how to make a rotary table made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

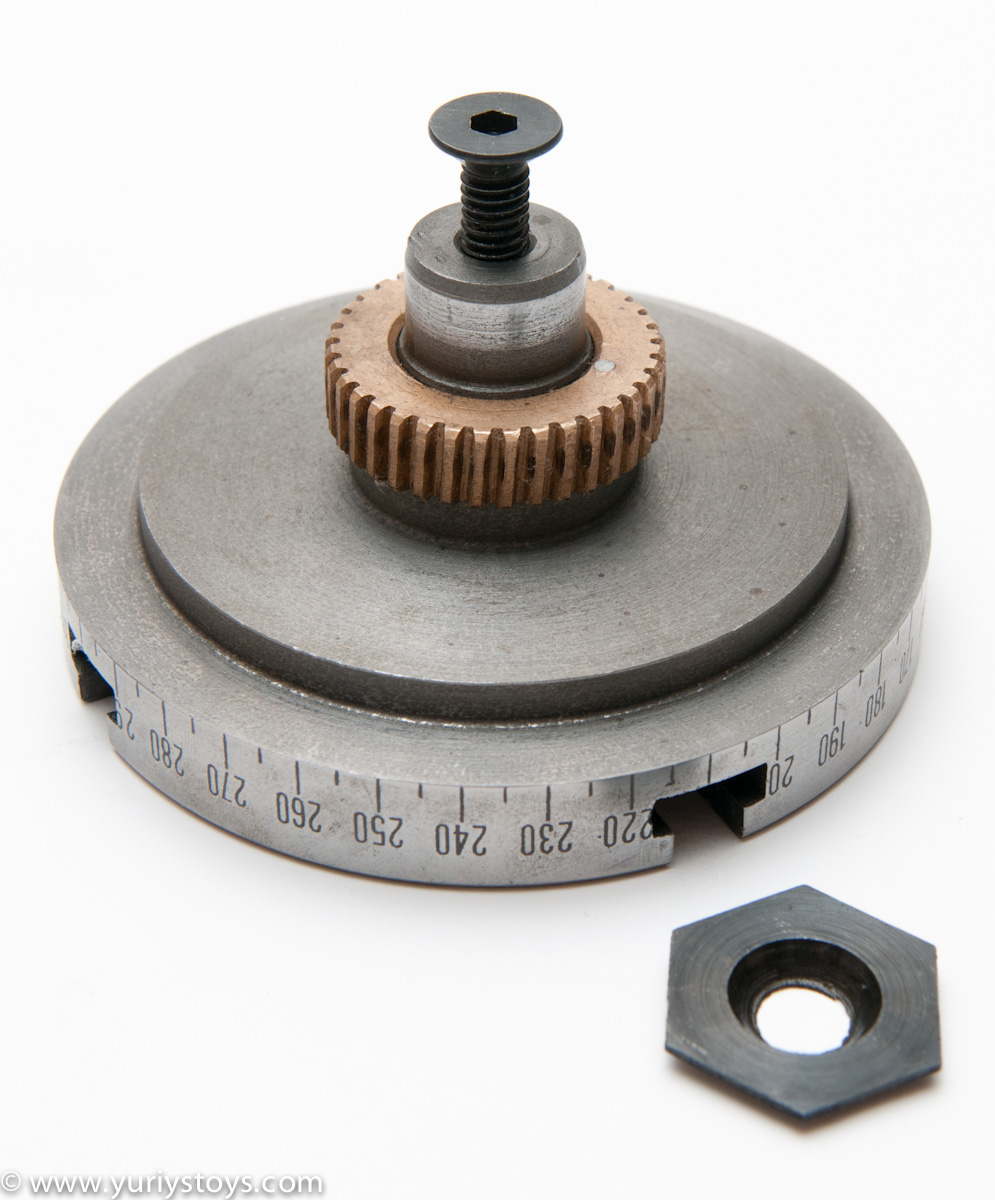

Please refer to the pictures and diagram to be sure the kit will mount to your table. Your rotary table should look similar to the one in the photo- for illustration only, the rotary table is not included with the CNC drive kit.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

Specifications Top Quality 304 Stainless steel for feeding bottle Dia 100cm Accumulative rotary table Standard diameter100cm, customized size available Top Quality 304 Stainless steel for feeding bottle Dia 100cm Accumulative rotary table Accumulative table& rotary table standard size diameter100cm, customized size is available Variable speed drive Material: SS201,SS304,SS316 Useage:for collecting bottle or bags. Top Quality 304 Stainless steel for feeding bottle Dia 100cm Accumulative rotary table Top Quality 304 Stainless steel for feeding bottle Dia 100cm Accumulative rotary table

My first rotab was a Wholesale Tool 6 inch. I was turning a 12 inch wheel center (had to weld it up to make it 12.25 dia) on the rotab with a large roughing endmill in the spindle while rotating the rotab (my lathe swing dia is 12.2 inches w/o locally grinding a divot into the lathe bed (partially into the tailstock way) - not that the tailstock would ever be that close to the chuck - I just did not want to be that much of a hack so I used the mill and rotab). I ended up shearing teeth on the ring gear in the rotab. Had I used a less aggressive cut, maybe roughed in the shape with a hand grinder before machining the rotab probably would have survived. Finished turning the wheel center at work during my lunch time (with the blessing of the guys in the machine/fab shop) on a 20 inch swing lathe - I"ve never operated a lathe that big and the pucker facter was high!

