how to build a rotary table price

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Update 03/19/2020:During this tough time I am offering these plans for free. To download the plans simple click here. Feel free the share the plans with others.

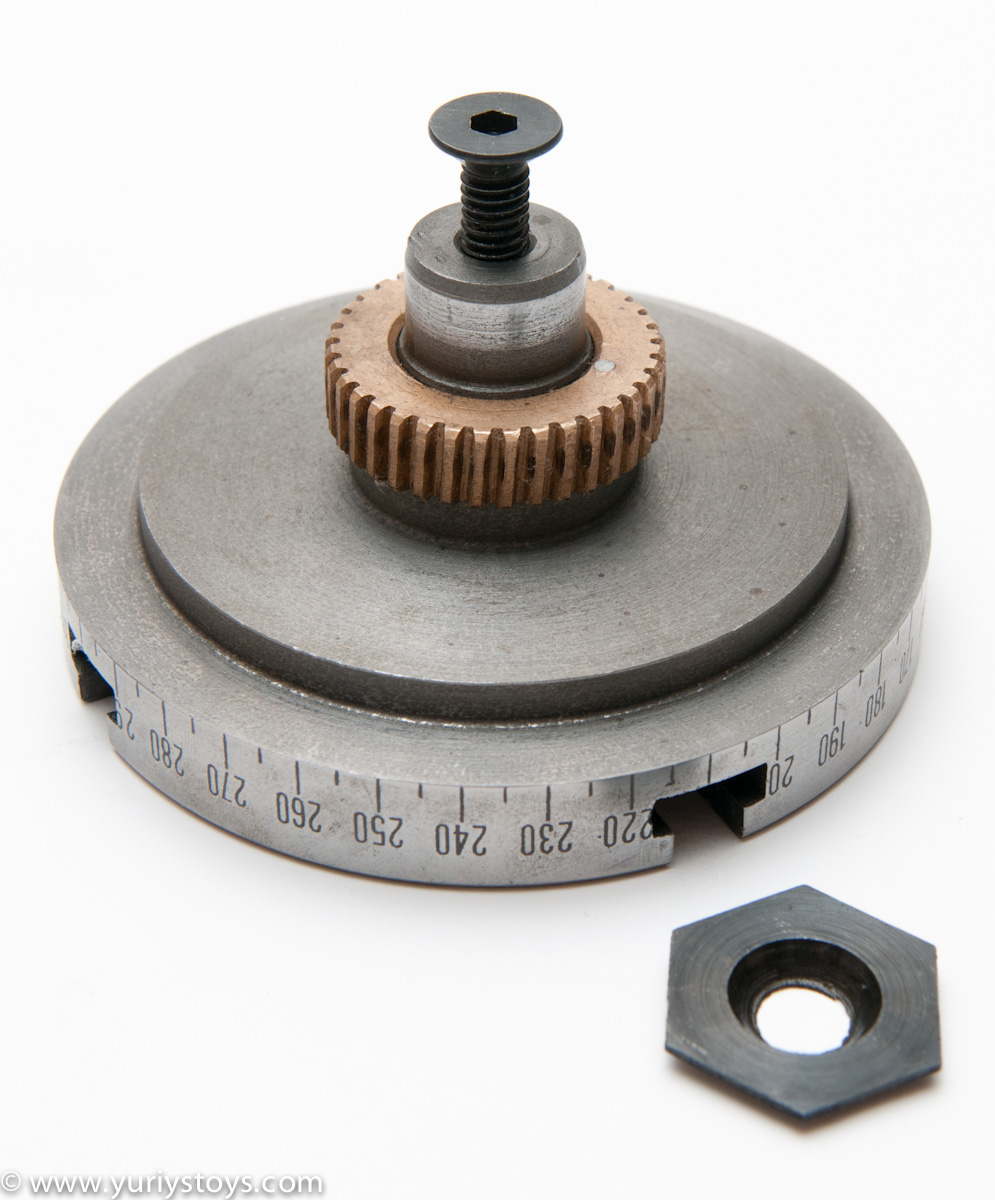

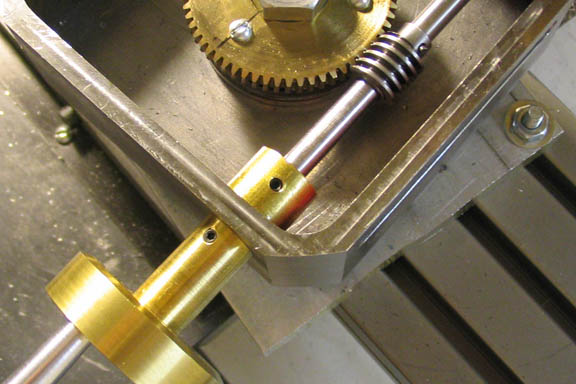

This product includes full detail drawings to construct a custom rotary table. This rotary table allows you to make accurate off-axis acoustical measurements of your speakers. The special design is simple to construct and does not require the purchase of any special hardware other than two regular door hinges.

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

Our 4C software and control system powers all models. Standard and optional equipment is the same across all models. The only differences between models are machine size, travels, spindle power, and part size capacity.

FWIW, I bought a six-inch rotary table a few years ago. As far as I can tell, it was made somewhere in eastern europe. It had some tight spots and a little backlash in the gears, and the scale engraving was crude. I can"t remember what the price was, but I know it was below $400.00. (Including a set of indexing plates.) I wanted a better one, but the budget was needed for other items. For the fraction of my shop time I need a rotary table, I considered the poor quality, low price workable.

