hiwin rotary table brands

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. HIWIN rotary tables are zero-backlash, extremely rigid, optimized for high torques, have robust dynamics and are especially well suited for tasks in a wide range of automation processes. Their lack of gear needed results in high efficiency and a quiet operation. Various sizes in diameter and height are available with the option to add a servo drive for a complete plug and play solution.

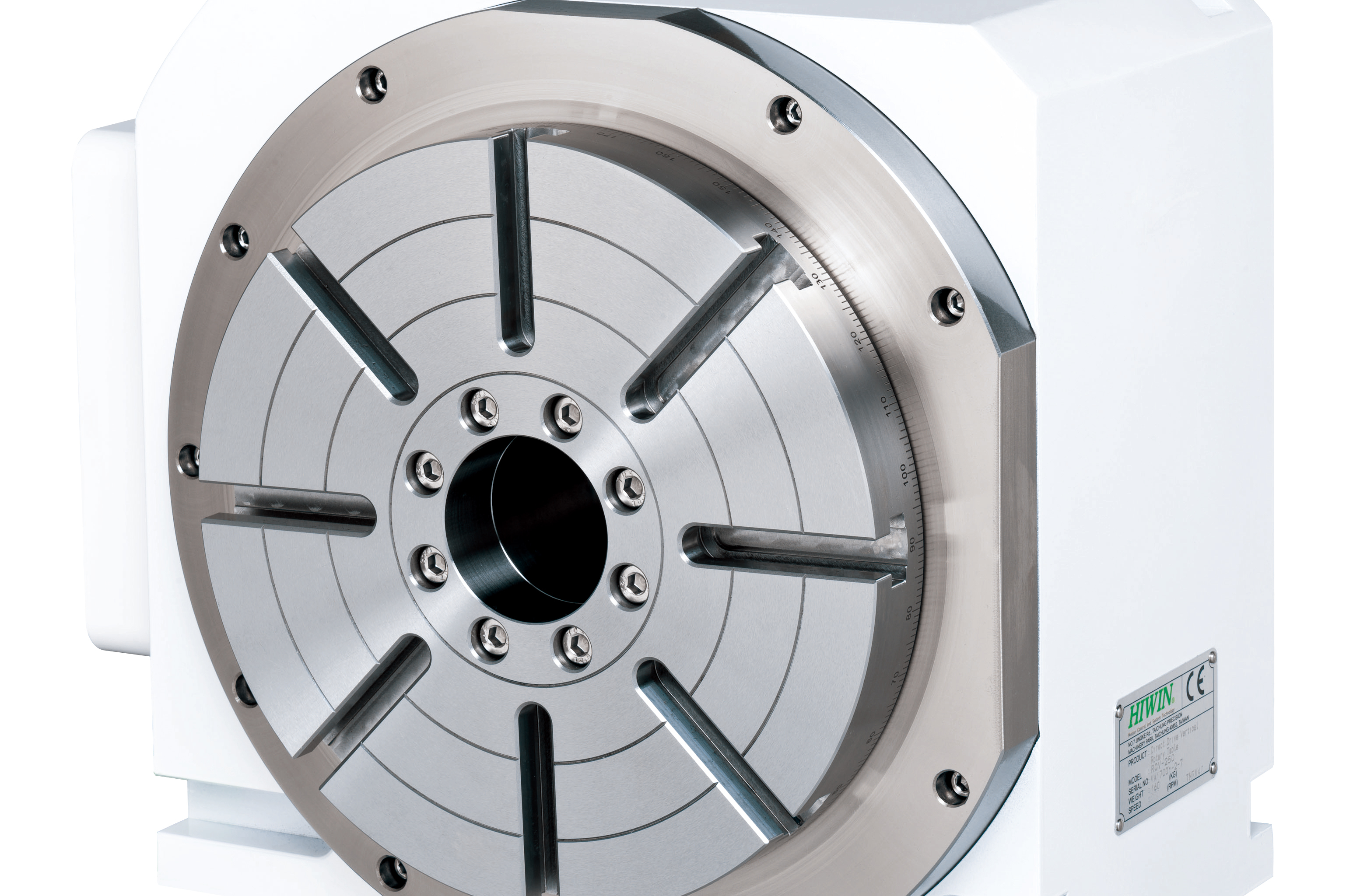

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

HIWIN Corp. will feature families of precision motion control components this year at IMTS, with their torque motor rotary tables as a highlight of their booth.

The TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates gear reducers, resulting in dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

The series is compatible with most major CNC brands and uses HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

HIWIN Corporation, a provider in motion control and system technology, will feature families of precision motion control components this year at IMTS, with their Torque Motor Rotary Tables, (TMRT), as a highlight of their booth. IMTS will be held September 12-17, 2022, in Chicago.

HIWIN’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlashes enable tighter part tolerance. Direct drives provide smooth motion, resulting in an improved part surface finish.

HIWIN Torque Motor Rotary Tables utilize HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Since 1992, HIWIN Corporation has focused on components, systems, and expertise in the motion control industry. HIWIN will be celebrating its 3oth anniversary in America at IMTS

HIWIN GmbH Brücklesbünd 1 D-77654 Offenburg Phone +49 (0) 7 81 9 32 78 - 0 Telefax +49 (0) 7 81 9 32 78 - 90 info@hiwin.de www.hiwin.de All rights reserved. Complete or partial reproduction is not permitted without our permission. Note: The technical data in this catalogue may be changed without prior

Motors, Drives & Accessories Direct Drive Rotary Tables HIWIN direct drive rotary tables are ready-to-install rotary axes that can be incorporated directly into the machine concept without the need for any design work. Thanks to the range of encoder interfaces provided, the direct drive rotary tables can be integrated easily into all commercially available machine control systems and thus all existing machine concepts.

