fourth axis rotary table quotation

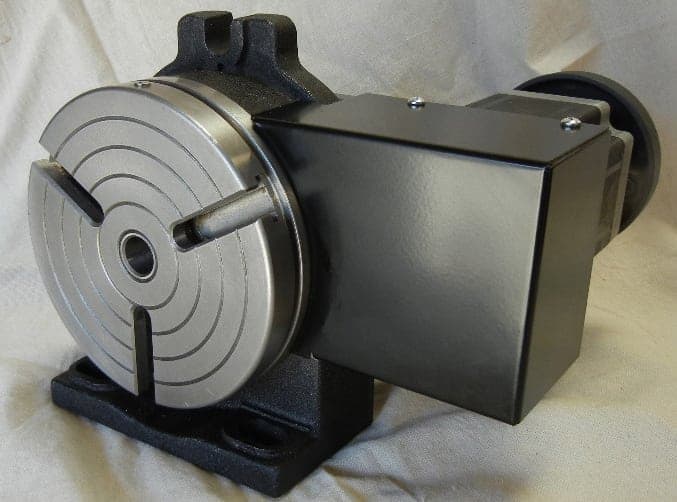

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

A rotary table is a workbench, designed to cut wood, metal, and other surfaces with a built-in tablebench, to make work easier. It is so compact and easy to use as a 4th axis tablebench, so that the work can be harder.

There are many types of rotary tables depending on your client"s needs. The rotary table is also called a rotary table, if it is a client"s design or a business, it can be compared to other rotary tables depending on the client"s needs. A rotary table is also called a rotary table, which allows users to cut many projects at once and have a different finish compared to the original rotary table.

KME CNC can design a trunnion for your application. Custom 5-axis trunnions can be made to specific matching needs including different drive configuration, large or smaller sizes, less

KME CNC’s trunnions have the lowest platter height in the industry, with 7.87” from table to platter, allowing maximum Z height clearance. KME CNC can also manufacture trunnions with 10” platters, depending on their specific needs. No additional drive cards necessary!

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

... ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other ...

... with 4th-axis drive and NGC software version 100.19.000.1100 or later for full 4th-axis operation. Stand-alone operation requires a Haas rotary control ...

... mill with 4th-axis drive and NGC software version 100.19.000.1100 or later for full 4th-axis operation. Stand-alone operation requires a Haas rotary ...

... mill with 4th-axis drive and NGC software version 100.19.000.1100 or later for full 4th-axis operation. Stand-alone operation requires a Haas rotary ...

... mill with 4th-axis drive and NGC software version 100.19.000.1100 or later for full 4th-axis operation. Stand-alone operation requires a Haas rotary ...

A wide range of models is available to make the whole range of HMCs complete. The rotary tables dedicated to the Spark line match the 5000 kg max load with ...

The Stallion Tombstone provides manufacturers with the ultimate time saver. With 4 sides, handling and tool change time decreases substantially. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Tombstone minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary. Our smallest tombstone model, at 4", is perfect for machining small parts at large volume.

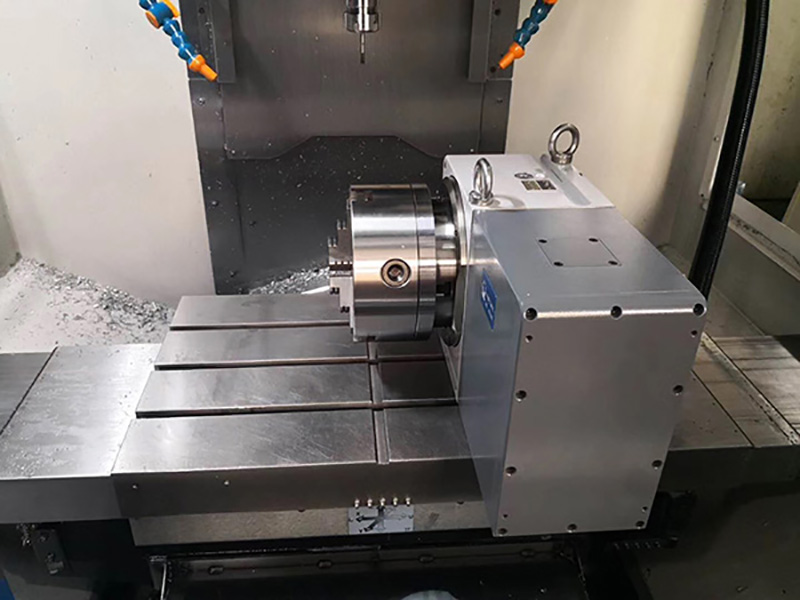

Martin Trunnion Tables offers complete 4th axis packages for Samchully rotary tables. Ready to be mounted into your machine, your Stallion Trunnion Table will already be attached to your Samchully rotary table and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis CNC machining. Scroll down for examples and package options! Don"t hesitate to reach out to us to discuss your manufacturing needs. Our applications engineers are always happy to help!

