are wood routers, 12%% are other machine tools accessories, and 5%% are table.

A wide variety of milling rotary tables options are available to you, such as manufacturing plant, machinery repair shops and energy & mining.You can also choose from 1 year, 6 months and 1.5 years milling rotary tables,As well as from not available, {2}, and {3}. and whether milling rotary tables is bearing, gear, or motor.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Centroid OEM Machine Tool Manufactures offer a wide variety of Centroid CNC equipped machine tools.. click to to find a Centroid equipped CNC machine tools..

Small Milling Machine CNC Control system: $18,385M400 3 axis with 1Kw AC Brushless Yaskawa servo motors and drivesMedium Milling Machine CNC control system: $22,175M400 3 axis with 2Kw AC Brushless Yaskawa servo motors and drivesLarge Milling Machine CNC Control system: $25,760M400 3 axis with 4.4Kw AC Brushless Yaskawa servo motors and drives

Knee Mills, Bed Mills, Routers:M400S $13,709 IN STOCK! Ready to Ship, use order #StockSFlat Bed Lathes, Small Slant Bed Lathes: T400S $13,279,click for pdf quote

Auto part set, Auto tool set, 3D contouring, 4th and 5th axis machining, Available in OEM configurations, Professional Installation with Service & Training and DIY CNC kits for both new machines and retrofit upgrades.

From the May issue of Modern Machine Shop Magazine " A CNC retrofit provides improved reliability and functionality compared to an older machine’s original control, and this is helpful in a number of ways. For example, a more intuitive control interface can help speed setups and minimize the chance for programming and/or setup mistakes, which could possibly damage or scrap a high-value work piece. Similarly, shops are also more confident in quoting work for large, expensive parts knowing the new control won’t hiccup partway through an operation and cause the part to be damaged. Shops also are better-positioned to take in “hot” jobs that require fast turnaround due to the retrofitted machine’s improved"... click here to see the complete article in PDF.

CENTROID Boss series II retrofit customer testimonial"The quality and workmanship of the CENTROID equipment was outstanding and very professional. CENTROID was able to custom tailor the control to allow us to continue to use our rotary milling arrangement as before and even expanded our capability. The short story is that we ended up with a four axis CNC mill for less than half the cost of the three axis Haas. This includes the work that was done by our staff."

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure ...

... the table is the rotation, the user may require the rotary table for drilling operations and milling. Using the servo drives in conjunction with the machine CNC control ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

Explore milling machine indexing table with simple designs on Alibaba.com for efficient metal cutting and strong support for the workpiece while cutting or grinding. The devices are vital components to various grinding equipment, and they are typically easy to mount. Standard machines that apply milling machine indexing table as installable or built-in parts include milling machines, boring tools, and drill presses. Some device applications include gear cutting, devising milling cutter flutes, and making bolt hole circles.

The innovative indexing head features a sturdy head and footstock or indexing centers for steady and reliable operation. Alibaba.com delivers different types of milling machine indexing table, including plain, optical, spiral, and universal spiral machines to cater to unique project requirements. The device components may operate as a unit or with extra attachments for enhanced accuracy and precision levels. Explore various direct index heads for fluting taps, milling squares, octagons, and many more.

Shoppers can use milling machine indexing table to verify precision angles, proportions and measures up to seconds of a degree using optical lenses for sensitive projects. Universal designs are well-suited for all forms of head indexing since they are configurable at any angle. Make indexing work more comfortable and enjoyable by having these machines in the workshop.

Compare mind-blowing milling machine indexing table options and exclusive deals on machinery on Alibaba.com. The quality-assured products come with sustainable warranties and are easy to operate and maintain. Customization for orders and aftersales support is also available from trusted dealers and distributors.

It works well. Functionally, it’s pretty great.It comes with some extras, but not much of an explanation. Because it can mount parallel or perpendicular, it lacks a way to clamp it to the table for parallel use. I had to machine a toe clamp to hold the other end. Thankfully, I have a mill. But, it’d have been so much easier to include one since it’s necessary.Otherwise, the 90 turns for 360 (1 for 4), works out pretty well for any angle divisible by four - 72, 60, 120, etc. I had to machine a way to attach my lathe chuck. Spent a half hour making the little piece I pictured… worked well for not using the dividing plates.Solid. Fairly precise. Works. But you’re going to have to make things to use it.

Under the guidance of Sh. Suresh Chandra Gupta, the company was started in 1975 with a small set up to start manufacturing the American type Turning and Parting Tool Holders to supply to the people exporting it in their name from India. Today after around four decades years of manufacturing experience & with his 2nd generation in business, WE are one of the leading manufacturers- Exporter from India of large variety of Machine Tools Accessories for Hobby Machinists, Model Makers, Wood Workers, Carpenters & Industrial applications supplying to the various renowned retailers of Europe, USA, Asia & Other parts of the Globe.

With the Help of our well developed production & tool room facilities, and by the ardent efforts of our experienced team who possess sound knowledge & experience of the industry, have enabled us in becoming one of the most reliable name in the market today. The company"s capabilities of manufacturing CUSTOM DESIGNED Items as per the customer"s specification has made ASSORTS Machine Tools Company, a trusted source for a wide & comprehensive range of Precision Tools of International Quality Standards at Competitive prices.

