edm rotary table supplier

Our product range includes single and multiple axes, tilt/rotating tables, and indexing and high-speed spindles. Additionally, we offer customized solution tables for customer requests or OEM projects.

Even for EDM machines that have been in use for decades, we will work with you to determine the ideal rotary indexing table and/or rotating/indexing spindle solution.

Our state-of-the-art rotary indexing tables and customizable reference and clamping systems provide endless application possibilities and highly efficient solutions.

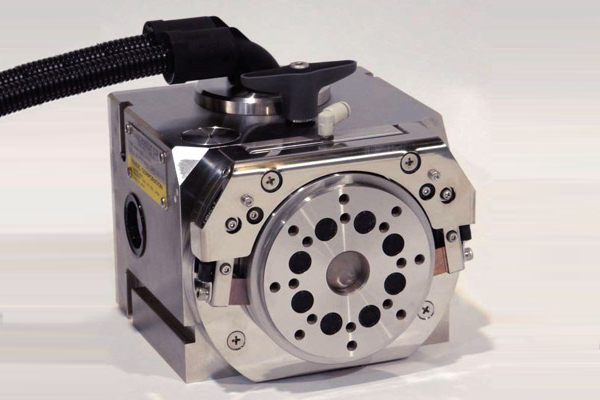

MK250RAV00 Rotary Table (includes Quinte Controller) with compact design, high performance nd improved mounting. The innovative triple disc brake system & friction welded construction gives substantially ...

This indexing unit with collet chuck is specially designed for use on wire-EDM machines provided. Through the mounting holes mounting on hole pattern 40 mm and 50 mm by M8 srews is possible.

... cantilever type tilting rotary tables are designed specifically for compact multi-sided EDM machining. Fully sealed, air purges, and impervious to EDM debris, oil or ...

Direct Drive Indexing Table is a kind of rotary table used for indexing operations which is very fast and accurate than conventional gear type indexing ...

The MMK Matsumoto Corp. MDW series single axis EDM rotary table is specifically designed for wire EDM applications. MDW series indexers are protected from the EDM environment, fully sealed, air purged and impervious to debris, oil and water.

These EDM rotary tables can be mounded on the A-axis or B-axis. The table’s internal structure is completely isolated from the electric current, and the unit is equipped with current-collecting brushes, which help to effectively distribute electricity charge.

Matsumoto MDW series EDM rotary tables are built from stainless still and can be fully submersed in oil or water. The tables feature an OTT (German) worm gear system with optional power chuck, tailstock, and additional brushes for enhanced performance.

Jauch & Schmider adds one, two, or three additional axes to an existing EDM machine. These ultra precise EDM tables are fully submergible and offered in standard and application specific multi-axis configurations. All tables are available for direct machine control integration or with the single/multi-axis Logipos control. Jauch and Schmider tables are designed to accommodate leading clamping systems such as Hirschmann, Erowa, System 3R, and others.komaprecision.com

As on of the leading rotary table manufacturer, OCEAN TECHNOLOGIES offers compact, light weight, high rigidity, high precision, flexibility and durability cnc rotary tables for global clients. Our rotary tables can be installed on the cnc machining centers and special purpose machines and are used in various workings and operations. And the very good keypoint is that cnc rotary tables can made complex motions more simpler and making the process more affordable to produce and reduce the cost in your company. If you have any product questions, please contact us today.

As on of the leading rotary table manufacturer, OCEAN TECHNOLOGIES offers compact, light weight, high rigidity, high precision, flexibility and durability cnc rotary tables for global clients. Our rotary tables can be installed on the cnc machining centers and special purpose machines and are used in various workings and operations. And the very good keypoint is that cnc rotary tables can made complex motions more simpler and making the process more affordable to produce and reduce the cost in your company. If you have any product questions, please contact us today.

Model MDHW and MDWAT 102B each hold and position workpieces in wirecut and sinker type EDM units. With stainless steel construction, each unit has environmental seals that allow unit to be completely submerged in dielectric fluid. Single-axis MDHW rotates 360° in fixed plane in 0.001° increments, while MDWAT has rotary axis with 360° of movement in .001° increments as well as tilt axis with 150° of movement in .001° increments.

