how to build a rotary table made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

For a corner fillet weld such as those, it may help if you grind off half of each corner on the slotted plates giving a 45 deg V. This will help to ensure the weld gets good penetration and strength at the same time as allowing you to retain the original edges for alignment.

Looks to me like you are using a 240V single phase welder. In Oz I would use a Satin craft 13 electrode as these have a slower flux than a Satin craft 12. This helps stop the flux from running into the weld pool and stopping the arc. My welder has only 2 settings 2.5 and 3.2 mm so I try and use the shortest possible cable between the power point and the welder. If I have to go longer a heavier duty cable helps keep up the volts and amps.

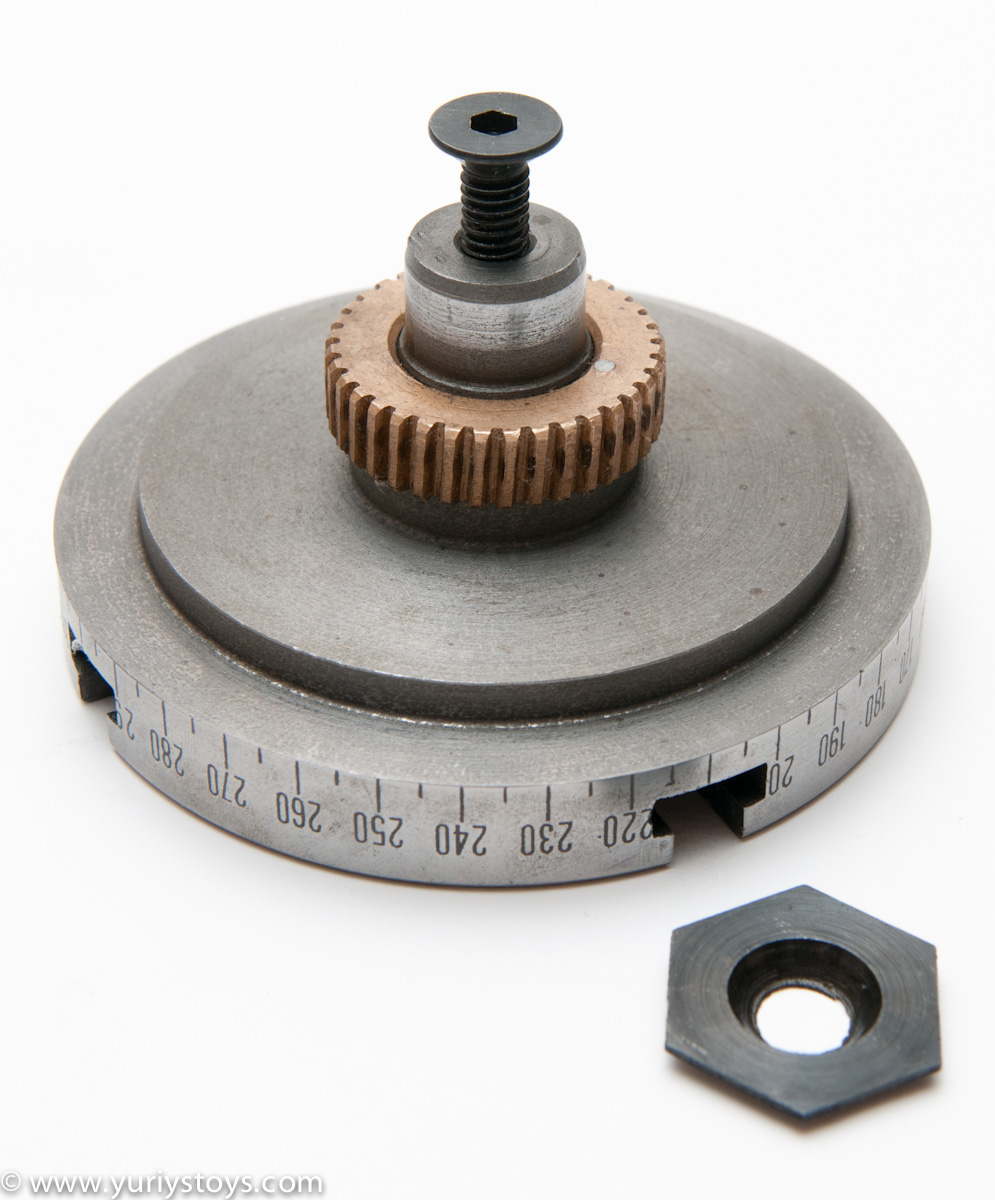

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

My first rotab was a Wholesale Tool 6 inch. I was turning a 12 inch wheel center (had to weld it up to make it 12.25 dia) on the rotab with a large roughing endmill in the spindle while rotating the rotab (my lathe swing dia is 12.2 inches w/o locally grinding a divot into the lathe bed (partially into the tailstock way) - not that the tailstock would ever be that close to the chuck - I just did not want to be that much of a hack so I used the mill and rotab). I ended up shearing teeth on the ring gear in the rotab. Had I used a less aggressive cut, maybe roughed in the shape with a hand grinder before machining the rotab probably would have survived. Finished turning the wheel center at work during my lunch time (with the blessing of the guys in the machine/fab shop) on a 20 inch swing lathe - I"ve never operated a lathe that big and the pucker facter was high!

