hydrostatic rotary table supplier

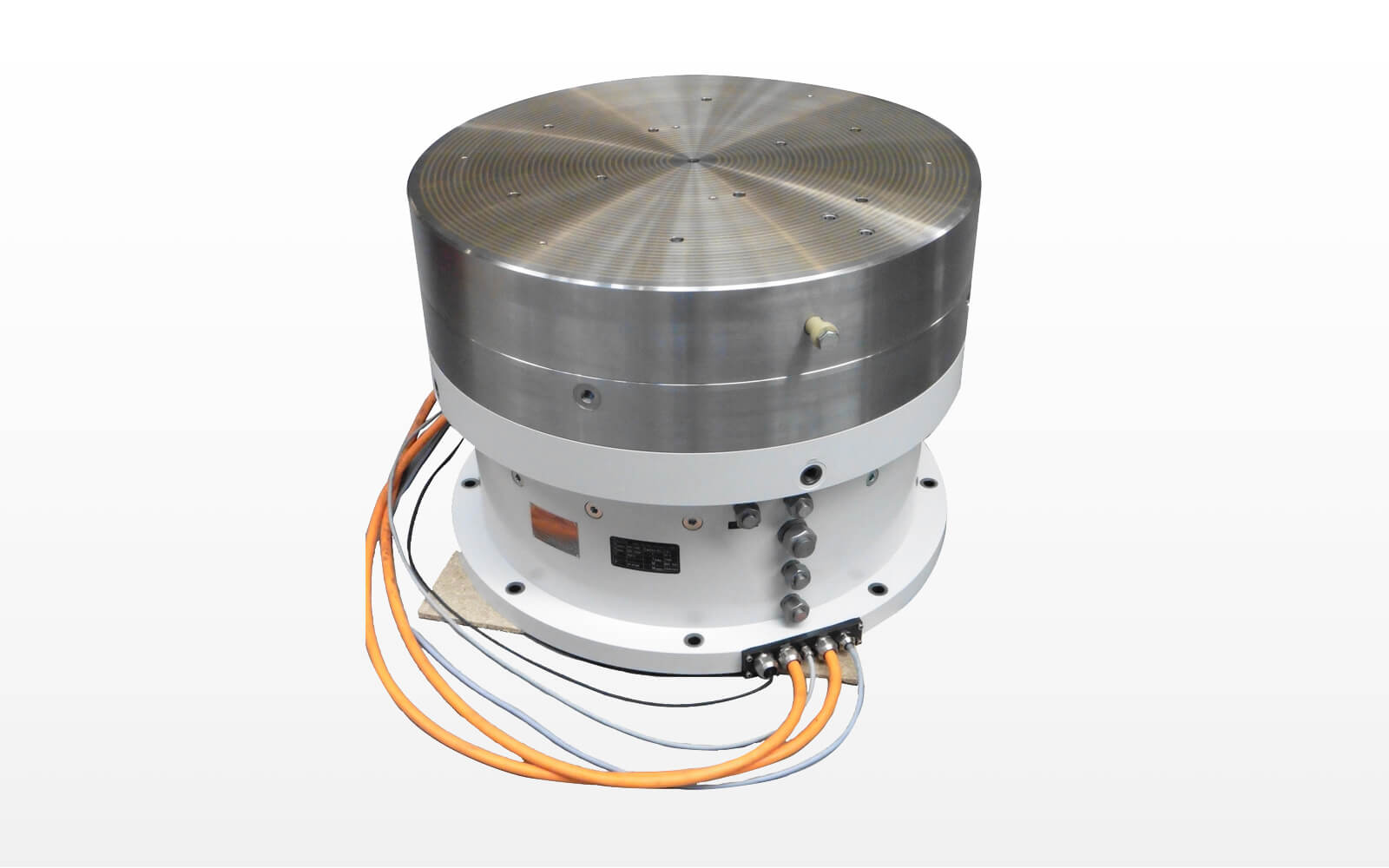

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure is set automatically and independently of production tolerances. The freedom from friction at low speeds prevents slip stick and therefore allows maximum positioning accuracy.

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

This is an example of a hydrostatic spindle designed for high speed grinding with CBN grinding wheels. The small bearing diameter in combination with high surface speed allows the use of CBN wheels even for undercuts in a camshaft application.

Rotary transmission leadthroughs serve as a rear inter face for fluid transmission into the spindle. A hydromechanic clamping unit or integrated clamping cylinder can be actuated with the media oil, air and coolant. The transmission of oil and coolant is possible at rotational speed.

