hacker rotary table supplier

All CategoriesBuildings (4)Drilling Equipment (162)Additional Drilling Equipment (1)Block (3)Centrifugal Pumps (2)Drilling Equipment - Misc. (1)Duplex Pumps (13)Power Swivels (15)Pump Parts (1)Pumps (54)Pumps - Misc. (10)Rotary Tables (7)Rotating Equipment (22)Sheaves (1)Traveling Equipment (4)Triplex Pumps (28)Drilling Equipment - Misc. (3)ENGINE (1)Fluid End Modules (2)Hoisting Equipment (5)Oilfield - Misc. (3)Additional Oilfield Equipment (1)Catwalks (2)Power Equipment (10)Air Compressors - Industrial (2)Engine Accessories (2)Engines - Other (3)Gear Boxes | Drives (1)Generators | Electric Power (2)Production Equipment (26)Compression Equipment (3)Gas Compressors (3)Tanks (6)Tanks - Misc. (4)Vessels - Horizontal | Vertical (2)Well Service Equipment (4)Well Service - Misc. (4)Pumps (69)Centrifugal Pumps (4)Duplex Pumps (12)Pump Packages (2)Pump Parts (3)Pumps - Misc. (18)Quintuplex Pumps (4)Triplex Pumps (24)Water Injection Pumps (1)Rig Structures (1)Rotating Equipment (28)Power Swivels (16)Rotary Tables (12)Support Equipment (36)Air Compressors - Industrial (4)Buildings (1)Catwalks (3)Doghouses (1)Engines - Other (8)Generators | Electric Power (2)Oilfield - Misc. (3)Power Equipment (14)Tanks & Vessels (15)Tanks - Horizontal | Vertical (1)Tanks - Misc. (12)Trailers (15)Traveling Equipment (16)Block & Hook Combos (4)Blocks (5)Sheaves (7)Triplex Pumps (4)Saltwater pumps (1)Trucks (2)Flatbed Trucks (1)Water Trucks (1)Well Service Equipment (9)Power swivels (1)Swabbing Unit (1)Triplex Pumps (1)

