horizontal boring mill with rotary table supplier

Our dealer and auctioneer members offer the most extensive selection of used machinery in the world, with thousands of machines available in warehouses and plants across the globe.

The PowerTec horizontal milling machine is a modern floor-type boring mill. It is a "full hydrostatic machine" including all linear and rotating axes and the extendable hydrostatic boring ...

The HBW series from KAAST is a collection of CNC horizontal boring mills that feature either a fixed or moving column design paired with hardened and ground guideways. These machines are made of strongly ...

Boring Machine with the most unique technological innovations of any other, in order to meet the ever-growing need of precision. The INVAR s level of accuracy is unmatched by any machine of comparable size today.

Lymco CBA T-type HBM is configured with moving column and rotary table for efficient multi face machining of large size workpieces. With the stack effect of different axis, the CBA-TR column moving HBM can provide a more ...

The new high-performing machine WHT 130 is a horizontal boring machining centre suitable for the most demanding operations that require precise boring, threading, vertical lathing and/or milling. The ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

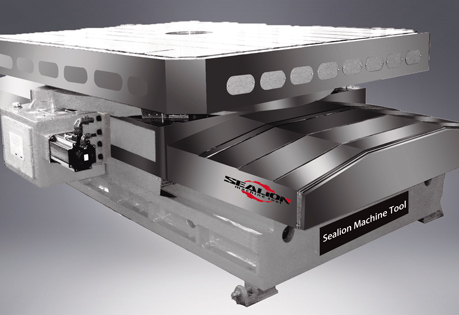

The rotary table is an accessory for the CNC floor type boring and milling machine. It can be working together with the floor type boring milling machine for milling angle, reverse boring, polyhedral machining, and other complex machining processes. It could do five sides machining if the main machine equipped the angle milling head.

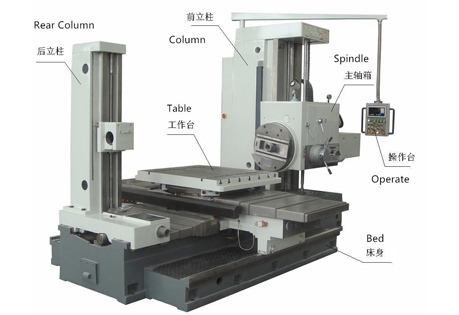

CNC rotary table is a common part of CNC milling machine, often used as a servo axis of CNC milling machine, namely C axis of vertical CNC milling machine and B axis of horizontal CNC milling machine. The CNC rotary table includes the foot of the turntable, a round turntable surface, four rolling bearing parts arranged on the upper surface of the foot of the turntable, and a center with a self-aligning bearing installed at the center of the upper surface of the foot of the turntable. Support, each rolling bearing component includes a rolling bearing and a support that supports the rolling bearing through the axle. The center of the lower surface of the turntable is provided with a vertical downward axle. The turntable is installed on the foot of the turntable. The inner ring of the self-aligning bearing is fixed, and the rotating surface of the rolling bearing is in rolling contact with the lower surface of the turntable surface.

The CNC rotary table has an inclinometer with two orthogonal test axes as the test tool. The inclinometer is set at the center of the turntable surface to be leveled, so that the two orthogonal test axes of the inclinometer are parallel to the turntable surface, by adjusting the milling machine turntable. The leveling mechanism under the base makes the tilt angle value output by the two test shafts of the inclinometer turntable in the leveling state.

CNC rotary table and swing head are the key components of multi-coordinate CNC machine tools. Traditional rotary tables and swing heads using high-precision worm gears and other transmissions are not only difficult to manufacture, costly, but also difficult to achieve the speed and accuracy required for high-speed machining. Therefore, it is necessary to develop a new electromagnetic drive system for the CNC milling machine turntable and swing head in a different way to realize the zero-drive drive of the rotational motion coordinates of the CNC machine tool.

1. The CNC turntable uses modular design technology. The PAN turntable and TILT turntable are independent components, which are easy to disassemble and can be controlled by linkage or individually.