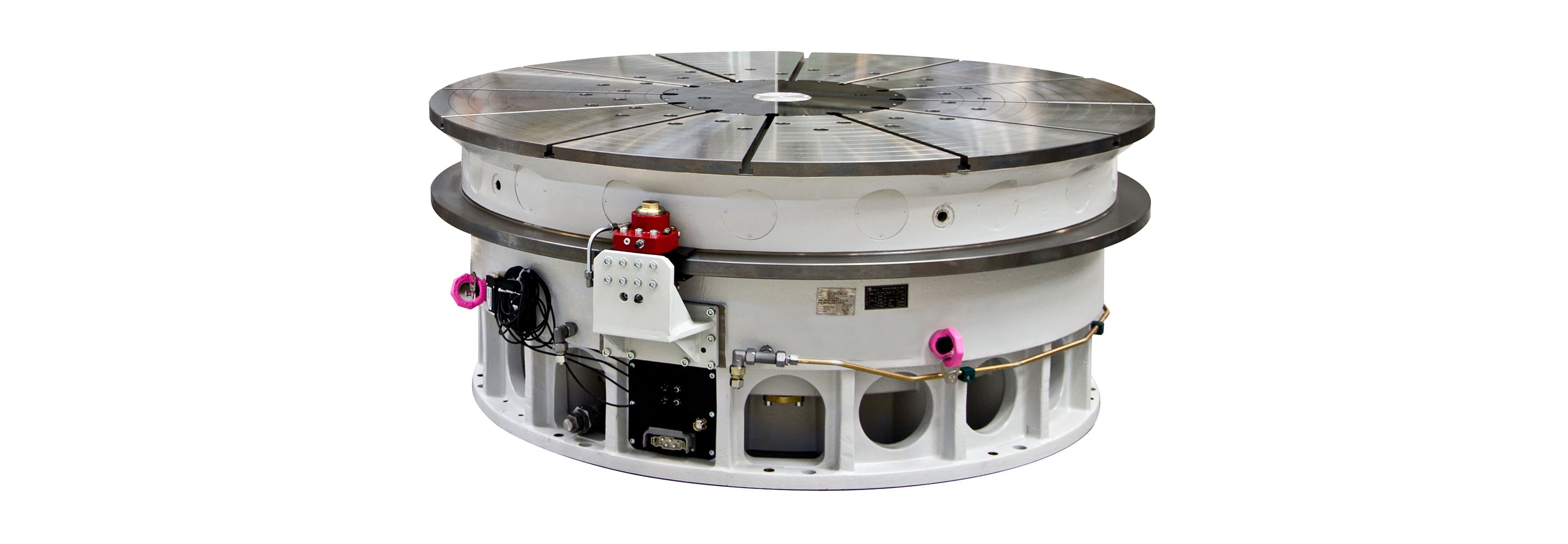

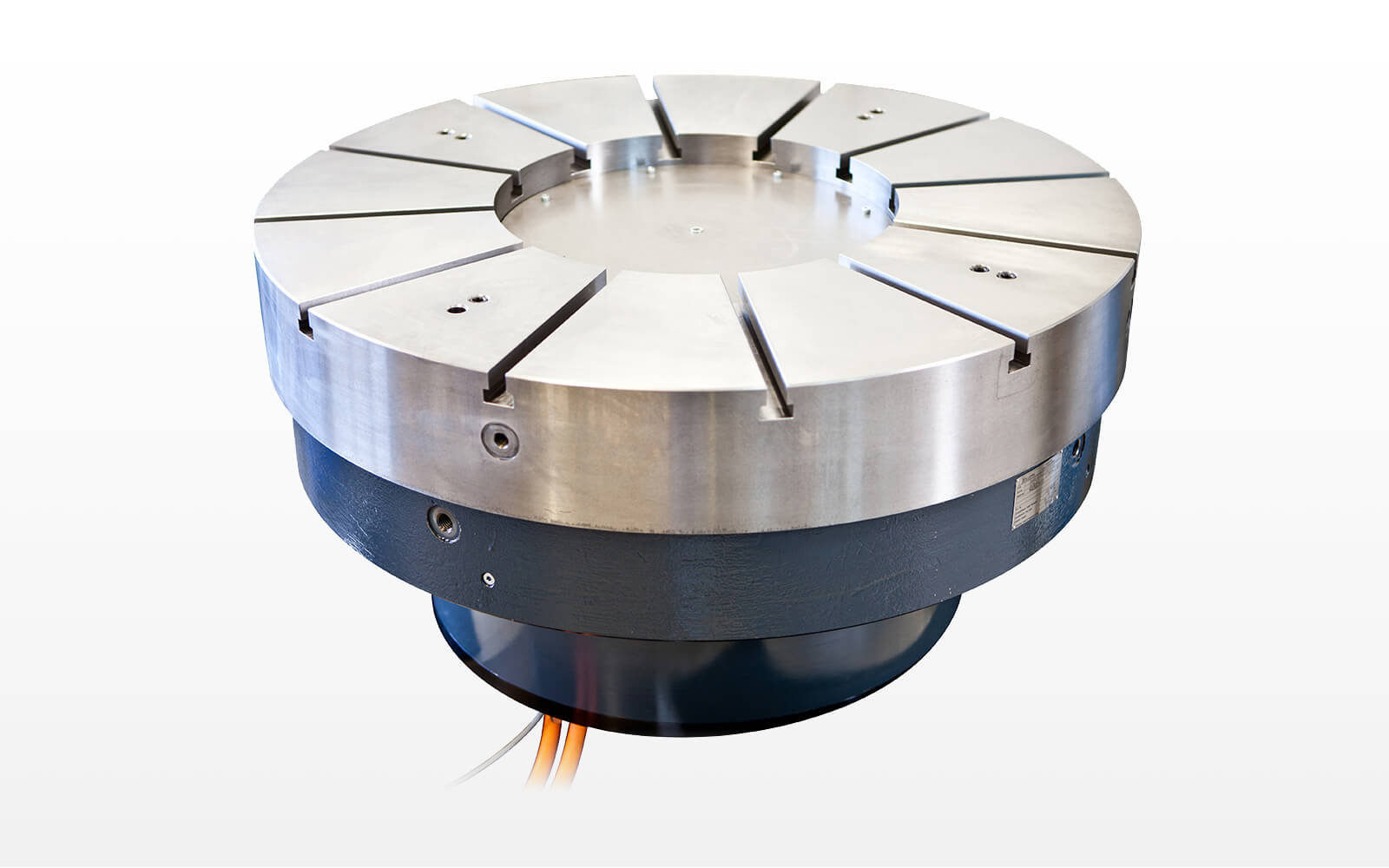

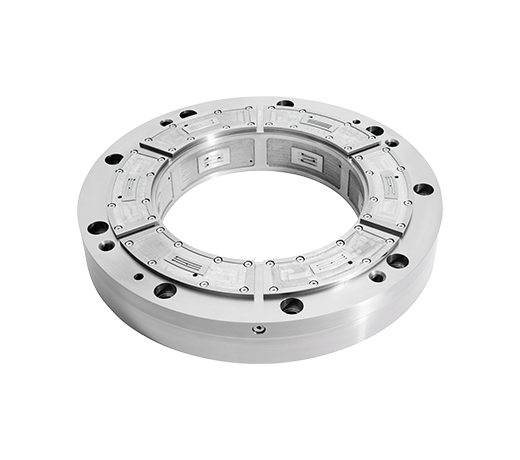

The hydrostatic rotary table is a large machine tool that utilizes hydrostatic bearings, it is used in a wide range of machining for large gears. Hydrostatics provide the rotary table substantially better load capacity than aerostatic bearings. Therefore, hydrostatic tables are commonly used to produce precise components for mills and other large gear applications, typically applied in a grinding system.

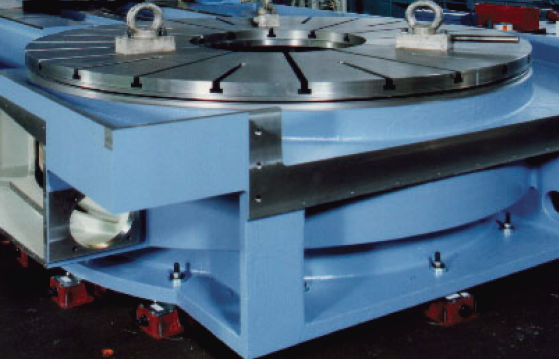

Hydrostatic Rotary tables nowadays are commonly applied on grinding machines, especially surface grinding. If extreme stiffness and high load capacity are the factors that the operators are considering, the hydrostatic rotary table will be an ideal choice.

The hydrostatic bearings provide a pressure supply in order to maintain clearance between the rotating and stationary elements. Between the moving surfaces, the lubrication is constantly supplied under pressure with the bearings.