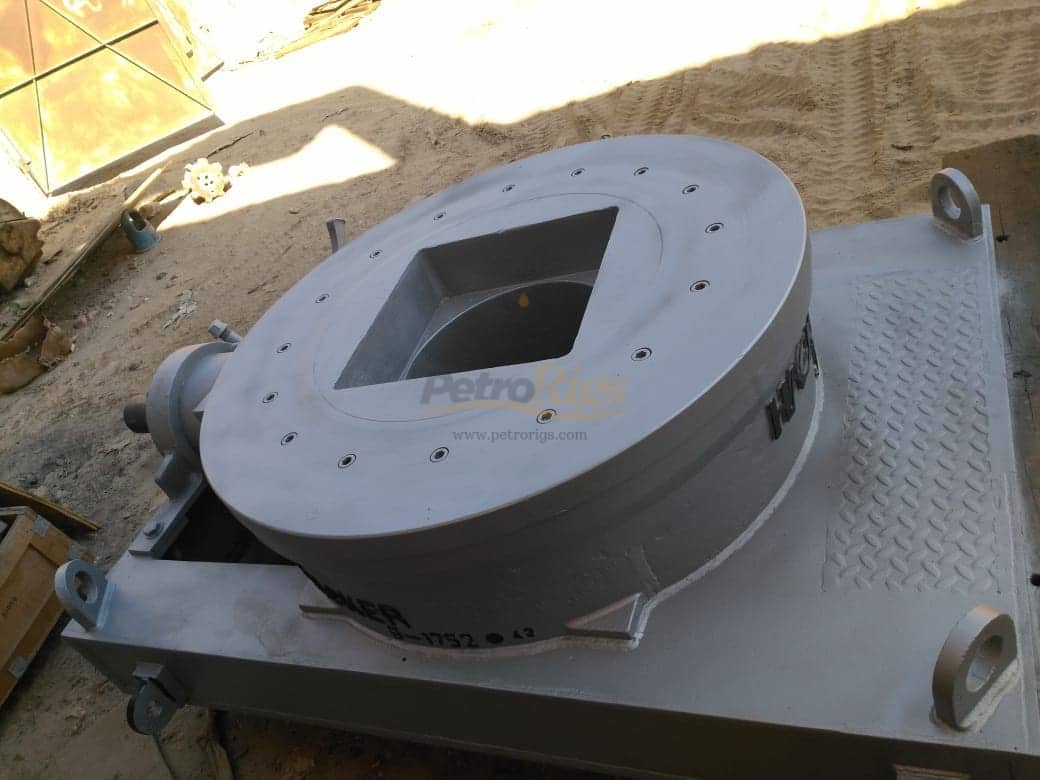

Manufacturer of drilling equipment; in-plant repair services; machine shop operations; threading per API specifications; rotary tables, kellys, drill collars, pipe straighteners, service & repair center, subs & API threading; API Spec 7 certified.

Looking for business intelligence data on Hacker International or other suppliers of Miscellaneous Product Manufacturer? Set up your free account with IndustrySelect.

EP Resources, Inc. was established in 2002 with the primary focus on using decades of oilfield experience to supply the industry with the highest quality oilfield equipment solutions. Today EP Resources, Inc. is the parent Company to EP Brake Solutions Inc., Hacker International LLC, Rig Systems & Components and EMT Investments.

Please note that while there are always risks associated with providing personal data, whether in person, by phone or over the Internet, and no system of technology is completely safe, "tamper or hacker- proof", Ringier Trade Media Ltd. has endeavoured to take appropriate measures to prevent and minimize risks of unauthorized access or improper use of your personal information.

We are proud to endorse your product and your company. We purchased the first mats for our rigs over 25 years ago and have continued to do so for every one of our now 20 rigs. We tried an import mat made of some kind of recycled material about 5 years ago, but it quickly started curling and created a trip hazard on our rig floor. We have also purchased your racking mats and center mats which have held up as well as the rotary mats. At Scandrill Inc. we appreciate the long term relationship and your willingness to repair or replace lost sections or damaged mats years and years after the original purchase date.

Our first Safety Pad II was installed on Rig #13 in November 1981. Since then, Rig #13 has logged over 700 operating days and the pad is still providing an effective slip resistant working surface around the rotary table. As you are aware, we continued purchasing Safety Pad II until all 17 of our land based rigs were equipped.

I am convinced that the Safety Pad II has been one of the wisest and most cost effective rig safety equipment investments we have made. I have not identified a single injury where insecure footing around the rotary table was the primary cause or a contributing cause, where the Safety Pad II was in use. I believe the secure fotting that the pad provides has been an important contributing factor to the 69% reduction in our disabling injury incidents rate from 1981 to 1984.

First off, the Safety Pad II reduces slip and fall incidents to practically nil. Employees are able to maintain traction around the rotary table even though it may be wet or covered with drilling fluids. Trip time, both going in and coming out of the hole is reduced as much as thirty (30) minutes per trip which equates to one hour per round trip.

On board "WEST VANGUARD" it has been in use approximately 10 months. We may also add that during this period, there has not been a single slip-fall injury on the rotary table.

It must be some of the best to be found on the market. We are extremely satisfied with it, and it has not been damaged at all. Subjected to very rough treatment. The undersigned introduced it on "WEST VENTURE" having seen it in use on "VILDKAT" where they also use oil based mud. It gives a remarkably good "footgrip" and despite spills of oilbased mud, it has increased the safety to the workers. Use of other remedies, such as Wallnut shells etc, has not nearly the same effect. These are dissolving, and may cause problems to the ball bearings for the rotary. It is strongly recommended by the undersigned.

I wanted to write you to let you know how much we have enjoyed your product, Safety Pad II. I have talked to the toolpushers on both hitches and most of the men we have on the Gulfdrill who are using it. Everyone has told me it"s the best way that they have seen yet to control the problem of slipping down on a muddy rotary table. From a safety supervisors out look it"s working out better than I thought. We have almost eliminated all of our accidents on the floor due to falls or slipping down with the Safety Pad.

