how to make a rotary table brands

For a corner fillet weld such as those, it may help if you grind off half of each corner on the slotted plates giving a 45 deg V. This will help to ensure the weld gets good penetration and strength at the same time as allowing you to retain the original edges for alignment.

Looks to me like you are using a 240V single phase welder. In Oz I would use a Satin craft 13 electrode as these have a slower flux than a Satin craft 12. This helps stop the flux from running into the weld pool and stopping the arc. My welder has only 2 settings 2.5 and 3.2 mm so I try and use the shortest possible cable between the power point and the welder. If I have to go longer a heavier duty cable helps keep up the volts and amps.

Generally speaking, older, larger sizes don"t sell well because they are heavy. If you"re able to move/slide heavy things, or creative enough to create a system where you don"t have to handle it, then you can often score old, big, quality products for little money.

That is the route I went. I found a new, old-stock Bridgeport 15" on ebay listed as "pickup only". Had an acquaintance in the area that was willing to pick it up for me. I won it for $200 give or take. I built a swing-arm on the side of my mill column that the ro-tab bolts to using the t-slots of table top (so the bottom is smooth). I just swing the arm out over the mill table, crank the knee up to take the pressure off the bolts so I can remove then, slide the rotab where I need it and bolt it down. The only time I ever "lift" it is if I"m attaching it to the 90 degree mount (got that from the same seller for $60 on ebay). I will say that if you do a lot of work with the table on 90 you may want to just go for one built for either orientation, and you may want to go smaller. I don"t do much 90 degree work and I"ve always been able to "make it work" when it was an issue. IE, I was once milling some key-ways spaced precisely around a small circular element (1.5" diameter) so I used my rotab (this was before I had a proper collet indexer). I had to extend the part out further from the table so the table (about 18" high when on the 90 degree mount) could stand up beside the head while the quill did the machining. You wouldn"t have that problem with an 8" rotab.

As far as brands: that depends on your desired precision level and fit & finish quality. Import products are cheap and they will work for many uses, but if you can score used name-brand for less or even similar money why not go with name-brand?

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

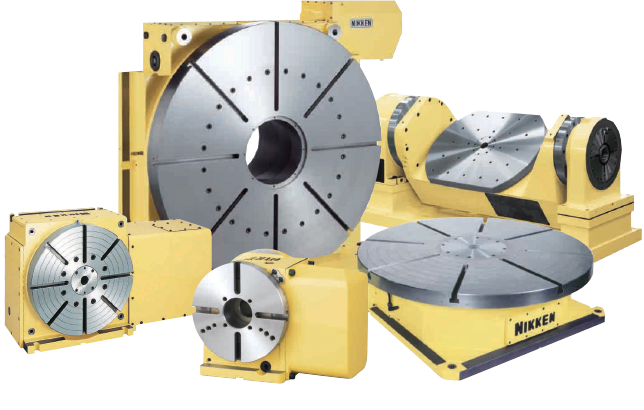

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

The main part of the RollerDrive mechanism consists of an input shaft and an output turret in which roller followers are embedded. An integral cross-roller bearing supports the output turret with ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

There are manual and motorized stages, open-loop and feedback stages, and stages of various sizes, so it is important to select the right one for each application.

In addition, since rotary motion is often performed for the purpose of processing, measurement, or some other subsequent operation, the use of rotary tables by themselves is rare.

Since the rotation stage itself can be mounted in various directions, it is used to determine whether it is more efficient to rotate the object to be processed or measured or the mechanical parts of the equipment.

High-precision rotation is required depending on the application, such as manual coarse rotation when a rough angle is required, and fine rotation when fine angle adjustment is required.

Rotation mechanisms used in chairs and other equipment are also classified as rotary stages in the broad sense of the term, so they are used not only in manufacturing but also in home applications.

