edm rotary table manufacturer

Our product range includes single and multiple axes, tilt/rotating tables, and indexing and high-speed spindles. Additionally, we offer customized solution tables for customer requests or OEM projects.

Even for EDM machines that have been in use for decades, we will work with you to determine the ideal rotary indexing table and/or rotating/indexing spindle solution.

Our state-of-the-art rotary indexing tables and customizable reference and clamping systems provide endless application possibilities and highly efficient solutions.

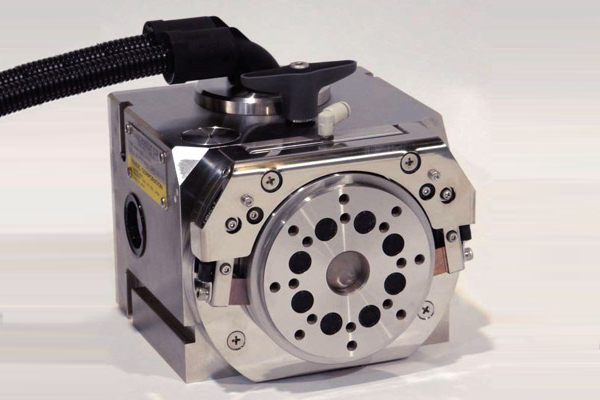

MK250RAV00 Rotary Table (includes Quinte Controller) with compact design, high performance nd improved mounting. The innovative triple disc brake system & friction welded construction gives substantially ...

This indexing unit with collet chuck is specially designed for use on wire-EDM machines provided. Through the mounting holes mounting on hole pattern 40 mm and 50 mm by M8 srews is possible.

... cantilever type tilting rotary tables are designed specifically for compact multi-sided EDM machining. Fully sealed, air purges, and impervious to EDM debris, oil or ...

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

The innovative rotary table incorporates a fully-closed feedback loop system using Fanuc servo motor and rotary encoder, making it the ideal addition to Fanuc EDM machines. As the CCR table is designed and manufactured by Fanuc, solely for the RoboCut EDM machines, it costs up to 50% less than a table from a third-party supplier and it has considerably more functionality built in.

The CCR table is equipped with a sensor that triggers a servo motor and an encoder alarm that sounds if a seal ruptures and water gets into the compartment where both are located. As a safety measure, this shuts down the machine and drains the water tank. This built-in technology minimises the potential for expensive water-related repairs to the motor and encoder.The robust 16kg CCR has a compact area of 155 by 170 by 130mm (LXWXH) that enables the operator to retain the spacious work envelope of the machine. The precision of the CCR is demonstrated by an indexing accuracy of 12 seconds and a repetition accuracy of +/-2 seconds. Despite its lightweight and highly accurate frame, the CCR permits a maximum workpeice weight of 40kg.

For some time, EDM customers have been adding rotary tables to their machines to accommodate the range of motion required to conduct work in high-tech markets such as the aerospace and medical sectors. This new CCR rotary table will now provide customers with this range of movement whilst adding speed, precision rigidity to the EDM process.

Rotary tables also have an economic impact on the manufacture of cutting tools, especially when paired with the relatively high production speeds of some Fanuc EDM machines. An example of this is the production of rotary PCD (polycrystalline diamond) tipped tool bodies where the CCR will deliver astounding benefits.

This control unit can be connected to any make or model of machine control and is started via M signal command. Programmable directly in either direction to any specified angle directly. The unit can be mounted vertically or horizontally at will. Motor is mounted to the left side on this device, through hole capability is closed due to the style and application of the device. Hofmann products are a high quality unit, this is no different being pre-owned is incredible value for money and come with a 1 year warranty. General dimensions are attached to this listing, however for clarity in vertical, the centre height is 160mm, the overall height is 250mm, in the horizontal plane, the height is 160mm. Carrying capacity vertically unsupported 120kg or 250kg with matching tailstock. Horizontal ;plane carrying capacity Is a very impressive 600kg. Net weight 60kg (Table and motor) This is a one only offer and cannot be repeated and is therefore subject to prior sale – contact technical sales for further information. The model number relates directly to the spindle and height, there is no faceplate with this unit.

