drilling rig rotary table components in stock

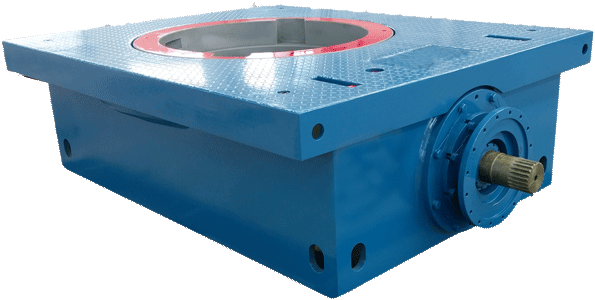

Cameron rotary tables range from 27 1/2 in to 60 1/2 in and feature a large oil capacity that adds to the unit"s durability. The rotary table includes a forged-steel fabricated housing and a heat-treated forged-steel turntable. Each rotary table is supplied with spiral-bevel, induction-hardened gears and two independent ratchet-type locks, with lever access from the top to lock the table in position.

Explore the various drilling rig parts rotary table products available for wholesale at Alibaba.com. Get a drilling rig parts rotary table for drilling water wells, water exploration holes, geological exploration, coal mines, and other kinds of mining. Some drilling rig parts rotary table options use caterpillar tread to move. Others use rubber tires, while others require a separate means of transport. Caterpillar tread propulsion can climb up to 25 degrees inclination. Some products in the range are capable of drilling over 200 meters, while others are only used for open-pit mining with depths of around 3 meters. Drilling can be done vertically downwards, horizontally, or in a slanting direction. Drilling speed depends on the power of the machine and the general hardness of the surface. The hole diameter can vary from 90mm to 200mm.

drilling rig parts rotary table options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Smaller products have a lifting power of around 25 kilonewtons and weigh about 2,500kgs. They’re ideal for small-scale drillings such as farms and homes. Larger ones are faster with more power, making them ideal for commercial use. Browse through Alibaba.com and find a drilling rig parts rotary table that’s ideal for your work scope. Buy mine drilling rigs for your wholesale business at competitive prices. Chinese wholesalers provide you with customization options and great after-sales services.

Welcome to Pickett Oilfield’s rotary tables web page. Our company has been in the oil & gas drilling equipment industry for over 38 years, supplying new and used rotary tables and rotary equipment to customers in practically every producing region in the world. We are here to serve all your drilling equipment needs – if you don’t see it on this site, just give us a call or email. We can get it, if you need it!

Pickett Oilfield, LLC offers prospective buyers and extensive selection of quality new and used oil & gas drilling equipment, including rotary tables to choose from at competitive prices. Browse our inventory of rotary tables and rotary table drilling components for sale at competitive rates.

Please call NDS for all of your rotary table needs, whether it may be for repairs or for new sales. We stock a wide variety of parts for the Gardner Denver 503 5-1/4″ rotary table, the 603 5-1/4″ rotary table with bottom ring gear, the 603 5-1/4″ rotary table with top ring gear, the 7-1/2″ 2003 rotary table with bottom ring gear, the 7-1/2″ 2003 rotary table with top ring gear, the 10″ 3003 rotary table, the 5-1/4″ GEFCO rotary table, the 7-1/2″ GEFCO rotary table, 7-1/2″ Mayhew table for a Failing Rig, 8-1/2″ Speedstar table, 8-1/2″ Mayhew Table for a Speedstar rig and the 8-1/2″ Midway rotary table. Portadrill, Mayhew, Failing and Midway rotary tables and parts are also available.

Rotary Tables - 37-1/2 IN. ROTARIES, FG-2A, 500 TON, 14 IN. - 2-3/8 IN. PIPE SIZES USE FOR TRIPPING AND CASING RUNNING. OPTIONAL HPCD AVAILABLE. ALL FG SERIES TOOLS ARE HYDRAULICALLY ACT... More Info

Rotary Tables - 49-1/2 IN. ROTARIES, FG-3A, 750/500 TON, 20 IN. - 2-3/8 IN. PIPE SIZES USE FOR TRIPPING AND CASING RUNNING. OPTIONAL HPCD AVAILABLE. ALL FG SERIES TOOLS ARE HYDRAULICALLY... More Info