Design Flexibility – The KRC HBM Series is a full line of table type and floor type Horizontal Boring Mills made to support a wide range of applications for machining large, heavy-duty workpieces. Built for extreme-duty roughing and high precision finishing, these horizontal boring mills offer modular designs and flexibility to meet the demands of various processes.

Superior Rigidity and Stability – The main structural components of these machines are made with high-quality alloy castings made according to Meehanite process and a heavily ribbed design allowing for maximum rigidity, vibration dampening and thermal stability.

Hydrostatic guideways can compensate for forces resulting from weight, machining and acceleration. These ways are ideal for horizontal applications, where machining and acceleration forces are lower than the weight forces on the pockets. The result of a hydrostatic way system includes better dampening characteristics, no vibration, minimal wear due to zero contact of surfaces, and no stick slip.

The Y-axis is equipped with a combination way system consisting of a box way with low friction material opposite tychoway bearings on hardened steel. The design provides the rigidity and dampening of sliding type box ways and the high accuracy contouring of bearing type guideways resulting in long term durability and reliability.

The headstock design features a modular 3 step gearbox which generates high torque, high speed and high horsepower for efficient part processing. The 3 step gearbox is designed and positioned for easy removal as a unit without disassembling the ram and spindle unit. The gearbox design also provides near constant power from base speed allowing the use of optimum cutting parameters.

The patented spindle design features the best dynamic performance available. Designed with a roller and ball bearing arrangement, the spindle has a hard nitrided surface and travels in a tempered steel sleeve for maximum support, rigidity and long wear. The spindle length is the shortest in the industry with equal w-axis travel. This allows for high rigidity, higher speed and increased accuracy.

The MB110e (4″) and MB130e (5″) Conventional Table Type Horizontal Boring Mills are used to mill, drill, bore, face, groove, etc. all types of steel and alloy components. These machines consist of 100% heavy duty cast iron construction for superior vibration damping and cutting accuracy. They feature a built in rotary table for machining four sides of a complex part in a single set up. They also have a built in facing head for expanded functionality. A heavy duty outboard support is optional for completing highly accurate line boring. Newall DRO’s are installed on the X, Y and Z axes for highly accurate machining.

All CategoriesBoring mills (90)CNC FLOOR HORIZONTAL BORING MILL (8)CNC FLOOR HORIZONTAL BORING MILL W/ AUTOMATIC TOOL CHANGER (1)CNC TABLE HORIZONTAL BORING MILL (10)CNC TABLE HORIZONTAL BORING MILL W/ AUTOMATIC TOOL CHANGER (4)CNC TABLE HORIZONTAL BORING MILL W/ ROTARY TABLE (1)CNC VERTICAL BORING MILL (13)CNC VERTICAL BORING MILL W/ AUTOMATIC TOOL CHANGER (3)CNC VERTICAL TURRET LATHE (4)FLOOR HORIZONTAL BORING MILL (4)HORIZONTAL BORING MILL TABLE (13)TABLE HORIZONTAL BORING MILL (1)VERTICAL BORING MILL (15)VERTICAL TURRET LATHE (5)CNC Lathes (3)2-AXIS CNC (2)CNC Milling (4)Cylindical Grinder (1)Drills (5)Beam Drill Line (1)RADIAL (4)EDM (1)Grinders (30)CYLINDRICAL UNIVERSAL (3)RECIPROCATING SURFACE HORIZONTAL (9)ROLL (2)ROTARY SURFACE VERTICAL (7)SURFACE, RECIPROCATING TABLE, HORZ. (1)Lathes (73)2-AXIS CNC (29)4-AXIS CNC (3)ENGINE LATHE (30)TURRET (3)Machining centers (40)HORIZONTAL MACHINING CENTER (4)HORIZONTAL MACHINING CENTER W/ PALLETS (10)PLANER TYPE, BRIDGE STYLE (1)VERTICAL MACHINING CENTER (8)VERTICAL MACHINING CENTER (BRIDGE) (10)Millers (2)Milling (4)Plasma Table (1)Plate Roll (1)Press Brake (1)Saws (6)Tables (1)ROTARY (1)