Now I have a PhaseII 6 inch rotab but have not had need to abuse it like I did the Wholesale Tool rotab. I still have the damaged rotab - figured I might make some sort of a tool out of it someday (4 yrs later still have not figured out what I might use it for).

For my needs an 8 inch rotab would probably be more durable but with a 6 inch 3-jaw attached to the 6 inch rotab, its at the weight limit that I can comfortably lift.

Axial-radial bearings are double-direction axial bearings for screw mounting with a radial guidance bearing. These ready-to-fit, pregreased units are very rigid, have high load-carrying capacity and operate with particularly high accuracy. They can support radial forces, axial forces from both directions and tilting moments free from clearance. ZKLDF axial angular contact ball bearings are low-friction, ready-to-fit, greased bearing units with high accuracy for very high speeds, high axial and radial loads and high demands on tilting rigidity. Axial-radial bearings with angular measuring system YRTM and YRTSM correspond in mechanical terms to series YRT and YRTS but are additionally fitted with an angular measuring system.

By continuing to use AliExpress you accept our use of cookies (view more on our Privacy Policy). You can adjust your Cookie Preferences at the bottom of this page.

The SV type are designed specially for servo motor gearbox for motion control applications. It takes full advantage of the flexibility of the servo motor, giving designers greater freedom of mechanism design.

It is a brand-new kind of rotating load device. Incorporating high transmission efficiency, high precision, high rigidity, and high cost performance, it combines the advantages of the servo motor and DD motor, obtaining a balance between these three products.

The adoption of the top spiral bevel gear and the optimized design of contact tooth surface makes the even load and allow high torque output. When it combined with planetary reducer or right angle reducer, the gear ratio shall become bigger up to 1:180.

Equipped with the servo motor, it can make segments at any angle, which can meet the digit control that the cam indexer cannot achieve. The positioning accuracy is comparable with the direct drive motor which can realize the positioning of the inertia load in a short time.

The equipment table and robot arm can be directly mounted on the output table of Rotary Table. It can save the time and cost for mechanical design, parts allocation, belt debugging, etc., which compared with the use of mechanical parts such as pulleys and belt.

Wiring and piping are more convenient and simple, and the advantages of this feature are particularly prominent in complicated wiring and piping environments.

Applied for many application like CNC Indexing Device, Military Radar, Gravity Sensor Test, Electronic Compass Test of mobile phone and other precise electronic product. It also can used for robot arm joints, testing device, laser cutting, etc.

when I was young, strong, healthy, and thought nothing of lifting it, a 10" H & V was my first choice. I still think it was a good choice for the work I mostly do, and this is where you may decide to compromise. If you do small work, an 8" table is much lighter and more convenient to set up. Stood vertical, it interferes less with the spindle to reach center. I don"t think a 6" is a good choice unless you know you will only be working miniature stuff. You use a considerable percentage of a small table just for set ups and hold down clamps on a lot of work, and a small table does not leave much room.

I like 90:1 gear ratio for circular milling, which is presumably your primary interest with a rotary table. My 10" table is 90:1, and that is a pretty good ratio for milling diameters (hand cranking) out to 12" or so. My 20" table is also only 90:1, and out near or past the rim (I do one part at 32" diameter) that always seems _very_ coarse.

If most of your work is small, round to begin with, and will actually be dividing work, where you index the table, lock it, and then drill a hole or mill a slot with the machine axis drive, you might find a dividing head more useful. For instance, I"ve made gears on a vertical rotary table, and in a spin index. On the table, you need an insert collet chuck or other arrangement in the center hole to get the work out far enough to clear the cutter. It"s a lot more convenient on a dividing head. OTOH, I don"t find it fun or convenient to do much circular milling on a dividing head if the work diameter is much over a few inches.

Dividing heads typically are 40:1, so faster to index, position to positon. But the milling capability on a radius is limited by the "coarse" ratio to smaller diameters, as is the usual work holding (collet or chuck) arrangement. A dividing head will tilt from below horizontal to past vertical, so you can mill, drill, bore or shape profiles at any angle in between.

an 8" H & V with dividing plates and set up, can usually be arranged somehow to do most of the work you might want to do on it. It is relatively light to move, and convenient to set up with reasonable space (spindle clearance, e.g.)limitations to be considered. A little bigger (10") is better, if you will ever need the capacity.