Rotary Tables - DEN-CON 49-1/2 IN. HMB BUSHING, 750 TON RATING, AVAILABLE WITH A VARIETY OF INSERT BOWLS INCLUDING CONVENTIONAL API BOWLS, 500 TON BOWLS AND 750 TON BOWLS. More Info

Rotary Tables - 37-1/2 IN. - 49-1/2 IN. ROTARIES, FG-6B, 350 TON, 8-5/8 IN. & SMALLER WORKOVER RISER. PURPOSE BUILT POWER SLIP FOR HANDLING WORKOVER RISER WITH UMBILICALS. IDEAL FOR RENT... More Info

Rotary Tables - POWER SLIPS ARE AVAILABLE FOR 27-1/2 IN., 37-1/2 IN. & 49-1/2 IN. ROTARY TABLES. RATED CAPACITIES FROM 350 TONS TO 750 TONS. 27-1/2 IN. ROTARIES, FG-5A, 350 TON, 9-5/8 IN... More Info

Rotary Tables - ADAPTER RINGS - 750 TON - SOLID & SPLIT RINGS - DEN-CON 60-1/2 IN. X 49-1/2 IN. ADAPTER RINGS. ADAPTER RING OUTSIDE CONFIGURATION AND INSIDE CONFIGURATION CAN BE DONE FOR... More Info

Rotary Tables - ADAPTER RINGS - 750 TON - SOLID & SPLIT RINGS - DEN-CON 49-1/2 IN. X 37-1/2 IN. ADAPTER RINGS. ADAPTER RING OUTSIDE CONFIGURATION AND INSIDE CONFIGURATION CAN BE DONE FOR... More Info

DrillingParts.com is in no way affiliated with the companies referenced in this website. References and/or mention of company names or the accompanying computer code are for ID purposes only and are not Trade Marks or Trade Names used by or affiliated with DrillingParts.com. Although under affiliate program agreements, DrillingParts.com may earn on qualifying purchases completed through third party associates such as Amazon, eBay and our marketplace vendors.

EC Tool’s drilling gear includes roller chains, draw-works, and many other items. We are happy to help you find the exact item you need, right down to the model. You can also request custom-made swivels, rotary table drawings, and more.

EC Tool specializes in the manufacturing and sales of oilfield drilling equipment and drilling rig packages. We supply the full line from SCR drive rigs to conventional and fast-moving rigs (truck-mounted, trailer-mounted, and skidding), drilling equipment, and rig accessories and parts.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

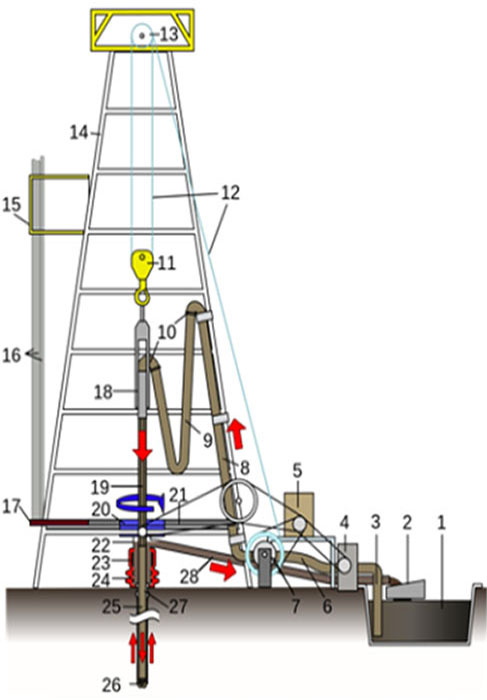

One or more valves installed at the wellhead to prevent the escape of pressure either in the annular space between the casing and the drill pipe or in open hole (for example, hole with no drill pipe) during drilling or completion operations. See annular blowout preventer and ram blowout preventer.†

A pit in the ground to provide additional height between the rig floor and the well head to accommodate the installation of blowout preventers, ratholes, mouseholes, and so forth. It also collects drainage water and other fluids for disposal.†

The arrangement of piping and special valves, called chokes, through which drilling mud is circulated when the blowout preventers are closed to control the pressures encountered during a kick.†

A centrifugal device for removing sand from drilling fluid to prevent abrasion of the pumps. It may be operated mechanically or by a fast-moving stream of fluid inside a special cone-shaped vessel, in which case it is sometimes called a hydrocyclone.†

