fanuc ddr rotary table factory

Designed to enhance the productivity of your FANUC ROBODRILL across an enormous range of applications, FANUC’s range of options give you the freedom to tailor your machining processes to your needs precisely. Like all FANUC products, FANUC accessories exhibit world-beating reliability, are simple to use and have been designed to help you get the most out of your ROBODRILL. Using them will allow you to increase output and maintain exacting quality standards regardless of how challenging your machining processes might be.

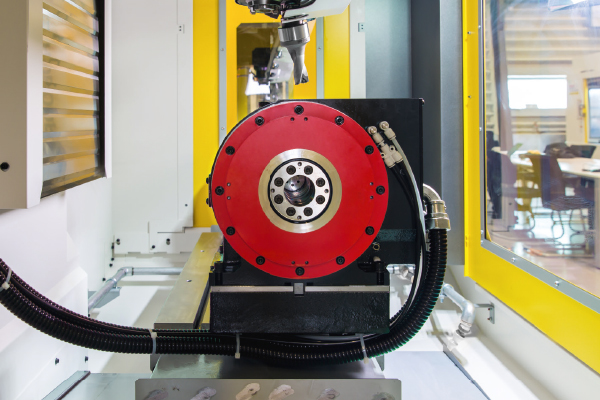

Thanks to its direct drive motor and improved rigidity for more accurate machining, the FANUC ROBODRILL DDR makes the perfect additional axis for your ROBODRILL. It"s direct drive and non-backlash structure enabling high speed and high precision machining. Benefits include an extremely fast indexing and clamping speeds. Extremely precise and reliable, the DDR offers the best value for your money.

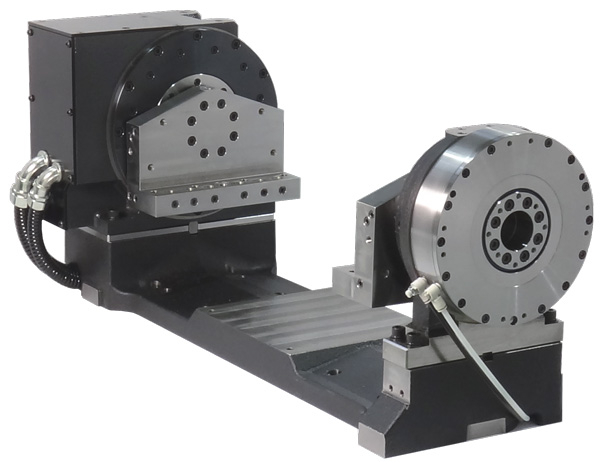

Depending on the application, we can equip your ROBODRILL with an extremely rigid DDR-T trunnion system that features all the benefits of the DDR rotary table and includes a support spindle and L-brackets. Its improved rigidity ensures even higher degrees of machining accuracy. All you need to do is add the fixture plate. The DDR-T"s practical design ensures that the existing X-axis travel remains the same as on the 3-axis design.

FANUC ROBODRILL offers a wide variety of spindle options in order to meet the optimum performance standards to a customer"s requirements and application.

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

Designed to enhance the productivity of your FANUC ROBODRILL across an enormous range of applications, FANUC’s range of dedicated software and hardware accessories give you the freedom to tailor your machining processes to your needs precisely. Like all FANUC products, FANUC accessories exhibit world-beating reliability, are simple to use and have been designed to help you get the most out of your ROBODRILL. Using them will allow you to increase output and maintain exacting quality standards regardless of how challenging your machining processes might be.

Designed to reduce the total time it takes you to get a drawing into production, FANUC MANUAL GUIDE i features an ergonomic Graphical User Interface (GUI) and user-friendly icons. Users also benefit from assisted and conversational programming of machining cycles, easy parts programming and simulation.

FANUC’s Robot Interface 2 enables the easy and inexpensive construction of a machining cell. You can easily connect four ROBODRILLs and one FANUC Robot without an additional system controller – the complete control software is included in the ROBODRILL PMC. In addition, the robot controller supports an automatic side door or an automatic front door.

FANUC ROBODRILL’s Nano Smoothing functionality reduces the need for manual finishing on processes, such as mould machining, that require sculptured surfaces. Look-ahead blocks expansion enables higher-precision machining on processes, such as die and mould machining, that involve cutting complex part-forms defined by numerous tiny program blocks. AI Contour Control I/II enables high-precision machining at optimal machining speeds, eliminating errors and increasing feed rates.

Thanks to its direct drive motor and improved rigidity for more accurate machining, the FANUC ROBODRILL DDRiB makes the perfect additional axis for your ROBODRILL. Benefits include an indexing time of just 0.55 seconds, ultrafast clamping and a clamp torque of 700 N-m.

Depending on the application, we can equip your ROBODRILL with an extremely rigid DDR-T trunnion system that features all the benefits of the DDR rotary table and includes a support spindle and L-brackets. Its improved rigidity ensures even higher degrees of machining accuracy. All you need to do is add the fixture plate. The DDR-T’s practical design ensures that the existing X-axis travel remains the same as on the 3-axis design. Clamp torque on the DDR-TiB is 1100 N-m.

The new generation ROBODRILL vertical machining centre promises unrivalled quality and precision at great hourly rates. With an unbeatable tool change time of 0.7 seconds and a turret capable of handling tools weighing 4 kg, the new advanced versions are both the fastest and strongest 5-axis CNC machines on the market. Advanced or standard, every ROBODRILL vertical machining centre is a real high-speed all-rounder offering incredible performance and unbeatable efficiency.

Dynamic Industrial Corporation is establish in the year2014. We are the leading Manufacturer and Supplier of SPM Machines, Maintenance Related Services & Spare Parts incluning Imports Items, Stockiest of Lubrication Grease Cartriges Daikin, Lube / Fanuc Batteries & Fan / Encoders / MPG Pendants. We are Specialist in Spindle, Ballscrew, Servo/PQ Valves & All CNC/VMC/Diecasting Machine Parts Repairing/Supplies. We are Specialist in Fanuc & Siemens Conrol Parts Repairing like Servo Drives/Other Control Cards. We provide the complete Maintenance Solutions under one Roof. Our Technically Skill Team had experience in Maintenance field More than 18 years

8613371530291

8613371530291