drilling rig rotary table components free sample

Cameron rotary tables range from 27 1/2 in to 60 1/2 in and feature a large oil capacity that adds to the unit"s durability. The rotary table includes a forged-steel fabricated housing and a heat-treated forged-steel turntable. Each rotary table is supplied with spiral-bevel, induction-hardened gears and two independent ratchet-type locks, with lever access from the top to lock the table in position.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

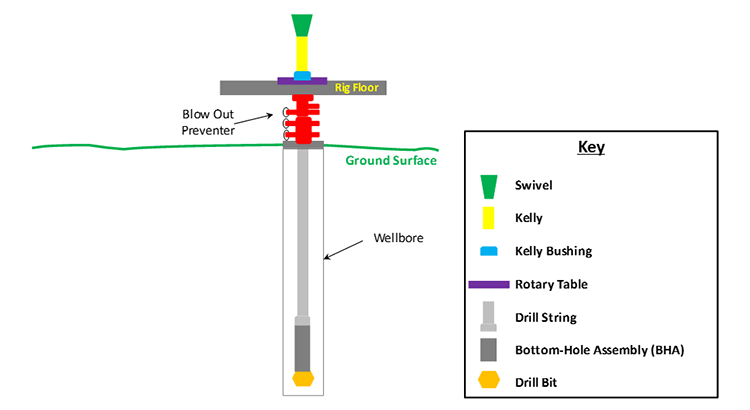

In this simple diagram of a drilling rig, #20 (in blue) is the rotary table. The drill string, while the rotary table rotates it. (Note: Force is not actually applied from the top (as to push) but rather the weight is at the bottom of the drill string like a pendulum on a string.)

A rotary table is a mechanical device on a drilling rig that provides clockwise (as viewed from above) rotational force to the drill string to facilitate the process of drilling a borehole. Rotary speed is the number of times the rotary table makes one full revolution in one minute (rpm).

The rotary table is also called a turntable. Most rotary tables are chain driven. These chains resemble very large bicycle chains. The chains require constant oiling to prevent burning and seizing. Virtually all rotary tables are equipped with a rotary lock". Engaging the lock can either prevent the rotary from turning in one particular direction, or from turning at all. This is commonly used by crews in lieu of using a second pair of tongs to makeup or break out pipes. The rotary bushings are located at the center of the rotary table. These can generally be removed in two separate pieces to facilitate large items, e.g. drill bits, to pass through the rotary table. The large gap in the center of the rotary bushings is referred to as the "bowl" due to its appearance. The bowl is where the slips are set to hold up the drill string during connections and pipe trips as well as the point the drill string passes through the floor into the wellbore. The rotary bushings connect to the kelly bushings to actually induce the spin required for drilling.

Most recently manufactured rigs no longer feature rotary drives. These newer rigs have opted for top drive technology. In top drive, the drill string is turned by mechanisms located in the top drive that is attached to the blocks. There is no need for the swivel because the top drive does all the necessary actions. The top drive does not eliminate the kelly bar and the kelly bushings.

Rotary drilling uses a sharp, rotating drill bit to dig down through the Earth’s crust. Much like a common hand-held drill, the spinning of the drill bit allows for penetration of even the hardest rock.

The idea of using a rotary drill bit is not new. Archeological records show that as early as 3000 B.C., the Egyptians may have been using a similar technique. Leonardo Di Vinci, as early as 1500, developed a design for a rotary drilling mechanism that bears much resemblance to technology used today. Despite these precursors, rotary drilling did not rise in use or popularity until the early 1900s.

Although rotary drilling techniques had been patented as early as 1833, most of these early attempts at rotary drilling consisted of little more than a mule, attached to a drilling device, walking in a circle. It was the success of the efforts of Anthony Lucas and Patillo Higgins in drilling their 1901 Spindletop well in Texas that catapulted rotary drilling to the forefront of petroleum drilling technology.

While the concept for rotary drilling – using a sharp, spinning drill bit to delve into rock – is quite simple, the actual mechanics of modern rigs are quite complicated. In addition, technology advances so rapidly that new innovations are being introduced constantly.

The basic rotary drilling system consists of four groups of components – the prime movers, hoisting equipment, rotating equipment and circulating equipment – that all combine to make rotary drilling possible.