Logansport, IN - Logansport Matsumoto Company has developed two compact NC Rotary Tables to hold and position workpieces in both wirecut and sinker type EDM units. Both feature stainless steel construction and employ environmental seals, which allow them to be completely submerged in the dielectric fluid.

The Model MDHW is a single-axis unit that rotates 360 degrees in a fixed plane in 0.001 degree increments. The Model MDWAT table is a two-axis unit that rotates and tilts the workpiece. The rotary axis has 360 degree of movement in .001 degree increments, and a tilt axis of 150 degrees of movement in .001 degree increments.

The MDWAT 102B two-axis NC Rotary Table measures just 445 mm (17.52 inches) wide by 240 mm (9.45 inches) deep by 210 mm (8.27 inches) high. The MDHW 100L single-axis NC Rotary Table is even smaller, measuring 301 mm (11.85 inches) wide by 187 mm (7.36 inches) deep by 178 mm (7 inches) high.

In addition to their compact footprint, both NC Rotary Tables can be fitted with a number of different chucks to hold a workpiece. The units normally come equipped with a System 3R chuck built into the table. Other chucks are available upon request.

Both tables are fitted with small, compact motors. Depending upon the application, LMC Rotary Tables can to married to the main EDM system control or furnished with their own dedicated control system.

The “cutting tool” in wire EDM is the energized wire that passes into and through a workpiece as it travels from reel to reel. This is a remarkably flexible and capable cutting process because the path and orientation of the traveling wire is highly maneuverable under the multi-axis command of the CNC program. In addition, workholding systems for wire EDM can greatly enhance this flexibility and capability by adding coordinated positioning of the workpiece.

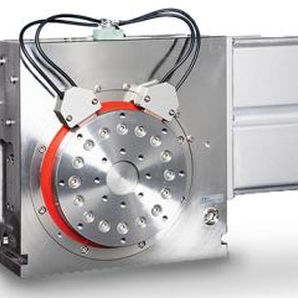

A prime example of this is the rotary tilt/turn hollow-access device from Hirschmann and marketed by Methods Machine Tools (Sudbury, Massachusetts) for its line of FANUC EDM units such as the RoboCut C600iA. This special tilt/turn table is available in different sizes. The model shown at IMTS and described here is the model JS FJRTH186RF-P-01.

“Rotary tilt/turn hollow-access” is a mouthful, but it is, in fact, a good way to characterize this device, which attaches to the tooling frame within the tank of the wire machine. It has two servo drives that are interfaced to the CNC. In operation, the unit enables the wire to cut complex openings that may have different paths at the top and bottom of the opening. The result is a “hollow” within a workpiece that may have a variably tapered and/or convoluted shape.

This complex hollowing is possible because the unit simultaneously rotates and tilts the workpiece. Unlike a tilting rotary table which typically rests on the surface of the worktable of a machining center, this unit is mounted from the sides and features a through-hole in which the workpiece is clamped. This arrangement enables the underside to remain open to the tank of the wire machine. In essence, the through-hole securely suspends the workpiece so that the travel of the wire is virtually unimpeded above and below for maximum access. The through-hole on this model is 5.86 inches (149 mm) in diameter and can handle a workpiece as heavy as 220 pounds (100 kg).

The three views of a sample workpiece on this page show the complexity of hollow openings that can be produced with this hollow-access device. This workpiece is 2.5 inches in diameter and 2.5 inches tall. Cutting such openings in this manner has advantages. This kind of tilt/turn table enables these complex contours to be machined while keeping the wire vertical. This means higher-tensile-strength wire can be used to obtain higher accuracy. Using higher-tensile-strength wire also makes wire threading more reliable for more efficient production runs. Because the upper and lower heads are always aligned, flushing with the dielectric water is improved, which results in faster cutting speeds and better surface finishes.

The RoboCut’s FANUC 31iWB control unit has the processing speed and power for the multi-axis simultaneous control required to coordinate the added rotary and tilting axes in the hollow access unit. The nano interpolation capability of the CNC complements the ±5 arcseconds indexing accuracy of the hollow-access unit’s rotary and tilt servodrives. In addition, the highly reliable wire-threading system and precise wire-tension control of the RoboCut 600iA support cutting of complex hollow openings in workpieces made of demanding materials for medical or aerospace.

8613371530291

8613371530291