All CategoriesRoot CatalogDefault CategoryAmplifier Power SuppliesAmplifiers, AC & DCFeatured AmplifiersAxis, Rotary & Turret MotorsBallscrews, Assemblies & Parts1) Ballscrew Only2) Ballscrew Assemblies4) Ballscrew Covers5) Ballscrew NutsBearings & KitsBelts & Belt GuidesBreakers & FusesBrushes, DC MotorCables & Wire HarnessesChain & Sprocket KitsChiller UnitCircuit Boards1010 Axis/Spindle1020 Clock Boards1030 Cmptr. Interface1040 Mill Interface1050 M Function1060 Mother Boards1090 Keyboards1100 Power Distribution1400 CPU Boards1420 Video Boards1460 Memory Expansion1550 Chiller Boards1610 Software Modules1900 Pendant InterfaceAll Other CNC BoardsUpgrade KitsCouplersCylindersDoor PartsDow Frost, Epoxy, GreaseDrawbar & Spindle PartsElectrical PartsEncoders, Resolvers & Tach.Eproms & SoftwareFansGibs & StrapsHardware, Misc. PartsHydraulic ActuatorIdler PartsKeyboardsLights and LampsLinear GuidesLube & Plumbing PartsMonitorsMPG Remote & PartsO-RingsOrientation PartsPower SuppliesPulleysPumps & Pump PartsRegulatorsRelaysRotary HeadsRotary Parts & KitsSealsSensors & SwitchesService ToolsSpindle DrivesSpindle Motors & PartsSpindles, New & RemanTool Changer PartsTransformersTurcite Kits & EpoxyValvesWay Covers & WipersUSB Mass StorageSprings1330 Dual Arm (DATC)New ArrivalsWaycoversLoad MeterTension Idler PartsLCD DisplaysSpecial OfferReman, Circuit Boards3) Bearing MountsFadal DecalFadal DecalScalesItsfadalpartsMotor MountsWay Lube CarriersHoses & Tubing

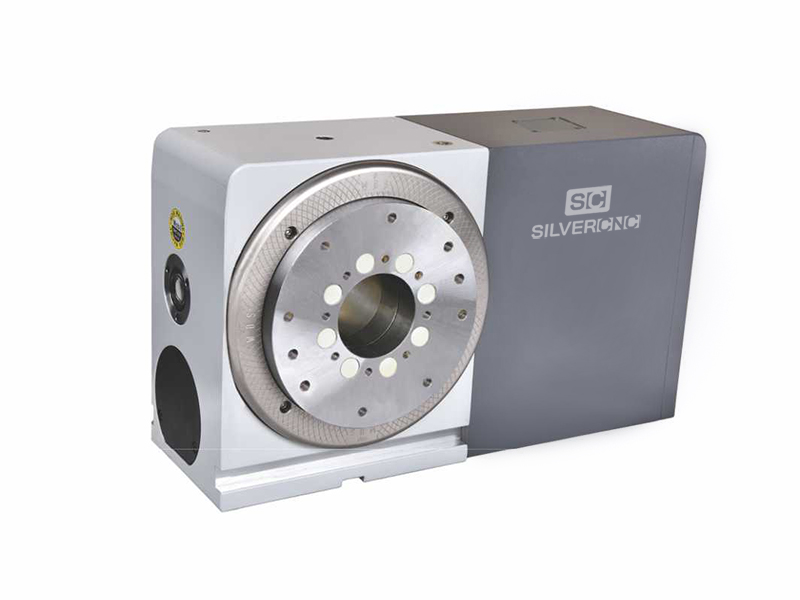

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

Let"s first have a look at the background of the video. In the video, the 4 axis multi head cnc router EA-1825RMS10 is milling 3D furniture parts with solid wood. There are two procedures in total: roughing and finishing. Two types of bits ( 12.7mm straight flute bits and 6mm V-shaped bits) and two pieces of toolpath files are used. Now you probably have a question:

A: For the exact design in the video, it takes 6 hours to finish. We got 10 pieces in 6 hours since 10 spindles and 10 pieces of the 4th axis work together. By calculation, we can know that each piece costs 0.6 hours on average.

Its biggest advantage comes from its dual-application working platform, a dual exchange table system for rotary and flat milling. The two platforms can be switched at will according to actual production requirements. One end of the rotational platform is a mobile carriage; when the flat platform is required, the mobile carriage can be pushed to the rear part of the machine and leave space for the flat table. So, we can get the flat table installed there and execute flat machining.

In order to make the installation easier, we installed several small pulleys under the flat table. Same as the rotational table, it is supported by the heavy-load round linear guides as well.

• The electrical part is designed with the most reliable performance standards. As shown below, the machine uses a total of 6 sets of Yaskawa servo motion systems; both the headstock and the Y-axis are dual-driven; It also uses 10 inverters, so that each one controls an electric spindle; this combination is undoubtedly the most reliable one since one control one is more stable than one control couple.

• The multi-head 4th axis cnc router machine is equipped with a WEIHONG 4-axis simultaneous motion controller based on the windows system. This is because multi-head router machines are mainly used for engraving, and the tool path files of such machining are often very large; a computer is prior to a handheld DSP unit on the performance of both reading and running files.

A: This machine has 10 spindles, and they are often worked simultaneously, so the load on the Z-axis is relatively heavy. If the machine uses the same Z-axis transmission structure as the ordinary machine, this part will soon stop working. In addition to the use of servo motors and dual-balanced cylinders, EagleTec CNC has also made a reasonable transformation of the connection between the motor and the ballscrew, which offers splendid durability in the Z-axis.

8613371530291

8613371530291