All crews on Continental Drilling Co. Rig #3 would like to thank the company for providing the rotary table mat on this rig, and would like to have these mats around floor as well.

MIDWAY2500 DRILL RIG (Ref#6722T) Gardner Denver 5-1/2 x 6 mud pump, 350x600 LeRoi air compressor with spare compressor for parts, 44M drawworks with spare 34M drawworks, injection pump for air drilling, Midway retractable rotary table, extended derrick with racking b oard to stand back drill pipe, both kelly block and hoist block are 4 line 19 x 7-5/8 non rotating with 2 spare spools (one 255" for kelly and 275" for hoist block), mounted on 1999 Kenworth tandem axle truck with Cat 3406E Cat engine, PTO

MIDWAY M1(Ref#1929T) Manufactured 1980"s, needs new truck, 5 x 6 mud pump, air compressor (air drilling), 18" retractable table, breakout wrench, rod box, 4 hyd leveling jacks, 3-7/8" x 25" kelly, mechanical clutches, pulldown chains need replacing, no pipe Price: $44,500

MIDWAY 2250 DRILL RIG(Ref#4410T) Manufactured 1975, mounted on 4 axle Crane Carrier, completely out of frame overhaul on 350 Cummins in 2014, 10 speed transmission, 12" Hacker rotary table, chain cases rebuilt 2009, drawworks 20,000 single line pull with both kelly and trip on six part line, 2rd sandline drum, 10,000# aux hyd winch new 2010, Gardner Denver 6 x 12 mud pump with twin 6 Detroits, Reusch 512 H pipe spinners new in 2010, Satellite Automatic Driller new 2010, elevators, slips, subs, 65 jts of 3-1/2" pipe, 32 jts of 4" pipe, (2) 30" drill collars, 48" flatbed pipe trailer, 35" oilfield float, 300 bbl water tank, doghouse with 2-pen Geolograph, skidded base for rig POR

MIDWAY 2250(Ref#10286Ta) Manufactured 1975, 3 drum drawworks – water cooled, 6 line traveling blocks 5/8" cable, hydraulic pull down, weight indicator, hydraulic spin chain and hydraulic spinners, 50" square tube derrick, 3-1/2" x 34-1/2" square kelly, 7-1/2" rotary table, Gardner Denver FXD 5-1/2" x 10" mud pump, mounted on Western Star truck, 4 leveling jacks Price: $255,000

MIDWAY 2000 MUD ROTARY DRILL RIG WITH REVERSE CIRCULATION CAPABILITIES(Ref#1081T) Refurbished, excellent condition, 10" boom extension, 6 x 10” Gardner Denver mud pump, Detroit 8V91 engine (rebuilt with low hours), 13” retractable table, 4 part kelly line, 4 part tool line, separate sand line, hydromatic brake, air clutches/throttle, weight indicator, 3” King swivel, 5” x 27’ hexagon kelly, automatic pump oiler, mud standpipe, air standpipe, reverse standpipe, 12VLED lighting, derrick mounted ladder with safety system, all bushings and wear items are brand new, mounted on brand new custom trailer Price: $370,000

MIDWAY 1500(Ref#11488T) 7-1/2 x 8 Gardner Denver mud pump, 667 GD air compressor, 5-1/2" retractable table, hydraulic pulldown, mounted on 2000 Peterbilt truck with Cummins engine, PTO

MIDWAY 1500(Ref#15626R) Manufactured late 1970’s, no mud pump, square kelly, no pulldown, 8” retractable table, mounted on newer Freightliner truck with diesel engine, air clutches, no pulldown, breakout tongs, 1 front and 2 rear hydraulic leveling jacks, no rod box, no pipe rack, 300’ of 20’ drill pipe (2-3/8” IF), Price: $54,500