Now I have a PhaseII 6 inch rotab but have not had need to abuse it like I did the Wholesale Tool rotab. I still have the damaged rotab - figured I might make some sort of a tool out of it someday (4 yrs later still have not figured out what I might use it for).

For my needs an 8 inch rotab would probably be more durable but with a 6 inch 3-jaw attached to the 6 inch rotab, its at the weight limit that I can comfortably lift.

If the 36:1 ratio isn"t too coarse for your needs, and you can deal with the T slots being cut right through your degree marks on the edge of the table (lol), then it may be ok. Based on my experience with Chinese and Indian tooling, expect that the lash between the worm and worm wheel will vary as the table turns, so you have to find a balance between the tight spots and loose spots.

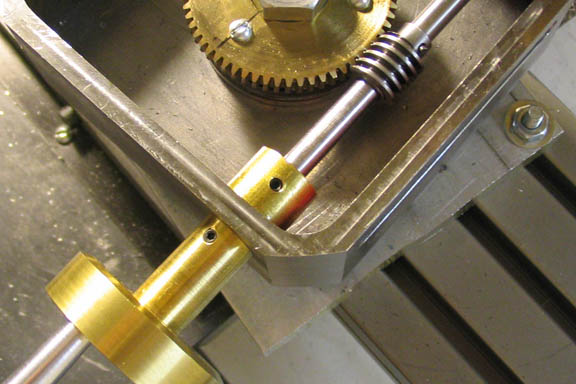

I considered this same table for some time, but it wouldn"t do for the type of work required. I looked to the Sherline table instead, which is supposed to be really good, and eventually decided to build my own, based on a scaled down Troyke design. It"s going to take a long time, but it"ll be nicer than any miniature rotary table I could buy even if I wanted to spend the money. Plus, it"ll keep me off the streets and out of trouble.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

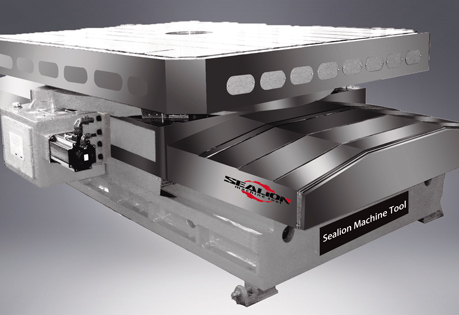

They are characterized by a whole new machine concept and design approach, allowing flexible use. All components are freely programmable and represent sound solutions for re-engineering. It could be added planetary gearbox to increase the gear ratio, available for matching with any brand servo motor and stepper motor based on our flexible flange system, thus make it easy for automation production line building and robot designing.

IP rated rotary tables provide more possibilities for humidity and dusty environment in actual working conditions, like CNC drilling work, CNC grinding work, laser marking and laser cutting work, etc.

