horizontal boring mill with rotary table manufacturer

Our dealer and auctioneer members offer the most extensive selection of used machinery in the world, with thousands of machines available in warehouses and plants across the globe.

The PowerTec horizontal milling machine is a modern floor-type boring mill. It is a "full hydrostatic machine" including all linear and rotating axes and the extendable hydrostatic boring ...

The HBW series from KAAST is a collection of CNC horizontal boring mills that feature either a fixed or moving column design paired with hardened and ground guideways. These machines are made of strongly ...

Boring Machine with the most unique technological innovations of any other, in order to meet the ever-growing need of precision. The INVAR s level of accuracy is unmatched by any machine of comparable size today.

Lymco CBA T-type HBM is configured with moving column and rotary table for efficient multi face machining of large size workpieces. With the stack effect of different axis, the CBA-TR column moving HBM can provide a more ...

The new high-performing machine WHT 130 is a horizontal boring machining centre suitable for the most demanding operations that require precise boring, threading, vertical lathing and/or milling. The ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

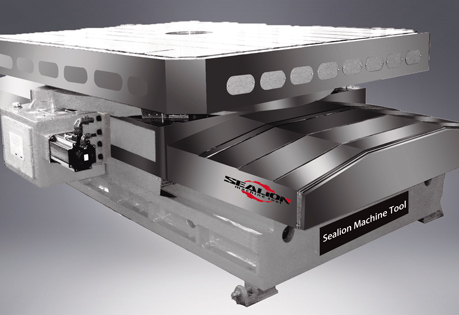

The rotary table is an accessory for the CNC floor type boring and milling machine. It can be working together with the floor type boring milling machine for milling angle, reverse boring, polyhedral machining, and other complex machining processes. It could do five sides machining if the main machine equipped the angle milling head.

CNC rotary table is a common part of CNC milling machine, often used as a servo axis of CNC milling machine, namely C axis of vertical CNC milling machine and B axis of horizontal CNC milling machine. The CNC rotary table includes the foot of the turntable, a round turntable surface, four rolling bearing parts arranged on the upper surface of the foot of the turntable, and a center with a self-aligning bearing installed at the center of the upper surface of the foot of the turntable. Support, each rolling bearing component includes a rolling bearing and a support that supports the rolling bearing through the axle. The center of the lower surface of the turntable is provided with a vertical downward axle. The turntable is installed on the foot of the turntable. The inner ring of the self-aligning bearing is fixed, and the rotating surface of the rolling bearing is in rolling contact with the lower surface of the turntable surface.

The CNC rotary table has an inclinometer with two orthogonal test axes as the test tool. The inclinometer is set at the center of the turntable surface to be leveled, so that the two orthogonal test axes of the inclinometer are parallel to the turntable surface, by adjusting the milling machine turntable. The leveling mechanism under the base makes the tilt angle value output by the two test shafts of the inclinometer turntable in the leveling state.

CNC rotary table and swing head are the key components of multi-coordinate CNC machine tools. Traditional rotary tables and swing heads using high-precision worm gears and other transmissions are not only difficult to manufacture, costly, but also difficult to achieve the speed and accuracy required for high-speed machining. Therefore, it is necessary to develop a new electromagnetic drive system for the CNC milling machine turntable and swing head in a different way to realize the zero-drive drive of the rotational motion coordinates of the CNC machine tool.

1. The CNC turntable uses modular design technology. The PAN turntable and TILT turntable are independent components, which are easy to disassemble and can be controlled by linkage or individually.

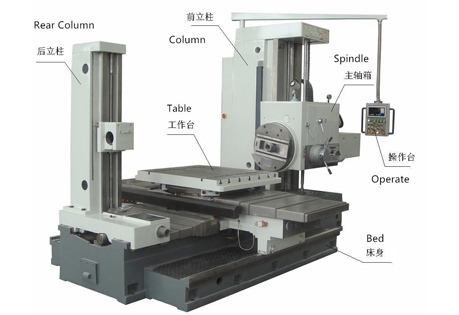

Horizontal Mills – The horizontal mills can perform a number of applications in one setup, and their configuration allows for machining large parts. The arrangement of the horizontal boring mill allows for easy access and placement of the workpiece on the machine table. Large workpieces can be placed on the machine table with an overhead crane and can overhang the table if needed. The arrangement also allows for easy chip removal from the machining operation.

We run five horizontal mills out of our shop. The largest of our horizontal mills has an operating window of 157″ in X and 92″ in Y. An auxiliary rotary table can be added to the mill for 4th axis milling, while a part is being rotated. This adaptation is used for machining parts such as fluted rolls and internal helical grooves inside bushings. Two of our horizontal mills have rotary tables, which allows for machining on different sides of the part in one setup.

Re-Machined and Retrofit in 1993, Fanuc OM 4-Axis Programmable CNC Control, Triple Vertical Ways, Bolt-On Manual 48" x 48" Rotary Table with Shot-Pin 90 Degree Positioning,NMTB 50 Taper Spindle, Programmable Spindle Speeds to 1,342 RPM, 200 IPM Rapid Traverse Rates, Coolant Pump and Tank, Hansen Oil Chiller, Machine Manuals, Assorted 50 Taper Tool Holders, 220 to 440 Volt Transformer

Re-Machined and Retrofit in 1993, Fanuc OM 4-Axis Programmable CNC Control, Triple Vertical Ways, Bolt-On Manual 48" x 48" Rotary Table with Shot-Pin 90 Degree Positioning,NMTB 50 Taper Spindle, Programmable Spindle Speeds to 1,342 RPM, 200 IPM Rapid Traverse Rates, Coolant Pump and Tank, Hansen Oil Chiller, Machine Manuals, Assorted 50 Taper Tool Holders, 220 to 440 Volt Transformer

FERMAT WFC10-M-1600 "New" CNC Table Type Horizontal Boring Mill, In Stock Now! #50 Taper, 4000 R.P.M , Optical scales, Operators Cabin. Delivery, Installation & Training.....

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

MDNA LOCATOR was founded in 1969 and is a wholly owned subsidiary of Machinery Dealers National Association (MDNA). We"re the premier online listing service for used machinery with tens of thousands of listings updated regularly.

The right machinery and equipment get the job done correctly, efficiently and on time. All are essential in making sure your project stays on or even under budget. With 20,000 square feet of manufacturing space and a wide selection of precision machining equipment, Westside Machine has all your precision machining, manufacturing, fabrication, repair and tooling needs covered.

If you have unique materials to work with, Westside Machine is for you. We have precision machining equipment that handles unusual metals, plastics, woods, foams and more.

And we have the roofed-in area you need for projects both large and small, no matter if the job calls for cnc machining or other precision equipment. With 20,000 square feet of manufacturing space, you"re set for any job.

Below is a sample of some of our cnc machining equipment as well as our other quality machining gear and industrial-quality tools. For more information on the mills, lathes and machining centers, just click on the image.

FERMAT is a highly professional Horizontal Boring Mill Manufacturer with the tradition of producing metal working and processing equipment in the Czech Republic. FERMAT has been into the design, manufacture, supply, and installation of Horizontal Boring Mills in Heavy Engineering and Precision Component Manufacturing Industries all over the world. The company is still growing and expanding into new markets through an active participation at renowned International Trade Fairs all over the world.

8613371530291

8613371530291