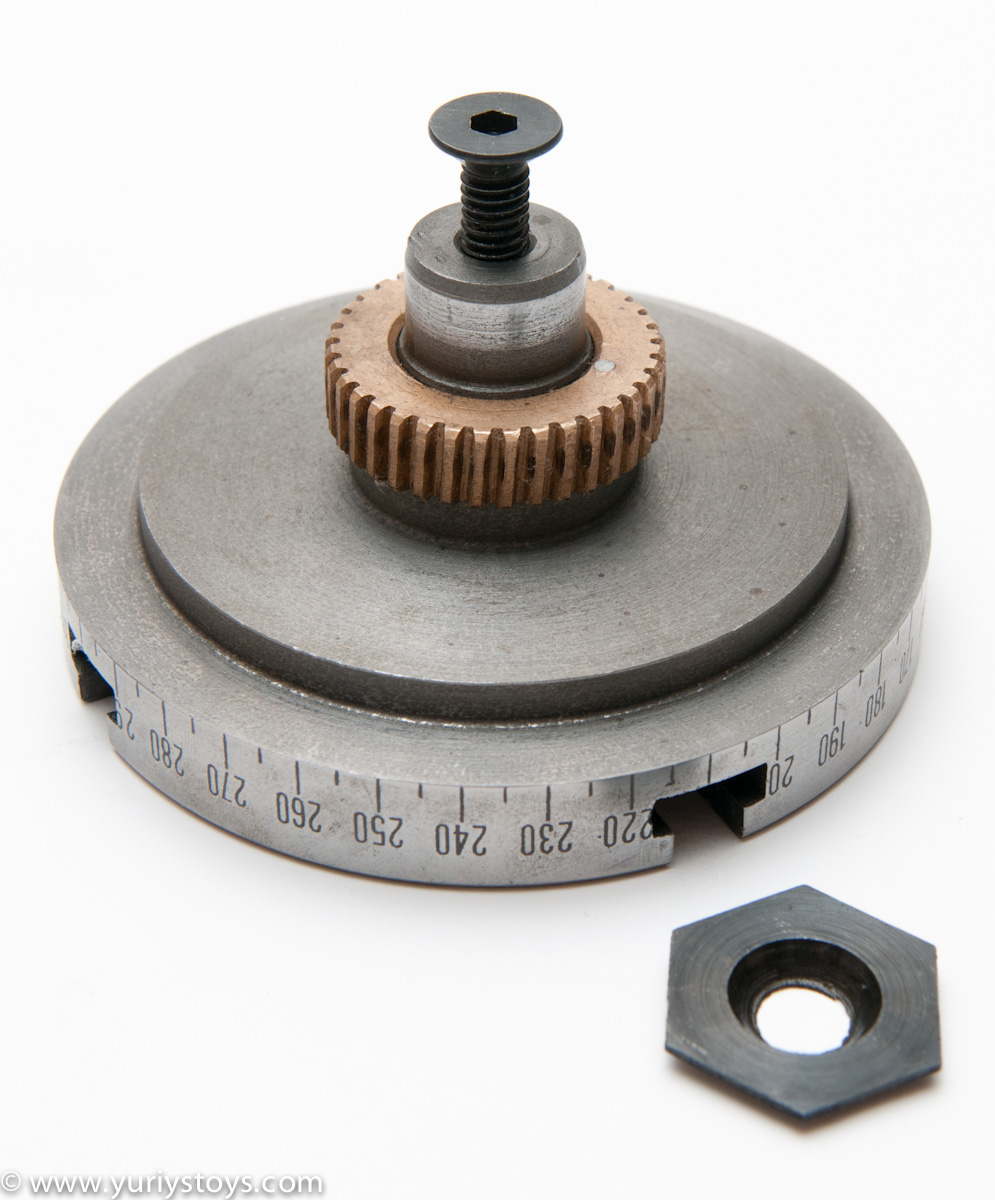

A crossed roller bearing is a bearing structure in which rollers are arranged between the inner and outer rings. The rollers are arranged in a straight row with a 45° contact angle, enabling the back bearing structure of a ball bearing to be realized with a single row, and the structure is capable of receiving loads from multiple directions simultaneously. The rotary table and cross roller bearings can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the rotary table is directly related to the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads can be used in the fine-tuning rotation mechanism to obtain high positioning accuracy.

