hv4 rotary table factory

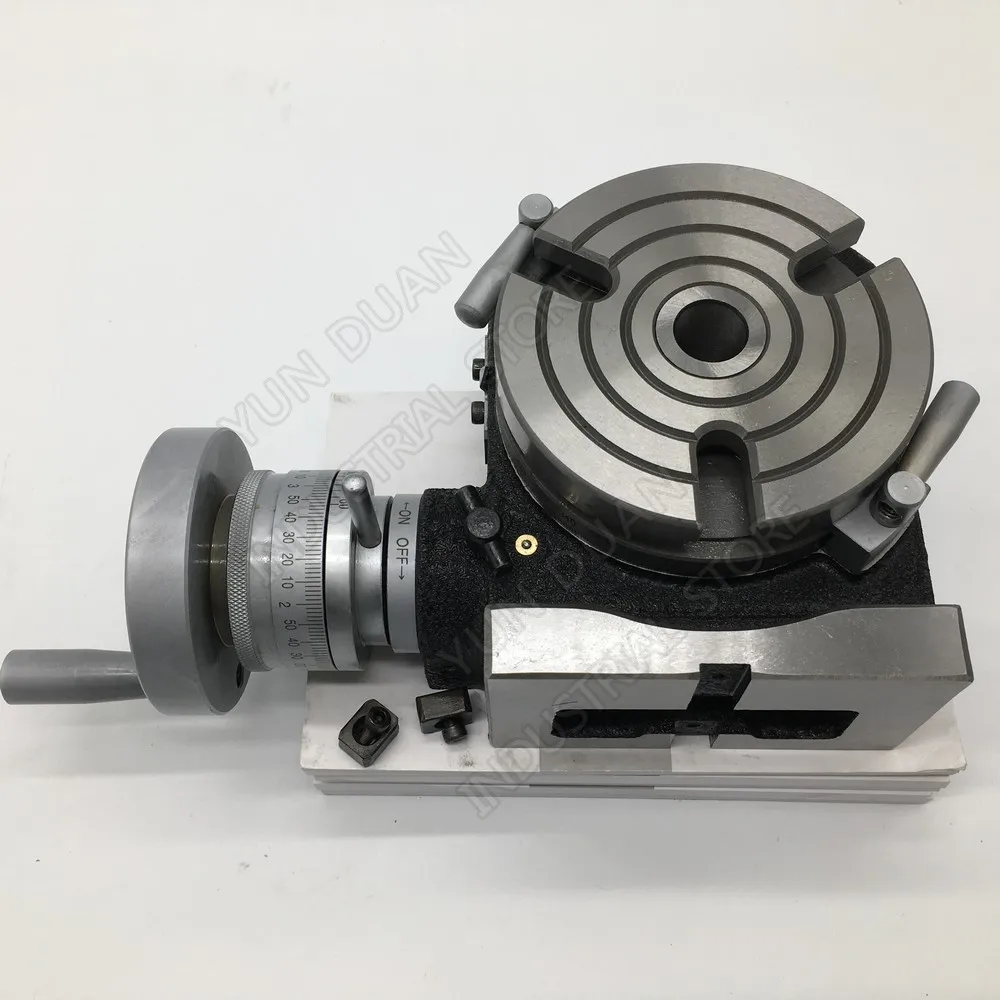

Kaka Industrial HV-4, 4”Horizontal Vertical Rotary Table Rotary table TSL Vertical & Horizontal MT3 Center Sleeve Rotary Table 3 slot Precision Milling Table 360 Degrees Precision Rotary Table

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. Some rotary tables allow the use of index plates for indexing operations, and some can also be fitted with dividing plates that enable regular work positioning at divisions for which indexing plates are not available.

One of the main points to consider when selecting a rotary table is to go as big as you can within the limits of the milling machine that you want to use the table with. I have a small 3″ table that I have used with my Unimat Mill and with the larger Mini Mill, but it is rather small and very limited in capacity and stiffness.

The thumb screw on the main body can be released and then the worm rotated to disengage from the gear thus allowing the table to rotate freely, this allows the to be rotated by hand to a given position.

The 2 table clamps lock the table and stop rotation – they are a tad clunky and caphead bolts would be better than the bars. The issue is the bolts are 6×1.25mm which is a very odd and rare thread.

The back of the table with the bolts that attach the back plate, again there is no play in the main table bearing in any direction. The image to the right shows me fitting a locking bolt to hold the ER25 collet chuck in place.

It was only after 6 months that I went to set the table up as a dividing head that I realised I had been sent 3 dividing plates, 2 of which were identical – an email to Warco and the missing dividing plate arrived 2 days later along with a free return address for one of the doubles that I had. Read more about gear cutting with the HV4 rotary table.

This calculation is available for free in a Workshop Calculations spreadsheet. That allows you to change the inputs for your own rotary table/head and division plates.

A solid 4″ rotary table that is actually nearly 4.5″ (110mm) and with a very sturdy worm drive. There are some oddities such as 6×1.25mm threads used for the locking nuts and the locking of the worm drive.