MIDWAY 1500(Ref#5407) Manufactured 1977, Model D1500WM39, drawworks air clutches, 42" mast, hydraulic drive, 8-1/2" retractable rotary table (rebuilt gear and pinion), hydraulic chain pulldown, Gardner Denver 5-1/2 x 8" mud pump, 5-1/2" slim hole to 1800" or 7-1/2" hole to 600" depth capacity, 2 winches, 2 rear hydraulic outriggers, rear operator hydraulic controls, 1100" of 20" pipe rack capacity, Mounted on 1977 Ford 9000 tandem axle cab and chassis w/400 Cummins diesel (REBUILT), recent out-of-frame rebuild, 5/4 transmission, 254" WB, 58,000# GVW (44,000# rear), Hendrickson suspension, 11.00 x 24 tires on Budd wheels, dual saddle tanks, tool boxes, overall good condition Price: $185,000

MIDWAY 1500HD(Ref#2038N) Manufactured 1980, 54" derrick with racking board, mounted on 1980 Ford tandem axle truck with Cummins 350 hp diesel engine, 4 leveling jacks, 5 x 8 mud pump, 7-1/2" retractable table, air clutch, chain pulldown, tools, wrenches, handling tools, currently drilling, includes Volvo pipe truck and 1700" of 2-7/8 IF x 20" drill pipe, doghouse with geolograph, Price: $325,000

MIDWAY 1300(Ref#4417) Manufactured 1975, 5 x 6 mud pump, 100S LeRoi compressor, mounted on 1995 International truck with 60 Series engine, 3-5/16" kelly, 7-1/2" fixed table, drill pipe Price on Request

MIDWAY 1300(Ref#3054N) Manufactured 1980, one owner/operator, 5 x 6 mud pump, 100 SDS LeRoi air compressor, mounted on 1980 Ford LT9000 tandem axle truck with 6V71 Detroit engine, 8-1/2" retractable table, 4" x 25" kelly, mechanical clutches, pulldown, 2 rear hydraulic leveling jacks, 400" of 2-7/8" x 20" pipe, some tools, excellent condition PRICE: $110,000

MIDWAY 1300(Ref#15314R) Manufactured 1978, mounted on 2006 Sterling 1300 with Mercedes diesel engine, approx 190,000 miles, PTO, Gardner Denver 5 x 8 mud pump, air compressor, 25" kelly, pulldown, mud tub, breakout tongs, brand new Gardner Denver non-retractable table used on less than 10 wells, new cable, pulleys and gearbox on tower, 540" of 2 3/8" x 20" drill pipe, new paint, good condition PRICED: $137,500

MIDWAY 1250(Ref#12353R) PTO, mounted on 1991 Mack with diesel engine, 5x6 mud pump, GD air compressor, 7-1/2" stationary table, pulldown, manual clutches, rod rack, 2 hydraulic leveling jacks, good condition Price: $67,500

MIDWAY 1200M(Ref#11519R) mounted on tandem axle Ford truck with diesel engine, 5x6 GD mud pump, 667 air compressor, 7-1/2" retractable table, 23-1/2" kelly, cathead, sandline, 3 leveling jacks, 300" pipe, currently drilling Price: $64,500

MIDWAY 15M(Ref#4410T) Manufactured 1982, extended derrick, 5-1/2 x 8 mud pump, 10" retractable table, no air, mounted on 1982 International truck Price: $92,500

MIDWAY 15M(Ref#7588R) Manufactured 1980, Midway 1500 drawworks, PTO, mounted on 1980 International f-2574 with 1996 Detroit engine, 10 sp transmission, 38000# rear axles, 24.5 bud wheels, 16000# front axle w/22.5 floatation tires, 4 leveling jacks, 5 ½ x 8 mud pump, new 8-1/2" Midway retractable table, 3-3/4" x 34" fluted kelly (new 2011), 3-3/4" x 5-1/4" new master bushing, 49"2" mast with new cylinders (can run 44"5" casing), 3" plumbing, 2" swivel, 2" kelly hose, hydraulic pulldown, new drivemotor 2013, hydraulic cathead, 792 Spicer transfer case (rebuilt 2013 with air controls), new lifting cylindes on mast, new main hyd pump 2012, 4 part linesm BVM breakout tong, heavy duty work floor with hinged trap door