A centrifugal device, similar to a desander, used to remove very fine particles, or silt, from drilling fluid. This keeps the amount of solids in the fluid to the lowest possible level.†

A small enclosure on the rig floor used as an office for the driller or as a storehouse for small objects. Also, any small building used as an office or for storage.†

The hoisting mechanism on a drilling rig. It is essentially a large winch that spools off or takes in the drilling line and thus raises or lowers the drill stem and bit.†

The cutting or boring element used in drilling oil and gas wells. Most bits used in rotary drilling are roller-cone bits. The bit consists of the cutting elements and the circulating element. The circulating element permits the passage of drilling fluid and uses the hydraulic force of the fluid stream to improve drilling rates.†

The heavy seamless tubing used to rotate the bit and circulate the drilling fluid. Joints of pipe 30 feet long are coupled together with tool joints.†

A wire rope hoisting line, reeved on sheaves of the crown block and traveling block (in effect a block and tackle). Its primary purpose is to hoist or lower drill pipe or casing from or into a well. Also, a wire rope used to support the drilling tools.†

On diesel electric rigs, powerful diesel engines drive large electric generators. The generators produce electricity that flows through cables to electric switches and control equipment enclosed in a control cabinet or panel. Electricity is fed to electric motors via the panel.†

The heavy square or hexagonal steel member suspended from the swivel through the rotary table. It is connected to the topmost joint of drill pipe to turn the drill stem as the rotary table turns.†

A device fitted to the rotary table through which the kelly passes. It is the means by which the torque of the rotary table is transmitted to the kelly and to the drill stem. Also called the drive bushing.†

A portable derrick capable of being erected as a unit, as distinguished from a standard derrick, which cannot be raised to a working position as a unit.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

A series of open tanks, usually made of steel plates, through which the drilling mud is cycled to allow sand and sediments to settle out. Additives are mixed with the mud in the pit, and the fluid is temporarily stored there before being pumped back into the well. Mud pit compartments are also called shaker pits, settling pits, and suction pits, depending on their main purpose.†

A trough or pipe, placed between the surface connections at the well bore and the shale shaker. Drilling mud flows through it upon its return to the surface from the hole.†

A diesel, Liquefied Petroleum Gas (LPG), natural gas, or gasoline engine, along with a mechanical transmission and generator for producing power for the drilling rig. Newer rigs use electric generators to power electric motors on the other parts of the rig.†

A hole in the rig floor 30 to 35 feet deep, lined with casing that projects above the floor. The kelly is placed in the rathole when hoisting operations are in progress.†

Shallow bores under the rig floor, usually lined with pipe, in which joints of drill pipe are temporarily suspended for later connection to the drill string.†

A mud pit in which a supply of drilling fluid has been stored. Also, a waste pit, usually an excavated, earthen-walled pit. It may be lined with plastic to prevent soil contamination.†

The hose on a rotary drilling rig that conducts the drilling fluid from the mud pump and standpipe to the swivel and kelly; also called the mud hose or the kelly hose.†