The prime movers in a rotary drilling rig are those pieces of equipment that provide the power to the entire rig. Steam engines provided the power to the early drill rigs. Gas and diesel engines became the norm after World War II. Recently, while diesel engines still compose the majority of power sources on rotary rigs, other types of engines also are in use; more so in the oil and gas industry than in the water well sector. Natural gas or gasoline engines commonly are used, as are natural gas- or gasoline-powered reciprocating turbines, which generate electricity on-site. The resulting electricity is used to power the rig itself. The energy from these prime movers is used to power the rotary equipment, the hoisting equipment and the circulating equipment, and, on large rigs, may be used as well to provide incidental lighting, water and compression requirements not directly associated with drilling.

The hoisting equipment on a rotary rig consists of the tools used to raise and lower whatever other equipment may go into or come out of the well. The most visible part of the hoisting equipment is the derrick, which serves as a support for the cables (drilling lines) and pulleys (drawworks) that serve to lower or raise the equipment in the well.

For instance, in rotary drilling, the wells are made with long strings of drill pipe extending from the surface down to the drill bit. If a drill bit needs to be changed, either due to wear and tear or a change in the subsurface rock, the whole string of pipe must be raised to the surface.

In deep wells, the combined weight of the drill pipe, drill bit and drill collars may be in excess of thousands of pounds. The hoisting equipment is used to raise all of this equipment to the surface so that the drill bit may be replaced, at which point the entire chain of drill pipe is lowered back into the well. The height of a rig’s derrick often can be a clue as to the depth of the well being drilled. Drill pipe traditionally comes in 20-foot sections, which are joined together as the well is goes deeper and deeper. This means that even if a well is 1,200 feet deep, the drill string must still be taken out in 20-foot sections. However, if the derrick is tall enough, multiple joints of drill pipe may be removed at once, speeding up the process a great deal.

The rotating equipment on a rotary drilling rig consists of the components that actually serve to rotate the drill bit, which, in turn, sends the hole deeper and deeper into the ground. The rotating equipment consists of a number of different parts, all of which contribute to transferring power from the prime mover to the drill bit itself. The prime mover supplies power to the rotary, which is the device that turns the drill pipe, which, in turn, is attached to the drill bit. A component called the swivel, which is attached to the hoisting equipment, carries the entire weight of the drill string, but allows it to rotate freely.

Below the drill pipe are drill collars, which are heavier, thicker and stronger than normal drill pipe. The drill collars help to add weight to the drill string, right above the bit, to ensure there is enough downward pressure to allow the bit to drill through hard rock. The number and nature of the drill collars on any particular rotary rig can be altered depending on the down-hole conditions experienced while drilling.

The final component of rotary drilling consists of the circulating system. There are a number of main objectives of this system, including cooling and lubricating the drill bit, removing debris and cuttings, and coating the walls of the well with a mud type-cake. The circulating system consists of drilling fluid, which is circulated down through the well hole throughout the drilling process.

The components of the circulating system include drilling fluid pumps, compressors, related plumbing fixtures, and specialty injectors for the addition of additives to the fluid flow stream.

Rotary drilling, as opposed to percussion drilling, cuts by rotating a bit at the bottom of the hole. In addition to rotation, downward pressure must be exerted and continued as the bit cuts it way through the formation.

Part of the art of rotary drilling is to match the bit type and pull-down pressure with the formation, and the use of drilling fluids to maintain circulation to keep the hole clear of cuttings and the bit lubricated and cool. A rotating table turns the drill string via a kelly bar passing through the table and attached to the top joint of the drill string.

hydraulically driven top-head, top-head unit with pull-down chains (more recent top-head-drive rigs are completely hydraulically driven, eliminating the need for chains or cables to provide pull-down forces); and

When beginning a new hole, and oftentimes during drilling operations, pull-down pressure from the drill rig is applied. This pull-down force is achieved by a screw, cable or chain arrangement, or by hydraulic motors. Hydraulically powered pull-down actions usually are found on more recently manufactured drill rigs, with screw, cable and chain pull-down arrangements more commonly found on older rotary rigs.

The driller controls the pull-down pressure and, thus, the speed of penetration. It must be noted that part of the art of rotary drilling is the matching of pull-down pressure to the formation. Excessive pull-down pressure can damage drill bits, drill pipe and the trueness of the borehole. Thus, applying more pull-down pressure is not always the best drilling practice.