MIDWAY 15M(Ref#5506R) Manufactured 1980, 38" x 60,000# hydraulically raised mast, mounted on International Paystar 5000 truck with Detroit diesel engine, hydraulic leveling jacks, 5-1/2 x 8" Gardner Denver duplex mud pump; 4" suction hose and 3" discharge, has air surge chamber, Detroit diesel on deck, 8-1/2" rotary table retractable to 18", 5 speed transmission, speeds 26 – 185 rpm, Depth capacity: 1500" (457m) with 3-1/2" drill pipe, 2,000" (610m) with 2-7/8" drill pipe, 2,500" (762m) with 2-3/8" drill pipe, located Europe Price: €100,000 Euros

MIDWAY 15M(Ref#5797RA) Manufactured 1979, PTO, mounted on 1979 Mack tandem axle truck with diesel engine, 47" mast, 5 ½ x 8 GD mud pump, 600/250 air compressor, 8" retractable table, 3" swivel, double drum, chain pulldown, 3 leveling jacks Price: $200,000

MIDWAY 15M(Ref#5797RB) Manufactured 1976, PTO, mounted on 2006 Mack tandem axle truck with diesel engine, 47" mast, 5 ½ x 8 GD mud pump, 600/250 air compressor, 8" retractable table, 3" swivel, double drum, chain pulldown, 3 leveling jacks Price: $235,000

MIDWAY 13M(Ref#5393R) 5 x 6 mud pump, 8-1/2" retractable table, new tires, 4 hydraulic leveling jacks, 400"+ of drill pipe, good condition Price on request

MIDWAY 13M(Ref#6704R) Manufactured 1977, 600 cfm Leroi air compressor, 5 x 6 Gardner Denver mud pump, 8-1/2" table retractable, pull down, 9 gpm Bean pump, mounted on 1977 Ford 9000 truck with 671 Detroit engine (overhauled 2014), 600" of 2-7/8" drill stem, well maintained, ready to work PRICE: $105,000

MIDWAY 13M(Ref#14795T) Manufactured 1978, PTO, mounted on 1979 Ford 9000 with Cat engine, 5x6 mud pump, Leroi 750cfm air compressor, 3" x 23" kelly, 8" stationary table, breakout wrench, rod box, hydraulic pulldown, mechanical clutches, mud pan, 300" of 2 7/8" x 20" drill pipe, no leveling jacks, good running condition PRICE: $54,500

MIDWAY 13M(Ref#5387N) Manufactured 1970"s, mounted on 1980 International tandem axle truck, 671 Detroit diesel, 13 speed transmission, 7-1/2 x 10" gaso pump, stationary table, tools, 560" of 2-3/8 packer pipe (brand new), Needs paint, sitting one year

2022 top rated 4 axis CNC router 1325 with 4x8 rotary table (4th axis) is popular for woodworking, cabinet making, home decorations, mold making, sign making, arts, and crafts, now the best budget 4x8 CNC wood router machine for sale at affordable price.

1325 refers to the CNC router table size of 1300mm x 2500mm, someone may name it as 4" x 8" by feet or 48" x 96" by inches. 1325 is the most common used model in CNC machines to make a full sheet project. As the name implies, it is named by the manufacturer according to the table size of the machine. The maximum table size is 2500mm in length, 1300mm in width, and 200mm in height. It is widely used in popular woodworking plans and projects, such as cabinets making, door making, home decoration, advertising, and sign making. CNC router 1325 is designed as 1325 single spindle, 1325 dual head, 1325 multi head, 3-axis 1325, 4th-axis 1325, 4-axis 1325, 5-axis 1325, and 1325 ATC CNC router with automatic tool changer spindle based on the configuration level.

4 axis is based on 3 axis, and the 4th axis (A axis) is added to the rotation axis. In addition, 4 axis is divided into four-axis three-linking and four-axis four-linking CNC machines, adding a rotating axis and the control system is also a four-axis linkage system to be called a true four-axis linkage CNC machine. Because of the rotary motion of the 4th rotary axis, 3D machining of cylindrical, arc, and circular surfaces is realized.

If the 4 axis you purchased has only three feed axes (X, Y, Z), the Y axis can be manually replaced with a rotary axis, and only a maximum of three axes can be linked. This is a four-axis three-link CNC machine, which is also known as 4th axis.

