edm rotary table in stock

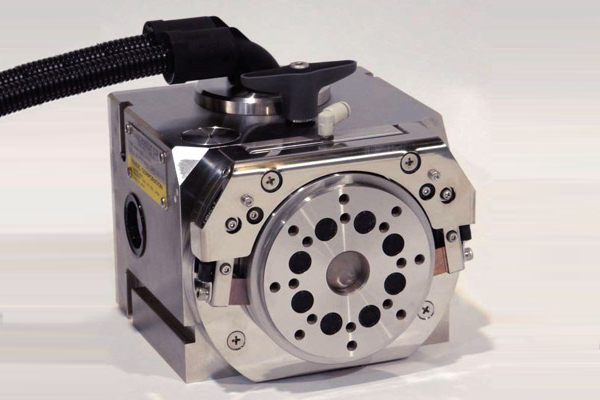

The MMK Matsumoto Corp. MDW series single axis EDM rotary table is specifically designed for wire EDM applications. MDW series indexers are protected from the EDM environment, fully sealed, air purged and impervious to debris, oil and water.

These EDM rotary tables can be mounded on the A-axis or B-axis. The table’s internal structure is completely isolated from the electric current, and the unit is equipped with current-collecting brushes, which help to effectively distribute electricity charge.

Matsumoto MDW series EDM rotary tables are built from stainless still and can be fully submersed in oil or water. The tables feature an OTT (German) worm gear system with optional power chuck, tailstock, and additional brushes for enhanced performance.

The manual rotary tables of the EXPERT-TÜNKERS EDM-series are a cost-efficient solution for simple automation applications up to a total mass of 1.000kg. Although the automation solutions and applications of our customers are continuously increasing in complexity, there is still a solid demand for safe and reliable manual human-machine-interface solutions.

The state-of the art in house produced ocean Technologies Rotary Table can fully submerged in water. The isolation grade of IP68 Rotary Table employs motorized spindle that features outstanding accuracy performance.

The innovative rotary table incorporates a fully-closed feedback loop system using Fanuc servo motor and rotary encoder, making it the ideal addition to Fanuc EDM machines. As the CCR table is designed and manufactured by Fanuc, solely for the RoboCut EDM machines, it costs up to 50% less than a table from a third-party supplier and it has considerably more functionality built in.

The CCR table is equipped with a sensor that triggers a servo motor and an encoder alarm that sounds if a seal ruptures and water gets into the compartment where both are located. As a safety measure, this shuts down the machine and drains the water tank. This built-in technology minimises the potential for expensive water-related repairs to the motor and encoder.The robust 16kg CCR has a compact area of 155 by 170 by 130mm (LXWXH) that enables the operator to retain the spacious work envelope of the machine. The precision of the CCR is demonstrated by an indexing accuracy of 12 seconds and a repetition accuracy of +/-2 seconds. Despite its lightweight and highly accurate frame, the CCR permits a maximum workpeice weight of 40kg.

For some time, EDM customers have been adding rotary tables to their machines to accommodate the range of motion required to conduct work in high-tech markets such as the aerospace and medical sectors. This new CCR rotary table will now provide customers with this range of movement whilst adding speed, precision rigidity to the EDM process.

Rotary tables also have an economic impact on the manufacture of cutting tools, especially when paired with the relatively high production speeds of some Fanuc EDM machines. An example of this is the production of rotary PCD (polycrystalline diamond) tipped tool bodies where the CCR will deliver astounding benefits.

Anyway, to answer your questions, I looked up the Hirschmann table you referenced and it looks to me like it"s a spinner and indexer, not a turn while burn table.

Hirschmann must have a similar provision to integrate their turn while burn capable tables to whatever machines they are going to be run on...I don"t think you can just buy one and bolt it to a machine without the interface kit to mate it to the control.

Turn while burn requires that the controller governs the rotary motion; this is because the rate of rotation has to be driven by the spark gap conditions in conjunction with the axis motion of the rest of the machine whether it"s X or Y or U or V.

It was faked by tilting the wire to an angle other than the thread helix angle with the U axis, then driving a fine pitch helix with B and X (B is the rotary axis on my machine).

You can imagine just how many passes that would take (a LOT), and you will always have a 0.005" radius at the junction of each flank and the root, which may or may not be acceptable depending on the application.

Our product range includes single and multiple axes, tilt/rotating tables, and indexing and high-speed spindles. Additionally, we offer customized solution tables for customer requests or OEM projects.

Even for EDM machines that have been in use for decades, we will work with you to determine the ideal rotary indexing table and/or rotating/indexing spindle solution.

Our state-of-the-art rotary indexing tables and customizable reference and clamping systems provide endless application possibilities and highly efficient solutions.

Methods Machine Tools, Inc., a supplier of precision machine tools, automation and accessories, has introduced a FANUC-built CCR Rotary Table on its FANUC Wire EDMs, including on the RoboCut a-CiA Series.

"The new single access, easy-to-use CCR Rotary Table is available exclusively on FANUC RoboCut EDMs," said a company spokesperson. "The table provides the range of motion that manufacturers in industries such as aerospace and medical require and allows for greater speed, precision and rigidity in EDM processes."

The CCR Rotary Table is a fully integrated all stainless steel table that is capable of full "turn and burn" machining and has a water leak monitoring function that shuts the machine down upon water detection, to minimize potentially costly water-related repairs.

Completely built by FANUC in Japan, the CCR Rotary Table weighs 35.27 lbs. (16 kg) and takes up minimal space - 6.1" x 6.7" x 5.1" (155 mm x 170 mm x 130 mm) - allowing the operator to retain the full work envelope of the machine. According to the company, index accuracy is 12 seconds and repeatability accuracy is +/- 2 seconds. The table can allow up to a maximum workpiece weight of 88.2 lbs. (40 kg). Standard configuration includes a faceplate for mounting a variety of workhold chucks or fixtures.

8613371530291

8613371530291