Another plus for the Sherline RT is Sherline sells a bunch of accessories for it as well. There is a 5" tooling plate, a tilting angle table, and a variety of center adapters to mount a chuck to the RT. They also have a full CNC conversion including a CNC indexer if you ever wanted to go that way.

I was going to say I didn"t see that much of a price advantage on the no name Ebay rotary tables, but the Sherline is almost $300. I didn"t remember it being that much, in fact I paid less for my 6" Taiwan RT although it was lightly used.

In favor of the import rotary tables some of them are available with indexing plates and tail stocks allowing them to be used as an indexer as well as a rotary table.

For a corner fillet weld such as those, it may help if you grind off half of each corner on the slotted plates giving a 45 deg V. This will help to ensure the weld gets good penetration and strength at the same time as allowing you to retain the original edges for alignment.

Looks to me like you are using a 240V single phase welder. In Oz I would use a Satin craft 13 electrode as these have a slower flux than a Satin craft 12. This helps stop the flux from running into the weld pool and stopping the arc. My welder has only 2 settings 2.5 and 3.2 mm so I try and use the shortest possible cable between the power point and the welder. If I have to go longer a heavier duty cable helps keep up the volts and amps.

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available. A rotary fixture used in this fashion is more appropriately called a dividing head (indexing head).

The table shown is a manually operated type. Powered tables under the control of CNC machines are now available, and provide a fourth axis to CNC milling machines. Rotary tables are made with a solid base, which has provision for clamping onto another table or fixture. The actual table is a precision-machined disc to which the work piece is clamped (T slots are generally provided for this purpose). This disc can rotate freely, for indexing, or under the control of a worm (handwheel), with the worm wheel portion being made part of the actual table. High precision tables are driven by backlash compensating duplex worms.

The ratio between worm and table is generally 40:1, 72:1 or 90:1 but may be any ratio that can be easily divided exactly into 360°. This is for ease of use when indexing plates are available. A graduated dial and, often, a vernier scale enable the operator to position the table, and thus the work affixed to it with great accuracy.

Rotary tables are most commonly mounted "flat", with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it "flat" on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the workpiece "between centers."

With the table mounted on a secondary table, the workpiece is accurately centered on the rotary table"s axis, which in turn is centered on the cutting tool"s axis. All three axes are thus coaxial. From this point, the secondary table can be offset in either the X or Y direction to set the cutter the desired distance from the workpiece"s center. This allows concentric machining operations on the workpiece. Placing the workpiece eccentrically a set distance from the center permits more complex curves to be cut. As with other setups on a vertical mill, the milling operation can be either drilling a series of concentric, and possibly equidistant holes, or face or end milling either circular or semicircular shapes and contours.

* To create large-diameter holes, via milling in a circular toolpath, on small milling machines that don"t have the power to drive large twist drills (>0.500"/>13 mm)

* With the addition of a compound table on top of the rotary table, the user can move the center of rotation to anywhere on the part being cut. This enables an arc to be cut at any place on the part.

Additionally, if converted to stepper motor operation, with a CNC milling machine and a tailstock, a rotary table allows many parts to be made on a mill that otherwise would require a lathe.

Heavy duty servo rotary table HRTJ280 series could be freely programmed for any angle indexing, with large central opening reach to 135mm, it is quite convenient for engineers to wiring and piping in automation rotary motion and provide more options for engineers.

Sango HRTJ280 heavy duty servo rotary table is making better performance than HRT280, more output torque but keep same positioning accuracy, bigger designed loading than HRT280.

An anti-overturning stabilization ring is arranged in the center hole of the turntable of HRTJ280, which can greatly enhance the overturning moment and solve the load-bearing problems such as side mounting and hoisting. The load can be directly fixed on the hollow rotating platform for transmission, and it is suitable for servo motors and stepping motors of various brands.

Free Model selection service is provided by Sango Automation. When below project information submitted to our technical sales, Sango experienced engineer shall make calculation based on the data, then advice the model for users with proper motor configuration and gear ratio.

80DTRotary Indexing Tableis a process where repeated angular displacement during a machine cycle is followed by motionless dwell. A rotary indexing table is specifically designed to make repetitive moves around a platform. Essentially, they are highly precise work-positioning devices that index parts to be worked or machined in multiple operations.

Being a professional Cam Indexer manufacturer in china mainland, Sango Automation provides 8 sizes of DT Cam Indexing Tables, ranges from 80DT, 110DT, 140DT, 180DT, 210DT, 250DT, 350DT, 450DT which is defined according to the shaft center distance between input shaft and output shaft respectively.

8613371530291

8613371530291