Indexing tables are used in a multitude of industries and in numerous applications. Their design is optimal for many manufacturing jobs, and they are a critical component in most automated manufacturing systems. Indexing tables are best defined as a machine tool positioning device. They carry components in a manufacturing environment with a repeating process of indexing (rotating) around an axis, stopping, dwelling while an operation is performed, then indexing again to repeat the process. They are usually made of circular steel plates, with one or more spindles, a drive system, encoders, sensors, controllers and slots or mounting holes to hold components.

Virtually any manufacturing operation can be performed on a part held by an indexing table including welding, grinding, drilling, assembly, painting, inspection, testing and more. In order to maximize operational efficiency, the machine doing the operation must also be built for the same intended application as the indexing table for them to work in synch. Similarly the machine that loads the indexing table with parts must also be synchronized. They must have the same capacity and be able to manage to the same dwell time for the system to work.

If the timing of these machines are coordinated, the time to operate on or assemble a product can be a fraction of that of workers assembling a product.

Industries that use indexing tables include automotive manufacturers, bottling companies, microchip manufacturers, pharmaceutical makers, consumer products companies and many more. They are invaluable to manufacturers pushing for automation and increased efficiency in their factories, turning work that used to take days into work that takes only hours. If a simple assembly task is required on small parts in a factory, there is no better way to complete the task than by coupling an assembly tool and an indexing table.

This kit has a has a special handwheel which is also a 60 XL037 pulley. Add this handwheel, bracket, motor and drive belt kit to your table and it will be both full manual and CNC operational. The motor is pre- configured to plug into the Gecko 540 drive. If you have a different CNC drive system, the DB 9 connector can be removed and your own connector added. The motor is a NEMA 23 with 450 OZ/IN torque.

PLEASE NOTE: This kit fits our 6" rotary tables. If you have an older unit from Shoptask or Shopmaster or some other brands of Indian rotary tables, this kit will fit. If you have the Chinese clone of the Indian 6" rotary, you will need kit # 100110CHINA. Please refer to the diagram to be sure the bracket will fit your rotary table.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

CNC Indexing & Feeding Technologies is proud to represent the TJR line of rotary tables, indexers and accessories. TJR originated as a rotary table sales and service agent and established itself as an OEM in 2009.

TJR tables feature an anti-wearing worm gear, durable, high-tensile brass shafts, and braking systems with a large clamping range. All new TJR tables come standard with a 3-year parts warranty.

Standard Rotary Tables. The AR Series is TJR’s standard 4th axis pneumatic brake rotary table. It is offered in both a Right hand motor mounting and Left hand motor mounting option. The HR Series is TJR’s standard hydraulic brake 4th axis rotary table.

CNC Indexing & Feeding Technologies offers a wide range of TJR rotary tables. However, many are unclear about what rotary tables can do for their business, as well as how they work in CNC machining. First, let’s consider the basics about a rotary table and how it works in the machining and manufacturing processes.

Milling and other industrial processes require cutting and shaping, usually with a high degree of precision. This creates the need for computer-guided systems that can create workpieces, prototypes or tools for companies on demand. The process is expedited, reducing or removing the need for large assembly line staff or other hand crafters.

In many cases, the work pieces created through CNC machining would be impossible without computer assistance. The code used to communicate between the CNC machine and computer software is specialized. Older machines, or manual machines, used hard wired controllers. However, new CNC machines rely on modern devices like CDs, USB drives, networks and so on.

A lathe or milling machine requires its own set of parts to work sufficiently. For example, an indexing head is needed to allow circular shaping. The indexing element allows the piece to be rotated at an angle or even divided into sections.

A rotary table can tilt and rotate. The table makes use of the indexing head in order to cut according to a specific technique. This makes it possible for the machine to create a workpiece with complete flexibility in rotation and angling.

A rotary table can help to create arcs and circles, an important process in part or tool fabrication. Tools can be specially made, such as car parts, machine parts, and many other objects.

The CNC process lets companies make straight cuts even with multiple angles and to cut small objects into even smaller parts. CNC rotary tables can also help in the processes of cutting gears, drilling or cutting holes.