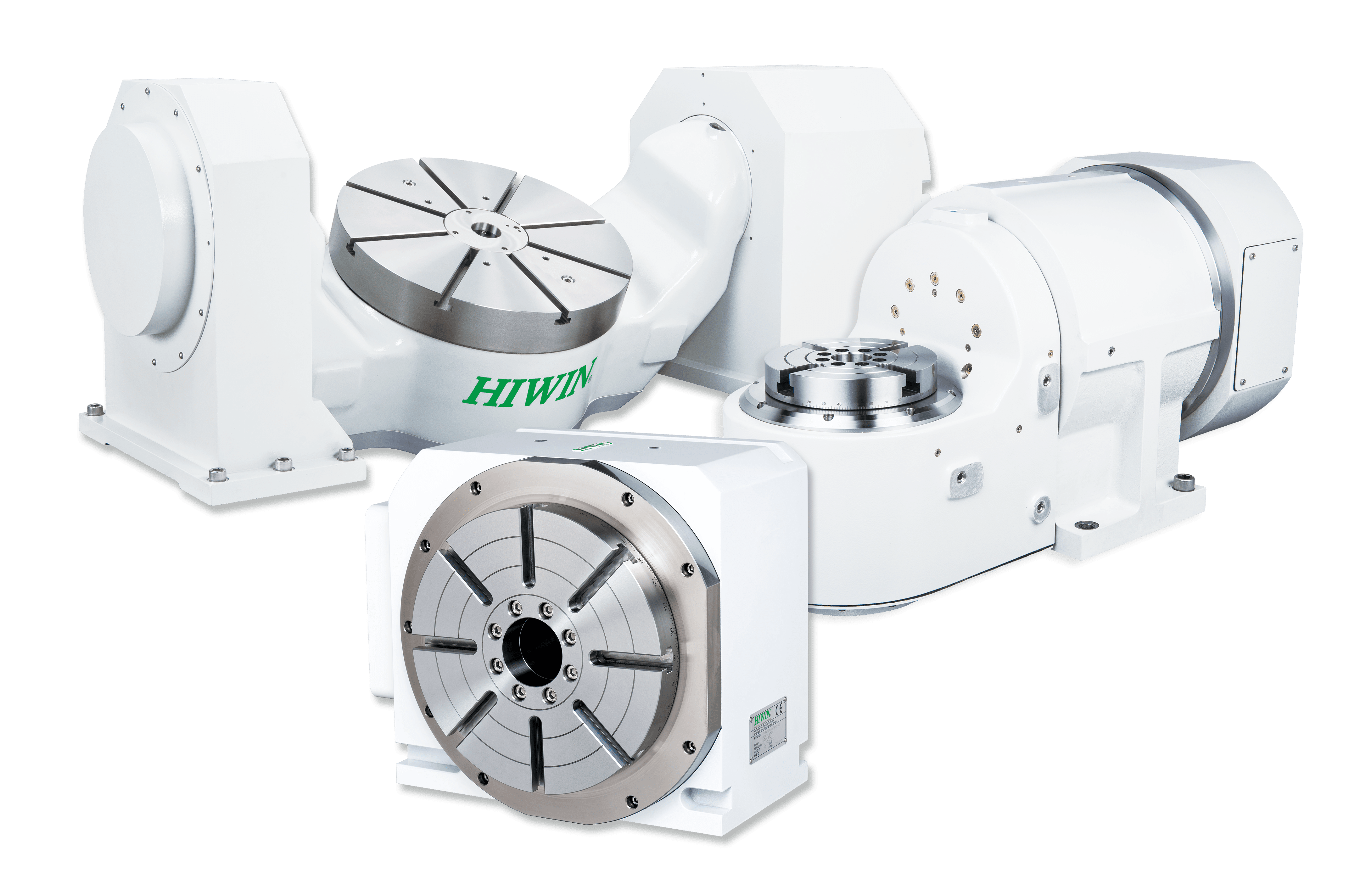

HIWIN RAB tilting axes { { Heavy-duty rotary and tilting axis Swivel drive on both sides HIWIN RAS tilting axes { { Vertical rotary table HIWIN RCH rotary tables { Compact rotary and tilting axis Swivel drive on one side HIWIN RCV rotary tables { Horizontal rotary table

Direct Drive Rotary Tables General information 2. General information 2.1 Properties of direct drive rotary tables HIWIN direct drive rotary tables are ready-to-install rotary axes that can be incorporated directly into the machine concept without the need for any design work. The maintenance-free direct drives they use ensure that the rotary axes deliver high-torque performance with exceptional accuracy. Thanks to the range of encoder interfaces provided, the direct drive rotary tables can be integrated easily into all commercially available machine control systems and thus all existing...

3. HIWIN RAB tilting axes 3.1 Properties of RAB tilting axes RAB tilting axes are directly driven, maintenance-free precision axes. They use water-cooled torque motors from the TMRW series, guaranteeing high levels of acceleration and torque. Equipped with various high-resolution encoders, the tilting axes achieve accuracies of just a few arc seconds and can be integrated into all standard control concepts. Featuring crossed roller and axial/radial bearings, the tilt-resistant mechanical design is able to accommodate maximum loads. Key features: { Plug-and-play tilting axis ready for...

Direct Drive Rotary Tables HIWIN RAS tilting axes 4. HIWIN RAS tilting axes 4.1 Properties of RAS tilting axes RAS tilting axes are directly driven, maintenance-free precision axes. They use water-cooled torque motors from the TMRW series, guaranteeing high levels of acceleration and torque. Equipped with various high-resolution encoders, the tilting axes achieve accuracies of just a few arc seconds and can be integrated into all standard control concepts. Featuring crossed roller and axial/radial bearings, the tilt-resistant mechanical design is able to accommodate maximum loads. Key...

Direct Drive Rotary Tables HIWIN RCV rotary tables 5. HIWIN RCV rotary tables 5.1 Properties of RCV rotary tables RCV rotary tables are directly driven, maintenance-free precision axes. They use water-cooled torque motors from the TMRW series, guaranteeing high levels of acceleration and torque. Equipped with various high-resolution encoders, the rotary tables achieve accuracies of just a few arc seconds and can be integrated into all standard control concepts. Featuring crossed roller bearings, the tilt-resistant mechanical design is able to accommodate maximum loads. Key features: {...

6. HIWIN RCH rotary tables 6.1 Properties of RCH rotary tables RCH rotary tables are directly driven, maintenance-free precision axes. They use water-cooled torque motors from the TMRW series, guaranteeing high levels of acceleration and torque. Equipped with various high-resolution encoders, the rotary tables achieve accuracies of just a few arc seconds and can be integrated into all standard control concepts. Featuring axial/radial bearings, the tilt-resistant mechanical design is able to accommodate maximum loads. Key features: { Plug-and-play rotary table ready for installation {...