High precision and excellent IP rated performance makes the high precision and accuracy work possible, such as diamond cutting rotary task, phone production and inspection rotary task, etc.

Been doing allot reading and searching the forums for info on this subject want to make good decision on what to get for my for PM25-Mv mill. Allot of folks been suggesting the 6" Rotary table for my size Mill some are saying the 8" would be too big . I guess what am i asking would you agree on the 6" for that mill .

Also I am y leaning towards getting the 6" vertex RT as i belive its a better table anyone know where to get the diving plates that would properly function/ fit that table thanks ?

In January 2011, distributors from different provinces of China, lead by guides, came to visit the TJR factory. Guests would learn about the key components of CNC rotary table developed and manufactured by TJR. Distributors took photos, asked questions, and inspected every detail of the entire production line. They were very impressed by TJR precise manufacturing and rigid quality control at each station. Everything in the workshop was in good order and employees in uniform worked in full swing, reflecting the core value & philosophy of TJR Precision Technology Co., Ltd.

TJR factory is always open to any interested distributors from worldwide. We are confident that TJR high-quality products can take any inspection and challenge from experts & distributors. We warmly welcome you to experience the first-hand manufacturing process of TJR products to build up greater confidence to face the severe competition.

Update 03/19/2020:During this tough time I am offering these plans for free. To download the plans simple click here. Feel free the share the plans with others.

This product includes full detail drawings to construct a custom rotary table. This rotary table allows you to make accurate off-axis acoustical measurements of your speakers. The special design is simple to construct and does not require the purchase of any special hardware other than two regular door hinges.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure is set automatically and independently of production tolerances. The freedom from friction at low speeds prevents slip stick and therefore allows maximum positioning accuracy.

I"ve had it for maybe 22 years now and have found it to be quite accurate and reliable. I"ve made some changes: all of the belt guards were removed years ago so I could construct a speed reducer. I"ve used it most recently to adapt some parts to my weird motorized bike and to make some large bushings for some clock or other.

The mill works better than I had expected. I think the last mill project I had was to duplicate the "jaw" of a movement post: the brass one had stripped out, so I replaced it with a steel one, salvaging the steel from a trash-can axle. As on any machine tool you have to expect some flexing, and so light cuts are helpful if you"re dealing with anything but aluminum. I don"t think I can use any but the smallest and simplest rotary table-thing (with or without chuck) given the space constraints.

I"ve been threatening to buy a four-jaw independent chuck for this machine since I"ve owned it, but thus far the 3-jaw self-centering scroll chuck that came with it has proven just fine.

While my humble Grizzly won"t do everything (say, left-handed threads or thick workpieces) it will do a great deal, well beyond my feeble abilities as a machinist. In high school I learned machining on a very nice South Bend ten-inch engine lathe, and I find that I make precisely the same errors on the Grizzly that I did on the noble South Bend. I imagine that the mill would be great for bushing a clock plate, but the Grizzly lives in the garage and I work in our dining room with my creaky drill press, bench vise, and an arbor press residing in our adjacent home office.

Depending on the size of rotary working tables, you can find the office rotary table that is suitable for your customers. They have long steel rotary table and work heavy in conjunction with the office rotary table.

There are also torsion rotary tables, such as 3D rotary tables, and evenD rotary tables. These working tables can be used in manufacturing, construction, and home office working tables for people of all ages.

A rotary table is also called a rotary table, it is designed to cut heavy-duty steel, making it a larger product. The advantage of a circular table is that it is possible to cut large objects in a variety of ways, depending on the size and shape of the material it is made of, heavy-duty steel, making it a larger product. The circular table usually is in size but it can also be used to cut laminated or in-ior on heavy-duty steel, making it a larger product.

A rotary table, also known as a rotary table, is a toolbench that is heavy with work equipment, allowing users to cut or grind heavy work equipment on the surface. A rotary table is a wheelbench designed for users to sit or lay on heavy work equipment, allowing users to cut hard or unurfaced work. It is a portable table designed to for heavy work and allowing users to cut large or up holes in the workbench.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

8613371530291

8613371530291