The table can also be used along with a dividing head and index plate, to further concentrate the shaping. Tables are also used to hold certain parts for superior milling techniques.

Adding rotary tables will improve your capacity to produce the parts you want and increase profits. This brings us to the primary advantage of CNC rotary tables: less time and greater accuracy in cutting.

Companies are often outsourced to create work pieces for larger brands. However, some companies simply create their own prototypes, tools or work pieces with their own facility for machining. There are also contract shops, mechanic shops, electronics companies, inventors, engineering, and retail companies.

Most companies save costs by scaling their needs with small productions. In many cases, they may only have one facility or work with one type of part. The key is not to create “anything” but to specialize in objects created so the process can be streamlined.

The benefits of using cnc rotary tables include consistency, faster production and increased capacity. Products and work pieces assembled through CNC systems are more reliable than products created manually or through other methods. The process is identical each and every time, so consistency can be guaranteed. This is critical for a company trying to ensure safety protocol.

Flexibility is another advantage, as the systems are programmable. These systems are designed to minimize downtime in between their running processes, offering greater flexibility.

The capacity of complexity of product is another benefit. Complex motions are made simpler by CNC rotary tables, making them more affordable to produce.

Naturally, such an intricate process cannot be unsupervised, since efficiency depends on optimal performance. A supervisor must oversee a rotary table operating with CNC controls to ensure the machine and software are configured correctly.

This involves setting the system up, installing the software, and watching over the production. If something goes wrong, the software must be fixed and the machine repaired. Machines are not constantly running, but must be evaluated and cleaned regularly, ensuring that they will be mostly self-sufficient.

We offer a wide variety of rotary tables to meet all of your needs. This includes standard rotary tables with full rotating axis capabilities, and vertical and horizontal mounting positions.

We also offer large rotary tables with hydraulic brake systems, which allow higher clamping torques. You can also find assistance with smaller rear mount rotary tables or tilt rotary tables.

Horizontal rotary tables are specially made for horizontal mounting and carrying a much heavier weight. Horizontal index tables are available, whether in manual or CNC index tables style. Finally, there are face gear rotary tables and rotary table accessories, ideal for projects that need higher degrees of accuracy.

Remember that quality production is synonymous with efficiency and accuracy. Product producers must have the right equipment operating at full capacity in order to guarantee consistency.

CNC Indexing & Feeding Technologies can help you find the machine tool accessories you need to meet your production demands. This includes simple rotating feature, larger work pieces, vertical and horizontal applications, or even 4 or 5 axis work. With TJR rotary tables, you can improve your cycle and process time, reduce your down time and increase your profits.

You can always reach us if you have additional questions regarding how to get started by calling us at 513.770.4200. It’s time to expand your business and your capability!

For over 50 years, Pfiffner has been developing rotary transfer machines that offer high precision and flexibility, marketing the most cost-effective solutions for high-volume workpieces. Thanks to our solution-oriented approach, well-developed expertise in the market, and a passionate innovative spirit, we"ve established ourselves as a leading partner for innovative industry sectors all around the world. Our success is based on a clear vision: We always remain a leap ahead of the times, ensuring satisfied customers every single day.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Malad West, Mumbai 21, Shripal Services Industrial Estate, Pawan Baug, Chincholi Phatak, Off. S.V.Road, Malad West, Malad West, Mumbai - 400064, Dist. Mumbai, Maharashtra

Sector 37D, Gurugram, Haryana 122006, Gurgaon, Dist. Gurugram Nath Tools Company , Garauli Khurd, main Pataudi Rd,, Sector 37D, Gurugram, Haryana 122006, Gurgaon - 122006, Dist. Gurugram, Haryana

DELHI,NCR,HARYANA,PUNJAB,UP,RAJASTHAN, Dharuhera, Dist. Rewari 347, Ganpati Plaza, NRP Bass Road, DELHI,NCR,HARYANA,PUNJAB,UP,RAJASTHAN, Dharuhera - 123106, Dist. Rewari, Haryana

Airoli, Navi Mumbai, Dist. Thane Krishna Kanhaiya, Sector No. 8, Plot No. 21, Shop No. 12 Ground Floor, Airoli, Airoli, Navi Mumbai - 400708, Dist. Thane, Maharashtra

