fanuc ddr rotary table in stock

Designed to enhance the productivity of your FANUC ROBODRILL across an enormous range of applications, FANUC’s range of options give you the freedom to tailor your machining processes to your needs precisely. Like all FANUC products, FANUC accessories exhibit world-beating reliability, are simple to use and have been designed to help you get the most out of your ROBODRILL. Using them will allow you to increase output and maintain exacting quality standards regardless of how challenging your machining processes might be.

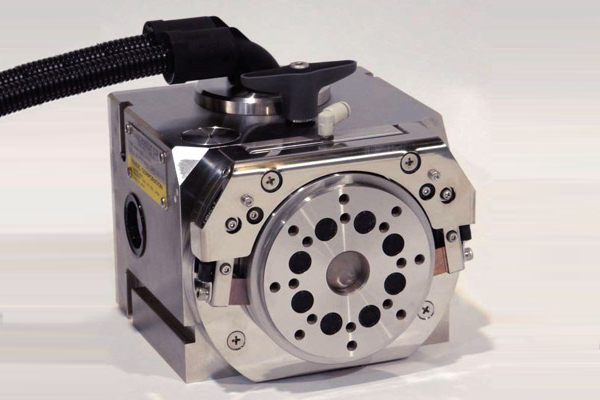

Thanks to its direct drive motor and improved rigidity for more accurate machining, the FANUC ROBODRILL DDR makes the perfect additional axis for your ROBODRILL. It"s direct drive and non-backlash structure enabling high speed and high precision machining. Benefits include an extremely fast indexing and clamping speeds. Extremely precise and reliable, the DDR offers the best value for your money.

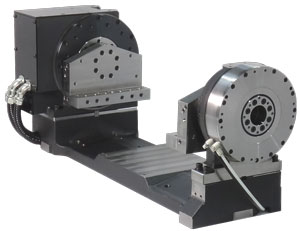

Depending on the application, we can equip your ROBODRILL with an extremely rigid DDR-T trunnion system that features all the benefits of the DDR rotary table and includes a support spindle and L-brackets. Its improved rigidity ensures even higher degrees of machining accuracy. All you need to do is add the fixture plate. The DDR-T"s practical design ensures that the existing X-axis travel remains the same as on the 3-axis design.

FANUC ROBODRILL offers a wide variety of spindle options in order to meet the optimum performance standards to a customer"s requirements and application.

A: We are a supplier ofthe most completeFanuc parts in China. There are more than 10,000 pieces of Fanuc parts in stock available. We’ll arrange the delivery after you order. Warmly welcome you to vist our company.

Designed to enhance the productivity of your FANUC ROBODRILL across an enormous range of applications, FANUC’s range of dedicated software and hardware accessories give you the freedom to tailor your machining processes to your needs precisely. Like all FANUC products, FANUC accessories exhibit world-beating reliability, are simple to use and have been designed to help you get the most out of your ROBODRILL. Using them will allow you to increase output and maintain exacting quality standards regardless of how challenging your machining processes might be.

Designed to reduce the total time it takes you to get a drawing into production, FANUC MANUAL GUIDE i features an ergonomic Graphical User Interface (GUI) and user-friendly icons. Users also benefit from assisted and conversational programming of machining cycles, easy parts programming and simulation.

FANUC’s Robot Interface 2 enables the easy and inexpensive construction of a machining cell. You can easily connect four ROBODRILLs and one FANUC Robot without an additional system controller – the complete control software is included in the ROBODRILL PMC. In addition, the robot controller supports an automatic side door or an automatic front door.

FANUC ROBODRILL’s Nano Smoothing functionality reduces the need for manual finishing on processes, such as mould machining, that require sculptured surfaces. Look-ahead blocks expansion enables higher-precision machining on processes, such as die and mould machining, that involve cutting complex part-forms defined by numerous tiny program blocks. AI Contour Control I/II enables high-precision machining at optimal machining speeds, eliminating errors and increasing feed rates.

Thanks to its direct drive motor and improved rigidity for more accurate machining, the FANUC ROBODRILL DDRiB makes the perfect additional axis for your ROBODRILL. Benefits include an indexing time of just 0.55 seconds, ultrafast clamping and a clamp torque of 700 N-m.

Depending on the application, we can equip your ROBODRILL with an extremely rigid DDR-T trunnion system that features all the benefits of the DDR rotary table and includes a support spindle and L-brackets. Its improved rigidity ensures even higher degrees of machining accuracy. All you need to do is add the fixture plate. The DDR-T’s practical design ensures that the existing X-axis travel remains the same as on the 3-axis design. Clamp torque on the DDR-TiB is 1100 N-m.