The rotary axis CNC router kit uses a DSP handle industrial control system. The four-axis linkage control has excellent and stable quality, good maintainability, and usability. It can control the completion of the 3D machining of the cylinder and the rotation of the tetrahedron. It is suitable for three-dimensional sculpture of figure statues and legs of European furniture. The cylinder engraving machine has the following advantages:

Woodworking industry: 3D wave board, furnitures, solid wood door, kitchen cabinets, wardrobe cabinets, tables, beds, computer desk, table legs, sofa legs, wood crafts, paint door, screen, windows, shoe polisher, game cabinets and panels, mahjong table, auxiliary machining.

4 axis CNC machine can do all 3 axis CNC machine can do. The 4 axis spindle (B axis) can rotate ±90 degree, which is suitable for side milling, drilling, cutting, lock slot and so on. It is especially designed for processing on different 3D curved surface carving.

We will offer you with our detail quotation according to the consulted 4x8 CNC machine. You will get the most suitable specifications, the best accessories and the affordable price.

All the CNC routers can be shipped worldwide by sea, by air or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with name, email, detailed address, product and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

CNC router with 4 axis rotary is STYLECNC STL1325R model, you can choose different diameters for the 4 axis rotary device, such as 100mm, 150mm, 200mm and 300mm.

The term “hacker” is popularly associated with cybercriminals harboring malicious intentions, when in reality, it’s a lot more. A hacker can be anyone who utilizes their computer software and hardware knowledge to break down and bypass a computer, device, or network’s security measures. It’s popularly believed hacking is illegal on principle, which isn’t the case if a system owner willingly and knowingly grants access. In fact, many private entities and government agencies hire hackers to help maintain their system’s security.

There are two main factors that determine what type of hacker an individual is: their motives and legality of their actions. Hackers are divided into three types—white, black, and grey hat, a naming system that was derived from old western films, where the protagonists would always wear white hats and vice versa for villain characters.

Black hat hackers are normally responsible for creating malware, which is frequently used to infiltrate computerized networks and systems. They’re usually motivated by personal or financial gain, but can also participate in espionage, protests, or merely enjoy the thrill. Black hat hackers can be anyone from amateurs to highly experienced and knowledgeable individuals looking to spread malware, steal private data, like login credentials, along with financial and personal information. Upon accessing their targets and depending on their motives, black hat hackers can either steal, manipulate, or destroy system data.

Also known as “ethical hackers,” they’re often employed or contracted by companies and governmental entities, working as security specialists looking for vulnerabilities. While they employ the same methods as black hat hackers, they always have permission from the system’s owner, making their actions completely legal. White hat hackers implement strategies like penetration tests, monitor in-place security systems, along with vulnerability assessments. Ethical hacking, the term used to describe the nature of a white hat hackers’ actions, can even be learned through independent sources, training, conferences, and certifications.

As the name suggests, these individuals utilize aspects from black and white hat hackers, but will usually seek out vulnerabilities in a system without an owner’s permission or knowledge. While they’ll report any issues they encounter to the owner, they’ll also request some sort of compensation or incentive. Should the owner not respond or reject their proposition, a grey hat hacker might exploit the newfound flaws. Grey hat hackers aren’t malicious by nature, but do seek to have their efforts rewarded. Since grey hat hackers don’t have permission to access the system by its owner, their actions are ultimately considered illegal, despite any alarming findings they might reveal.

The first step was to work out rough sizing. I drew a circle in Solidworks and laid out a pentagon around it – matching the design from the show. Solidworks is pretty pricey if they don’t sponsor your Hackerspace with a license (Thanks Dassault!), but you don’t actually need it - I just used it because it was a quick way for me to get a basic idea. I laser cut the parts out of scrap plexiglass, built a few test bracelets in different sizes, and they were all terrible. Turns out wrists aren’t pentagon-shaped, so the corners constantly caught on things, and the whole bracelet was far too bulky. While accuracy was a priority, I wanted to make this real, and real meant usability was the main priority. After playing with a few different polygons, I settled on a hexagon as the most comfortable shape. If you want to go with the original pentagon, you should be able to modify your part order to do so. I believe in you!