Hydrostatic rotary tables are supported by oil film between guideways. The bearing surfaces are always separated by a thin lubricant film at static pressure. There is no friction between two contact surfaces when using a hydrostatic guideway. With the flow controller, a hydrostatic fluid film of the guideway, the hydrostatic rotary table can achieve high stiffness, high stability, great precision, and control without gear wear.

However, the accuracy can still be improved by regulating the oil film thickness of the hydrostatic rotary table. The oil film thickness can be controlled by the pressure control and the speed control via a variable hydraulic motor.

The hydrostatic lead screws are used to translate the rotation from a servo motor into linear motion. Compared to ball screws, lead screws have substantially smoother, cleaner, and quieter motion. The hydrostatic lead screw of the rotary table is self-lubricating, totally wear-free while the hydrostatic nut floats on a thin oil film.

Hydraulic motors are mechanical actuators that are designed to convert hydraulic pressure or fluid energy into mechanical power. A hydraulic pump, on the other hand, converts mechanical power into fluids or hydraulic power. Hydraulic motors can provide the driving force for the rotary table, supporting the motion to move an external load.

The oil filter, the pressure relief valve, and the throttle are also required in hydraulic machinery. Oil filters are designed to remove the contaminants from the hydraulic oil in hydrostatic rotary tables. The dirty oil would pass through the filter when pushed by pressure and return to the central hole, then the oil would re-enter the system. Most pressurized lubrication systems work with pressure relief valves, controlling oil to bypass the filter if the flow restriction is excessive. If the oil is thickened or the filter is clogged, pressure valves will also regulate the oil to bypass.

High Accuracy: During machining and grinding, generally, oscillation motions can lead to lower accuracy or even failures over time. However, a hydrostatic rotary table that utilizes hydrostatic guideways and hydrostatic lead screws creates little wear and little loss of accuracy in oscillation motions. With the arrangements, the machining and grinding run in maximum positioning accuracy.

Almost Frictionless Motion: Hydrostatic bearings provide hydrostatic rotary table significant advantages over tables that use mechanical bearings or other approaches to the rotation. Without mechanical attaching parts to wear or generate friction drag, the bearings of the hydrostatic rotary tables provide almost frictionless, smooth, accurate, and repeatable rotation.

Stiffness and Durability: Remarkable stiffness and durability of hydrostatic rotary tables provide the machine almost unlimited life. Even when it is exposed to harsher environments or an accident happens, often the bearings only need to be repaired but no need for replacement.

Hosea offers hydrostatic rotary tables, our hydrostatic tables with a high-quality, user-friendly display and record function, which can satisfy the need of our customers. Design flexibility is the reason our hydrostatic rotary tables are meeting the ultra-precision motion demands. If you are interested in our hydrostatic rotary table, just send us an inquiry to know more detail!

Hosea provides a diversity of Hypoid gear rotary tables for customers to choose from, our Hypoid gear rotary tables with stable index accuracy and high transmission efficiency. Moreover, they are easy to adjust. Please feel free to contact us as you are interested in our products detail!

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

The new CNC Rotary Table from GANRO has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on ...

... high-performance and flexible series from Peiseler. An extremely modern design with a good price characterises these NC rotary tables. The basis for this successful design is the complete ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

CNC rotary tables of the ETS series are our solution for your 4th axis. The ETS models are equipped with a spindle holder according to ISO 702-1. Interchangeable discs for all common ...

Directly driven Motor Power Company"s rotary tables, provide versatile applications due to their backlash free structure. If necessary a compact servo system with high torque and high accuracy, SKA Rotary ...

... combination case of Large Aperture Rotary Table with planetary reducer with model number GSN200M-50K-SV which has table size 200mm gear ratio 1:50 for servo motor. GIGAGER provides combination ...

LINCH is a high-tech company that integrates research, manufacture,sales and specialises in providing a complete range of hydrostatic bearing systems. Relying on international cutting-edge technology and attaching importance to personnel training and technological innovation, we have a professional technological development and management team engaged in hydrostatic bearing systems.

LINCH is mainly engaged in the development, production and sales of hydrostatic bearing series; providing professional and systematic products and technical services.LINCH"S featured products are hydrostatic spindles with ultra-high rotation accuracy,ultra-high stiffness, excellent vibration resistance,long accuracy duration, mainly used for high efficiency, high speed and high precision CNC machining equipment.

We use the hydrostatic rotary table for the big vertical lathe, which provides better performance and high accuracy. machine of technology Hydrostatic Rotary Table We use hydrostatic rotary table for the big vertical lathe, which provides a better performance and high accuracy. #hydrostatic #rotary #table

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

8613371530291

8613371530291