fourth axis rotary table price

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

2022 top rated 4 axis CNC router 1325 with 4x8 rotary table (4th axis) is popular for woodworking, cabinet making, home decorations, mold making, sign making, arts, and crafts, now the best budget 4x8 CNC wood router machine for sale at affordable price.

1325 refers to the CNC router table size of 1300mm x 2500mm, someone may name it as 4" x 8" by feet or 48" x 96" by inches. 1325 is the most common used model in CNC machines to make a full sheet project. As the name implies, it is named by the manufacturer according to the table size of the machine. The maximum table size is 2500mm in length, 1300mm in width, and 200mm in height. It is widely used in popular woodworking plans and projects, such as cabinets making, door making, home decoration, advertising, and sign making. CNC router 1325 is designed as 1325 single spindle, 1325 dual head, 1325 multi head, 3-axis 1325, 4th-axis 1325, 4-axis 1325, 5-axis 1325, and 1325 ATC CNC router with automatic tool changer spindle based on the configuration level.

4 axis is based on 3 axis, and the 4th axis (A axis) is added to the rotation axis. In addition, 4 axis is divided into four-axis three-linking and four-axis four-linking CNC machines, adding a rotating axis and the control system is also a four-axis linkage system to be called a true four-axis linkage CNC machine. Because of the rotary motion of the 4th rotary axis, 3D machining of cylindrical, arc, and circular surfaces is realized.

If the 4 axis you purchased has only three feed axes (X, Y, Z), the Y axis can be manually replaced with a rotary axis, and only a maximum of three axes can be linked. This is a four-axis three-link CNC machine, which is also known as 4th axis.

If the 4 axis you bought has four feed axes (X, Y, Z, A), it can be processed by four-axis linkage, and it can process planes, reliefs, cylinders, non-standard three-dimensional patterns, corner repair of 3D patterns, etc.

The rotary axis CNC router kit uses a DSP handle industrial control system. The four-axis linkage control has excellent and stable quality, good maintainability, and usability. It can control the completion of the 3D machining of the cylinder and the rotation of the tetrahedron. It is suitable for three-dimensional sculpture of figure statues and legs of European furniture. The cylinder engraving machine has the following advantages:

Woodworking industry: 3D wave board, furnitures, solid wood door, kitchen cabinets, wardrobe cabinets, tables, beds, computer desk, table legs, sofa legs, wood crafts, paint door, screen, windows, shoe polisher, game cabinets and panels, mahjong table, auxiliary machining.

4 axis CNC machine can do all 3 axis CNC machine can do. The 4 axis spindle (B axis) can rotate ±90 degree, which is suitable for side milling, drilling, cutting, lock slot and so on. It is especially designed for processing on different 3D curved surface carving.

We will offer you with our detail quotation according to the consulted 4x8 CNC machine. You will get the most suitable specifications, the best accessories and the affordable price.

All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

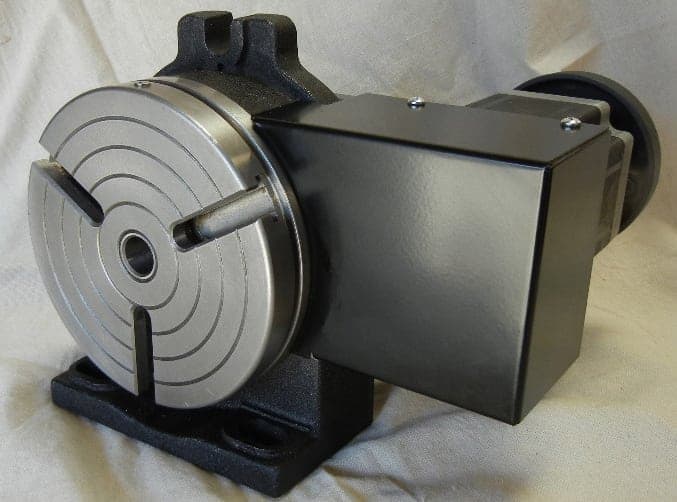

Our rotary table has a custom mount, 3.25" chuck with machinable and replaceable jaws. The custom made low inductance 280oz stepper motor is also included.

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

This is a really nice used Troyke 5C Dual Head CNC 4th Axis Rotary Table. It is set up with built in pneumatic collet closing units.This is ready for you to put right into production!

USED 16" WALTER 400 NES $ 7,500.00This is a Used 16" Walter 400 NES CNC 4th Axis Rotary Table. Quality German Built Rotary Table. Turn your Vertical into a Horizontal. SEE OUR CHICK TOMBSTONES in my other listings as well !!

In a four-axis CNC router, there is an additional rotary axis (A-axis) that allows you to do rotary cutting and indexing for making cylindrical/round parts.