Aligning the rotary table – a simple method to align the rotary table centre with the mill spindle and then to align a part on the table and clamp it down. This is rather rough and ready approach, but it works to a degree. I’ve then gone on to try a number of different methods and then measured the accuracy using a dial indicator.

Gear Cutting with the Warco HV4 Rotary Table – I’ve now used this table with the indexing plates a number of times and the results are superb. This is a very easy to use table that is simple to setup with the plates and easy to again turn back to a normal rotary table.

This little beauty is from a world class factory! It features 3 3/8 inch t-slots for fastening the work to the table and is constructed of high density Meehanite casting. It is inspected by the HEIDENHAIN process and is guaranteed flat and parallel. Gear ratio is 90 to 1 and the worm is hardened and ground. The table is graduated a full 360 degrees and the micro adjust collar is graduated in steps of 1 minute. Vernier scale makes settings down to 10 seconds achievable. MT-2 center hole. We do offer tail stocks and dividing plates for these units as well. Unit is 3.11 inches high.

This little beauty is from a world class factory! It features 3 3/8 inch t-slots for fastening the work to the table and is constructed of high density Meehanite casting. It is inspected by the HEIDENHAIN process and is guaranteed flat and parallel. Gear ratio is 90 to 1 and the worm is hardened and ground. The table is graduated a full 360 degrees and the micro adjust collar is graduated in steps of 1 minute. Vernier scale makes settings down to 10 seconds achievable. MT-2 center hole. We do offer tail stocks and dividing plates for these units as well. Unit is 3.11 inches high.

The Vertex Rotary Table is manufactured from high-density Meehanite cast iron with ground surface areas on the table and body to ensure smooth rotation

I’ve been looking at the Soba and Vertex HV4 rotary tables (for my Warco WM 16 mill). Both tables seem to have HV4 in the name, and both (label not withstanding) seem to look identical in photographs. Does anybody know if they are actually the same thing and just badged differently ?

I don"t have either but Vertex are supposed to be quite good whilst I have heard one nor two negative comments about the SOBA. Having said that I have a SOBA milling vice which is very nice. I"ll be getting the Vertex HV4 when I need one though!

It’s really interesting that there is lots of advice to go bigger. I’ve spent much time debating this to myself, and have seen there are people on the WM16\240 thread that have also gone for the 6inch table. I was about to do the same, but talking to Warco they seemed quite adamant that 6inch was too big. Certainly the vertex HV6 looks fine for horizontal mounting, but I’m worried there just won’t be enough room in the vertical position (I want to have a go a cutting gears\cams) ?

The most important thing is the height you have above the table, especially if you mount a lathe chuck on it, by the time you fit something in the chuck, and if you have a Jacobs chuck in the mill you might find you don"t have room for the drill bit (re-sharpened broken drills work here).

Having looked at manufacturing operations for these specific products in China as well as in India (plenty of sub-contract makers of different ilk in a small area), my personal preference would be for Vertex, based on product consistency, rather than price. Number of slots in the table may or may not be an issue for you, rotary table size and height may be an issue too. If you intend to use the rotary table regularly, the Vertex product would be a better option, in my current opinion, subject to the number of slots on the table you can live with.

If you want to have a go at making gears, then in reality you need to have an RT that can be fitted with a dividing setup. I think RDG sell cheap sets to fit both the Soba and Vertex 4" tables.

With regards to size of table, the 4" would suit you better for that type of job as the larger one as I would think you will be getting rather tight for throat depth on your machine. Besides, if you did need a larger table for horizontal work, you could easily mount a larger disk onto the RT, I have fitted a 9" plate to my 6" Vertex RT to give me more surface area.

After having done some measuring and looking at spec sheets I’m coming to the conclusion that the Vertex HV6 is looking like my best choice. Height when mounted horizontally is 80mm, and that compares to 72mm for the HV4 so the difference is negligible. When mounted vertically the HV6 has a centre height of 102mm, and I’ve 165mm from table to 13mm drill tip in a drill chuck – that’s worse case and still gives me 60 mm clearance. Only down side seems to be the three slots rather than four slots issue, but all things considered (including price I think I can live with this).

One of my concerns is the weight of the 6" unit, especially with a chuck mounted on it. I"m still leaning towards the Vertex HV4 to be used with my 4" four jaw or 4" collet chucks used on my Lathe. Johns idea of using a larger TEE slotted backplate leads me to believe it"s a workable solution for me and the HV4. A 6" TEE slotted backplate should suffice and if I can"t find one I have seen a couple of threads of folks that have made their own. This would also get round the 3 - 4 slot issue. The HV4 is also slightly more affordable.

The Vertex Rotary Table has been designed to be used where a precision work positioning device is required. It allows the operator to mill or drill components at exact intervals around a fixed axis.

The Vertex Rotary Table is manufactured from high-density Meehanite cast iron with ground surface areas on the table and body to ensure smooth rotation

A wide variety of hv rotary tables options are available to you, such as manufacturing plant, machinery repair shops and energy & mining.You can also choose from 1 year, 6 months and 1.5 years hv rotary tables,As well as from not available, {2}, and {3}. and whether hv rotary tables is bearing, gear, or motor.

8613371530291

8613371530291