Hacker Radio Limited manufactured domestic radio and audio equipment. The company was formed in Maidenhead by brothers Ron and Arthur Hacker in 1959, and traded successfully until 1977. Financial difficulties resulted in the company being sold and relaunched with the name Hacker Sound which closed in 1979.

The Hacker brothers, Ron (born 1908) and Arthur (born 1910), founded Dynatron in the late 1920s with help from their father Harry, but in 1955 Ekco took over the company, which at the time employed 150 people. By 1959, the number of employees had risen to 250, but the Hacker brothers were uncomfortable with the arrangements and decided to set up their own company, Hacker Radio Limited. In December 1960 Ekco merged with Pye, then Pye was bought by Philips in 1967. In 1981, Roberts Radio bought Dynatron from Philips.

The Hacker brothers acquired a factory in Cox Green, Maidenhead, and started producing a range of transistor portable radios, beginning with the RP10 Herald. Throughout the 1960s, profits were healthy and the workforce increased. In 1973, the company was awarded its first Royal Warrant of appointment, and gained a second in 1976. But financial difficulties experienced in the 1970s caused the company significant problems, and despite cost-cutting measures, the firm"s bankers called in the receivers in May 1977. The assets were bought by Pullmaflex and the company reformed as Hacker Sound; the Hacker brothers were retained as consultants. Arthur Hacker"s son John, who had been made a director in 1975, was made Technical Director. However, difficulties continued, and the company was bought by Motoradio, who moved the operation to Bournemouth. Finally, a fire put an end to activities, and the Hacker trademark was purchased by Roberts Radio.

Hacker Radio primarily marketed its products to the UK domestic market, and were priced towards the top of the market. This, plus the relatively short period of operation (only two decades) results in a lower brand awareness today compared to other household names such as Roberts Radio. However, Hacker products have a strong following among vintage radio enthusiasts and collectors. An active group on Yahoo

The stated Hacker philosophy was to focus on technical performance rather than cost, and words to this effect are frequently found in printed material from the time. Many examples of their products survive today, and it is widely accepted among vintage radio enthusiasts that the build quality is higher than most similar sets from the same era.

Hacker produced many products during their 19 years of trading. Some of their more notable models are described below - a full list is available on-line.

The first product launched was the RP10 Herald. In common with many of their 1960s designs, this was built into a wooden case covered in leathercloth, with foam padding under the front and rear panels and a turntable to enable the set to be rotated for best reception (the internal ferrite rod aerial being highly directional). It featured a large (5 inch by 8 inch) 30Ω loudspeaker, and was powered by two PP9 batteries. Initial sets used Ediswan transistors; later sets used Mullard devices, including the AF117, which unfortunately went on to suffer from tin whisker formation within the encapsulation.

The next Herald, the RP30, retained the same loudspeaker and grill, but had a restyled cabinet that retained the padded leathercloth, which was available in charcoal black, blue or red (the latter with brass trim). The electronic design was revised, and the audio amplifier was rather more complex, incorporating rotary bass and treble controls. Coverage was MW and LW as before, but a version including short wave (16.5 to 50 metres) was offered (the RP31SW). Later, another version offering Marine Band (70 to 200 metres) in addition to MW and LW was released (the RP32), but this sold in relatively small numbers, and few exist today. These sets continued to use the Mullard AF11x-series of transistors.

Another AM Herald, the RP82, was introduced towards the end of Hacker"s existence, but these are very scarce indeed. Electrically, they are based on the very basic AM-only RP70 Ranger.

The RP37 VHF Herald looked like a third-generation Herald, but the presence of a telescopic aerial indicated that this is an FM-capable receiver; indeed it was an FM-only radio. Like most Hacker sets from the 1960s and early 1970s, this set used two PP9 batteries. They were available in the same colour choices as the RP35 AM Herald, and there was a variant with a revised scale in royal blue that incorporated the Open University logo in place of the local stations. The terms of this arrangement are presently unclear.