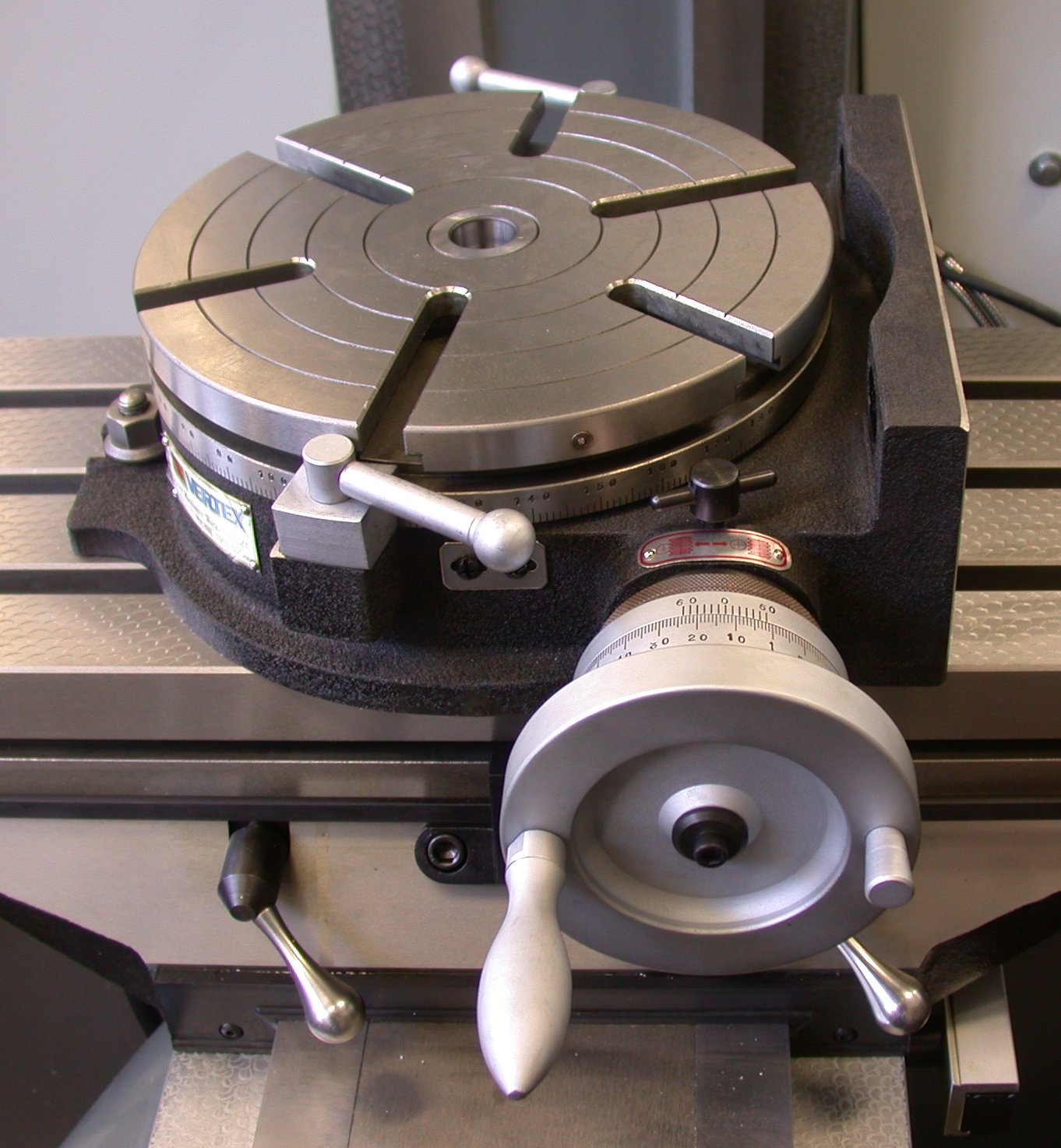

Rotary Tables are the perfect solution to reduce part handling and shorten cycle times. Travers offers a variety of Rotary Tables to hold medium to large parts for multi-side machining or complex contouring. The Rotary Tables are available in sizes 4 inches to 16 inches. These heavy-duty Rotary Tables can be mounted vertically or horizontally. Cross slide or Tilting models are available. They feature precision T-slots in sizes ranging from 0.39 inch to 0.625 inch. The large through-holes are ideal for versatile fixturing. We have over 20 types of Rotary Tables from leading manufacturers like Phase II, Yuasa, and Palmgren. Some models come with dividing plate accessories and adjustable tailstock. Use the search selection matrix to take a look at the available Rotary Table models Travers has to offer. Pick the model that suits you best depending on fixture type, fixture plate size, table T-slots sizes. You can also choose Rotary Tables that are in stock directly from New York, South Carolina, or California.

The operator plays a critical role in a typical application of one or two HMCs being served by a pallet pool of 8, 10, or 12 pallets with one or more 5 or 6-axis rotary tables.

Until now, with a rotary table in the cell, the operator had to couple and uncouple the cables from the machine tool to the rotary table through an operator-coupled interface. Now, the Autocoupler, cell controller, and machine tool take care of all coupling and uncoupling. The operator is not involved.

With no need for an operator, shops can run true lights-out manufacturing. In addition to cost saved by not having an operator on the third shift, other savings come from reduced downtime, the result of not having an operator climbing in and out of the machine making manual connections.

The Autocoupler fits most HMCs. One side of the coupler affixes to the center post of the HMC on the pallet-shuttle door, outside the harsh environment of chips and coolant. The other side of the coupler mounts to the back side of the rotary table. A guide pin on the coupler mounted to the machine tool ensures precise mating of the Autocoupler halves and the electrical and pneumatic connections between machine tool and rotary table.

The machine tool"s PLC and the cell controller communicate so the machine tool knows it has an Autocoupler, as opposed to manual coupling, and the cell controller knows that it"s picking up a pallet with a rotary table equipped with an Autocoupler.