Direct Drive Rotary Tables HIWIN RCH rotary tables 6.3 Dimensions of RCH rotary tables RCH-600 dimensions Ø350 Ø390 1) Size varies depending on the choice of distance measuring system

7. Selection tables for direct drive rotary tables Table 7.1 Control system compatibility with rotary table Series RAB FANUC MITSUBISHI Control system SIEMENS HEIDENHAIN NUM Syntec Lynuc Huazhong CNC GSK Compatible Table 7.2 Selecting a distance measuring system for the rotary table Series Distance measuring system

Direct Drive Rotary Tables Project planning sheet for direct drive rotary tables Project Planning Sheet Direct Drive Rotary drive rotary 8. Project planning sheet for directTables tables Company: Technical consultant: Purchasing consultant: Project name: Project plan (current state of project/schedule/aimed price) Product selection Series Table diameter Simultaneous machining Simultaneous machining Simultaneous machining Simultaneous machining Cyclic operation Cyclic operation Cyclic operation Cyclic operation Control system Operating mode Other brands ______________________ Available cable...

Linear Guideways Linear Axes Linear Axis Systems Torque Motors Linear Motor Components Rotary Tables Drives & Servo Motors Germany HIWIN GmbH Brücklesbünd 1 D-77654 Offenburg Phone +49 (0) 7 81 9 32 78 - 0 Fax +49 (0) 7 81 9 32 78 - 90 info@hiwin.de www.hiwin.de Taiwan Headquarters HIWIN Technologies Corp. No. 7, Jingke Road Taichung Precision Machinery Park Taichung 40852, Taiwan Phone +886-4-2359-4510 Fax +886-4-2359-4420 business@hiwin.tw www.hiwin.tw Taiwan Headquarters HIWIN Mikrosystem Corp. No. 6, Jingke Central Road Taichung Precision Machinery Park Taichung 40852, Taiwan Phone...

HIWIN GmbH Brücklesbünd 1 D-77654 Offenburg Phone +49 (0) 7 81 9 32 78 - 0 Telefax +49 (0) 7 81 9 32 78 - 90 info@hiwin.de www.hiwin.de All rights reserved. Complete or partial reproduction is not permitted without our permission. Note: The technical data in this catalogue may be changed without prior

Motors, Drives & Accessories Rotary Tables Directly-driven rotary tables from HIWIN have a backlashfree and very rigid design, making them highly versatile. The compact design makes the tables easy to integrate and allows for a space-saving setup. Various diameters and heights simplify the process of selecting the right rotary table. On request, the rotary tables are also supplied as a complete system with drive.

HIWIN rotary tables DMS Standard series Torques up to 450 Nm Integrated rotary encoder Outer diameter 110 – 300 mm With pneumatic clamping as an option HIWIN rotary tables DMN Extremely flat design Torques up to 39.6 Nm Outer diameter 118 – 230 mm Integrated

Rotary Tables Sample applications 2. Sample applications 2.1 HIWIN rotary tables optimise transport processes The specification Rapid positioning when transporting the work-pieces between the interlinked system parts on a vertical circular path = special requirements apply to acceleration and braking due to the short distances travelled Flexible solution, allowing changes or additions to be made during commissioning It should be possible for the system to be stopped in any position in order to inspect the parts Our solution Swivel drive minimises the cycle times = saves time and money...

3. HIWIN rotary tables DMS 3.1 Characteristics of the DMS rotary tables DMS rotary tables are directly driven rotary tables and do not therefore have a gearbox. The extremely rigid connection between the motor and load, coupled with a high-quality servo drive controller, ensures outstanding acceleration capabilities and movement with good uniformity. Due to the hollow shaft design, DMS rotary tables are especially well suited to automation tasks. Media, cable systems or mechanisms can pass through with ease. Key features: Backlash-free and extremely dynamic Brush-less and high-torque...

Rotary Tables HIWIN rotary tables DMS 3.3 Technical data for DMS 3.3.1 Technical data for DMS0 Table 3.1 Technical data for DMS0 HIWIN rotary tables Symbol Unit Continuous torque Stall torque Inertia of rotating parts Nominal speed (at 400 VAC, 30 % duty cycle) Technical data of rotary table Position accuracy Radial run-out Axial run-out Protection class Technical data of motor Peak current (for 1 sec.) Continuous current Motor constant Electrical time constant Torque constant Thermal resistance Thermal time constant All the specifications in the table (except dimensions) are in ± 10 % of...