This was Hacker"s premium portable model, featuring AM and FM reception, and the name was used for four generations of the receiver. The first three versions featured separate tuners and IF stages for the AM and FM sections. The first generation, the RP18 Sovereign, was released in 1964, and was slightly larger than the contemporary Herald. The case was leathercloth-covered wood with padding for the front and rear panels, and was only available in charcoal black. The same large loudspeaker was used. The FM front end was bought in from German company Görler, and the rest of the tuner sections used Mullard AF11x-series transistors. User-adjustable station markers were provided to indicate the position of three favourite stations - but as these could only be moved over the lower half of the FM band (which only extended to 101 MHz), they were intended to locate the three national BBC services available at the time.

The final Sovereign - the RP77MB Sovereign IV - was rather different. It used simpler and cheaper circuitry that no longer had separate AM and FM sections. The case was somewhat larger because it was originally designed to accommodate a cassette mechanism; the RP77MB Sovereign IV was a radio-only version of the RPC1 radio-cassette recorder. The styling was similar to the previous model, with a black anodised finish to the aluminium components. The turntable was dropped for this model. As with the Sovereign III, operation is from eight D-cells or the mains supply, and MW, LW and FM (to 104 MHz) bands are covered. The amplifier circuitry is simpler than the Sovereign III; in fact, it"s electrically very similar to that used in the Sovereign II - though with some component changes. The loudspeaker is a 5 by 8 inch model made by Elac.

There was a variation of the third-generation Sovereign called the RP75 Super Sovereign. This took the basic RP72 Sovereign and added two short wave bands - the only Hacker set to include both FM and SW. Coverage was 10.9 to 33 metres and 27.5 to 89 metres. Electronic fine-tuning (band-spread) was provided, and switchable ISM returned to the FM band; separate switches are provided for ISM and AFC, unlike the Sovereign II where these functions were combined on one switch. A signal-strength (and battery test) meter was provided. Echoing the development of the RP72, a mains power supply was added (the RP75MB), then the FM coverage was extended to 104 MHz. With the MB models, an ATU (aerial tuning unit) was included to improve short-wave reception. The speaker fitted to the RP75 and RP75MB was the same as the RP72, but with a larger magnet.

The RP38 VHF Hunter was released in 1969, and was intended to be an "economy" set. It had MW, LW and VHF coverage. The cabinet was also cheaper to make and lacked a turntable. Initial models used the same 5" by 8" Goodmans loudspeaker as the contemporary RP35 Herald/RP25 Sovereign, but a model from Elac quickly replaced this.

An updated version followed a year later: the RP38A. This added bass and treble controls, using an amplifier that was electrically very similar to that in the RP35/RP25. This model was in production for many years, and went through several cosmetic changes before production ended in 1976. Initially available with side panels in finished hardwood or covered with black leathercloth, and black leathercloth covered front and rear panels (with no padding), the grill was thin aluminium perforated sheet which picks up dents rather easily. In 1973, a new grill was introduced - the same as the Sovereign III "family" - which was a heavy and thick aluminium extrusion. At some point afterwards, the handle is changed to a three-part unit that matches the rest of the Hacker range, and then towards the end of the run, the silver tone control knobs are replaced with black plastic versions. All versions of the Hunter have an FM band that is limited to 101 MHz (and non-switchable AFC).

In 1962, Hacker released the RV14 Mayflower; an FM-only valve table radio finished in striking veneers. Unusually for a Hacker, this set had coverage to 108 MHz - the FM front end was supplied by Görler. The audio sections were based around a pair of ECL86 triode/pentode valves that operated in push-pull, delivering around 7 watts in ultra-linear mode to a large (10 by 7 inch) loudspeaker. An EM84 "magic eye" tuning indicator valve was used.

Hacker made many mono record players, most of which could be converted to stereo with the purchase of a matching amplified loudspeaker; the GP15 Cavalier, GP42 Gondolier and GP45 Grenadier being commonly encountered examples. They also made a number of radiograms, and later music centres with matching loudspeakers and badge-engineered cassette decks from Japanese manufacturers including Sanyo and Nakamichi.

8613371530291

8613371530291