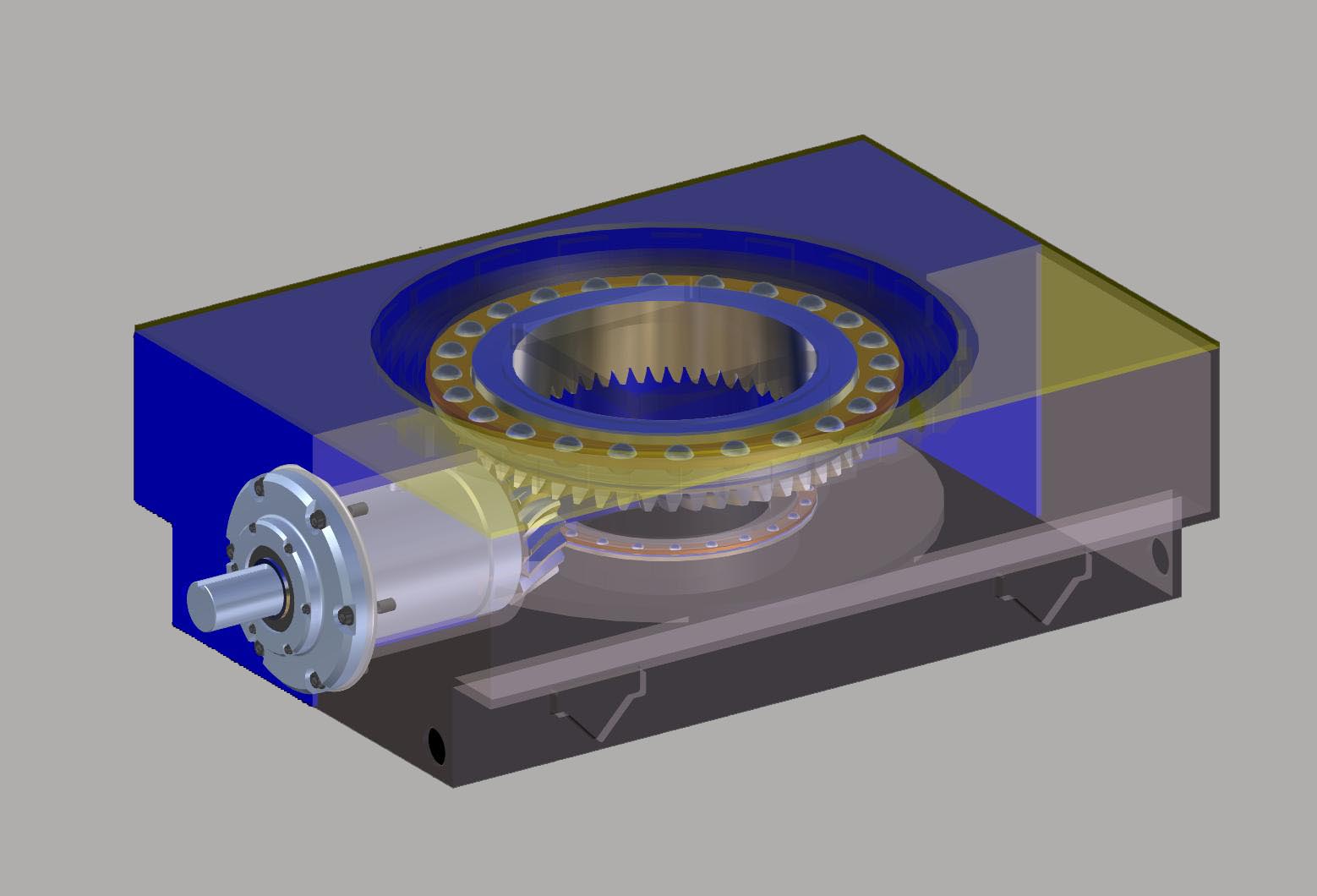

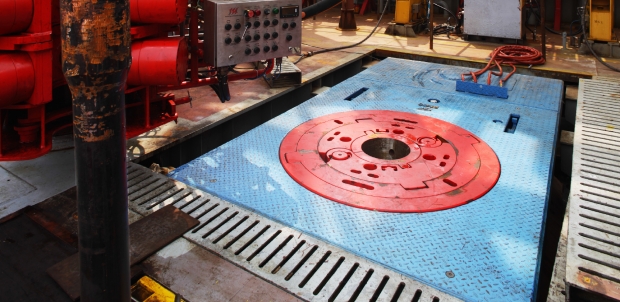

The principal component of a rotary, or rotary machine, used to turn the drill stem and support the drilling assembly. It has a beveled gear arrangement to create the rotational motion and an opening into which bushings are fitted to drive and support the drilling assembly.

A series of trays with sieves or screens that vibrate to remove cuttings from circulating fluid in rotary drilling operations. The size of the openings in the sieve is selected to match the size of the solids in the drilling fluid and the anticipated size of cuttings. Also called a shaker.†

Wedge-shaped pieces of metal with teeth or other gripping elements that are used to prevent pipe from slipping down into the hole or to hold pipe in place. Rotary slips fit around the drill pipe and wedge against the master bushing to support the pipe. Power slips are pneumatically or hydraulically actuated devices that allow the crew to dispense with the manual handling of slips when making a connection. Packers and other down hole equipment are secured in position by slips that engage the pipe by action directed at the surface.†