FANUC RoboDrill VMCs include the FANUC D21LiA5-10K featuring a FANUC DDRT 4-Axis rotary table and Renishaw OMP400 spindle probe demonstration; a FANUC D21MiA5-24K featuring a Koma 5-Axis RTT-111CA rotary table with Erowa quick change chuck, Blum laser, high pressure coolant system and MistBuster; a FANUC D21MiA5-ECO (the most economical RoboDrill model) with a FANUC DDR-260iB, and a FANUC D21SiA5-NTRL Automated Cell featuring two machines and a manufacturing cell with robot load-and-unload demonstration.

FANUC RoboCut Wire EDM Machines include the C400-10″ Wire EDM with a micro finishing unit, featuring a FANUC rotary table demonstration, and a C600-12″ Wire EDM with a Renishaw probe and PCD power supply that will be cutting 3D puzzle gifts.

FEELER machines include a HV-800 VMC with a MCU tool breakage monitoring system using FANUC Profibus software; a FT-250MC horizontal turning center that features a type “A” parts catcher and a programmable tail stock, and a VMP-580APC 40-taper VMC that features a dual pallet changer, 15,000rpm spindle and 24-tool ATC.

At 10 a.m. on both days Mr. Mark Foster, president of Applied Geometrics, Inc., will present a seminar titled, “GD&T (Geometric Dimensioning and Tolerancing) in the Manufacturing World Today.” An additional seminar each day at 2 p.m. will highlight FANUC Robotics and Automation, Dual Check Safety, along with material handling solutions and costs. Seating is limited and registration is required.

The new generation ROBODRILL vertical machining centre promises unrivalled quality and precision at great hourly rates. With an unbeatable tool change time of 0.7 seconds and a turret capable of handling tools weighing 4 kg, the new advanced versions are both the fastest and strongest 5-axis CNC machines on the market. Advanced or standard, every ROBODRILL vertical machining centre is a real high-speed all-rounder offering incredible performance and unbeatable efficiency.

FANUC’s legendary reliability coupled with easy preventative maintenance procedures keeps downtime to an absolute minimum and makes for an unbeatable return on investment.

FANUC ROBODRILL vertical machining centre lets you achieve superior parts quality using CNC functions such as Nano interpolation, 3-D machining or AI contour control.

The world’s most reliable CNC FANUC 31i-B5 isat the core of ROBODRILL. User friendly and easy to program, it contains tweenty easy-to-configure M-codes to control additional devices. Further customisstion is achieveable via the custom PMC function.

Thanks to its direct drive motor and improved rigidity for more accurate machining, the FANUC ROBODRILL DDRiB makes the perfect additional axis for your ROBODRILL.

For heavier workpieces, the extremely rigid DDR-T trunnion system features all the benefits of the DDR rotary table and includes a support spindle and L-brackets.

1- What kind of rotary table/unit do you have? If this is a Fanuc DDR, or any other linear/direct motor type, there should be no backlash. If it"s a worm drive, or rotary cam drive, there could be backlash, but I doubt it. Even for rotary axes, there"s parameters for backlash compensation.

1- Indicate the table at "A0.0" to make sure it"s truly flat. Across the "Y" direction, but also across the "X" direction as well. If it"s not flat across the "Y" axis direction in the "A0.0" position, then you may have to tweak the "home" position. If it"s not flat in the "X" direction, then either the head is out of tram, or the rotary unit itself is not parallel to the table. Sweep across the trunnion table, and the table itself to see if they"re parallel. Rotate the rotary 180* and sweep the same face again - the error should be opposite now, of the same amount.

If the trunnion and table are parrallel, yet when you tram the trunnion table with your indicator (rotate the spindle/indicator, and keep the table stationary) and this check shows the trunnion/table are not square to the spindle, then then the head is out of tram...

2- Rotate the table 90*, as you would in the program. As in, mimic the program as much as possible. If the table is at "A0.0" and you have a "G0 A90.0" line in the program, then go to MDI mode, and execute the same "G0 A0.0" line to mimic the direction, and speed of the index. Then, indicate the same face with the machine, by moving the Z-axis up/down to check this face. Write down your results. Cut the face, and then indicate the same face, using the same method again. Compare results to see if anything moved, which would indicate deflection.

If the Z-axis is truly square to the table, and the head is trammed square to the table, then you should end up with a square part. If something is not square, then either the Z-axis is not square to the table, or the head is out of square.

8613371530291

8613371530291