PRO4896 CNC uses a PRO rack and pinion system with linear guides to guide the X and Y-axis machine movement. Y-axis is driven by two stepper motors to prevent it from racking.

Avid provides many upgrade options for the PRO4896 CNC. The Rotary Axis attachment is the one you need to achieve fourth axis capability on this CNC router.

Their post-processor uses inverse time feed rates that prevent the production speed from slowing down during programs with combined linear and rotary motion.

The rotary axis is highly versatile, it can be mounted to the PRO4896 CNC router parallel to the X or Y-axis and can be recessed to the machine to help maximize the workpiece diameter.

The 49" rotary axis used in the Avid PRO4896 CNC router can be mounted with a maximum workpiece length of 34" if mounted parallel to Y-axis, and 28" if mounted parallel to X-axis.

Avid CNC"s post-processor for rotary control is available for all the Ventric software products and for the Autodesk Fusion 360 software. It can be downloaded either directly from the Avid CNC website.

They also have detailed instructions on assembly, different mounting options, and the electronics of the rotor axis. It is available on the website and in the user manual.

Avid offers various accessories like a leg kit, auto Z and corner finding touch plate, proximity sensor kit, composite nailer, dust shoe, plasma kit, and a rotary axis.

The chuck and tailstock of ShopSabre"s 4th axis system don"t come attached to a frame, so each can be mounted on the worktable in different configurations.

ShopSabre 23 has a wide list of accessories like the 4th axis kit, braille kit, computer mount, digitizing touch probe, laser sight, tool measure switch, tabletop, vacuum pump, warning light bar, and wireless pendant.

GDAE10 6040 CNC router is the best budget-friendly 4-axis CNC router on this list. It comes with a rotary axis that can be attached along the Y-axis to attain 4-axis control.

The fourth axis control in GDAE10 6040 CNC is achieved through a rotary system with a 3-jaw chuck and a tailstock. It comes with a belt, tailstock, rotary axis, and five wrenches.

There are a lot of videos on youtube on cutting different materials using GDAE10"s 4th axis, you can refer to them to get a visual idea of its operation.

The 6040 CNC router has a large user base because of its low price. It is a great introductory 4-axis CNC to many people trying to come into 4-axis CNC machining.

The iQ CNC router machine can be upgraded with the Laguna Fourth-Axis Attachment for achieving 4-axis control. It helps you machine complicated designs.

The 4th axis attached to Laguna iQ can work on workpieces having a length ranging from 12" - 26" and a maximum diameter of 7" depending on the optional table size you opted for.

You can use 4-axis G-codes generated from any G-code generator directly on Laguna iQ through a USB flash drive and iQ CNC can operate without a computer.

Next Wave CNC"s Shark HD520 is a popular choice among small businesses and many woodworkers. It can do 4-axis machining with a 4th axis rotary system installed in its work area.

The Shark HD520 CNC can be upgraded with the Shark Standard 4th axis rotary system. The rotary system provides 4-axis machining capability to your HD520 CNC router.

You can place the 4th axis driver board on the controller slot by facing the pins out of the box, then you"ll have to tighten it with provided screws to hold it in place.

The 4th axis post-processor can be downloaded from the Next Wave CNC"s website. These post-processors are used to process and convert designs and toolpaths to CNC readable G-Code.

In most cases, a 4-axis router kit is used to achieve 4-axis machine movement but to control this additional axis you"ll need to have a 4-axis compatible controller.

To put it in a simple form, the standard 3-axis together with the A-axis gives you a 4-axis setup. A-axis is the rotational axis that turns the workpiece.

4-axis machining brings in a great deal of flexibility to your CNC machining process, enabling you to create some of the complex designs that otherwise would not be possible.

4-axis CNC machines are costly because there is a lot of research and development going into building all these machines. You require 4-axis supported controllers, software, and CNC machines to do 4-axis machining.

Also, 4-axis designs require a high precision system to design those models. To make high precision systems you need to use a rigid machine built with well-calibrated electronics. As there are more moving parts in the machine, the operating complexity increases, and a lot of support systems are required to keep the machine running.

In 5-axis machining, two rotational axes operate separately to rotate the workpiece in many different angles with respect to the cutting tool. The machine may utilize either A-axis or B-axis with the C-Axis to achieve this feat, all these are rotational axes.

In 4-axis CNC machining only one rotational axis is there, but with 5-axis machining you can achieve two rotational axes that can operate independently. It brings in a great deal of flexibility in your CNC machining.

Yes, due to the advanced system, a 4-axis CNC requires specialized software to control the movement of the fourth axis. It requires CAM and control software that supports 4-axis machining. To control the machine properly, the software must understand the geometry of the 4th axis and how it relates to the other axes.

8613371530291

8613371530291