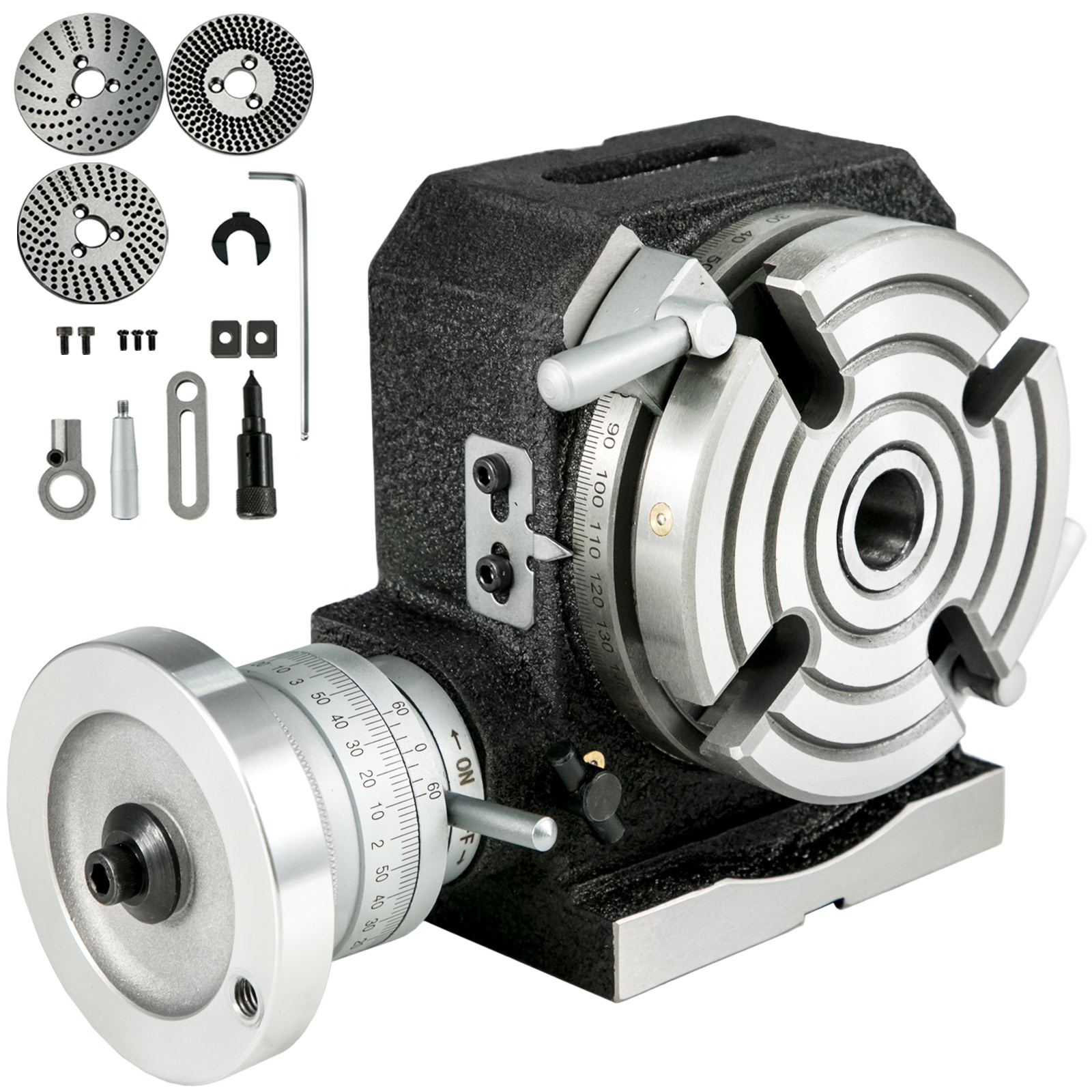

Our main Product line range includes Lathe"s Quick Change Tool Posts, Lathe Parting & Turning Tool Holders, Rotary Tables & Its accessories Like Clamp Kits, Dividing plates, Tailstocks, ER Collets Adaptors & Small Chucks with Back Plates, Knurling Tools, Lathe Alignment Test Bars, Vee Blocks, Revolving Centers, Vertical Milling Slides, Boring Heads, Fly Cutters, Arbors, Sleeves, Precision Vises For Milling, Drilling & Grinding, Bench Vises, HSS Lathe Form Tools & Carbide Brazed Tools Set, Lathe Chucks, Angle Plates, Surface Inspection Plates, Various DIY Hand tools, Punches, Jwelry Tools, Indexale Tools & many more.....

Very soon after buying a milling machine I can guarantee you will be looking at rotary tables. A rotary table feels like a must have. Use it to machine:arcs

Small rotary tables such as 3″ and 4″ are ok, but unless you are machining very small parts it can be difficult to clamp parts down. A 6″ rotary table is a better size and makes clamping parts down practical. Also, a 6″ table will fit under most mini milling machines.

A 6″ rotary table is a better size and makes clamping parts down practical. Also, a 6″ table will fit under most mini milling machines. Just remember that you need to be able to machine beyond the centre of the table, check the spindle to pillar dimension on the mill.

The location of the table to the milling table can be a challenge. The fixing of parts and alignment to the rotary table can be a bigger challenge and you will need to spend time making fixtures…

A dial gauge was then used to centre the part, rotating it back and forth whilst nudging it into location. The nut was then tightened and a second locking nut added.

The given size of a rotary table is the diameter of the table itself. Kind of obvious really, but you need to fix items to the table, normally using the T-slots. This means you lose a significant amount of the diameter.

I can now accurately drill steam cylinder covers, machine nut heads and cut gears.When using the division plates you need to stay focused as even with the brass fingers you need to carefully count the rotations. This is very rewarding and very calming. Trust me though that you won’t want interruptions.

8613371530291

8613371530291