The machine tool knows when the pallet has been delivered. Once machining is complete, the PLC and cell controller again communicate and the Autocoupler disconnects and the pallet moves out into the pool. Ortman points out the Autocoupler is virtually maintenance free. "If this were in a big cell," he says, "once an hour would probably be at the high end of the number of times a rotary table would be brought to the machine to run a part. This means coupling and uncoupling about 24 times a day. We have an Autocoupler system on our floor that"s run more than 18,000 cycles with no maintenance — the equivalent of more than 750 days of continuous operation."

Risk of Contamination: Traditional sealtight cable is susceptible to cracking and splitting when exposed to some coolants and continuous flexing. Over time, cracking and splitting will lead to higher failure rates.

Their sealtight connections on the back of the rotary table create additional potential contamination points. These threaded connectors also make connecting and disconnecting the table a time-consuming and difficult process.

Two cables can create a tangled mess, which can cause premature wear. Two cables require four connections and four-times the chance for contamination.

Locating the connection points close to coolant and chips creates a greater chance for failure, as traditional sealtight will collect coolant. Furthermore, the cables could easily be pinched during machine movement or part loading.

Has it suddenly stopped working and you"re panicking about downtime? Don"t worry - at CNC we can repair or deconstruct and fully rebuild your device back to its former glory.

At CNC Rotary, we offer a quick, dependable service where we will collect your table, take it back to our workshop, fix it and deliver it back to you as quickly as possible.

Penn Tool Co. has a variety of precision rotary tables for sale. Simplify your production work with a rotary table that can be used for many different machining applications. In production, it is essential that jobs are done quickly, efficiently, and precisely. In the industry of intricate metalworking, precision matters and can make all the difference. All of the parts should look identical in the end, and our tools can help you do just that. To ensure quality and durability, we only carry top-rated, premium brands you can trust including Vertex, Harig and Phase II. With an easy-to-operate precision rotary tablefrom Penn Tool Co., get the accuracy you need and a timely, beautiful end result. Browse our collection, and order today!

8613371530291

8613371530291