For me, the price/quality issue was being compared to my other choices (then) of a smaller, higher-quality RT or a home-made one, or some improvised way to accomplish the machining task I needed done at the time. Do I wish a went for a better one, of course. Am I sorry I bought it, No. I have cut curved housings and slots, machined round things that couldn"t be done on my mini-lathe, and cut gears and simple cams.

I also disassembled and turned the shaft down to help clean up the tight spots, as first described by Chuck Fellows. I can not find that post to provide a link.

I also bought a 4-inch rotary table from Grizzly a while back with the intent of making it indexable via stepper motor and arduino control, but that project did not work out and the table itself is just too hard to use: Another future project to sort out.

I just purchased a Sherline RT (lists at 270$U) & can vouch for it. Much better than some of the offshore stuff (although quality does vary by brand/origin, so I"m generalizing here).

I already have a larger RT. But many jobs are small setups that I"m hoping to be easier & faster setup with 4". I"m in the process of making a baseplate so the assembly will just drop in my 6" mill vise, saving removing the vise & setting up larger RT (although you can mount it conventionally too). Do a search on the forum & you will see some impressive projects using this RT.

- neat feature, threaded insert plug (comes with RT) which then allows mounting Sherline 3 or 4 jaw chucks & they are self centered. These are kind of small, but suite the overall scale of RT, You could mount a larger chuck but would hav eto make adapter plates.

- hold-downs are 10-32 type cap screws & matching T-nuts kind of unique to Sherline. You could make them yourself, but they are reasonable cost. This lends itself to smallish setups & also the slots come closer to center than common. I"m going to also make some gridded pre-threaded tooling plates to clamp on the table so I can orient odd-ball parts easier yet.

Sherline offers one of the finest small rotary tables on the market. It is available in manual or CNC. It can even be purchased with a controller to be used as a programmable indexer. It’s popular among industrial shops due to its compact size, solid construction, and long-lasting accuracy.

The rotary table also is available with larger, 15/32″ through hole to which you cab mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

![]()

${{result.values.onspecial === "true" && parseFloat(result.values.catalogprice) > parseFloat(result.values.price) ? result.values.catalogprice.slice(0, result.values.catalogprice.indexOf(".")).replace( /\d{1,3}(?=(\d{3})+(?!\d))/g , "$&,") : result.values.msrp.slice(0, result.values.msrp.indexOf(".")).replace( /\d{1,3}(?=(\d{3})+(?!\d))/g , "$&,")}}{{ result.values.onspecial === "true" && parseFloat(result.values.catalogprice) > parseFloat(result.values.price) ? result.values.catalogprice.slice(result.values.catalogprice.indexOf(".")+1) : result.values.msrp.slice(result.values.msrp.indexOf(".")+1)}}

${{result.values.price.slice(0, result.values.price.indexOf(".")).replace( /\d{1,3}(?=(\d{3})+(?!\d))/g , "$&,")}}{{result.values.price.slice(result.values.price.indexOf(".")+1)}}

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is applicable). Packaging should be the same as what is found in a retail store, unless the item was packaged by the manufacturer in non-retail packaging, such as an unprinted box or plastic bag. See the seller"s listing for full details.See all condition definitionsopens in a new window or tab

MachineStation is keenly involved in the auction facilitation helping sellers capitalize on their surplus assets. Whether it be a Complete Plant or individual equipment. We work with nationally recognized auctioneers in finding the type of auction best suited for the seller’s unique situation.

The VH-6 is the smallest rotary table we offer featuring 6.3" (160mm) diameter spindle with a 1.5" through hole. The VH-6 features a newly designed pneumatic braking system which offers 120 ft-lbs of brake holding. The VH-6 maintains a rigid design with dual bearings both in the front and rear of the spindle. The centerline is 5.5". There is an optional 6" 3-Jaw chuck and adapter plate available as well as a 5C nose piece with either manual or air collet closer.

The Index Designs VH-6 is a true 4th-axis rotary table that comescomplete with compatible servo motor, and 9" extension cables ready to plug into you 4th-axis ready CNC machine.

For machines that are not 4th-axis ready: Add 4th-axis kit for each rotary table. Kit includes all parts necessary to make CNC machine 4th-axis ready. Prices vary by machine. Call for quote. Does not include installation.

Don"t need true 4th-axis? Just need point-to-point indexing?A cost-efficient solution for any CNC machine that is not 4th-axis-ready. This single-axis, programmable control box will add indexing or semi-4th-axis capability to any machine. It can be easily interfaced using a spare M-code from your CNC machine. Indexing position moves to practically any angle are programmed directly through the front panel of the control box and are triggered by an M-code, or utilize the control box"s DNC function to run a complete machine program file from a USB key.

Easily interfaces to any CNC machine and control including Fanuc, Mitsubishi, Fadal, Haas, Hurco and many others. No expensive 4th axis drive needed.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and other dealer installed accessories are not included. All prices are in U.S. dollars.

Drill holes and bolt-hole patterns, mill intersecting slots and curved slots precisely. Includes worm drive hand wheel with Vernier ring for 4-degree table movement per turn, three T-slot ways for easily mounting a chuck, and two table clamp handles for stability. Main body mounts horizontally and vertically. You will need the table, tailstock, and chuck to complete your rotary table. The 6” table is a complete pack including the dividing plates and the tailstock. The 8” table takes 1/2” T-slot nuts (35-110) and has an MT3 bore. The 6" table uses 10 mm t-slot nuts and has an MT2 bore.

8613371530291

8613371530291