The International School of Well Drilling (ISWD) was established in May 2002 to serve the needs of the water well, environmental and geotechnical sectors of the drilling industry. Since opening, ISWD has trained students both nationally and internationally. These students have included those seeking to enter the drilling industry, and those currently employed at a junior level in the industry, as well as industry regulators and licensed well drillers seeking to further their knowledge.

Since 2005, the ISWD’s focus has shifted to offering training to those already in the water well drilling industry. Continuing education as a requirement for license renewal is required in 27 states. The remaining states are likely to join the majority over time. ISWD is proud to offer continuing education credits for the well drilling industry online.

Explore the various drilling rig parts rotary table products available for wholesale at Alibaba.com. Get a drilling rig parts rotary table for drilling water wells, water exploration holes, geological exploration, coal mines, and other kinds of mining. Some drilling rig parts rotary table options use caterpillar tread to move. Others use rubber tires, while others require a separate means of transport. Caterpillar tread propulsion can climb up to 25 degrees inclination. Some products in the range are capable of drilling over 200 meters, while others are only used for open-pit mining with depths of around 3 meters. Drilling can be done vertically downwards, horizontally, or in a slanting direction. Drilling speed depends on the power of the machine and the general hardness of the surface. The hole diameter can vary from 90mm to 200mm.

drilling rig parts rotary table options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Smaller products have a lifting power of around 25 kilonewtons and weigh about 2,500kgs. They’re ideal for small-scale drillings such as farms and homes. Larger ones are faster with more power, making them ideal for commercial use. Browse through Alibaba.com and find a drilling rig parts rotary table that’s ideal for your work scope. Buy mine drilling rigs for your wholesale business at competitive prices. Chinese wholesalers provide you with customization options and great after-sales services.

Explore the various rotary table for drilling rig parts products available for wholesale at Alibaba.com. Get a rotary table for drilling rig parts for drilling water wells, water exploration holes, geological exploration, coal mines, and other kinds of mining. Some rotary table for drilling rig parts options use caterpillar tread to move. Others use rubber tires, while others require a separate means of transport. Caterpillar tread propulsion can climb up to 25 degrees inclination. Some products in the range are capable of drilling over 200 meters, while others are only used for open-pit mining with depths of around 3 meters. Drilling can be done vertically downwards, horizontally, or in a slanting direction. Drilling speed depends on the power of the machine and the general hardness of the surface. The hole diameter can vary from 90mm to 200mm.

rotary table for drilling rig parts options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Smaller products have a lifting power of around 25 kilonewtons and weigh about 2,500kgs. They’re ideal for small-scale drillings such as farms and homes. Larger ones are faster with more power, making them ideal for commercial use. Browse through Alibaba.com and find a rotary table for drilling rig parts that’s ideal for your work scope. Buy mine drilling rigs for your wholesale business at competitive prices. Chinese wholesalers provide you with customization options and great after-sales services.

Depending on the size of your drilling pipes, Forum offers clamp types C, T, CXL and AMP to ensure a perfect fit while making-up or breaking-out the string.

The rotary system on a drilling rig is the system that causes the drill bit rotate at the bottom of wellbore. We have discussed some components of the rotary system when we discussed rotary table and top-drive rigs, but we have not yet discussed the entire system.

A schematic of the rotary system is shown in Figure 9.07. As we can see in Figure 9.07, the rotary system shares many components with the circulation system. This is because in the rotary system, these components rotate in support of causing the bit to rotate, while in the circulation system, these components act as conduits for the drilling fluid.

In Lesson 8, we saw that the rotary table imparted the torque for the drill string in a conventional rotary table rig, while the top-drive imparted this torque on a top-drive rig. We also saw that drill pipe was added to the drill string one joint at a time on a rotatory table rig, while a top-drive could add multiple joints of drill pipe during one connection operation.

The Bottom-Hole Assembly is comprised of any bottom hole equipment required to drill the current section of the well. A bottom-hole assembly may be as simple as a Drilling Collar. Drill collars are sections of heavy, thick walled pipe used to add weight-on-bit to the drill string. More complicated bottom-hole assemblies may include Jars, downhole directional steering and positioning equipment, logging-while-drilling, and measure-while-drilling equipment.