A relatively short length of chain attached to the tong pull chain on the manual tongs used to make up drill pipe. The spinning chain is attached to the pull chain so that a crew member can wrap the spinning chain several times around the tool joint box of a joint of drill pipe suspended in the rotary table. After crew members stab the pin of another tool joint into the box end, one of them then grasps the end of the spinning chain and with a rapid upward motion of the wrist "throws the spinning chain"-that is, causes it to unwrap from the box and coil upward onto the body of the joint stabbed into the box. The driller then actuates the makeup cathead to pull the chain off of the pipe body, which causes the pipe to spin and thus the pin threads to spin into the box.†

A vertical pipe rising along the side of the derrick or mast. It joins the discharge line leading from the mud pump to the rotary hose and through which mud is pumped going into the hole.†

A rotary tool that is hung from the rotary hook and traveling block to suspend and permit free rotation of the drill stem. It also provides a connection for the rotary hose and a passageway for the flow of drilling fluid into the drill stem.†

The large wrenches used for turning when making up or breaking out drill pipe, casing, tubing, or other pipe; variously called casing tongs, rotary tongs, and so forth according to the specific use. Power tongs are pneumatically or hydraulically operated tools that spin the pipe up and, in some instances, apply the final makeup torque.†

The top drive rotates the drill string end bit without the use of a kelly and rotary table. The top drive is operated from a control console on the rig floor.†

The rotary system includes all of the equipment used to achieve bit rotation. Originally, the main driver in the system of all rigs was the rotary table. The main parts of the rotary system with a rotary table are the swivel, kelly, and drillstring.

The rotary swivel (Fig. 1)serves two important functions in the drilling process. It is a connecting point between the circulating system and the rotary system. It also provides a fl uid seal that must absorb rotational wear while holding pressure. The upper section of the swivel has a bail for connection to the elevator hook, and the gooseneck of the swivel provides a downward-pointing connection for the rotary hose.

The kelly is the fi rst section of pipe below the swivel. The outside cross section of the kelly is square or (mostcommonly) hexagonal to permit it to be gripped easily for turning. Torque is transmitted to the kelly through kelly bushings, which fi t inside the master bushing of the rotary table. The kelly thread is right-handed on the lower end and left-handed on the upper end to permit normal right-hand rotation of the drillstring.

During drilling operations, in every connection, a new pipe is added below the kelly. To avoid premature wear in the kelly’s threads, a kelly saver sub is used between the kelly and the fi rst joint of drillpipe. Kelly cock valves are located on either end of the kelly.

Modern rigs use a topdrive to replace the kelly, kelly bushings, and rotary table. Drillstring rotation is achieved through hydraulic or electric motors. One type of topdrive is shown in Fig. 2

Topdrives are suspended from the hook and can travel up and down the derrick. This will allow drilling to be done with stands of pipes, instead of single joints, which will save considerable time. Comparing with the conventional process, where a new pipe must be added to the drillstring after the length of just one joint has been drilled, using a topdrive system, a new connection will occur only after the length of one stand (two, three, or four pipes) has been drilled.

Fig. 1 —(a) Rotary swivel (Steven M. Hain Company, Inc. 2010); used with permission from Steven M. Hain Company, Inc.; (b) rotary swivel (courtesy of OSHA).

The drillstring connects the surface equipment with the drill bit at the bottom of the well. The rotary table, or the topdrive, rotates the drillstring and, consequently, rotation is transmitted to the bit.

Range 2 drillpipe is used most commonly. Since each joint of pipe has a unique length, the length of each joint must be measured carefully and recorded to allow a determination of total well depth during drilling operations.

The BHA is the lower section of the drillstring. Even though a BHA may have many different tubulars depending on the complexity of the operation, most of the BHA is composed of drill collars (Fig. 3c). The drill collars are thick-walled, heavy steel tubulars used to apply weight to the bit. The buckling tendency of the relatively thinwalled drillpipe is too great to use it for this purpose. The smaller clearance between the borehole and the drill collars helps to keep the hole straight. Stabilizers (Fig. 4)often are used in the drill collar string to assist in keeping the drill collars centralized. Other types of tubulars used include shock absorbers and drilling jars. In addition, heavyweight drillpipes, a type of drillpipe with thicker walls, are commonly placed on top of the BHA to make the transition between the heavier drill collars and the drillpipes.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291