Re-Machined and Retrofit in 1993, Fanuc OM 4-Axis Programmable CNC Control, Triple Vertical Ways, Bolt-On Manual 48" x 48" Rotary Table with Shot-Pin 90 Degree Positioning,NMTB 50 Taper Spindle, Programmable Spindle Speeds to 1,342 RPM, 200 IPM Rapid Traverse Rates, Coolant Pump and Tank, Hansen Oil Chiller, Machine Manuals, Assorted 50 Taper Tool Holders, 220 to 440 Volt Transformer

Re-Machined and Retrofit in 1993, Fanuc OM 4-Axis Programmable CNC Control, Triple Vertical Ways, Bolt-On Manual 48" x 48" Rotary Table with Shot-Pin 90 Degree Positioning,NMTB 50 Taper Spindle, Programmable Spindle Speeds to 1,342 RPM, 200 IPM Rapid Traverse Rates, Coolant Pump and Tank, Hansen Oil Chiller, Machine Manuals, Assorted 50 Taper Tool Holders, 220 to 440 Volt Transformer

"twitter:title": "Horizontal Boring Mills - HILLARY MACHINERY OKLAHOMA CNC MACHINE TOOL DEALER VERTICAL MACHINING CENTERS HORIZONTAL MACHINING CENTERS, TURNING CENTERS AUTOMATION AND ROBOTICS",

"og:title": "Horizontal Boring Mills - HILLARY MACHINERY OKLAHOMA CNC MACHINE TOOL DEALER VERTICAL MACHINING CENTERS HORIZONTAL MACHINING CENTERS, TURNING CENTERS AUTOMATION AND ROBOTICS",

"og:site_name": "HILLARY MACHINERY OKLAHOMA CNC MACHINE TOOL DEALER VERTICAL MACHINING CENTERS HORIZONTAL MACHINING CENTERS, TURNING CENTERS AUTOMATION AND ROBOTICS",

]Horizontal Boring Mills - HILLARY MACHINERY OKLAHOMA CNC MACHINE TOOL DEALER VERTICAL MACHINING CENTERS HORIZONTAL MACHINING CENTERS, TURNING CENTERS AUTOMATION AND ROBOTICS

AS A FULL TURNKEYED MACHINING SOLUTION, Fives G&L milling machine product offerings are as varied as the parts they process. From high speed drilling of aluminum to heavy-duty boring and milling o...

The HNK HB-130C is ideal for precision and heavy-duty boring and milling operation. This horizontal boring mill has a long nose spindle head and wide table working area to provide flexible machinin...

The HNK HB-130S is ideal for precision and heavy-duty boring and milling operation. This horizontal boring mill has a long nose spindle head and wide table working area to provide flexible machinin...

WITH OVER 11 MODELS IN THEIR LINE-UP, HNK horizontal boring mills range from 4.3" to 5.1" to 5.9" diameter spindles; 60"~236" X-axis, 60"~137.8" Y-axis; 39"~78" Z-axis; and 13"~39" W-axis travels w...

The KBN135 is manufactured using the latest state-of-the-art manufacturing technology and is one of the most versatile members of HYUNDAI-WIA’s outstanding line of CNC Horizontal Boring Mills. The ...

The KBN135C is manufactured using the latest state-of-the-art manufacturing technology and is one of the most versatile members of HYUNDAI-WIA’s outstanding line of CNC Horizontal Boring Mills. The...

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

For maximum productivity at a minimal cost, the Giddings & Lewis T-bed horizontal boring mill is hard to beat. Fives has a tradition of building rigid, accurate and reliable machine tools. The Giddings & Lewis T-bed HBM carries on that tradition but at a price level that will appeal to every shop.

8613371530291

8613371530291