Dimensions of the DMS0 HIWIN rotary table (For values, see Table 3.1) Mk Fr Rotating hollow shaft 6-M5 × 0.8P × 10DP P.C.D Ø60 (Rotor fixation) Home position Marker (Stator fixation) Motor connection (built-in socket M17) Encoder connection (built-in socket M17)

Rotary Tables HIWIN rotary tables DMS 3.3.2 Technical data for DMS1 Torque-speed curves (DC bus voltage: 560 VDC) Table 3.2 Technical data for DMS1 HIWIN rotary tables Symbol Unit Continuous torque Stall torque Inertia of rotating parts Nominal speed (at 400 VAC, 30 % duty cycle) Technical data of rotary table Position accuracy Radial run-out Axial run-out Height Protection class Technical data of motor Peak current (for 1 sec.) Continuous current Motor constant Electrical time constant Torque constant Thermal resistance Thermal time constant All the specifications in the table (except...

Dimensions of the DMS1 HIWIN rotary table (For values, see Table 3.2) Mk Fr Rotating hollow shaft 6-M6 × 1P × 9DP P.C.D Ø60 (Rotor fixation) Home position (Stator fixation) Motor connection (built-in socket M17) Encoder connection (built-in socket M17)

Rotary Tables HIWIN rotary tables DMS 3.3.3 Technical data for DMS3 Torque-speed curves (DC bus voltage: 560 VDC) Table 3.3 Technical data for HIWIN rotary tables DMS3 Symbol Unit Continuous torque Stall torque Inertia of rotating parts Nominal speed (at 400 VAC, 30 % duty cycle) Technical data of rotary table Position accuracy Radial run-out Axial run-out Height Protection class Technical data of motor Peak current (for 1 sec.) Continuous current Motor constant Electrical time constant Torque constant Thermal resistance Thermal time constant All the specifications in the table (except...

Dimensions of the DMS3 HIWIN rotary table (For values, see Table 3.3) Mk Fa Home position Rotating hollow shaft Encoder connection (built-in socket M17) Motor connection (built-in socket M17) Connecting thread 10 × M6 × 9DP

Rotary Tables HIWIN rotary tables DMS 3.3.4 Technical data for DMS7 Torque-speed curves (DC bus voltage: 560 VDC) Table 3.4 Technical data for DMS7 HIWIN rotary tables Symbol Unit Continuous torque Stall torque Inertia of rotating parts Nominal speed (at 400 VAC, 30 % duty cycle) Technical data of rotary table Position accuracy Radial run-out Axial run-out Height Protection class Technical data of motor Peak current (for 1 sec.) Continuous current Motor constant Electrical time constant Torque constant Thermal resistance Thermal time constant All the specifications in the table (except...

Dimensions of the DMS7 HIWIN rotary table (For values, see Table 3.4) Mk Fa Connecting thread Marker Home position Encoder connection (built-in socket M17) Rotating hollow shaft Motor connection (built-in socket M17) Connecting thread 9× M8 × 16DP Ø12H7 × 2.6DP

Rotary Tables HIWIN rotary tables DMN 4. HIWIN rotary tables DMN 4.1 Characteristics of the DMN rotary tables The particularly flat and light precision rotary tables of the DMN series are suited to all applications in which high rigidity and accuracy are needed along with the smallest dimensions possible. Typical areas of use include the manufacture of LEDs, solar cells and semiconductors. The zero-maintenance DMN rotary tables use precision bearings and optical encoders to achieve very high positioning and repeat accuracy. Key features: Backlash-free and extremely dynamic Extremely flat...

Hiwin Corp., a manufacturer in motion control and system technology, highlights its families of precision motion control components with a focus on its Torque Motor Rotary Tables (TMRT).

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy, Hiwin says. Directly coupled encoders and zero backlash intend to enable tighter part tolerance. Direct drives are designed provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, promoting thermal stability even during high-duty cycle, high-load conditions, which yields consistent part quality, Hiwin says.

Hiwin Torque Motor Rotary Tables utilize Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hexram CNC machines feature FANUC controls, moving gantry, moving portal, moving table, as well as moving and fixed rotary table options. According to the company, a selection of durable cutting heads enable manufacturers to take on applications from nearly any industry.

HIWIN rotary tables are ready-to-install rotary axes consisting of a torque motor, bearing, motor housing, and positioning measuring system. The rotary tables are play-free direct drives that are always used where classical motor/gear combinations come up against their limits. The fascinating features of these rotary tables are their unvarying torque, their rigid load coupling, and their maximised dynamic response, specifically under high load as well. Thanks to their high efficiencies and lack of gears, these rotary tables operate to great effect and are extremely quiet.