At the end of the drill string and bottom-hole assembly is the drill bit. There are many types of drill bits, but we will focus on two types of drilling bits, the Tri-Cone (or Roller Cone) Bit and Fixed-Cutter Bit. In addition, we will be discussing two variants of the tri-cone bit: the milled-tooth bit and the insert bit. All of these bits can be classified as in the following bullet list:

Tri-cone bits are the most common drilling bits and, historically, have been the workhorse of the drilling industry. As the name implies, tri-cone bits contain three cones, each of which contain cutting teeth.

The two-cone bit (an early version of the tri-cone bit) was invented by Howard Hughes Jr.’s father (Howard Sr.). The tri-cone bit and the formation of the Hughes Tool Co. (now part of Baker-Hughes, a subsidiary of the General Electric Corporation) was the source of the Hughes family wealth. In case you do not know who Howard Hughes Jr. was, he was an award winning pilot in the 1920s and 1930s (holder of several aerial speed records and subject of the movie “The Aviator”), a filmmaker (had controlling interest of RKO Studios and actively produced several notable silent and early “talkie” films), airplane designer (owner of Hughes Aircraft – contractor for the world’s largest wooden airplane, “The Spruce Goose,” with Howard as its only pilot in 1947), and a billionaire by the 1970s and 1980s (back when a billion dollars had some value).

One design feature of the tri-cone bit is the interaction of the teeth on the different cones helping to remove any small cuttings or sticky shales/clays (Gumbo Shales) that may get lodged between the teeth and reduce the efficiency of the bit. This phenomenon of cuttings and clays getting lodged between bit teeth is referred to as Bit Balling and results in slower Rates-of-Penetration (ROP) of the drilling process. The self-cleaning action of the teeth in a tri-cone bit is designed to reduce the bit balling.

Milled-tooth tri-cone bits are mainly used for drilling through soft rock formations. This is because, no matter how strong the steel used in the construction of the cone, hard rock can cause excessive wear and degradation of the teeth.

While the insert bit helps to alleviate the issues with tooth-wear, there is an additional source of wear that can shorten the life of a drilling bit. Due to the moving parts associated with a tri-cone (or roller) bit, the bit requires a bearing where the moving parts meet and move past one another. Thus, the wear on the bearings may also shorten the life of the bit.

The PDC bits are used to drill through very hard rock formations or for extended bit-life drilling. These bits have a large initial cost but because of the hard teeth and lack of any moving parts have a longer bit-life. One recent innovation for PDC bits in geologic basins with many shallow (short-footage) drill sites is the ability to rent the drill bit from the drilling company rather than to purchase it from a tool company. This innovation allows for an operating company to rent the bit and to use it for the footage that they require before relinquishing it to another operating company.

We have discussed that the tri-cone bits and the fixed cutter bits have different drilling actions. Here is a YouTube video, "Drill Bits - Oil and Gas Drilling: From Planning to Production" (3:26), that demonstrates the differences of the explosive, gouging, and crushing action of the tri-cone bit and the scraping action of the fixed cutter bits:

While we"re out of the hole the operator also wants to switch to a track hone bit. This style of bid is less aggressive than a PDC and will drill a little slower. Bit selection is very important part of drilling a well so let"s go review that now.

While we"re out of the hole the operator also wants to switch to a track hone bit. This style of bid is less aggressive than a PDC and will drill a little slower. Bit selection is very important part of drilling a well so let"s go review that now.

Tungsten carbide insert, or TCI bits, have tungsten carbide treated inserts that gouge, chip, and crush rock. Tungsten carbide is one of the hardest materials known and TCI bits are capable of drilling some of the hardest and most abrasive formations. Tungsten carbide inserts come in a variety of shapes and because of their appearance TCI bits are often called button bits.

Polycrystalline diamond compact, or PDC bits, have tungsten carbide cutters topped with hard caps of diamond composite material. The cutters are angled and arranged to shear channels in the rock. The diamond caps are made by heating and compressing artificial diamond grit with tungsten carbide and other metallic binders. PDC bits come in a variety of designs that can be used for an extensive range of drilling requirements. PDC bits are much more expensive than roller cone bits but can generally penetrate faster and last longer than roller cone bits which saves drilling costs.

8613371530291

8613371530291