As on of the leading rotary table manufacturer, OCEAN TECHNOLOGIES offers compact, light weight, high rigidity, high precision, flexibility and durability cnc rotary tables for global clients. Our rotary tables can be installed on the cnc machining centers and special purpose machines and are used in various workings and operations. And the very good keypoint is that cnc rotary tables can made complex motions more simpler and making the process more affordable to produce and reduce the cost in your company. If you have any product questions, please contact us today.

Roller cam: Compared with worm gears type it is with higher wear resistance, high transmission efficiency , affordable prices and basically maintenance-free of table.

Table directly driven by a motor, high rotary speed , no backlash, no weariness and low inertia. But relatively technical requirement is high and difficulty, the price is the most expensive. Generally used for five-axis machine tools.

Our rotary table can be used in the aerospace industry, 3C high-tech industry semiconductor parts, auto parts and components automation manufacturing, or bathroom equipment and daily necessities manufacturing etc.

The backlash control of our rotary table is stable and reliable, it can be adjusted at the same time and is easy to operate to meet high-precision processing and production requirements, so that it can help customers reduce costs and create more profits.

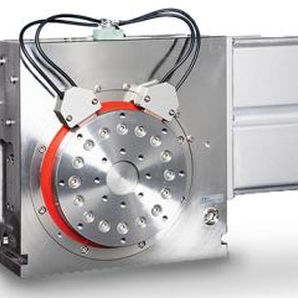

MMK Matsumoto Corp. is offering its SATii161, a stainless steel cantilever-style tilting EDM rotary table designed for 5-axis EDM machining of complex parts.

According to MMK Matsumoto, the SATii161 is fully impervious for complete submersion in oil or water and is equipped with current collectors and an isolated faceplate, making it usable for both wire EDM and sinker EDM applications.

The A/B axis indexer has a total load capacity of 50 kg, tilting capabilities of up to +/-179° and the ability to add a rotary joint for the use of a pneumatic power chuck. By lowering the table face to the tilt axis center height, the SATii161 helps increase efficiency by reducing machine axis travels. In order to meet the needs of a growing aerospace industry, precision indexing accuracy comes standard on the SATii161, said the company.

Jauch & Schmider adds one, two, or three additional axes to an existing EDM machine. These ultra precise EDM tables are fully submergible and offered in standard and application specific multi-axis configurations. All tables are available for direct machine control integration or with the single/multi-axis Logipos control. Jauch and Schmider tables are designed to accommodate leading clamping systems such as Hirschmann, Erowa, System 3R, and others.komaprecision.com

HPI-Yukiwa has designed the new JNC140-EDM CNC rotary table indexer with a special sealing system that is highly adaptable and effective for use in submersible applications with EDM dielectric fluids. The sealing system is combined with the patented Auto Air Purging System that removes any possible condensation accumulation inside the indexer housing, eliminating any of the problems typically associated with faulty electrical components.

The indexer weighs 27 kg and has a stainless steel face plate with a diameter of 140 mm and a center height of 110 mm. The table center through-hole diameter is 28 mm and the maximum work diameter is 140 mm. The maximum workload when mounted vertically is 136-lbs and 275-lbs when mounted horizontally. Indexing accuracy is ± 20 seconds.

Heartech Precision Inc. (HPI), headquartered in Elk Grove, Illinois, is the North American master distributor for HPI tools and YUKIWA tables, and presetters, PMT air chucks and other machine tool accessories. HPI has been serving the North American machine tool market for nearly 20 years and maintains a network of sales offices and stocking distributors.

The MMK Matsumoto Corp. MDW series single axis EDM rotary table is specifically designed for wire EDM applications. MDW series indexers are protected from the EDM environment, fully sealed, air purged and impervious to debris, oil and water.

These EDM rotary tables can be mounded on the A-axis or B-axis. The table’s internal structure is completely isolated from the electric current, and the unit is equipped with current-collecting brushes, which help to effectively distribute electricity charge.

Matsumoto MDW series EDM rotary tables are built from stainless still and can be fully submersed in oil or water. The tables feature an OTT (German) worm gear system with optional power chuck, tailstock, and additional brushes for enhanced performance.

8613371530291

8613371530291