Hiwin Corporation, a leader in motion control and system technology, will feature families of precision motion control components this year, with its torque motor rotary tables (TMRT) as a highlight of its booth.

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

Hiwin torque motor rotary tables use Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Since 1992, Hiwin Corporation has focused on components, systems, and expertise in the motion control industry. Hiwin will be celebrating its 30th anniversary in America at the show at Booth #134514.

Hiwin (Booth 134514) will feature families of precision motion control components this year at IMTS, with the company"s Torque Motor Rotary Tables (TMRTs) as a highlight.

HIWIN’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

HIWIN Corp. manufactures an extensive line of linear and rotary motion components, positioning systems and complete motion solutions, with superior quality at competitive prices. Mechanical components include a variety of precision ground and rolled ballscrews, linear guideways, ball splines, crossed roller bearings, and strain-wave gears. Mechatronic and robotic products include single ball screw stages and AC Servo motors, linear motors and stages, rotary tables, and the drives, controllers, and know-how to make multi-axis motion systems. Many of these items are in stock for on-site cutting, machining and fast shipment. Our robots include articulated, delta, SCARA and more.

In the past, Taiwan has to purchase “Torque Motor Rotary Table” from European and Japanese suppliers. The high import cost, long delivery time and no timely after services affects competitiveness of Taiwan machine makers. HIWIN is the only supplier in Taiwan which can mass produce torque motor. RAS-170 is made of HIWIN self-developed key components.

HIWIN Technologies Corp. is the world leading brand of motion control and system manufacturer. With its core technologies, HIWIN focuses on creating innovative products with high speed, high precision, eco-friendly, and energy-saving. Our products, from components to sub system and system, include Ballscrew, Guideway, Bearing, Robot Reducer, Industrial Robot, Medical Robot, Torque Motor Rotary Table. HIWIN products are widely applied by the Automation, Semi-Conductor, Electronics, Medical, Precision Machine, and Transportation Industries etc. HIWIN commits to be a manufacturing service company by creating innovative intelligent products and providing mechatronic total solution to serve customers and build a great work environment and well-being to improve human’s life. With company motto “Professional Excellence, Working Enthusiasm, and Ethics & Responsibility”, HIWIN has the vision to develop a sustainable company.

Through perseverance HIWIN became well-known overseas with high quality. After receiving global acknowledge, HIWIN finally won domestic recognition under the contempt of Taiwan brand.

HIWIN is now top tier in motion control and system with 14 subsidiaries and over 300 distributors. HIWIN believes “Manufacturing is not a purpose, it is a means to satisfy human needs”, which leads to innovation for better life! Nikkei Business 2017 “ASIA 300 Market Growth”, HIWIN is ranked No.1! HIWIN, a MIT company, being the No.1 above the Asia public companies is a honor for Taiwan! HIWIN proves branding is difficult but rewarding.

Different factors affect the effectiveness of a hiwin rotary table. One, it’s the load requirements. Here check the linear guide weight capacity and size before purchase to make sure you order a machine that will support your intended use. Secondly, check the orientation of the slide. This will help you know the motion and location of a load; hence, you can determine the repeatability and accuracy of the load. Since linear guides come with different orientations and mounting types, this will guide you in choosing the right hiwin rotary table for your application. Third, make sure you know the installation requirements and the application design before ordering a hiwin rotary table online. With that, you can determine which linear guide is ideal for your application. Check also whether a machine has a self-lubricating feature which can be either grease fittings or polymer place. These features supply lubrication to your slide bearings, enhancing the effectiveness of the system. It also increases the linear guide durability as the lubrication reduces friction which can cause damage to the linear guide. You should also check the linear guide durability as buying a durable product will reduce the maintenance and repair cost.

There are two categories of linear guides; plain bearing slides and roller or ball bearing slides. The plain bearing slides use plain surface bearings that have minimum lubrication and friction. This hiwin rotary table is strong and fit for both lateral and radial loads. They include dovetail slides, cylindrical column slides, and Boxway slides. On the other hand, bearing slides rely on a roller element that minimizes friction. They are ideal for light-duty uses as the bearing tends to break or deform when high pressure is applied.

8613371530291

8613371530291